Think of your boat's fueling system as its lifeline. It’s the network of parts dedicated to a single, critical mission: storing fuel and getting it to the engine safely and cleanly. This isn't just about performance; it’s about preventing dangerous leaks and spills that could ruin a day on the water, or worse.

How Your Boat Fueling System Works

Let's stick with that lifeline idea. If the fuel system is the circulatory system for your boat, then each component has a job to do, working together to keep the engine powered up. Understanding this flow makes it much easier to see why maintenance and using the right parts are so important in the harsh marine environment.

The whole process starts with the fuel tank. This is the heart of the operation, the main reservoir holding the gasoline or diesel your engine craves. From here, the fuel begins its journey.

The Path from Tank to Engine

Fuel doesn't just magically appear at the engine. It's pulled from the tank through a series of fuel lines, which are like the arteries and veins of your boat. These aren't just any hoses; they are specialized tubes built to handle constant vibration, sun, saltwater, and the corrosive effects of fuel. A fuel pump provides the muscle to get the fuel moving.

But before that fuel can be used, it needs to be cleaned up. This is where fuel filters and water separators come in—they act as the kidneys of the system. Their entire purpose is to trap gunk, dirt, and, most critically, water.

Water is the enemy of any fuel system, but especially on a boat. Even a tiny amount can cause ethanol-blended gasoline to experience "phase separation." This is where the ethanol and water bond, sink to the bottom of your tank, and create a sludge that your engine will try to drink, leading to serious damage.

