A fuel tank overfill alarm is your best defense against the messy, dangerous, and expensive problem of fuel spills. Think of it like the auto-shutoff feature on the nozzle at a gas station, but for much larger tanks. It's a simple, crucial safety device that alerts you when the tank is almost full, so you can stop the flow before it's too late.

Your First Line of Defense Against Fuel Spills

Imagine you're responsible for filling a massive industrial storage tank. How do you know when to stop? Guessing is not an option. Overfilling isn't just a small mistake; it’s a recipe for disaster. A single spill can mean huge financial losses, serious environmental harm, and major safety risks for everyone nearby. This is exactly why a fuel tank overfill alarm is so essential.

This system is the first and most important safeguard in modern fuel management. It solves a complex problem with a straightforward solution. Whether it's a loud siren, a bright flashing light, or a signal that automatically shuts off the pump, the alarm takes human error and guesswork out of the picture.

For any operation that stores fuel in bulk—from airports and marinas to data centers and hospitals—these alarms aren't just a nice-to-have. They are a core part of running a safe and responsible facility.

Fuel Tank Overfill Alarm at a Glance

To quickly get up to speed, here’s a simple breakdown of what these systems are all about.

| Aspect | Description |

|---|---|

| Primary Function | To alert operators when a fuel tank is approaching its full capacity during a filling operation. |

| Key Components | A sensor inside the tank, an alarm panel (with audible/visual alerts), and wiring connecting them. |

| Alert Types | Common alerts include loud horns (95-100+ dB), bright strobe lights, or signals to shut off a pump. |

| Typical Use Cases | Above-ground and underground storage tanks at commercial, industrial, and municipal facilities. |

| Main Benefit | Prevents spills, protecting personnel, the environment, and the company's finances. |

In short, it's a dedicated warning system designed to head off trouble before it starts.

Understanding the Stakes of an Overfill

The fallout from a fuel overfill goes way beyond just cleaning up a mess. A spill sets off a chain reaction of negative consequences for safety, your budget, and the environment.

- Safety Hazards: Spilled fuel like diesel or gasoline releases highly flammable vapors. All it takes is one spark from a piece of equipment or even static electricity to cause a devastating fire or explosion, putting lives and property at risk.

- Environmental Contamination: When fuel soaks into the ground, it can poison the soil and seep into groundwater, contaminating local ecosystems and even drinking water supplies. The cleanup is almost always a long, difficult, and very expensive process.

- Regulatory Penalties: Environmental agencies have strict rules for fuel storage. A spill can lead to massive fines, legal trouble, and government-mandated cleanup efforts that can financially cripple a business.

The importance of these systems is reflected in their market growth. The global fuel tank alarm market was valued at approximately $2.5 billion in 2023 and is projected to reach about $3.8 billion by 2028. This growth is largely driven by stricter environmental rules aimed at preventing fuel leaks. You can explore more about these market trends and their drivers.

A fuel tank overfill alarm is a proactive measure that addresses these serious risks head-on. That simple alert can be the one thing that stands between a routine fuel delivery and a dangerous, costly catastrophe.

