In high-stakes environments, from aviation and chemical processing to everyday marine fueling, safety isn't just a policy; it's the bedrock of operational excellence. A robust Safety Management System (SMS) moves organizations from a reactive, 'fire-fighting' posture to a proactive state of continuous improvement. It's about systematically identifying hazards, assessing risks, and implementing controls before incidents occur.

This proactive approach creates a culture where potential problems are addressed at their source. For instance, proactive safety management is exemplified by initiatives focused on ensuring student safety in educational environments, where identifying risks in advance is paramount. The same principle applies directly to the marine world, where seemingly minor oversights can lead to significant consequences. By prioritizing proactive measures, marinas and boat owners can prevent accidents, protect the environment, and build a reputation for reliability and care.

This article explores six powerful safety management system examples, offering a deep dive into the frameworks that have revolutionized industries. We will analyze the strategies behind each system, extract actionable tactics, and demonstrate how these principles can be scaled to fit any operation. For the marine community, we’ll show how these concepts can be applied to enhance on-the-water and dockside safety, particularly through innovative tools like CLiX Fueling Solutions, which tackles the common but hazardous issue of fuel spills.

You will learn how to:

- Analyze established safety frameworks like ICAO, PSM, and ISO 45001.

- Identify replicable strategies from Behavior-Based Safety and High Reliability Organizations.

- Apply these proven principles to your own marine operations for tangible safety improvements.

1. Aviation Safety Management System (SMS) - ICAO Framework

The aviation industry operates with razor-thin margins for error, making safety its highest priority. The International Civil Aviation Organization (ICAO) framework for Safety Management Systems (SMS) is the gold standard, providing a systematic and proactive approach to managing safety risks. It moves organizations beyond simply reacting to incidents to proactively identifying and mitigating hazards before they cause harm.

At its core, an SMS integrates safety into the fabric of an organization. It's not just a manual on a shelf; it's a living system built on four key pillars:

- Safety Policy: Establishes senior management's commitment and sets the safety objectives.

- Safety Risk Management: A formal process for identifying hazards, assessing risks, and implementing controls.

- Safety Assurance: Measures and monitors safety performance to ensure controls are effective.

- Safety Promotion: Fosters a positive safety culture through training, communication, and continuous improvement.

This framework is one of the most powerful safety management system examples because it transforms an organization's culture from reactive to predictive.

Analysis: Why the Aviation SMS Model Excels

The success of the ICAO framework lies in its structured, data-driven nature. Airlines like United Airlines have used their SMS to achieve a remarkable 70% reduction in safety events since 2009. Similarly, Singapore Airlines credits its robust SMS for helping maintain its long-standing record of zero fatal accidents.

These results are not accidental. They stem from a deep commitment to treating safety as a core business function, not just a regulatory hurdle.

Strategic Insight: The most effective SMS programs are not top-down mandates alone. They thrive on data from the front lines, empowering every employee, from baggage handlers to pilots, to be a safety sensor for the organization. This creates a powerful feedback loop for continuous improvement.

For marine businesses, such as marinas or fueling operations, the aviation model offers a blueprint for achieving a similar level of systemic safety. While a boat is not a Boeing 747, the principles of identifying hazards (e.g., fuel spills, faulty equipment), assessing risks, and implementing controls are universal.