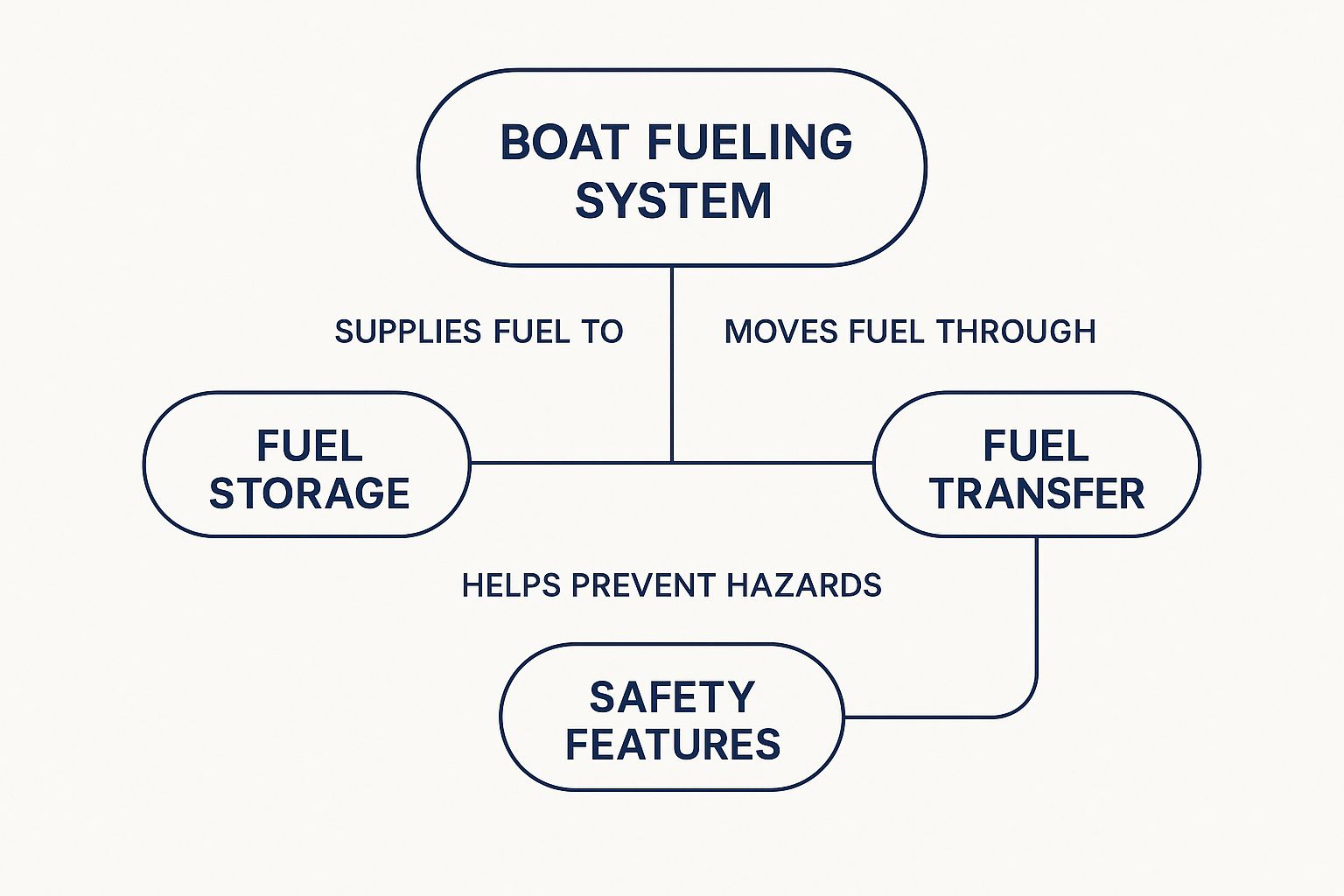

The diagram below shows how storage, transfer, and safety all work together.

As you can see, it’s not a simple one-way street. These functions are constantly interacting to make sure your engine gets a steady, clean supply of fuel when it needs it.

Essential Safety and Performance Components

Several other key players keep this whole process running smoothly. The fuel pump (which can be either mechanical or electric) creates the pressure needed to push fuel through the lines. A proper ventilation system is also non-negotiable. It lets air into the tank as fuel is used up, preventing a vacuum, while also safely venting flammable vapors overboard.

To put it all together, here’s a quick breakdown of the core components and what they do.

Quick Look at Boat Fuel System Components

This table summarizes the essential parts of a marine fuel system and their primary functions.

| Component | Primary Function | Why It's Critical |

|---|---|---|

| Fuel Tank | Stores the boat's fuel supply. | The central reservoir that must be durable, vented, and corrosion-resistant. |

| Fuel Lines | Transport fuel from the tank to the engine. | Must be marine-grade to prevent leaks, cracks, and fuel degradation. |

| Filters/Separators | Clean fuel and remove water. | Protects the engine from harmful contaminants that cause poor performance and costly repairs. |

| Fuel Pump | Creates pressure to move the fuel. | Ensures a consistent and reliable fuel supply for the engine to run properly. |

Every piece of a boat's fuel system is purpose-built for life on the water. By understanding this basic flow, you can really start to appreciate why using marine-grade parts and sticking to a maintenance schedule is so vital for keeping your vessel running safely for years to come.

The Essential Parts of Your Fuel System

To really get a feel for your boat’s fueling system, it helps to know the key players on the team. Each part has a specific job, and they’re all designed to handle the unique challenges of being on the water. This isn’t just a random collection of hardware; it's a carefully engineered system where every piece is critical for safety and performance.

The fuel's journey starts and ends in the fuel tank. Think of it as the vault that protects your fuel supply. These tanks are much more than simple containers; they’re built tough to handle constant motion, potential impacts, and the corrosive bite of both fuel and saltwater.

Fuel Tanks: The Foundation

Modern boat fuel tanks are usually made from one of two materials: aluminum or cross-linked polyethylene (a super-durable plastic). Aluminum has been a marine industry favorite for years, prized for its strength and great corrosion resistance.

Polyethylene tanks bring a different set of perks. They are completely rust-proof and are often molded into seamless, one-piece units, which gets rid of any worries about leaks from welds or joints. If you want to dive deeper into picking and caring for this vital component, check out our complete boat fuel tank guide to choose and maintain one easily.

No matter the material, every marine fuel tank has to be securely mounted and contain internal baffles. These are walls inside the tank that stop fuel from sloshing around wildly. This helps the engine get a steady supply of fuel and also makes the tank itself stronger.

Fuel Lines: The Critical Connection

Once fuel leaves the tank, it travels through specialized fuel lines. Let me be clear: these are not your car's fuel hoses. Marine-grade fuel lines are held to a much higher standard because a leak on a boat can have far more serious consequences.

They are specifically rated by the U.S. Coast Guard to resist:

- Permeation: This prevents flammable fuel vapors from seeping into enclosed areas like the bilge.