How Overfill Alarm Systems Actually Work

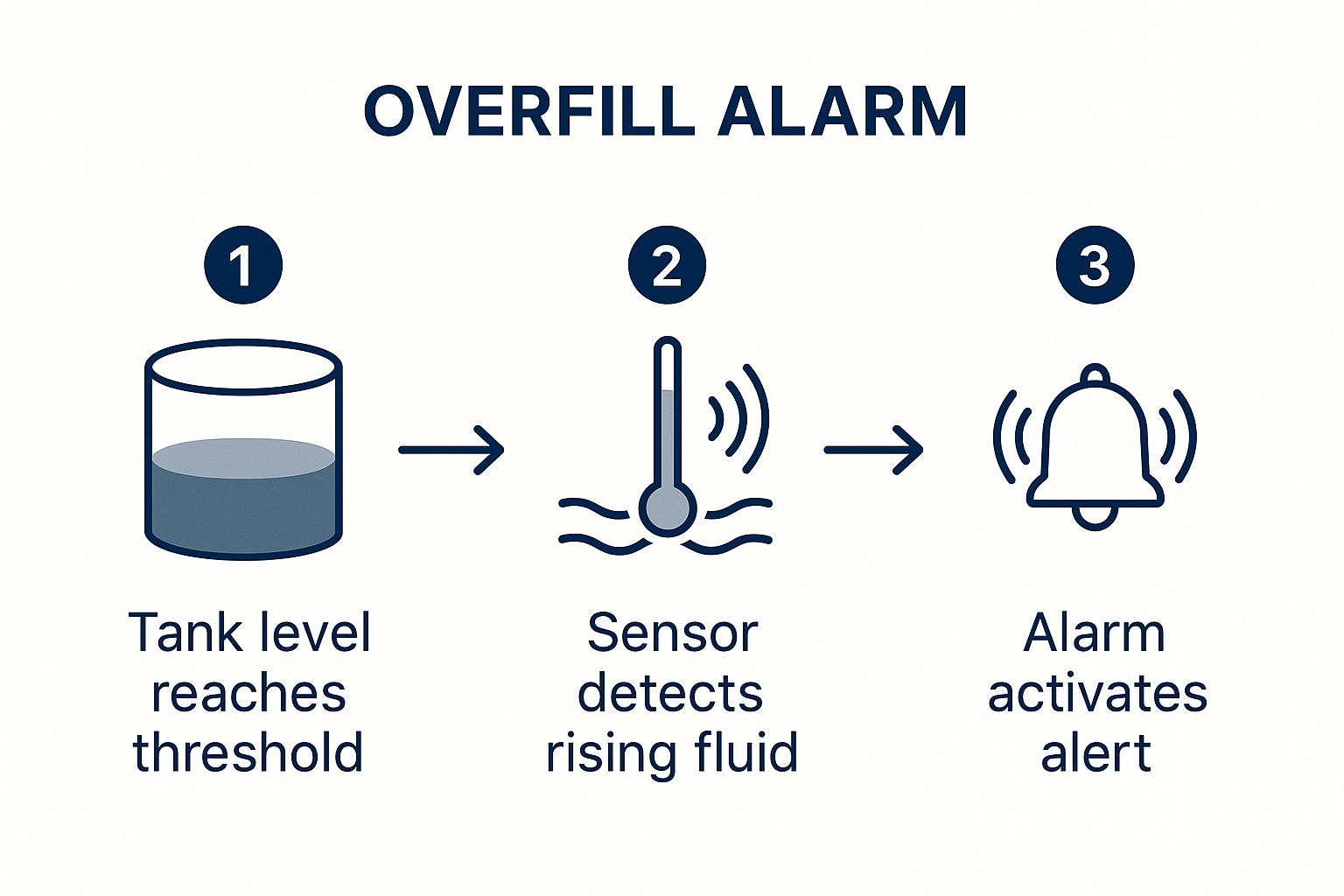

To get a real feel for how a fuel tank overfill alarm works, don't think of it as complex tech. Instead, picture a simple, three-person crew. Each member has one specific job, and they have to work together perfectly to stop a spill before it starts.

At the heart of it all, you have a sensor, a control unit, and an alarm. The sensor is your lookout, the control unit is the brain, and the alarm is the loudmouth that makes sure everyone knows there’s a problem.

This image breaks down how they all communicate in a split second.

As you can see, it's a straightforward chain reaction. The rising fuel trips the sensor, the sensor tells the control unit, and the control unit sounds the alarm. It's this direct, no-fuss process that makes these systems so reliable in the field.

The Sensor: The First Responder

The sensor is the component that actually lives inside the tank, keeping a constant eye on the fuel level. When the fuel hits a pre-set high-water mark—usually somewhere between 90% and 95% of the tank’s total capacity—the sensor trips. It’s a lot like the float in the back of your toilet; as the water rises, it lifts the float arm, which eventually stops the flow.

Sensors aren't all the same, though. They use different technologies to get the job done. The most common types you’ll run into are:

- Mechanical Float Switches: These are the old-school, tried-and-true option. A buoyant float simply rises with the fuel. When it gets high enough, it physically flips a switch and completes a circuit, telling the alarm to go off.

- Optical Sensors: A bit more modern, these use a beam of infrared light. When fuel submerges the sensor's prism, it changes how the light refracts, and that change is what triggers the alarm.

