At its simplest, a boat fuel level sensor is the device sitting inside your fuel tank that figures out how much fuel you have left. It then relays that info up to the gauge on your dashboard. It's the critical link—the one piece of equipment that keeps you from the dreaded experience of running out of fuel miles from shore.

Think of it as the most important, yet often forgotten, instrument on your entire console.

Why Your Boat's Fuel Sensor Matters

The fuel gauge on your boat’s dashboard is only as good as the sensor feeding it information. If that sensor is off, the reading is more than just an inconvenience; it's a genuine safety risk. We've all heard the stories—the engine sputters and dies just as the sun dips below the horizon, leaving a boater stranded and far from any marina. This is exactly the nightmare scenario a reliable fuel sensor is there to prevent.

The whole system is really just two main parts: the fuel sending unit (the sensor itself, inside the tank) and the fuel gauge on your dash. The sender is constantly measuring the fuel and turning that physical level into an electrical signal. That signal zips up to the gauge, which then shows you what you need to know, usually with a classic needle pointing somewhere between "F" and "E."

More Than Just an Empty-Tank Warning

Its main job, of course, is telling you when to head back for a fill-up. But a high-quality sensor does so much more, making your boating experience both safer and more budget-friendly. When you can trust your gauge, you can plan your trips with confidence and know your real range.

A reliable fuel sensor transforms your fuel gauge from a simple dial into a strategic tool for safety, engine protection, and cost savings. It provides the critical data needed for worry-free time on the water.

This kind of accuracy also helps protect your marine engine. Running a tank bone-dry is a bad idea, as it can suck any gunk or water sitting at the bottom of the tank straight into your fuel lines. That can lead to clogged filters and even damage to your engine's sensitive parts.

The Economic Advantage of Accuracy

On top of the safety aspect, knowing your true fuel level has some nice financial benefits. It gives you the power to:

- Optimize Fuel Consumption: By tracking your usage with precision, you can figure out your boat’s most efficient cruising speed, which saves you real money on every outing.

- Prevent Overfills: An accurate reading helps you stop pumping at the right time, avoiding messy, expensive, and environmentally harmful fuel spills at the dock.

- Detect Issues Early: If you see the fuel level drop way faster than it should, it could be a red flag for a leak or even fuel theft. Catching it early can save you a much bigger headache down the road.

How Different Types of Boat Fuel Sensors Work

Not all fuel sensors are built the same. The technology tucked inside a boat fuel level sensor can differ quite a bit, which directly affects its accuracy, lifespan, and price tag. Getting a handle on how they work is the first step to understanding why some are a much better fit for the demanding marine environment than others.

Let's break down the common types you'll find out on the water.

Traditional Float Arm Sensors

The old-school standard is the resistive float arm sensor. The easiest way to picture this is to think about the float inside your toilet tank. As the water level changes, an arm connected to a float moves up or down with it. It’s the same idea in your fuel tank: a float on an arm rises and falls with the fuel level.

This arm is connected to a variable resistor. When the tank is full, the arm is high, creating a specific electrical resistance. As you burn through fuel, the arm drops, changing that resistance. Your fuel gauge reads this change and displays the new, lower level. It’s a straightforward mechanical system that’s been the go-to for decades.

But for all its simplicity, this design has some real downsides on a boat. The constant sloshing of fuel in choppy water makes the float arm bounce around like crazy. The result? A needle on your gauge that jumps all over the place, giving you a reading you can't really trust. On top of that, the moving parts—especially the wiper that contacts the resistor—can wear out, leading to spotty readings or complete failure.

Modern Non-Contact Sensor Technology

To get around these problems, engineers developed newer technologies that can measure fuel without any moving parts sitting in the liquid. A great example is the ultrasonic fuel sensor.

Think of it like a bat using echolocation to navigate in the dark. The sensor is mounted at the top of the tank and sends a silent, high-frequency sound wave down to the surface of the fuel. It then listens for the echo and measures the exact time it takes for that sound wave to bounce back.

This time measurement is instantly converted into a precise distance, telling the system exactly how far the fuel surface is from the sensor. Because there are no floats, arms, or wipers submerged in the fuel, these sensors are far more reliable and aren't tricked by sloshing fuel. Their accuracy stays sharp for a much longer time.

By measuring fuel without direct contact, modern sensors like ultrasonic models eliminate the common failure points of older mechanical float arms, offering superior reliability and accuracy for boaters.

