We’ve all been there. That sinking feeling at the fuel dock as diesel gushes out of the deck fill, creating a rainbow slick on the water. It’s more than just a frustrating moment; it’s a costly disaster that can sour a perfect day on the water. A good diesel fuel nozzle adapter is the answer, creating a solid, spill-proof seal between the high-speed pump and your boat.

The Real Cost of a Diesel Spill

Anyone who’s spent time on a boat knows the dread that comes with seeing that iridescent sheen spreading from your vessel. Beyond the immediate, foul-smelling cleanup, the true costs of a fuel spill are often hidden and can stick around long after the odor fades.

It's More Than Just a Mess on Deck

A diesel spill is a direct attack on your boat's finish. It can permanently stain and even soften the gelcoat, often requiring a professional to come in and fix it. That's not cheap.

Your non-skid surfaces are especially at risk. Diesel can eat away at the texture, making your deck slippery and leaving a nasty, discolored patch. And if you have beautiful teak decking? The fuel soaks deep into the wood, creating dark stains that are a nightmare to remove without aggressive sanding that damages the wood.

Think of it this way: the cost isn't just cosmetic. Every spill weakens the very materials protecting your boat from the harsh marine environment. It accelerates wear and tear, which ultimately hits you in the wallet when it's time to sell. An adapter isn't a gadget; it's insurance for your investment.

Environmental Fines and Financial Headaches

The financial risk goes way beyond just your boat. Environmental laws are no joke, and even a small, accidental spill can lead to hefty fines from the Coast Guard or local marine patrol. As the captain, you are legally on the hook for any environmental damage, and all it takes is a visible sheen to get you reported.

Knowing what to do in the moment can make a huge difference. Putting together a simple fuel spill response plan template for your boat ensures you and your crew can act fast to contain a spill and report it correctly, which can help minimize the penalties.

It’s no surprise that the technology behind fuel dispensing is always improving to tackle these problems. The global market for diesel dispensing nozzles is expected to jump from USD 1.2 billion to USD 1.8 billion by 2033, driven by the need for safer, more efficient fueling. A diesel fuel nozzle adapter is a simple, direct way to bring that modern safety and efficiency right to your own fuel dock experience.

Finding the Right Adapter for Your Boat

Picking the right diesel fuel nozzle adapter isn't a one-size-fits-all deal. The best choice really comes down to your boat, your boating style, and how much you value reliability. Honestly, a poorly matched adapter can cause just as many headaches as not having one at all.

The absolute first thing you need to do is match the adapter to your boat's deck fill. Most boats out there have a standard 1.5-inch deck fill, but you'd be surprised how many variations exist. Don't just eyeball it. Grab a ruler or calipers and get an exact measurement of the inside diameter of your fuel fill opening. If it's too loose, you won't get a proper seal, and if it's too tight, well, it's not going on. Getting this right is the first step to a clean, spill-free fill-up.

What's It Made Of? Comparing Materials

Once you’ve got your size nailed down, it’s time to think about materials. Your main choices are metal or polymer, and each has its own set of pros and cons, usually boiling down to cost versus durability.

-

Marine-Grade Stainless Steel: This is the top-of-the-line option. If you want something that will last a lifetime and stand up to saltwater and harsh conditions, steel is the way to go. For long-distance cruisers or liveaboards who might be fueling up in remote places, the peace of mind that comes with stainless steel is worth every penny.

-

Durable Polymers: Don't discount high-quality plastics. Modern, specially formulated polymers are tough, lightweight, and perfectly capable of resisting diesel and UV damage. If you're a weekend boater or a sportfishing captain who’s constantly refueling, a polymer adapter is a smart, budget-friendly choice that gets the job done.

We get into the nitty-gritty of this topic in our guide to choosing a fuel tank adapter, which is worth a read if you're still on the fence.

A Quick Tip from Experience: Your boating routine should guide your choice. A sportfishing captain trying to get back out on the water fast will love a quick-connect system for its speed. The owner of a classic trawler might prefer the solid, traditional feel of a threaded stainless steel adapter. Your gear should make your life easier, not harder.

The Connection Makes All the Difference

Finally, consider how the adapter actually attaches to your boat and the fuel nozzle. This is where you’ll notice the biggest impact on your experience at the pump.

Basic screw-on adapters are common and straightforward. You just thread them into the deck fill. While they create a secure fit, they can be a bit clumsy to get started, especially if you're in a hurry or the boat is rocking. There's always that small risk of cross-threading it, which is the last thing you want to deal with.

This is exactly why quick-connect systems like CLiX are such a game-changer. With a diesel fuel nozzle adapter from the CLiX system, the process is foolproof. You install a receiver into your deck fill one time, and that's it. After that, the adapter clicks into place with a simple push and a twist. You get a perfect, locked-on seal every single time, removing all the fumbling and guesswork. It's especially useful at fuel docks with high-speed pumps, as the secure lock means no more surprise pop-outs and messy spills.

