Environmental compliance training is more than just a mandatory program to teach your team about environmental laws and company policies. Think of it as your first line of defense—a system designed to prevent pollution, keep operations safe, and protect your business from the very real consequences of a mistake. In a high-stakes field like fuel handling, it’s not a formality; it's fundamental.

Why Effective Training Is Your Best Defense

Let's be direct: handling fuel is a risky business where a single error can spiral into a major incident. Just knowing the regulations isn't enough. Proactive environmental compliance training is what turns your team from passive rule-followers into an active part of your risk management strategy. It’s the difference between checking a box and building a genuine culture of prevention.

I’ve seen it happen. A new marina employee, without the right training, overfills a boat’s fuel tank. The spill leads to a five-figure cleanup, bad press, and hefty fines from the EPA. Now, picture a well-trained employee in the same situation. They know to use tools like CLiX Fueling Solutions, they recognize the sounds and signs of a nearly full tank, and they know exactly what to do to contain a small drip before it becomes a big problem. That’s the power of good training.

Shifting from Reaction to Prevention

The goal here is to build proactive habits, not just to clean up messes. When everyone—from the newest hire on the fuel dock to the general manager—understands their specific role in protecting the environment, you create a powerful defense that equipment alone can’t offer.

A well-trained team is your most valuable asset in risk management. Their knowledge and vigilance can prevent incidents that even the best technology can't, turning compliance from a cost center into a competitive advantage.

This educational focus is no longer optional, especially as regulations become more complex. With evolving climate policies and customers demanding more responsible business practices, solid training is essential for navigating the landscape.

To give you a clearer picture, your training should zero in on several critical areas. Each has its own objective and significant risks if overlooked.

Key Focus Areas for Fuel Handling Compliance

| Compliance Area | Core Training Objective | Associated Risks of Failure |

|---|---|---|

| Spill Prevention & Response | Equip staff to prevent spills and respond immediately and correctly if one occurs. | Fines, environmental damage, costly cleanups, operational shutdowns. |

| Equipment Handling | Ensure proper use of nozzles, hoses, and systems like CLiX. | Equipment damage, personal injury, fuel loss, potential for large spills. |

| Regulatory Knowledge | Understand federal (EPA), state, and local fuel handling laws. | Non-compliance penalties, legal action, loss of operating permits. |

| Record-Keeping & Reporting | Maintain accurate logs and report incidents according to legal requirements. | Audit failures, fines for improper documentation, inability to prove compliance. |

Covering these domains thoroughly ensures your team is prepared for the real-world challenges they'll face every day.

Building a Culture of Safety

A true culture of safety starts with training that is easy to access and constantly reinforced. When every single person handling fuel feels confident in their duties and understands the "why" behind the rules, compliance simply becomes part of the job.

This means your training program can't be a dusty binder on a shelf. It has to be engaging, relevant, and consistently revisited. Modern tools can make a huge difference here. In fact, many organizations are exploring how interactive training videos are becoming more accessible and effective to boost what their teams remember and keep them engaged long-term.

Building a Rock-Solid Training Foundation

Before you even think about designing training materials, you’ve got to lay the groundwork. Any effective environmental compliance training program is only as good as its foundation, which needs to be built on a realistic assessment and crystal-clear goals. If you rush this first part, you’re basically building a house on sand. It just won’t hold up when things get real.

The best first move is a practical needs assessment. This isn’t about creating more paperwork; it’s about getting out there and doing some honest observation. Watch your team on a busy day. Are they consistently checking for drips? Do they know exactly what to do the second a small spill happens? Pinpointing these real-world gaps in knowledge is far more useful than just guessing what they need to learn.

Once you know where your team stands, you can set specific, measurable goals for them. Vague targets like "improve safety" don't cut it. You need to aim for tangible outcomes you can actually see and track.

Defining Your Training Objectives

A strong training objective is one you can measure. I've always found it helpful to frame goals around the specific actions and results you want to see from your crew.

-

Weak Objective: "Train staff on spill prevention."

-

Strong Objective: "Ensure all dock staff can correctly deploy a spill kit in under 60 seconds."

-

Weak Objective: "Teach employees about regulations."

-

Strong Objective: "All staff must score at least 90% on a quiz covering our site-specific spill reporting procedures."

See the difference? This kind of clarity lets you design laser-focused content and gives you a clear benchmark for what "success" looks like. These objectives should directly support both regulatory requirements (like those from the EPA) and your own company’s operational standards.

Securing Management Buy-In

Getting your management team on board is absolutely essential. You have to present this training not as just another cost, but as a smart investment in protecting the business and reducing risk. Frame it in terms of clear business benefits.

Every dollar spent on proactive training can save ten times that amount in potential fines, cleanup costs, and reputational damage. It’s not about avoiding penalties; it’s about protecting the business.