- Vibrating Fork Sensors: These use a small, tuning-fork-like probe that vibrates at a very specific frequency. The moment fuel covers the fork, the liquid dampens the vibrations. The system detects this frequency change and signals a high-level alert.

The Control Unit and Alarm: The Brain and the Voice

As soon as the sensor trips, it zaps an electrical signal over to the control unit. Think of this as the system's central command. It gets that "high-level" signal and immediately does what it’s programmed to do.

In the most basic setups, its only job is to turn on the alarm. This isn't just a quiet beep, either. We're usually talking about a combination of:

- Audible Alarms: Incredibly loud sirens or horns that blast at over 100 decibels. They're designed to cut through the noise of running pumps and heavy machinery on a busy site.

- Visual Alarms: Bright, flashing strobe lights, typically red or amber, that are impossible to miss, even on a sunny day.

But many modern systems go a step further. The control unit can be tied directly into the fueling equipment itself. This is where you see things like LVDT applications in fuel controls for extremely precise monitoring and action.

When it gets that high-level signal, the control unit doesn't just sound the alarm—it can also instantly send a command to shut off the fuel pump or close a valve in the line, stopping the flow dead in its tracks. This automatic shutoff is a game-changer because it takes human reaction time (and human error) completely out of the equation.

It’s this powerful trio of detection, alerting, and automated action that creates a nearly foolproof defense against dangerous and expensive fuel spills.

The Real-World Benefits of Overfill Alarms

Sure, the main job of a fuel tank overfill alarm is to stop a spill before it starts. But thinking that's all it does is missing the bigger picture. A good alarm system does more than just make noise—it brings real, practical benefits to your operation by improving safety, protecting the environment, and ultimately, saving you money.

Think of it less as just another piece of equipment and more as a fundamental investment. Let's break down exactly what you get out of it.

Elevating On-Site Safety and Security

First and foremost, these alarms prevent accidents. When you're dealing with flammable liquids like gasoline or diesel, a spill means you've just released highly volatile vapors into the air. All it takes is one spark—from machinery, static, anything—to ignite those fumes and cause a fire or explosion.

An overfill alarm is your best defense against this worst-case scenario. It takes human error out of the equation by giving a loud, clear warning that you can't ignore.

It's not just about fire risk, either. Direct contact with fuel can lead to skin irritation, respiratory problems, and other serious health issues for your crew. By keeping the fuel where it belongs, you’re creating a much safer workplace for everyone.

An alarm system is what separates a routine fuel transfer from a full-blown emergency. It's the critical control that ensures every fill-up ends safely.

Guarding Against Environmental Damage

A fuel spill isn't just a site-specific problem; it's an environmental mess waiting to happen. Once fuel gets out of the tank, it contaminates everything it touches, and the cleanup is always difficult and expensive.

A reliable overfill alarm is your most effective tool for preventing that contamination. It helps you meet your environmental obligations and stay on the right side of tough regulations.

- Preventing Soil Contamination: Spilled fuel soaks into the ground almost immediately, poisoning the soil and killing off plant life. This can make the land unusable for years and requires costly, intensive cleanup.

- Protecting Water Resources: From the soil, fuel can easily make its way into the groundwater, contaminating aquifers that might feed local drinking water supplies. A single spill can have a ripple effect across the entire local ecosystem.

- Meeting EPA Standards: The Environmental Protection Agency (EPA) has very strict rules for storing fuel. An overfill alarm is a key piece of equipment that shows you're doing your due diligence and helps you avoid massive fines.

Delivering a Strong Financial Return

Finally, let's talk money. The cost of a single major overfill can be staggering, easily reaching tens or even hundreds of thousands of dollars. When you compare that potential disaster to the one-time cost of an alarm system, the value proposition is obvious.

The financial argument is solid. The global market for tank overfill protection was valued at $1.2 billion and is projected to more than double to $2.5 billion by 2033. This boom is happening because businesses have realized prevention is far cheaper than reaction. You can dive deeper into the market trends in this detailed market analysis.