Getting Your CLiX System Installed for a Spill-Free Seal

Alright, let's get this CLiX system installed. The good news is you don’t need to be a marine engineer to get this done. Think of it as a small, one-time project that pays off every single time you head to the fuel dock. The whole point is to create a solid, leak-proof connection, and I'll walk you through how to do it right.

First, let's get our tools together. You won't need a massive toolbox for this one. Just grab your CLiX adapter kit, a clean rag, and whatever spanner wrench or tool you use for your deck fill cap. Before you do anything else, give the area around your deck fill a good wipe-down. Get rid of any salt, dirt, or gunk. A clean starting surface is non-negotiable for a perfect seal.

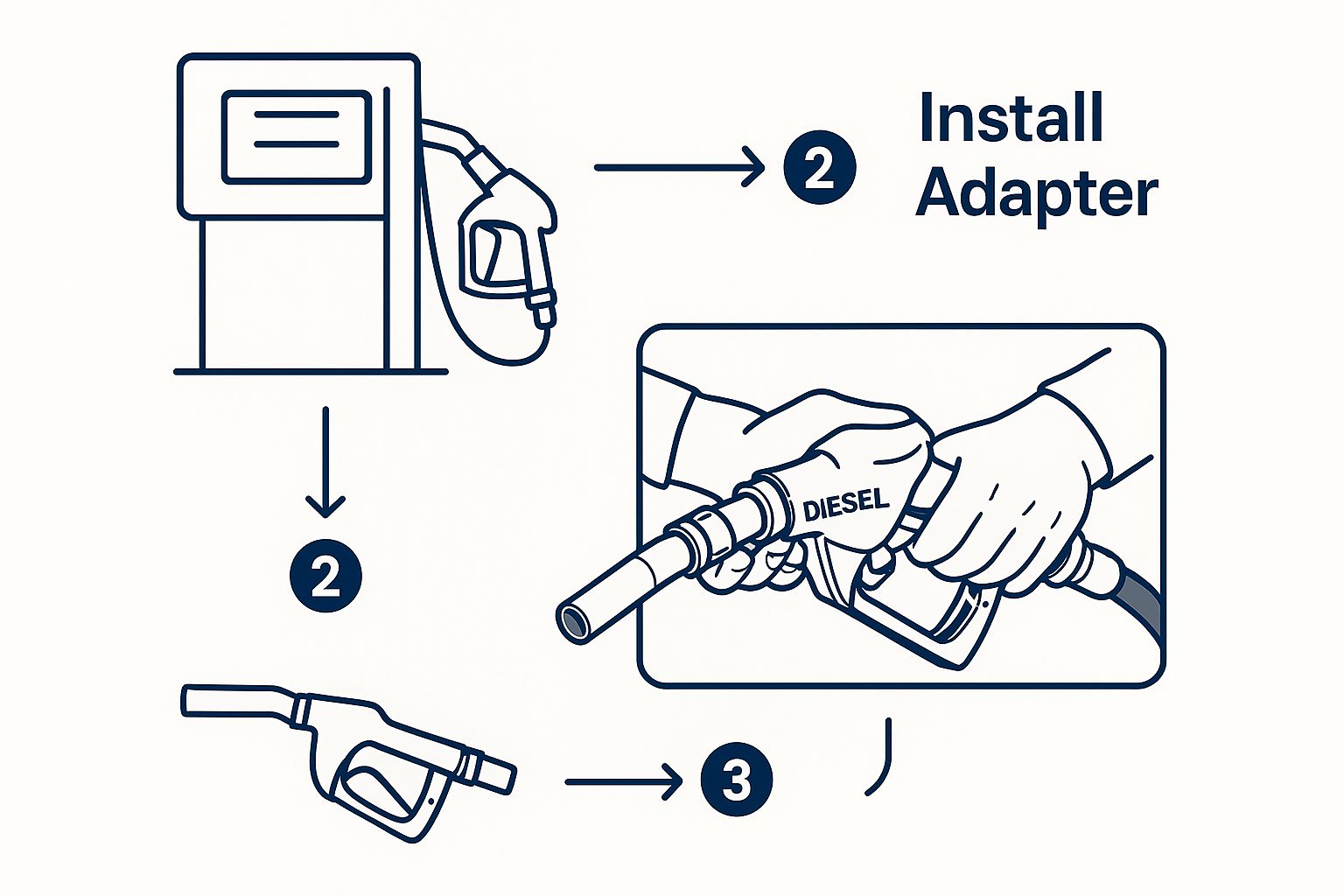

This picture gives you a great visual of how the adapter bridges the gap between the fuel nozzle and your boat.