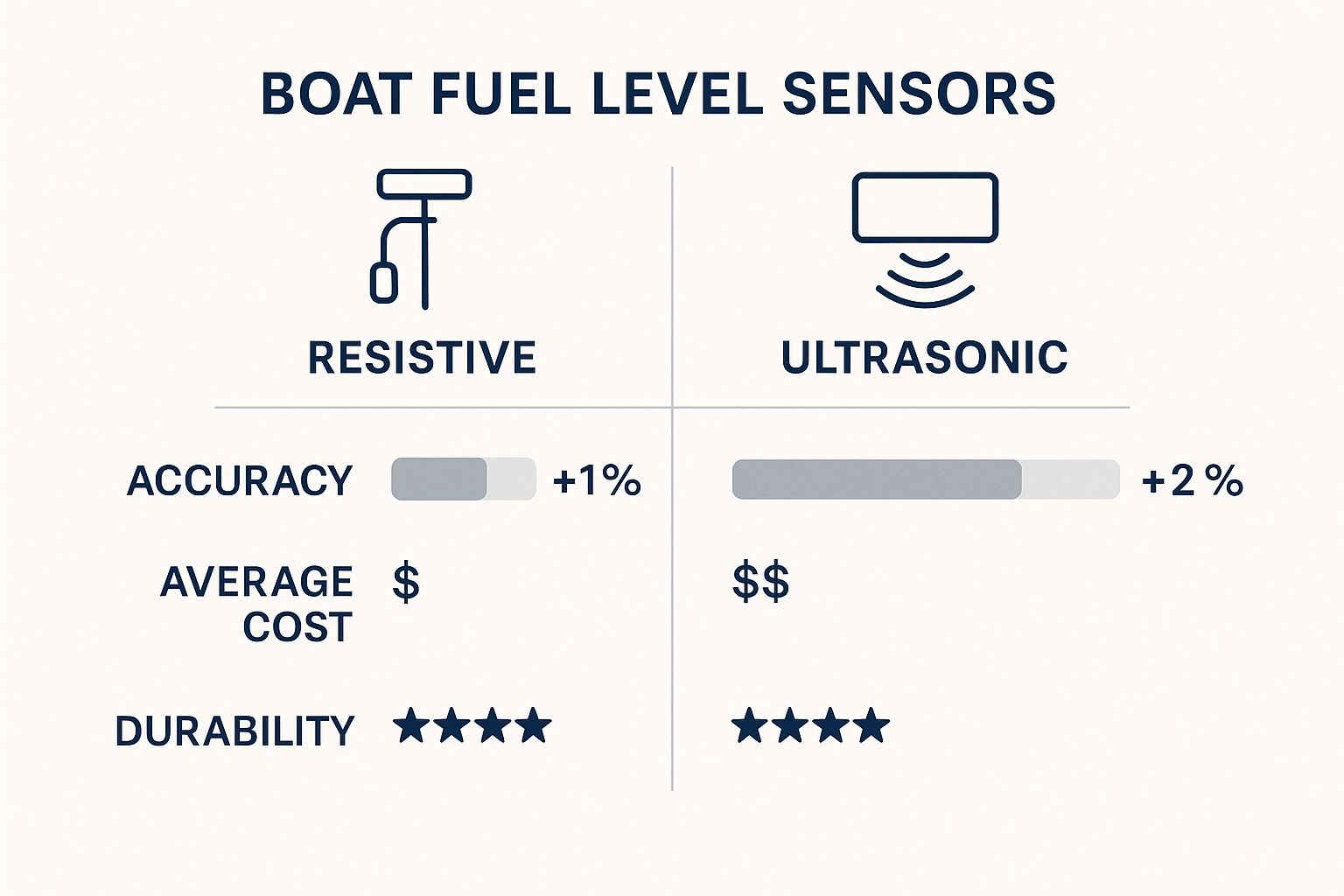

This infographic really highlights the differences between the old and new school tech.

As you can see, while ultrasonic sensors might have a higher upfront cost, the payoff in accuracy and long-term durability is huge.