A spill unleashes a whole chain of costs that can devastate a budget. You’re suddenly on the hook for:

- Cleanup Expenses: This means hiring specialized crews, paying for hazardous material disposal, and conducting environmental tests. The bills add up fast.

- Regulatory Fines: The fines for breaking environmental laws are steep, and that's often just the beginning of your legal headaches.

- Lost Product: The fuel you spilled is a direct financial loss.

- Operational Downtime: While cleanup and investigations are underway, your operations grind to a halt, which means lost revenue. Having a response plan is critical, as we cover in our complete guide to fuel spill cleanup procedures.

A fuel tank overfill alarm is a simple, effective way to sidestep all of these financial landmines.

Choosing the Right Overfill Alarm System

Picking the right fuel tank overfill alarm isn’t about finding a one-size-fits-all solution, because there isn't one. It’s about matching the system to your real-world needs—the kind of fuel you store, the tanks you use, and the environment you work in. Getting this right is about more than just checking a compliance box; it's about genuine safety and long-term reliability.

The decision really comes down to a few key factors. You have to think about the fuel itself, the physical setup of your tank, and even how your team operates day-to-day. A system that’s perfect for a small diesel day tank inside a hospital basement will likely be a poor choice for a massive gasoline storage vessel at a bustling marina.

Key Factors for Your Decision

Before you even start looking at specific models, you need to get a crystal-clear picture of what you require. Think of it like drawing up a blueprint. Nailing down these details first makes the rest of the process much smoother.

- Fuel Type and Properties: Are you working with something corrosive? Does your fuel tend to foam up or create a lot of vapor during a fill? These details matter. Aggressive chemicals, for instance, might eat away at a standard sensor, meaning you'll need one made from something tough like PVDF or stainless steel to last.

- Tank Size and Shape: The depth and internal layout of your tank are critical. A really deep tank might need a sensor with a longer probe or a different technology altogether, like radar, to get an accurate reading from top to bottom. If your tank has internal pipes, baffles, or ladders, they can trip up certain types of sensors.

- Operational Environment: Where is this tank located? Is it sitting outside in the blistering sun or freezing cold? Does it have to deal with heavy vibrations from nearby machinery or a hazardous atmosphere? A system on a coastal dock, for example, has to be tough enough to handle constant moisture, salt spray, and wild weather swings. For anyone managing marine fuel systems, this is a huge deal, and our boat fuel tank guide offers more detailed advice on selecting and maintaining these components.

Comparing Sensor Technologies

The sensor is the heart of any overfill alarm. The technology it uses is probably the single most important choice you'll make, as it directly impacts everything from accuracy and reliability to cost and maintenance. While there are many variations out there, most alarms are built around one of a few core technologies.

The most crucial step is to match the sensor's strengths to your application's demands. A simple, low-cost solution might seem appealing, but if it's prone to false alarms or failure in your specific environment, it becomes a liability rather than an asset.

Let's take a closer look at the most common options and see how they really stack up.

Comparison of Overfill Alarm Sensor Technologies

To help you decide, here’s a breakdown of the leading sensor types. Each has its place, but knowing the pros and cons is key to finding the best fit.

| Sensor Type | How It Works | Best For | Key Advantages | Potential Drawbacks |

|---|---|---|---|---|

| Mechanical Float | A buoyant float rises with the fuel. When it hits a set point, it physically flips a switch. | Simple, non-foaming liquids in standard tanks. | Low cost, easy to install, and the switch itself needs no power. | Moving parts can wear out, jam, or get stuck. Not great for sludgy or turbulent liquids. |

| Ultrasonic | Emits high-frequency sound waves that bounce off the fuel's surface. The sensor times the echo's return to calculate the level. | Non-contact measurement in tanks with clear headspace. | Very accurate, no moving parts, and isn't affected by fuel color or density. | Can be confused by heavy foam, dense vapors, or a turbulent surface. Needs a clear path. |

| Radar | Sends out microwave pulses that reflect off the fuel. It measures the "time of flight" to find the level. | Challenging conditions, including foam, vapor, and extreme temperatures. | Extremely accurate and reliable. It can "see" through foam and vapor. | Higher upfront cost compared to other types. |

| Vibrating Fork | A two-pronged probe vibrates at a set frequency. When fuel covers it, the vibrations dampen, triggering the alarm. | High and low-level alarms for a huge range of liquids. | Super reliable, self-cleaning, and isn't bothered by foam, bubbles, or viscosity. | Only detects a single point level, doesn't provide continuous measurement. |

By carefully thinking through these factors and understanding how each technology works, you can move past generic recommendations. You'll be ready to choose a fuel tank overfill alarm that not only meets regulations but is perfectly suited to give you years of dependable, worry-free service.