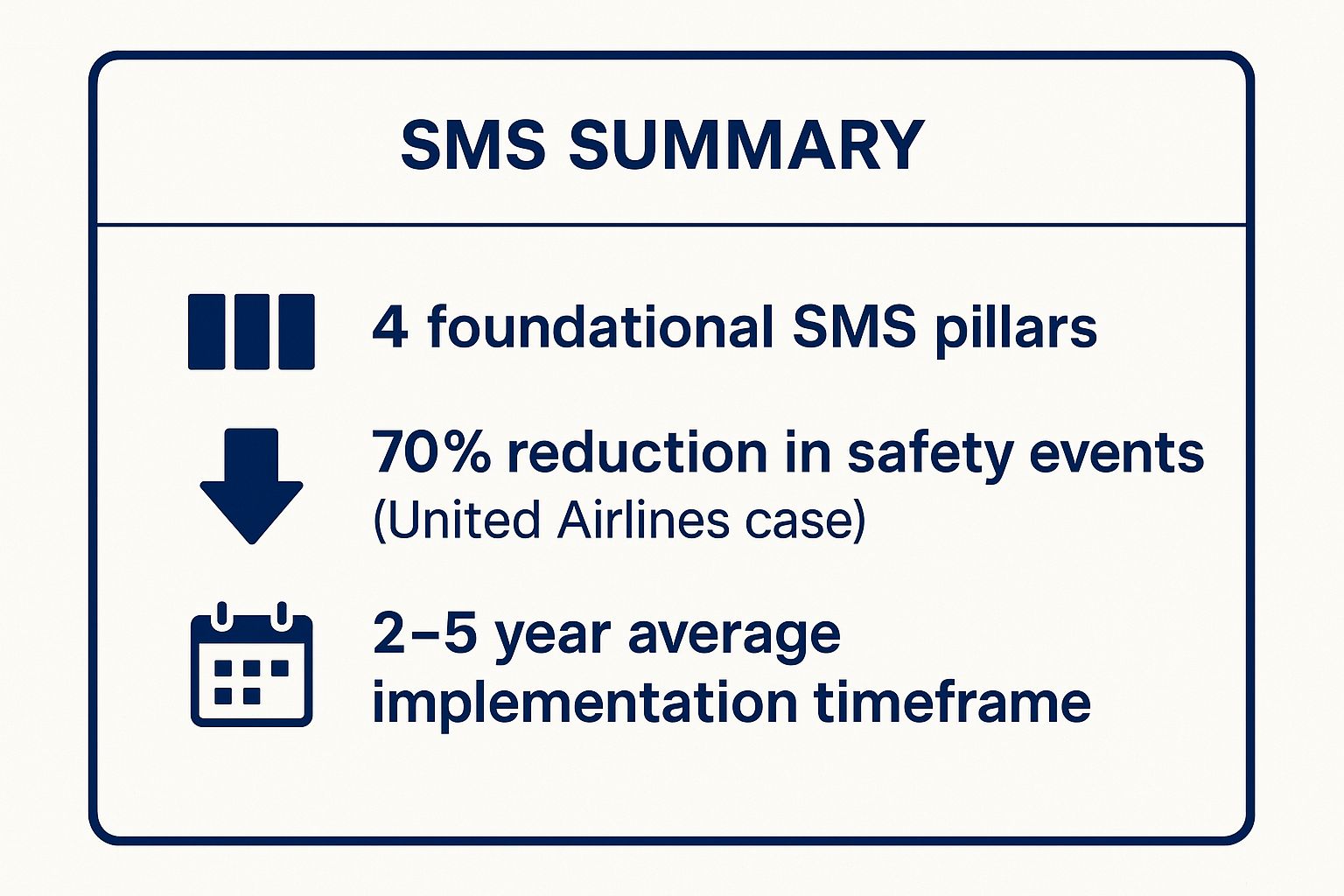

This infographic summarizes the core components and impactful results of a well-implemented aviation-style SMS.

The data clearly shows that a structured, four-pillar approach yields significant, measurable safety improvements, though it requires a multi-year commitment to fully mature.

Actionable Takeaways for Marine Operations

Marina operators and marine fuel providers can adapt the aviation SMS model to significantly enhance their own safety protocols.

- Establish a Clear Safety Policy: Start with a written commitment from leadership. This policy should clearly state safety objectives, like "zero spills during fueling operations" or "100% compliance with pre-departure checklists."

- Implement Hazard Reporting: Create a simple, no-blame system for staff and even boaters to report potential hazards. This could be a simple form, an email address, or a digital tool. The easier it is to report, the more data you will collect.

- Use Digital Tools for Assurance: A key part of Safety Assurance is monitoring performance. This is where modern solutions like CLiX Fueling Solutions come in. By providing real-time data on fuel flow, tank levels, and system integrity, CLiX automates the monitoring process, ensuring that your safety controls for fueling are always working as intended and immediately flagging anomalies that could indicate a risk.

2. Process Safety Management (PSM) - Chemical Industry Standard

In industries where hazardous materials are handled, safety isn't just a priority; it's a license to operate. The Process Safety Management (PSM) standard, pioneered by OSHA, provides a comprehensive framework for managing highly hazardous chemicals to prevent catastrophic releases. It is a rigorous, systematic approach focused on the integrity of processes, from design and engineering to maintenance and operation.