A Quick Comparison of Sensor Types

Choosing the right sensor often comes down to balancing cost, accuracy, and durability. This table breaks down the key differences to help you see which technology best fits your needs on the water.

| Sensor Type | Operating Principle | Pros | Cons |

|---|---|---|---|

| Resistive Float Arm | A float on a mechanical arm moves with the fuel level, changing electrical resistance. | Low cost, simple technology. | Prone to wear and tear, inaccurate readings in rough water due to sloshing. |

| Ultrasonic | Sends a sound wave to the fuel surface and measures the echo's return time to calculate distance. | Highly accurate, no moving parts, unaffected by sloshing. | Higher initial cost, requires careful installation. |

| Capacitive | Acts like a capacitor, where the fuel level changes the capacitance between two probes. | No moving parts, good accuracy. | Can be affected by fuel additives and water contamination. |

Ultimately, while traditional float sensors are affordable, their mechanical nature is a significant weak point in a marine setting. Both ultrasonic and capacitive sensors offer a solid-state solution that stands up much better to the challenges of boating, with ultrasonic often being the preferred choice for its robustness.

The Rise of Advanced Sensor Types

Beyond these, the world of sensors is always evolving. Technologies like optical and even piezoelectric sensors are used in various industries. However, for marine and industrial use, ultrasonic sensors have really taken the lead. Their non-contact nature and reliability in tough environments make them a standout choice that drastically cuts down on maintenance headaches.

Now, with wireless technology becoming more common, these advanced sensors are being integrated into smart fuel management systems. This is paving the way for real-time data analytics and much smarter fueling decisions. You can explore more about the broad fuel level sensor market to see how these advancements are making an impact across different sectors.

The Real Benefits of Accurate Fuel Management

Think of an accurate boat fuel level sensor as the brain behind a smart fueling strategy. Sure, its most basic job is keeping you from getting stranded, but the real magic happens when you look a little deeper. A reliable sensor can turn your fuel gauge from a simple needle into a powerful tool for every trip you take.

The biggest benefit, without a doubt, is safety. When you can actually trust your fuel reading, you can plan your journeys with real confidence. No more of that nagging "range anxiety" when you’re debating a trip to that distant fishing spot. You know exactly what your boat is capable of, which is crucial for avoiding dangerous situations far from shore.

Saving Money and Spotting Problems Early

Beyond the peace of mind that comes with safety, precise fuel data offers some serious perks for your wallet. When you have reliable information, you can pinpoint your engine's sweet spot—that perfect RPM range where it sips fuel instead of guzzling it. Those small adjustments add up to big savings over a full boating season.

A good sensor also acts as an early warning system for problems you might not otherwise notice.

- Engine Health: Is your fuel level dropping way faster than it should be? That could be a sign that your engine is running rich or has another issue that needs a mechanic's touch.

- Fuel Theft: A sudden, sharp drop in your fuel level while docked is a major red flag for fuel theft, which is a lot more common at marinas than most people think.

- Leak Detection: Even a slow, steady decline in fuel when the boat isn't running could point to a dangerous leak in the tank or fuel lines.

Getting this kind of accuracy is what it’s all about. In fact, applying general techniques for optimizing measurement accuracy can make any fuel sensor system that much more dependable.

At the end of the day, knowing your exact fuel level just lets you relax. It takes away that constant, low-level worry about how much time you really have left, so you can actually focus on enjoying the water.

This move toward precision isn't just happening in boating. The global market for fuel level sensors was valued at around $2.5 billion in 2024 and is climbing fast. That growth shows just how vital these devices are for efficiency everywhere.

Ultimately, smart fuel management is about more than just filling up the tank. A modern boat fuel management system brings together accurate data and smart technology to protect your investment, your budget, and the environment.

How to Choose the Right Fuel Level Sensor

Picking the perfect boat fuel level sensor isn’t just about grabbing the most expensive one off the shelf. It’s about finding the right match for your specific boat and how you use it. A little thought up front can save you a lot of headaches and give you reliable readings for years to come.

Think of it like buying tires. You wouldn't put slick racing tires on a 4x4 truck you take through the mud. In the same way, the best sensor for a small plastic tank on a pontoon is probably the wrong choice for a deep, oddly shaped tank on a sportfishing yacht.

Your journey starts with a good, hard look at your boat’s fuel tank. This one piece of equipment really dictates your options.

Consider Your Fuel Tank First

Before you even start looking at sensors, you need to know your tank inside and out. The material, shape, and depth are the most critical factors.

- Tank Material: Is your tank metal (like aluminum or stainless steel) or is it plastic (polyethylene)? Some sensor types, especially certain capacitive models, can be sensitive to the tank material. Ultrasonic sensors, on the other hand, usually play nice with both.