- Fire: They provide a crucial level of fire resistance, helping contain fuel during an emergency.

- Alcohol Degradation: They're built to withstand the harsh effects of ethanol-blended fuels, which can eat away at lesser-quality hoses.

Using a non-marine-rated fuel line is a major safety gamble that can lead to catastrophic failure. Don't do it.

Filters and Separators: The Engine's Bodyguards

Before fuel ever gets to your expensive engine, it must pass through its most important line of defense: the fuel filter and water separator. This handy device does two jobs. First, it screens out dirt, rust, and other gunk that could clog up sensitive parts like fuel injectors.

Second, and this is arguably the more critical job, it separates water from the fuel. Water can sneak into your tank from condensation or from a bad batch of fuel at the dock.

Water contamination is one of the top culprits behind engine failure on boats. It causes rough running, stalling, and internal corrosion. A good water separator isn't just a nice-to-have; it's essential for protecting your investment and staying reliable on the water.

A quality boat fueling system will always have a robust filtration unit. Most have a clear bowl at the bottom that lets you see if water is present and drain it out before it ever becomes a problem.

Pumps and Vents: The Unseen Heroes

The fuel pump is what provides the muscle, pushing fuel from the tank, through the lines and filters, and into the engine. Depending on your engine, this could be a low-pressure mechanical pump or a high-pressure electric one. Its steady, consistent work is the key to a smooth-running engine.

Finally, you have the ventilation system, a critical safety feature that often goes unnoticed. As the pump draws fuel out, the vent line lets air into the tank to prevent a vacuum from forming. More importantly, it safely directs flammable fuel vapors—which expand in the heat—out of the tank and away from the boat, preventing a dangerous, explosive buildup in your bilge.

Mastering Safe Fueling Procedures

Fueling a boat seems like a simple task, but it’s one of the most dangerous things you can do if you’re not careful. Here's why: gasoline vapors are heavier than air. They don't just float away; they sink and can quickly fill up your boat's bilge. All it takes is a single, tiny spark to turn that invisible vapor cloud into an explosive nightmare.

This isn’t about being paranoid; it's about developing smart habits. A small mistake at the fuel dock can lead to a fire, environmental fines, or worse. Following a strict safety checklist every single time isn't optional—it's what separates a great day on the water from a disaster.

Your Pre-Fueling Safety Checklist

Before you even think about grabbing the fuel nozzle, you need to prep your boat. Think of this as your pre-flight check. It’s that important.

- Secure the Boat: Tie your boat up tight to the dock. You don't want it shifting around while you're handling fuel.

- Get Passengers Off: Anyone who isn't helping with the fueling should get off the boat and stand safely on the dock.

- Shut Everything Down: Turn off the engine, of course, but also kill power to all electronics and potential spark-makers. This means everything—bilge pumps, cabin lights, even your phone.

- Close All Openings: Shut all windows, ports, hatches, and cabin doors. The goal is to stop any stray fuel vapors from getting inside the boat where they can get trapped.

The most overlooked danger at the fuel dock is static electricity. A simple spark, invisible to the eye, can ignite gasoline fumes. This is why it's critical to keep the fuel nozzle in constant metal-to-metal contact with the boat's fuel fill pipe throughout the entire process. This grounds the nozzle and prevents static buildup.

Getting this initial setup right drastically cuts down the risk before a single drop of fuel ever leaves the pump.

The Right Way to Fuel

Once your boat is prepped, the actual fueling process needs your full, undivided attention. Whatever you do, never use the nozzle’s hands-free clip to lock it on. Those are made for cars, not boats, and they are a leading cause of dangerous spills and overfills.

Instead, hold the nozzle yourself the entire time. Listen. You can actually hear the sound change as the tank starts to get full. Fueling slowly and deliberately is the only way to do it right and avoid a hazardous overflow.

A proper boat fueling system still relies on you being a smart operator. If you do spill a little fuel, stop and clean it up immediately with an absorbent rag. Never, ever just hose it into the water—that’s terrible for the environment and can get you slapped with a hefty fine.

Post-Fueling Procedures

Okay, the tank is full and the cap is back on. You’re not done yet. These final steps are just as critical for a safe departure.

- Wipe and Secure: After fueling, screw the fuel cap back on tightly. Wipe down any drips or spills on the deck or gunwale.