Unlike general safety programs that focus on slips, trips, and falls, PSM targets low-probability, high-consequence events like fires, explosions, and toxic leaks. It is built on 14 interconnected elements, including:

- Process Hazard Analysis (PHA): A systematic evaluation to identify and control process hazards.

- Operating Procedures: Clear, written instructions for conducting activities safely.

- Mechanical Integrity: Ensuring critical equipment is designed, installed, and maintained correctly.

- Management of Change (MOC): A formal process for reviewing any modifications to technology, equipment, or procedures.

This framework is one of the most critical safety management system examples for any operation handling volatile substances, transforming safety from a checklist into an engineering discipline.

Analysis: Why the PSM Model Is So Effective

The strength of PSM lies in its detailed, prevention-oriented requirements. Chemical giants like DuPont and Shell have built global safety programs around PSM principles. For instance, Shell's focus on process safety has helped it achieve a reported 60% reduction in Tier 1 incidents (the most serious losses of containment) over a decade.

These results are driven by a deep understanding that catastrophic failures often originate from small, seemingly minor deviations. PSM forces an organization to manage change meticulously and maintain the integrity of its physical assets and procedures.

Strategic Insight: The most powerful element of PSM is its emphasis on the 'system' rather than individual components. It recognizes that a failure in one area, like training or maintenance, can cascade and cause a major incident. True process safety is achieved when all 14 elements work in concert, creating multiple layers of protection.

For a marine fueling operation, which handles flammable liquids like gasoline and diesel, the PSM model offers a robust blueprint for preventing fires, spills, and vapor releases. While not every marina needs to implement all 14 elements of OSHA's PSM, the underlying principles are directly transferable.

Actionable Takeaways for Marine Operations

Marina operators can borrow core concepts from PSM to create a safer fueling environment and prevent catastrophic events.

- Conduct a Process Hazard Analysis (PHA): Systematically review your entire fueling process, from fuel delivery to the dock to dispensing into a vessel. Identify potential failure points, such as hose ruptures, overfills, or ignition sources, and implement specific controls for each.

- Establish a Management of Change (MOC) Procedure: Before making any change to your fueling equipment, suppliers, or procedures, use a simple checklist to evaluate how the change could impact safety. This prevents unintended consequences.

- Focus on Mechanical Integrity and Training: Implement a rigorous inspection and maintenance schedule for all fueling equipment, including hoses, nozzles, tanks, and emergency shutoffs. This must be paired with comprehensive training, a key component of effective environmental compliance programs. You can learn more about environmental compliance training on clixfueling.com.

- Leverage Digital Monitoring for System Integrity: PSM emphasizes maintaining the integrity of the system. Tools like CLiX Fueling Solutions support this by providing constant, real-time monitoring of your fuel infrastructure. It can instantly detect leaks, pressure drops, or other anomalies that indicate a breach in mechanical integrity, allowing you to address risks before they escalate into a major incident.

3. ISO 45001 Occupational Health and Safety Management System

ISO 45001 is the global benchmark for occupational health and safety (OH&S) management. Published by the International Organization for Standardization (ISO), it provides a robust framework for organizations of any size to proactively improve employee safety, reduce workplace risks, and create better, safer working conditions. It shifts the focus from reactive compliance to a proactive, integrated system built on leadership commitment and worker participation.

Unlike industry-specific regulations, ISO 45001 is designed to be applicable to any organization, regardless of its industry, size, or nature of work. It is structured around the "Plan-Do-Check-Act" (PDCA) model for continuous improvement and emphasizes:

- Context of the Organization: Understanding internal and external factors that impact OH&S.

- Leadership and Worker Participation: Making safety a core responsibility for everyone, from top management to frontline staff.

- Planning: Identifying hazards, assessing risks and opportunities, and setting OH&S objectives.

- Support: Providing the necessary resources, competence, awareness, and communication.

- Operation: Implementing and controlling processes to manage risks.

- Performance Evaluation: Monitoring, measuring, and analyzing OH&S performance.

- Improvement: Taking action to continually enhance the system.

This comprehensive approach makes it one of the most powerful safety management system examples for creating a holistic and sustainable safety culture.

Analysis: Why the ISO 45001 Model Excels

The strength of ISO 45001 lies in its integration with core business processes and its emphasis on a risk-based approach. Global manufacturing giant 3M uses the framework to manage OH&S across its incredibly diverse business units, ensuring a consistent standard of safety worldwide. Construction leader Balfour Beatty reported a 40% reduction in its accident frequency rate after implementing the standard, proving its real-world impact.