- Tank Shape and Depth: A simple, rectangular tank is a breeze to measure. But let's be honest, many boats have deep, weirdly shaped tanks tucked into tight spaces to make the most of the hull design. For these, a basic swing-arm float sensor can be wildly inaccurate. As the fuel sloshes around, the readings can jump all over the place. A modern, programmable digital sensor—like an ultrasonic one—is a much better bet because you can calibrate it to the tank’s specific geometry.

- Fuel Type: Most sensors handle standard gasoline and diesel without a problem. But if you’re running ethanol blends or other specialty fuels, you absolutely have to check for compatibility. Some additives can mess with capacitive sensors or even eat away at the materials in cheaper units over time.

Choosing the right sensor starts with understanding your fuel tank. Its material, shape, and depth are the most important factors that will determine which technology provides the most accurate and reliable readings for your boat.

Once you’ve got a handle on your tank, the next step is making sure a new sensor will actually work with the rest of your boat.

Check for System Compatibility

A fancy new sensor is completely useless if it can’t talk to your existing gauges or displays. This all comes down to two things: your dashboard gauge and your boat’s data network, if you have one.

If you're doing a simple swap, you have to match the sensor’s electrical resistance to what your gauge is designed to read. There are two main standards you’ll run into:

- American Standard: 240-33 Ohms (240 Ω when empty, 33 Ω when full)

- European Standard: 0-180 Ohms (0 Ω when empty, 180 Ω when full)

Get this wrong, and your gauge will read backward, get stuck, or just won't work at all.

For more modern boats equipped with an NMEA 2000 network, you’ll want a sensor that can plug right into that system. This is a game-changer. It lets you see your fuel level directly on your multifunction display (MFD) right alongside your GPS chart, engine data, and fishfinder. This kind of integration is at the heart of a modern boat fuel system, putting all your critical information in one place.

In the end, the goal is to find a sensor that not only fits your tank perfectly but also fits seamlessly into your boat's existing setup. That’s how you get trustworthy data that makes every trip safer and more relaxing.

A Practical Guide to Installation and Maintenance

A high-quality boat fuel level sensor won't do you much good if it's installed improperly. Getting this part right is the key to getting the accurate, trustworthy readings you need out on the water. While calling in a marine technician is never a bad idea, many boat owners can tackle this job themselves with a bit of know-how and a focus on safety.

Before you even think about touching a wrench, let's talk safety. Fuel fumes are no joke—they're incredibly flammable. Always work in a space with plenty of fresh air, disconnect your boat’s battery completely, and double-check that there are no sparks, open flames, or other ignition sources anywhere nearby. It's also best to work with a tank that's empty or as close to it as you can get.

The Installation Process Step-by-Step

With your work area secured, the actual installation is pretty straightforward. You’ll usually begin by taking out the old sending unit, which is typically mounted with five screws in a standard SAE bolt pattern.

- Remove the Old Unit: Go ahead and unscrew the old sensor. Before you disconnect the wires, snap a quick picture with your phone. You’ll thank yourself later when you’re hooking up the new one.

- Prep the Opening: Clean the mounting surface on the tank really well. You want to get rid of any old gasket gunk or sealant to ensure the new one sits flush.

- Position the New Sensor: Lay down the new gasket, then gently insert the new sensor. If you're using a model with an adjustable float arm, you'll need to set its length to match your tank’s depth based on the manufacturer's guide.

- Secure and Seal: Tighten the mounting screws in a star pattern. This applies even pressure and creates a solid, leak-proof seal. Be careful not to overtighten—you could damage the gasket or the threads.

- Connect the Wires: Now, reconnect the wiring. Pay close attention to which wire is the signal (positive) and which is the ground. A bad ground connection is the number one reason fuel gauges give bizarre and inaccurate readings.

The most critical parts of the install aren't just dropping the sensor in place. It's all about creating a perfect, fuel-tight seal and ensuring you have a rock-solid electrical ground. A weak ground will make even the most expensive sensor unreliable.

Ongoing Maintenance for Long-Term Reliability

The good news is that your fuel sensor doesn't demand a lot of attention once it's in. However, a few quick checks now and then can save you from major headaches down the road. A simple maintenance routine is all it takes to keep your sensor working reliably for years.