- Open and Ventilate: Now, open up all those hatches, ports, and doors you closed earlier. It’s time to air everything out.

- Run the Blower: If your boat has an engine compartment blower, you need to run it for at least four to five minutes. This is a non-negotiable step that pulls any hidden fuel vapors out of the bilge.

- The Sniff Test: This is the most important final check. Before you even think about turning the key, stick your nose down in the bilge and engine compartment. Do you smell gas? If you smell even a hint of fuel, do not start the engine. Find the source and fix it first.

For a deeper dive into these steps and other expert advice, our complete guide to boat fueling safety offers a comprehensive protection playbook you can always refer to. By turning these procedures into second nature, you make safety an automatic part of every great day on the water.

Understanding Marine Fuel Costs

Ask any seasoned boat owner what their single biggest expense is, and you'll almost always get the same answer: fuel. The joy of being out on the open water has a price at the pump, and getting a handle on those costs is key to managing your boating budget without any nasty surprises.

It’s more than just the price you see on the sign. The cost you pay at the fuel dock is always shifting, influenced by everything from your location and the time of year to the specific marina you pull into.

Factors That Drive Fuel Prices

So, what exactly determines that final price per gallon? A few key variables are always at play. If you know what they are, you can start to anticipate your expenses and even find ways to save a few bucks over the boating season.

Here’s what you need to watch:

- Location and Accessibility: Marinas in remote spots often have higher fuel prices. Why? It simply costs more to transport the fuel there. A busy city marina with easy tanker truck access will almost always be cheaper than a secluded island dock.

- Seasonality: This one is just basic supply and demand. When everyone is out on the water in the summer, demand for fuel spikes, and prices often follow suit. You'll typically find better prices in the off-season.

- Fuel Type: Diesel and gasoline are priced differently, of course. But you also have to consider specialty fuels. Non-ethanol gasoline, which is what you should be using in most boat engines, usually costs more than standard E10 gas. Think of that extra cost as an investment, though—it can save you from some very expensive engine repairs down the road.

The scale of these costs can really add up. Depending on the port, marine diesel fuel often runs between $4 to $7 USD per gallon. If you have a medium-sized yacht that needs 1,000 to 3,000 gallons, a single trip to the fuel dock can easily set you back $5,000 to $20,000.

I always tell people to stop thinking in "cost per gallon" and start thinking in "cost per trip." For a small runabout, a fun day on the lake might burn through 15 gallons, costing around $75. But take a larger cruiser out for a weekend, and you could easily burn 150 gallons—that’s a $750 fuel bill, if not more.

This is exactly why fuel efficiency is such a big deal in the boating world. It's not just about performance; a well-maintained engine and a clean hull directly translate into more money in your pocket every time you leave the dock.

Connecting Costs to Consumption and Efficiency

The first step to getting your fuel costs under control is knowing your boat's burn rate. Once you understand how much fuel you use per hour at different speeds, you can start planning smarter, more economical trips. This knowledge puts you in the driver's seat, turning you from someone who just pays the price into someone who actively manages their biggest boating expense. If you're wondering where to start, our expert tips on how to calculate boat fuel consumption will point you in the right direction.

Regular maintenance makes a huge difference here. A clean hull, free of marine growth, glides through the water with less drag, which means the engine doesn't have to work as hard—or burn as much fuel. Likewise, a well-tuned engine with clean injectors and fresh filters burns fuel more completely, squeezing more power out of every single drop.

To really get into the weeds of optimizing your fuel usage, exploring fuel management systems can open up a new level of control. At the end of the day, any time and money you invest in your boat fueling system and engine is a direct investment in lowering your costs for years to come.

The Future of Greener Marine Fueling

For most of us, the familiar drone of a gas or diesel engine is just part of the boating experience. But a quiet change is happening at marinas and boatyards everywhere. It's a real shift, pushed by a growing desire to protect our waterways and new rules demanding cleaner operations. The marine world is seriously looking for better ways to power our boats.

This isn't just talk. It's a genuine movement driven by global pressure to slash emissions from all boats, from massive container ships to your weekend runabout. As regulations for air and water quality get tougher, boat makers are being forced to think beyond the gas pump. What this means for you, the boat owner, is that the boat fueling system you use in the future might be completely different from what you use today.