These results are driven by the standard's focus on proactive risk management and meaningful worker involvement, turning safety from a departmental silo into a shared organizational value.

Strategic Insight: The most successful ISO 45001 implementations are those that prioritize genuine worker participation over mere documentation. When employees are actively involved in hazard identification and risk assessment, the system becomes a living tool for prevention rather than a static set of rules to follow.

For marine businesses, the ISO 45001 framework offers a clear path to building a world-class safety system. The principles of leadership engagement, hazard control, and continuous improvement are directly applicable to managing risks in a marina, from slip-and-fall hazards on docks to the complex processes of boat maintenance and fueling.

Actionable Takeaways for Marine Operations

Marina operators and boatyard managers can leverage the principles of ISO 45001 to build a safer environment for staff and customers.

- Secure Leadership Commitment: Management must lead by example. This means actively participating in safety walks, allocating budget for safety improvements, and setting clear, measurable OH&S objectives like "reduce lost-time incidents by 20% annually."

- Empower Your Team: Create a formal committee with representatives from all departments (dockhands, technicians, office staff) to discuss safety issues. This fosters ownership and ensures that insights from the front lines inform your safety planning.

- Integrate Safety into Daily Operations: Don't treat safety as a separate task. Build safety checks directly into your existing procedures. For instance, a pre-fueling safety brief or a pre-lift equipment check should be a standard, non-negotiable part of the job. Making sure you have the right gear is a fundamental first step, so review your boating safety equipment checklist regularly.

- Focus on Continuous Training: An effective OH&S system requires ongoing education. To keep your team engaged, explore ways to create engaging employee training videos that clearly demonstrate correct procedures for tasks like spill response or equipment handling.

4. Behavior-Based Safety (BBS) Programs

Traditional safety systems often focus on conditions and rules, but Behavior-Based Safety (BBS) takes a different approach. It acknowledges that human actions are a major factor in most workplace incidents. A BBS program is a systematic process that focuses on identifying, measuring, and modifying at-risk behaviors while reinforcing safe ones. It's about empowering employees to become active participants in their own safety.

This approach is built on a foundation of observation, feedback, and positive reinforcement. Instead of simply punishing mistakes, BBS creates a culture where employees look out for each other and proactively address unsafe actions before they lead to an accident.

- Identify Critical Behaviors: Pinpoint specific actions that have the highest potential to cause injury.

- Observe & Collect Data: Train employees to conduct non-punitive observations of their peers to gather data on the frequency of safe and at-risk behaviors.

- Provide Feedback: Offer immediate, specific, and constructive feedback to reinforce safe work practices and correct unsafe ones.

- Use Data to Improve: Analyze observation data to identify trends and implement targeted improvements, whether through training, engineering controls, or process changes.

BBS programs stand out as powerful safety management system examples because they directly address the human element, creating a lasting cultural shift towards safety.

Analysis: Why the BBS Model Is So Effective

The success of Behavior-Based Safety lies in its focus on proactive, positive engagement. For example, industrial giant DuPont developed its famous STOP (Safety Training Observation Program), which has been adopted globally to drastically reduce incidents. Similarly, aluminum producer Alcoa leveraged BBS to achieve world-class safety performance, viewing it as a prerequisite for operational excellence. Construction leader Turner Construction also reported a 70% reduction in injuries after implementing its BBS program.

These results are driven by a fundamental shift in mindset. Safety becomes a shared responsibility, not just a management mandate. This approach also underscores the critical role of understanding human error and highlights the need for a non-punitive environment where employees feel safe reporting observations without fear of blame.

Strategic Insight: The core of a successful BBS program is not about "catching" people doing something wrong. It's about creating a culture of caring where peer-to-peer feedback is a normal, positive part of the daily routine. This builds trust and encourages genuine, voluntary participation.

This video from Dr. E. Scott Geller, a pioneer in the field, provides an excellent overview of the core principles behind a people-based safety culture.

Actionable Takeaways for Marine Operations

For marinas and fuel docks, where staff and boaters perform repetitive tasks like mooring and fueling, the BBS model is highly adaptable and effective.

- Define Critical Safe Behaviors: Identify key safety actions for fueling operations. Examples include "verifying the correct fuel type before pumping," "maintaining a firm grip on the fuel nozzle at all times," and "deploying absorbent pads before every fueling."