As you can see, it’s all about creating a direct, secure path for the fuel—no gaps, no drips, no mess.

Prepping the Deck Fill and Receiver

First things first, unscrew your existing deck fill cap and put it somewhere safe. Now, take your clean rag and thoroughly wipe the threads inside the deck fill opening. You're hunting for any grit, bits of old sealant, or corrosion that could mess up your new connection. We want those threads spotless.

Next, grab the CLiX receiver—this is the piece that will live inside your deck fill from now on. Take a close look at its O-rings. They should be soft and completely free of any nicks or cuts. From experience, even a tiny flaw in an O-ring can be the source of a frustratingly persistent leak.

My Two Cents: I always put a very thin coat of O-ring lubricant or even just a dab of clean diesel on the O-rings before installation. It helps them slide into place without twisting or getting pinched, which is a common mistake that leads to problems later.

Once they're lubed up, gently thread the receiver into the deck fill by hand. It should go in smoothly. If you feel any resistance or binding, back it out immediately and start again. Cross-threading is the last thing you want to deal with here. Keep turning until it's hand-tight.

Securing the System and Making Final Checks

Once the receiver is hand-tight, grab your spanner wrench and give it one last, gentle turn. We're talking about a quarter-turn at most. The goal here is snug, not Herculean. If you crank on it too hard, you risk damaging the O-rings or even the deck fill threads themselves. Remember, the O-rings are what create the seal, not brute force.

With the receiver installed, it's time for a quick test fit. Take the diesel fuel nozzle adapter (the part that clicks in) and practice connecting it. You're looking for a solid, satisfying click as it locks into place.

- Listen for that "click." It's the sound of the locking mechanism engaging properly.

- Give it a little wiggle. Once it's locked in, the adapter should feel totally secure with no slop.

- Practice taking it off. Get the hang of the release mechanism now so it's second nature after you've finished fueling.

Before you head out for your first fill-up, do one final visual check. Eyeball the seam where the receiver meets the deck fill—it should look perfectly even all the way around. Taking a few extra minutes to get this installation just right is what ensures your new system works flawlessly and keeps your deck clean, every single time.

Mastering Spill-Free Fueling at the Dock

Having the right diesel fuel nozzle adapter is a game-changer, but knowing how to use it is what really makes the difference between a clean fueling and a messy, frustrating one. Once you get the hang of it, you’ll develop a smooth, repeatable process that turns a dreaded chore into a simple, confident routine.

Here's a pro tip that starts before you even step on the boat: attach your adapter to the fuel nozzle while you're still standing firmly on the dock. This way, you can get a perfect, solid connection without leaning awkwardly over the water. Once it's locked on, you can approach your boat holding a single, ready-to-use unit.

Flow Control and Listening for the Right Cues

One of the biggest mistakes I see boaters make is trusting the pump's auto-shutoff feature. Those things are designed for cars and are notoriously unreliable for boats. The complex venting in marine fuel tanks just doesn't create the right back pressure to trigger the shutoff in time, and that's how overflows happen.

A seasoned captain once told me, "Never trust the click." He was absolutely right. You are the only reliable auto-shutoff on your boat. Always keep your hand on the trigger, ready to stop the flow yourself.

Instead of squeezing the handle for all it's worth, aim for a steady, moderate flow rate. Going about halfway is usually the sweet spot. This pace prevents the fuel from foaming up too much in the tank and drastically cuts down on "blow-back," that frustrating moment when fuel spits back out of the fill.

As your tank gets closer to full, start listening. You’ll hear a very distinct change in the sound coming from your fuel vent and the fill pipe. The hollow echo will become a higher-pitched gurgle as the fuel level rises. This is your signal to slow down even more and get ready to stop. For a deeper dive into all the components at play, check out our complete guide to the boat fueling system.

The Last Few Steps for a Clean Finish

When you think you're within the last few gallons, let go of the nozzle completely. Give the foam a moment to settle so you can get a true sense of the remaining space. From there, you can top off with short, careful bursts until you're satisfied.

Once the tank is full, you’re not quite done. Disconnecting the nozzle is where that last, annoying drip always seems to happen. Here’s how to prevent it:

- Tip the Nozzle: Before you remove the adapter from your deck fill, tilt the fuel nozzle upward slightly. Gravity will help drain any leftover fuel from the spout back into the hose, not onto your deck.

- Get Your Rag Ready: Always have an absorbent rag in your hand to wrap around the adapter as you disconnect it. It’s your last line of defense for catching any stray drips.

- Disconnect and Cap: With the rag in place, release the adapter from the deck fill and immediately screw your deck fill cap back on.