Try to give it a look once a year. Check that the mounting screws are still snug and that the seal around the unit is solid, with no cracks or signs of fuel weeping. More importantly, inspect the wiring and all the electrical connections. Corrosion is the constant enemy in a marine environment, so clean or replace any terminals that look green or fuzzy. If your sensor has moving parts, a quick check to make sure no gunk is getting in the way can also go a long way. This little bit of prevention will keep your fuel gauge honest and give you one less thing to worry about.

Troubleshooting Common Fuel Gauge Issues

It’s a feeling every boater dreads: you look down at your fuel gauge, and something is clearly wrong. Maybe it’s stuck on full, jumping around like crazy, or just completely dead. It's a frustrating and frankly, a nerve-wracking problem.

The good news? The culprit is almost always one of three things: a bad gauge on the dash, faulty wiring, or a failing boat fuel level sensor inside the tank. The trick is to figure out which one it is without just throwing parts at the problem. A logical approach, starting with the simplest checks, will save you a ton of headaches.

Think of it like a simple electrical chain. The sending unit in your tank creates a signal, a wire carries that signal to the gauge, and the gauge needs a good ground to display it properly. A break anywhere in that chain means you get a bad reading.

Diagnosing the Problem

Your first stop should be the dashboard gauge itself—it's usually the easiest part to get to. More often than you'd think, the problem is just a loose or corroded ground wire. Take a look at the back of the gauge. If that ground connection looks crusty or feels loose, clean it up and tighten it down. You might be surprised how often this simple fix gets things working again.

If the ground is solid, the next step is to test the gauge. To do this, disconnect the wire coming from the sending unit (it's usually labeled "S" or "Send"). With that wire off and the power on, a good gauge should read "Empty."

Next, take a small piece of wire and jump the sender terminal on the gauge directly to a good ground. This should make the needle swing all the way to "Full." If your gauge passes both of these tests—going to empty when disconnected and full when grounded—then the gauge itself is working perfectly. The problem lies elsewhere, either in the wiring run or with the sending unit in the tank.

For a more in-depth guide, check out our post with expert tips for troubleshooting your marine fuel gauge.

A systematic approach is key. By testing the gauge first, then the wiring, and finally the sender, you can isolate the problem without replacing perfectly good parts. This method saves you time, money, and frustration.

Got Questions About Fuel Sensors? We've Got Answers.

When you're dealing with marine electronics, a few questions are bound to pop up. And when it's your boat fuel level sensor we're talking about, getting straight answers is critical for staying safe and keeping things running smoothly. Let's tackle some of the most common questions boaters ask.

Can I Just Replace the Fuel Sender and Keep My Old Gauge?

Most of the time, yes you can. But here's the catch: they have to be compatible. Think of the sender and the gauge as a matched pair that speaks the same language—in this case, electrical resistance.

American standard gauges, for instance, typically operate on a 33-240 ohm range. European gauges, on the other hand, usually use a 10-180 ohm range. If you install a sender that doesn't match your gauge's expected range, you'll get wildly inaccurate readings. Your gauge might scream 'Full' when you're actually at half a tank, which is a recipe for a bad day on the water.

So, before you buy anything, double-check the specs on both your old sender and the new one you're considering.

How Do I Calibrate a New Boat Fuel Level Sensor?

This really comes down to what kind of sensor you're installing.

- Traditional Float-Arm Sensors: These are calibrated mechanically. You'll likely need to physically adjust the float arm itself—bending it or changing its length—so its swing accurately reflects your tank's depth from empty to full.

- Modern Digital Sensors: Ultrasonic or capacitive sensors are a different story. They're calibrated electronically, usually through a display unit or a smartphone app. You'll digitally "teach" the sensor what 'empty' and 'full' look like for your specific tank.

No matter the type, following the manufacturer's instructions to the letter is the only way to ensure you get it right.

What if you've installed a brand new, compatible sensor and the readings are still off? The problem probably isn't the sensor. Check for poor electrical connections first—a weak or corroded ground wire is the usual suspect. A faulty gauge could also be the culprit.

It's also worth noting that oddly shaped fuel tanks can fool basic sensors. This is where advanced digital sensors really shine. They allow for multi-point calibration, letting you map out the tank's unique shape to get much more precise fuel readings.

Stop guessing and start fueling with confidence. CLiX Fueling Solutions offers a simple, spill-free system that prevents overfills and protects your boat and the environment. Discover a better way to fuel up.