Essential Installation and Maintenance Practices

A high-quality fuel tank overfill alarm is an incredible safety tool, but it's only as good as its installation and maintenance. Proper setup and regular check-ups are what turn a piece of equipment into a reliable safety system you can count on. Skipping these steps is like having a top-of-the-line fire extinguisher that you never inspect—it might fail you the one time you actually need it.

Think of the installation as the foundation. It has to be solid from the very beginning. The main goal here is to make sure the alarm can accurately read fuel levels and send out a clear warning without any hiccups.

Proper Installation Is The First Step

Getting the installation right is about more than just hooking up a few wires. It's about being smart with sensor placement and system integration to ensure everything works perfectly from day one.

Optimal Sensor Placement: The sensor has to be set at just the right high-level mark, which is usually 90-95% of the tank’s safe fill capacity. It needs to be mounted securely, away from fill pipes or any areas where splashing fuel could trigger a false alarm. It’s also vital that the sensor has a clear, direct path to the fuel's surface, particularly for ultrasonic or radar models.

Secure Wiring and Connections: All wiring should be run through a protective conduit to guard against damage, moisture, and corrosion. Every connection must be tight and secure—a single loose wire could take the whole system offline. This becomes even more critical if the alarm is tied to an emergency shut-off valve, which demands thorough testing right after installation.

Of course, the alarm is just one part of a larger system. For boats and marine environments, paying attention to things like LPG gas hose safety is just as important for overall safety.

A Simple Maintenance Checklist For Peak Reliability

Once it's installed, your overfill alarm is not a "set it and forget it" device. Consistent, preventative maintenance is the key to making sure it works flawlessly every time. A simple, repeatable checklist is the best way to stay on top of it.

Keeping a detailed maintenance log isn't just good practice; it’s often required to pass compliance audits. This log serves as clear proof that you're proactively managing your facility's safety systems.

Follow this straightforward schedule to keep your system in prime condition:

- Monthly Functional Test: Manually set off the alarm to make sure the horn sounds and the light flashes. This quick test confirms the basic alert functions are working.

- Quarterly Sensor Inspection: Take a look at the sensor for any buildup, corrosion, or damage. If you have a float switch, make sure the float can move up and down freely.

- Semi-Annual Power Verification: Check the main power supply. If your system has a backup battery, test it to ensure it can still hold a charge and power the alarm during an outage.

- Annual System-Wide Check: Run a full test by simulating a high-level event. This is to confirm that any connected pumps or valves shut off exactly as they should.

This hands-on approach ensures your fuel tank overfill alarm will always be a safeguard you can trust.

Absolutely. Here is the rewritten section with a more natural, expert tone, following all your requirements.

Navigating Compliance and Industry Standards

Let's be honest, dealing with regulations can feel like trying to read a different language. The world of fuel storage compliance is full of acronyms and dense rules that can be intimidating. But getting this right isn't optional—it's the bedrock of a safe and responsible operation.

Think of a certified fuel tank overfill alarm as more than just a noisemaker. It’s your tangible proof of due diligence. When an inspector shows up, that alarm system demonstrates you’re being proactive, not just reactive. Let's cut through the jargon and look at what you actually need to know.

Key Regulatory Bodies and What They Mandate

In the United States, the Environmental Protection Agency (EPA) is the main player. Their rules are all about preventing fuel spills that can poison soil and groundwater. While your state or city might have its own specific twists, the EPA’s regulations are the foundation for everyone.

The EPA requires that all Underground Storage Tanks (USTs) and Aboveground Storage Tanks (ASTs) have some form of overfill prevention. You generally have three choices: an automatic shutoff device, a flow restrictor, or a high-level alarm. Of these, a high-level alarm—set to go off at no more than 95% capacity—is one of the most common and trusted methods.