When you can clearly show leadership how a well-trained team prevents expensive mistakes, reduces downtime, and protects valuable assets (like customer boats and your own equipment), the conversation shifts. It’s no longer a chore; it becomes a strategic priority. For a deeper dive into handling incidents, our expert response guide to fuel spill cleanup procedures lays out exactly what’s at stake.

Involving the Right People

Finally, remember that the most successful training programs are built with help from the people who will actually be using them. Pull your frontline fuel handlers, dock managers, and maintenance crew into the planning. Ask them about the challenges they face every day and what would make the training genuinely useful for them.

Their on-the-ground insights are pure gold. They know about that one quirky valve on dock B or the specific challenges that come with fueling a certain type of boat. Using their feedback ensures your environmental compliance training is not just correct in theory, but actually works on a busy Saturday afternoon. This kind of collaboration builds relevance and makes the team feel a sense of ownership over the safety protocols.

Designing Training That Actually Sticks

Once you've got your foundation in place, it’s time to actually build the training. And let's be honest, the key to great environmental compliance training isn’t just what you teach, but how you teach it. We’ve all sat through those mind-numbing PowerPoint presentations where critical safety information goes in one ear and right out the other.

To make sure your training is memorable, you need to mix things up. This is often called a blended learning approach, but it really just means moving beyond static slides and using a combination of visuals, interactive exercises, and hands-on practice. The goal is to get your team engaged, not just talk at them.

Move Beyond Theory with Scenarios

The best training I've ever seen puts employees right in the middle of the action. Don't just tell them about spill prevention; create realistic scenarios that force them to solve the kinds of problems they'll actually face on a busy day at the fuel dock.

This method turns abstract rules into something tangible. It makes your team think on their feet about what they would do in a real situation, which is far more effective than just having them memorize a checklist.

Think about situations like these:

- A distracted customer: The boater is on their phone and doesn't realize their tank is nearly full. What are the verbal and visual cues your employee needs to use to step in safely and prevent an overfill?

- A slow drip: An employee notices a small but steady drip from a fuel hose connection. What are their first three moves to contain it and report it up the chain?

Scenarios like these build muscle memory. They make the training feel relevant and practical, so the right actions become second nature when it really counts.

The best training doesn't just present information; it prompts action. By challenging staff to solve realistic problems, you bridge the gap between knowing the rules and knowing what to do.

Deliver Bite-Sized Lessons with Microlearning

Let's face it, nobody has the attention span for an hour-long training session anymore. A better approach is to break down complex topics into small, digestible chunks. This is where microlearning shines.

Instead of one massive training block, you can create short, focused modules. Imagine a three-minute video showing the proper way to attach a CLiX Fueling Solutions device or a quick quiz on spotting a faulty valve. This strategy is completely changing the game for environmental compliance training because it’s flexible and far more engaging.

In fact, research shows that delivering content in short bursts significantly improves retention. It’s one of the key trends shaping the future of compliance training. This way, employees can learn at their own pace and pull up a quick refresher on their phone whenever they need it.

Make It Hands-On and Interactive

Finally, nothing drives a lesson home like actually doing it. Reading about how to use a spill kit is one thing; practicing with it is another. Your training absolutely must include a hands-on component.

Get your team out on the dock. Have them practice deploying a spill boom, using a fire extinguisher, and handling the exact fueling equipment they’ll use every day. Pair this with interactive quizzes that give them immediate feedback. When you see your team confidently and correctly performing these critical tasks under supervision, you’ll know the training is working.

Launching and Reinforcing Your Program

You can create the best training content in the world, but if the rollout is clunky and the lessons fade away after a week, it’s all for nothing. A smart launch is just as vital as the materials themselves. This next phase is all about getting your environmental compliance training into your team's hands and making sure the knowledge actually sticks.

The first hurdle is always scheduling. How do you get everyone trained without grinding daily operations to a halt? I've found a blended approach works best. Core concepts can be handled through flexible online modules that employees can tackle during slower periods. You can then schedule shorter, in-person workshops for the hands-on stuff, which is far less disruptive than pulling everyone off the floor for a full day.

Keeping the Knowledge Alive

Let’s be clear: the real goal here is to bake compliance into your team's daily DNA. It’s a habit, not a one-time event. Launching the training is just the starting pistol, not the finish line. From here on out, it’s all about consistent reinforcement.

Here are a few methods that have worked wonders for us:

- Daily Toolbox Talks: Before a shift kicks off, hold a quick, five-minute huddle. Focus on one single, specific topic. Maybe it's spotting a worn-out hose or the right way to react to a minor drip. Short and sharp is the key.

- Visual Aids at the Dock: Post simple, easy-to-read reminders and checklists right where the action happens. A visual guide showing what's in the spill kit or the steps for using a CLiX device can make a huge difference in the heat of the moment.

- Regular Competency Checks: Every now and then, casually ask an employee to walk you through a safety procedure. This isn't about catching them making a mistake; it's a low-pressure way to spot knowledge gaps before they become problems.