This disciplined approach is what responsible fueling is all about. It’s no surprise that the technology behind this is a big deal. The global Automatic Fuel Nozzle Market was valued at nearly USD 1.5 billion, and it's expected to grow as regulations and boaters demand safer, more efficient gear. Mastering these simple steps ensures every trip to the fuel dock is a clean one.

Simple Care for Long-Term Reliability

Your diesel fuel nozzle adapter is a tough little piece of gear, but like everything else on a boat, it needs a bit of attention to keep working flawlessly. Think of it as protecting your protector—this adapter keeps corrosive diesel off your deck, so spending a few seconds caring for it is a smart trade.

I've learned the hard way that ignoring the small stuff leads to bigger problems. The most important habit I've developed is cleaning the adapter after every single fueling. It’s simple.

A quick rinse with fresh water and a wipe with a clean rag is all it takes. This gets rid of the salt and grime that inevitably builds up and could mess with the seals or moving parts.

A Quick Inspection Guide

Before the season kicks off, or more often if you’re out on the water a lot, give your adapter a closer look. The O-rings are the real heroes here, creating that spill-proof seal.

- Look for Wear and Tear: Check the O-rings for any cracks, flat spots, or signs of becoming brittle. A healthy O-ring should be soft and perfectly round.

- Trust Your Gut (and Your Hands): When you attach the adapter, it should feel snug. If it feels even a little bit loose, that’s a dead giveaway the O-rings are shot and need to be replaced.

Don't wait for a fuel spill to tell you it's time for new O-rings. They cost next to nothing and are simple to swap out. I always keep a spare set on board—it’s cheap insurance against a messy and frustrating day at the fuel dock.

Troubleshooting and Smart Storage

Ever notice the adapter getting a little tough to attach? It happens. Usually, it's just from a bit of dried salt or gunk building up in the grooves. A good cleaning with a soft brush and some soapy water almost always does the trick.

Ultimately, keeping your gear in top shape comes down to the basic principles of preventive maintenance. This applies to everything from your engine to this small but critical adapter.

When you're not using it, tuck your diesel fuel nozzle adapter away in a dry locker or toolbox. Leaving it out on deck is a sure way to let the sun and salt destroy the seals. Taking care of this little tool ensures every refuel is a clean one. After all, we rely on diesel because of its power—it packs about 15% more energy than gasoline, which is what makes diesel engines so efficient. That efficiency is why having quality components to handle the fuel is so important.

Got Questions? We've Got Answers

Even after you get the hang of how they work, it's smart to have a few questions before adding any new gear to your boat. When it comes to something as important as a diesel fuel nozzle adapter, getting it right is key for both safety and your own peace of mind. Let's tackle some of the common questions I hear from fellow boaters.

A big one is whether a so-called "universal" adapter will actually work. In my experience, there's rarely a one-size-fits-all solution for anything on a boat, and this is no exception. While many deck fills are a standard 1.5 inches, you'll find plenty of variations out there. The only way to guarantee a perfect, no-spill fit is to pull out a ruler and measure your deck fill before you buy.

Can These Adapters Handle High-Speed Pumps?

This question comes up a lot, and it's a critical one. Can these adapters stand up to the high-flow pumps you find at commercial fuel docks? The short answer is yes, absolutely—as long as you stay in control.

A well-made adapter is designed for the pressure, but you should never, ever lock the pump handle and walk away. The trick is to feather the trigger yourself. Start the fuel flow slowly, then ramp it up to a steady, manageable pace. This simple step prevents the pressure from spiking and causing that dreaded fuel geyser from your deck fill. A hands-on approach is always the safest way to fuel.

A classic mistake is trusting the pump's auto-shutoff. Those are calibrated for cars, not the complex venting systems of boat tanks. They're notoriously unreliable on the water, so always be ready to cut the flow yourself.

How Do I Know When to Replace the O-Rings?

Your O-rings are the unsung heroes here, creating that perfect seal. So, how often should you replace them? I make it a habit to give mine a quick visual check before the season kicks off, or any time I suspect a leak.

It's a really simple inspection. Look for any signs of wear and tear:

- Cracking or Dryness: If the rubber looks brittle or has tiny cracks, it’s toast. Time for a new one.

- Flat Spots: A good O-ring is perfectly round. If yours has been squashed flat, it won't create a tight seal anymore.

- A Sloppy Fit: If the adapter suddenly feels loose when you connect it, the O-rings have likely lost their shape and need to be replaced.

O-rings are cheap and incredibly easy to swap out. If you spot even a single drop of fuel during a fill-up, don't put it off. Changing them out is a two-minute job that can save you from a major cleanup headache later on.

Ready to make fuel spills a thing of the past? The slick CLiX Fueling Solutions system gives you a solid, spill-proof connection every single time. Do yourself—and the environment—a favor and head over to the CLiX website to find the right setup for your boat.