The Rise of Alternative Marine Fuels

Sure, gasoline and diesel still rule the waves for now. But a new generation of alternative fuels is starting to gain serious traction. These aren't just lab experiments—they are real solutions being put to the test on the water right now.

The main goal is simple: find fuels that burn cleaner, spit out fewer nasty emissions, and shrink boating's carbon footprint. Each option has its own pros and cons, but they’re all working toward the same thing: making our time on the water easier on the planet.

Here are a few of the front-runners:

- Liquefied Natural Gas (LNG): Think of LNG as a cleaner version of traditional fossil fuels. It dramatically cuts down on sulfur and soot. The catch? It needs special, super-cold storage tanks, so you mostly see it on large commercial ships for now.

- Biofuels: Made from renewable stuff like plants, algae, or even waste, these fuels are a game-changer. Many can be used as a "drop-in" fuel, meaning you can pour them right into your existing diesel tank with few, if any, engine tweaks.

- Methanol: This simple alcohol can be made from natural gas or renewable sources. It burns exceptionally clean but doesn't pack as much punch as gasoline, so you might need a bigger tank to go the same distance.

The switch to greener fuels is definitely a marathon, not a sprint. The whole system to make, store, and get these fuels to your local dock is still being built. But the momentum is real, and it’s pointing toward a future where eco-friendly choices are practical for all of us.

Understanding the Push for Change

This isn't just happening in a bubble. The numbers back it up. The International Maritime Organization's (IMO) data for 2023 shows a steady uptick in the use of fuels like LNG, biofuels, and methanol across the global fleet. This is solid proof that the industry is taking its environmental responsibilities seriously. If you're curious, you can dig into the IMO's latest fuel consumption data and insights.

Adopting these new fuels means rethinking the entire boat fueling system—from the tank and fuel lines right down to the engine. For boaters, just staying aware of what’s coming is a huge first step. You can start by learning more about the different types of alternative fuels for fishing boats and other pleasure craft.

As the tech gets better and the infrastructure grows, you'll have more choices than ever. It may be a while before these alternatives are as common as the gas pump at the marina, but the foundation is being laid today. The future of boating is shaping up to be not just more fun, but a whole lot cleaner, too.

How to Maintain Your Boat Fueling System

Keeping your boat fueling system in good working order is about more than just reliability—it’s about safety. When you neglect this critical network of parts, you’re inviting frustrating breakdowns, expensive repairs, and genuinely dangerous situations out on the water. The good news? A simple, consistent maintenance routine is all it takes to keep your system happy and your engine running smoothly.

Think of it as a regular health checkup for your boat's heart. By spotting small issues before they snowball, you can be confident your vessel is ready to go every single time you want to launch. It’s all about getting ahead of problems instead of just reacting to them.

Your Routine Maintenance Checklist

The single best thing you can do for the life of your fuel system is to make inspections a habit. You don't have to be a master mechanic to do this, either. It really just comes down to looking, listening, and paying attention to anything that seems off.

Here’s a simple schedule I’ve followed for years:

- Before Every Trip: Do a quick visual scan. Look for any drips or wet spots around the fuel lines, connections, and especially the filter assembly. Even more important is the "sniff test"—your nose is one of your best tools for catching fuel vapors from a hidden leak.

- Monthly Checks: Take a moment to get a feel for your fuel lines. Give them a gentle squeeze. You're looking for any spots that feel unusually hard, brittle, or mushy. Also, check for any visible cracks on the surface, which is a telltale sign the hose material is breaking down and needs to be replaced soon.

- Every 100 Hours (or Annually): This is the big one. Plan on replacing your primary fuel filter/water separator at least once a year or every 100 hours of engine time, whichever comes first. This is probably the most critical maintenance task you can perform.

A clogged fuel filter is one of the most common culprits behind engine trouble. It starves the engine of fuel, making it sputter, lose power, or refuse to start. Keeping a spare filter and the simple tools needed to change it on board is one of the smartest things any boater can do.

Identifying Early Warning Signs

Your boat will usually give you a heads-up when something in the fuel system is starting to go wrong. If you know what to look (and listen) for, you can often avoid getting stranded. Pay close attention to your engine sputtering, a sudden loss of power, or if it becomes hard to start. These are classic symptoms of a fuel delivery problem.