An auditor's visit shouldn't be a source of anxiety. With a properly installed and maintained overfill alarm, you already have one of the most critical pieces of evidence they look for. They want to see that your system is functional, regularly tested, and that you keep records of these checks.

Don't underestimate the consequences of falling short. Fines for non-compliance can run into thousands, or even tens of thousands, of dollars per day for each violation. The cost of a good alarm system pales in comparison to that kind of financial risk.

Understanding Industry Best Practices Like API 2350

Beyond what the government legally requires, you have industry standards that outline best practices. For overfill protection, the most important one is API Standard 2350 from the American Petroleum Institute. It was written for large petroleum facilities, but the principles it lays out are gold for any operation, big or small.

API 2350 gives you a complete playbook for building and managing an overfill prevention system. It's all about creating multiple layers of safety and making sure everyone involved in a fuel transfer knows exactly what their job is.

A crucial insight from API 2350 is that just having a fuel tank overfill alarm isn't enough. The system's integrity is what matters. This means you also have to:

- Regularly test every part of the alarm system to make sure it works.

- Train your crew on what the alarm means and what to do in an emergency.

- Keep clear records of every test, inspection, and training session.

Following standards like API 2350 builds a true culture of safety that’s about more than just passing an inspection; it's about making sure your entire operation is designed to prevent spills from happening in the first place. This same big-picture thinking applies to marine fuel management, where blending technology with smart procedures is key to both safety and savings.

By getting a handle on these regulations and industry standards, you can run your business with confidence. Your alarm system stops being just another piece of equipment and becomes the cornerstone of a smart strategy to protect your company, your people, and the environment.

Of course. Here is the rewritten section with a more natural, human-expert tone.

Commonly Asked Questions About Overfill Alarms

When you're looking into fuel tank overfill alarms, the same handful of questions always seem to pop up. It's one thing to read a spec sheet, but it's another to understand how these systems work day-in and day-out. Let's dig into some of the most common questions we get from operators on the ground.

These are the practical, real-world concerns that matter most when you're trying to run a safe and tight operation.

What Causes a False Alarm?

There's nothing more frustrating than an alarm blaring when you know for a fact the tank isn't full. When a false alarm happens, it’s almost always due to one of three culprits:

- Turbulence During Filling: Think of it like a choppy sea in a teacup. High-flow pumps can cause fuel to splash and slosh around, tricking the sensor into thinking the fuel level is much higher than it actually is.

- Sensor Buildup: Over time, a layer of gunk, sludge, or other residue can build up on the sensor itself. This film can easily interfere with its ability to get an accurate reading.

- Electrical Faults: Sometimes the problem isn't the fuel or the sensor, but the wiring. A loose connection, a bit of moisture getting into the electronics, or even a power surge can be enough to trigger the alarm.

A little bit of routine maintenance and a good cleaning schedule can go a long way in preventing most of these headaches.

How Often Should I Test My Alarm System?

Regular testing isn't just a "best practice"—it's a core safety habit. Your local regulations will have the final say, but a great approach is to set up a simple, tiered testing schedule.

We recommend a quick functional test every month. Just manually trigger the alarm to make sure the horn sounds and the lights flash. Then, once a year, do a more comprehensive check to confirm the entire system works as intended, especially if it’s tied into automatic shut-off valves or pumps.

This habit ensures your alarm will actually do its job when you need it most.

Can an Overfill Alarm Be Used on Any Type of Fuel?

Mostly, yes—but you absolutely have to match the sensor to the fuel. For standard stuff like gasoline and diesel, most common alarms will work just fine. But when you get into more aggressive or specialized liquids, the material of the sensor becomes critical.

For instance, certain biofuels or industrial chemicals can eat right through standard sensor materials. For those applications, you’ll need a sensor built from something tougher, like stainless steel or PVDF, to make sure it doesn't corrode and fail. Always double-check that the sensor's materials are compatible with what you're storing.

Are you tired of the stress and mess of fueling your boat? CLiX Fueling Solutions offers a simple, automatic shut-off system that prevents dangerous overfills and protects your boat and the environment. Enjoy spill-free fueling every time by visiting the official CLiX Fueling website to learn more.