- Train Staff as Observers: Teach your dockhands how to perform quick, friendly, and non-judgmental observations. The goal is to provide helpful reminders and positive reinforcement, such as saying, "Great job putting those absorbent pads down first."

- Focus on Positive Reinforcement: When you see a team member or a boater performing a task safely, acknowledge it. Positive feedback is a powerful tool for making safe habits stick.

- Integrate BBS with Technology: While BBS focuses on human behavior, technology can reinforce those safe actions. For example, CLiX Fueling Solutions requires a secure, physical connection before fuel can flow, acting as an engineering control that complements safe behaviors. It ensures the "connect nozzle securely" behavior is performed correctly every single time, automating a critical safety check and providing data to confirm safe practices are being followed.

5. High Reliability Organization (HRO) Principles

High Reliability Organizations (HROs) operate in complex, high-stakes environments where even minor errors can lead to catastrophic failure, yet they manage to maintain exceptionally low accident rates. The HRO approach is less a formal system and more a cultural mindset focused on collective mindfulness and resilience. It was developed by studying organizations like US Navy nuclear submarine crews and air traffic control centers, which achieve near-perfect safety records despite constant risk.

An HRO is not defined by checklists alone but by its deep-seated culture of reliability. It’s built on five key principles that create an environment of constant awareness and rapid response:

- Preoccupation with Failure: A focus on identifying and understanding small errors and near-misses before they escalate.

- Reluctance to Simplify: Resisting the urge to create overly simple explanations for complex problems, instead digging for root causes.

- Sensitivity to Operations: Maintaining a constant awareness of what is happening on the front lines, where the real work gets done.

- Commitment to Resilience: Developing the capability to detect, contain, and bounce back from errors.

- Deference to Expertise: Shifting decision-making authority to the person with the most relevant knowledge, regardless of their rank or title.

This model is one of the most profound safety management system examples because it builds a workforce that is inherently resilient and hyper-aware of potential risks.

Analysis: Why the HRO Model Is So Effective

The success of HRO principles comes from empowering human expertise and fostering a culture of psychological safety. The US Navy Nuclear Submarine Program, for instance, has operated for over 60 years with zero reactor accidents. This incredible record is attributed to its HRO culture, where even the most junior sailor is expected to question a senior officer if they spot a potential safety issue. Similarly, Kaiser Permanente has applied HRO principles to patient safety, dramatically reducing medical errors by encouraging open communication and learning from near-misses.

These outcomes are achieved by treating safety as a dynamic, moment-to-moment activity, not a static set of rules. It requires constant vigilance and a collective commitment to preventing harm.

Strategic Insight: The core of the HRO model is "collective mindfulness." It's the idea that safety is everyone's job, and the organization is only as strong as its most observant team member. It replaces a culture of blame with a culture of inquiry, where every near-miss is a valuable lesson.

For a busy marine environment like a fuel dock or boatyard, this mindset is transformative. The principles of deferring to expertise (e.g., listening to the experienced dockhand over the new manager about a specific pump's quirks) and being preoccupied with failure (e.g., analyzing why a minor fuel drip occurred) are directly applicable.

Actionable Takeaways for Marine Operations

Marina operators can integrate HRO principles to build a deeply ingrained safety culture that anticipates and prevents incidents.

- Foster a Questioning Attitude: Actively encourage staff to speak up if something doesn't look right, without fear of reprisal. A simple phrase like, "If you see something, say something, and we will listen," can set the tone.

- Analyze Near-Misses Rigorously: Don't just dismiss a close call as "getting lucky." Treat every near-miss (e.g., a boat almost hitting the dock, a tangled fuel hose) as a free lesson. Hold brief debriefs to understand what happened and how to prevent it.

- Empower Frontline Expertise: When a complex docking or fueling situation arises, defer to the most experienced crew member on site, even if they aren't the designated supervisor. Value hands-on knowledge over hierarchy.

- Automate Operational Sensitivity: A key HRO principle is sensitivity to operations. Modern tools like CLiX Fueling Solutions provide this by offering a real-time, digital view of your fueling operations. CLiX monitors every transaction, tracks fuel inventory, and flags system anomalies, giving you the operational awareness needed to spot deviations before they become dangerous incidents.