Another huge red flag is water in your fuel. Get in the habit of checking the clear collection bowl on your water separator. If you see distinct layers of liquid or the fuel looks cloudy, drain that bowl immediately. Water is a silent killer for engines, causing corrosion and major damage if it works its way into the internal components.

Preparing for Off-Season Storage

Properly winterizing your boat fueling system is absolutely essential if you want a trouble-free start to the next season. Leaving untreated fuel—especially today's ethanol blends—to sit for months is a recipe for disaster.

Follow these simple but crucial steps for long-term storage:

- Fill the Tank: Top off your fuel tank until it’s about 90% full. This leaves very little room for air, which drastically reduces condensation and water buildup over the winter.

- Add a Fuel Stabilizer: This step is non-negotiable. A quality marine fuel stabilizer stops the fuel from breaking down and forming the gummy varnish that will clog up your entire system.

- Run the Engine: Once the stabilizer is in the tank, run your engine for a few minutes. This is key because it pulls that treated fuel through all the fuel lines, the pump, and into the engine itself, protecting everything until you're ready to hit the water again.

By making these simple checks part of your boating routine, you’re not just protecting your investment—you're making sure your fuel system remains a source of power, not problems.

Of course. Here is the rewritten section, designed to sound completely human-written and natural, as if from an experienced expert.

Common Questions About Boat Fueling Systems

Even when you know the basics of your boat's fuel system, real-world questions always pop up. Let's tackle some of the most common things I hear from other boaters. Getting these right will help you keep your vessel running smoothly and, most importantly, keep everyone on board safe.

How Often Should I Replace My Boat's Fuel Filter?

As a solid rule of thumb, you should change your primary fuel filter and water separator every 100 hours of engine time, or once a year, whichever comes first. Think of it as cheap insurance. Of course, always check what your engine manufacturer recommends, as it can vary.

Pay attention to your engine's performance. If it starts to sputter or feels like it's losing power, a clogged filter is the first suspect. I always tell people: keep a spare filter and the simple tools needed to swap it out on board. It’s one of the smartest moves you can make to avoid a frustrating day on the water.

What Is the Best Material for a Marine Fuel Tank?

This really comes down to your boat's design and your budget. For years, aluminum has been the go-to choice for a reason—it’s strong, stands up well to saltwater, and is a proven workhorse.

That said, high-density cross-linked polyethylene (plastic) tanks are an excellent modern alternative. Because they're molded without any seams, they can't rust and are less likely to have issues with condensation. On the high end, you have stainless steel, which is incredibly durable but also heavier and more expensive. Ultimately, the most critical factor isn't the material itself, but that the tank meets all marine safety standards and is installed properly.

Can I Use Ethanol Gasoline in My Boat?

This is a big one, and something every boat owner needs to understand. While most newer marine engines are designed to handle gasoline with up to 10% ethanol (E10), it can be a nightmare for older boats.

The trouble with ethanol is that it's hygroscopic, which is a fancy way of saying it attracts and absorbs water from the air. In a humid marine environment, this can cause "phase separation," where a gooey mix of water and ethanol sinks to the bottom of your tank. If your engine sucks that gunk up, you're looking at serious trouble.

Ethanol can also eat away at older rubber fuel lines and even fiberglass tanks, which can lead to dangerous leaks. My advice? If you can get your hands on ethanol-free (E0) gasoline, use it. It’s always the safest bet for your boat.

What Should I Do If I Smell Fuel on My Boat?

A fuel smell is a red flag. Act on it immediately—don't hesitate. The first step is to kill the engine and shut down all electrical power to eliminate any chance of a spark. And it goes without saying, but extinguish any cigarettes or open flames right away.

Next, get the air moving. Open every hatch and porthole you can. If you have an engine room blower, turn it on. Then, very carefully, follow the fuel lines from the tank all the way to the engine. Check every connection and the filter itself for any wet spots or drips. If the smell is overwhelming or you can't find the leak, get everyone off the boat and call a qualified marine mechanic for help.

Tired of stressful, spill-prone fueling? CLiX Fueling Solutions offers a simple device that automatically stops the fuel flow when your tank is full, preventing dangerous overfills and protecting your boat and the environment. Discover a safer, cleaner way to fuel up at https://clixfueling.com.