6. Six Sigma Safety Implementation

Six Sigma is a highly disciplined, data-driven methodology originally developed for manufacturing quality control, but its principles are incredibly effective when applied to safety management. This approach treats safety incidents, hazards, and near-misses as "defects" in a process. The goal is to systematically identify and eliminate these defects, driving the rate of safety failures down to near-zero levels.

The core of Six Sigma is the DMAIC (Define, Measure, Analyze, Improve, Control) framework. It provides a structured, scientific way to solve problems:

- Define: Clearly define the safety problem, project goals, and requirements.

- Measure: Collect data to measure the current performance of the safety process.

- Analyze: Analyze the data to identify the root causes of safety defects.

- Improve: Develop, test, and implement solutions to eliminate the root causes.

- Control: Implement controls to sustain the gains and monitor the improved process.

Using this framework makes Six Sigma one of the most rigorous safety management system examples, as it relies on statistical proof rather than guesswork to improve workplace safety.

Analysis: Why Six Sigma for Safety Works

The power of Six Sigma in a safety context comes from its relentless focus on process and data. Companies like Motorola, the pioneer of the methodology, applied it to reduce safety incidents by a staggering 95%. Similarly, General Electric under Jack Welch integrated Six Sigma into every facet of its operations, including safety, achieving world-class performance in its manufacturing facilities.

These successes are built on treating safety not as a matter of luck or behavior alone, but as a manageable process that can be optimized. It moves safety management from a subjective art to a quantifiable science.

Strategic Insight: The most profound shift with Six Sigma Safety is changing the question from "Who caused the incident?" to "What part of the process failed and allowed the incident to occur?" This removes blame and focuses the entire organization on fixing systemic flaws, which is far more effective for long-term safety improvement.

For marine operations, Six Sigma offers a powerful toolkit. A marina can use the DMAIC cycle to tackle a recurring problem like minor fuel spills. Instead of just reprimanding staff, they can measure spill frequency, analyze the causes (e.g., faulty nozzles, poor training, difficult hose access), implement improvements, and then control the process with new equipment or procedures.

This process-oriented approach drives continuous improvement and creates a culture where problems are seen as opportunities to get better.

Actionable Takeaways for Marine Operations

Marina operators and fuel providers can apply Six Sigma principles, even without full certification, to dramatically improve their safety outcomes.

- Define a Specific Safety Problem: Start small. Instead of "improve safety," define a goal like "reduce slip-and-fall incidents on docks by 50% in 6 months" or "eliminate fueling errors leading to overfills."

- Measure Your Baseline: You can't improve what you don't measure. Track incidents, near-misses, and inspection findings related to your defined problem. This data is your starting point. You can create a simple quality control checklist to help standardize this data collection and ensure consistency.

- Focus on Process, Not People: When analyzing the data, look for patterns in the process. Do spills happen more often at a specific fuel dock? With a particular type of nozzle? At certain times of the day? Use this analysis to improve the process itself, for example, by installing better equipment or changing a workflow. This is where systems like CLiX Fueling Solutions add immense value by providing precise data that helps identify process-level failures in the fueling system itself, enabling targeted improvements.

Safety Management Systems Comparison

| Approach | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Aviation Safety Management System (SMS) | High complexity; 2-5 years for full rollout | High initial and ongoing resource demands | Significant reduction (e.g., 70% safety events ↓); proactive hazard ID | Commercial aviation; regulated operators | Proactive risk management; strong safety culture; regulatory compliance |

| Process Safety Management (PSM) | Complex; requires specialized expertise | High cost for analyses and equipment integrity | Dramatic reduction in catastrophic chemical incidents | Chemical manufacturing, oil refining, petrochemicals | Comprehensive lifecycle coverage; proven accident prevention |

| ISO 45001 OH&S Management System | Moderate complexity; flexible framework | Moderate; certification and audit costs | Consistent, improved workplace safety and participation | Any organization aiming at OH&S improvements | Globally recognized; worker engagement; continuous improvement |

| Behavior-Based Safety (BBS) Programs | Moderate; requires ongoing management commitment | Moderate; training and observation resources | 50-90% reduction in workplace injuries; culture change | Workplaces focusing on behavioral risk reduction | High employee engagement; cost-effective; proactive prevention |

| High Reliability Organization (HRO) Principles | High cultural complexity; sustained organizational effort | Potentially high; extensive culture change | Exceptional safety in high-risk environments; resilience | Healthcare, nuclear, emergency services, aviation | Resilience; mindfulness; learning from near misses |

| Six Sigma Safety Implementation | High complexity; requires Six Sigma expertise | High initial training and analytical tools | Dramatic incident reduction; data-driven continuous improvements | Manufacturing, complex processes with rich data | Statistical rigor; measurable ROI; structured process improvement |

Integrating Lessons for a Safer Tomorrow

Throughout this article, we've journeyed through diverse and powerful safety management system examples, from the skies with aviation's ICAO framework to the factory floor with Process Safety Management. We’ve seen how ISO 45001 creates a universal language for occupational health and safety, how Behavior-Based Safety puts human psychology at the forefront of risk reduction, and how the relentless pursuit of perfection in High Reliability Organizations and Six Sigma transforms safety from a goal into a core operational value.

Each framework, though unique in its application, reinforces a singular, powerful truth: effective safety is not accidental. It is the deliberate result of a structured, systematic, and proactive approach to identifying and mitigating risk. The most profound lesson from these examples is that world-class safety is never a destination; it's a continuous journey of improvement.

Synthesizing Core Principles for Your Operation

While you may not be managing an airline or a chemical plant, the foundational principles from these elite systems are directly applicable to any environment where safety is a priority, especially in the marine world. Whether you're a marina operator, a fleet manager, or a recreational boater, the core tenets remain the same. The challenge is translating these high-level concepts into practical, everyday actions.

Let’s distill the most crucial takeaways that can be adapted for your specific needs:

- Proactive Hazard Identification: Don't wait for an incident. Constantly look for potential failures. The HRO principle of "preoccupation with failure" means actively searching for small problems, like a worn fuel hose or an unclear safety sign, before they escalate.

- Systematic Risk Assessment: Once a hazard is identified, evaluate its potential impact. The aviation industry's formal risk matrix can be simplified for your use. Ask: "What is the likelihood of this happening, and how severe would the consequences be?" This helps prioritize what to fix first.

- Documentation and Standardization (SOPs): ISO 45001 emphasizes clear, accessible procedures. For a marina, this means having documented Standard Operating Procedures (SOPs) for fueling, boat maintenance, and emergency response. This ensures consistency and provides a clear benchmark for performance.

- Fostering a 'Just Culture': A key element of Behavior-Based Safety is creating an environment where people feel safe reporting errors and near-misses without fear of blame. When a crew member reports a small fuel spill, they should be thanked for the report, not punished. This data is invaluable for preventing a larger incident.

- Commitment to Continuous Improvement: The Six Sigma "Define, Measure, Analyze, Improve, Control" (DMAIC) cycle is a powerful mindset. Regularly review your safety data, however simple. Are near-misses increasing? Are safety inspections being completed on time? Use this information to make targeted improvements.

From Theory to Action: Practical Next Steps

Understanding these safety management system examples is the first step; implementing them is what creates real change. The most effective safety programs start small, focusing on simple, high-impact changes. It’s about building a culture of safety one process, one tool, and one decision at a time.

A crucial insight from Process Safety Management (PSM) is the "Hierarchy of Controls," which prioritizes engineering controls, the solutions that design the hazard out of the process, over reliance on human procedure alone. This is where tangible tools become a cornerstone of your safety system. For any marine operation, managing fuel is a critical risk point, with spills posing a threat to personnel, property, and the marine ecosystem.

Strategic Insight: The most resilient safety management systems do not just rely on procedures and training. They build safety directly into the operation with engineering controls that make the right way the easy way, and the wrong way difficult or impossible.

This is why adopting a tool like an automatic shutoff fueling nozzle is not just a convenience; it's a strategic safety decision. It embodies the principles of HROs by anticipating failure (overfills and spills) and the Six Sigma goal of eliminating defects (spills) in a critical process (fueling). It is a simple, physical manifestation of a sophisticated safety philosophy, proving that you don't need a complex bureaucracy to achieve a higher standard of safety. By integrating the right tools, you embed safety directly into your daily workflow, building a resilient system that protects what matters most.

Ready to implement a key engineering control that elevates your fueling safety? CLiX Fueling Solutions offers a simple yet powerful way to apply the principles we've discussed by preventing costly and hazardous fuel spills before they happen. See how our automatic shutoff technology can become a cornerstone of your safety management system at CLiX Fueling Solutions.