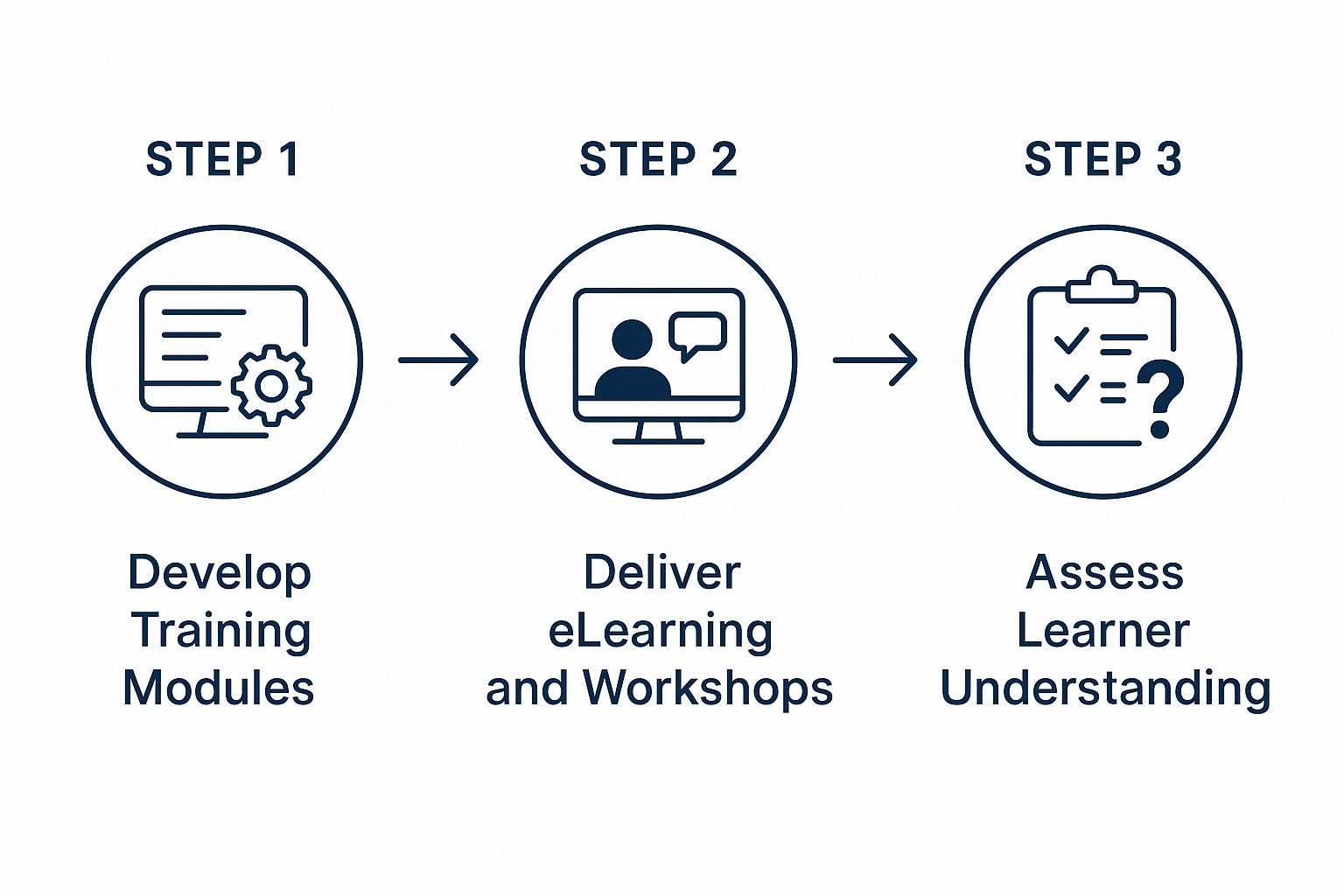

This is the flow you want to follow—from creating the training to making sure everyone actually gets it.

As you can see, developing and delivering the program are just the first two pieces. The final, most important step is checking if the information truly sunk in.

The Supervisor’s Critical Role

When it comes down to it, the long-term success of your training program really hinges on your supervisors and managers. They're your coaches on the ground, the ones responsible for turning abstract training concepts into everyday reality. Their actions speak louder than any manual.

When a supervisor consistently models safe behavior—like double-checking connections and immediately addressing a near-miss—they send a powerful message that this stuff isn't optional. That kind of leadership is more effective than any classroom session.

Push your supervisors to be active coaches. They should be correcting mistakes constructively, giving kudos for proper procedure, and leading by example. When people see their direct boss taking safety seriously, they will too. This creates a self-sustaining culture of awareness and accountability, which is the true sign of a program that works. Your supervisors are the bridge between the training room and the fuel dock. Don't forget it.

Using Technology to Simplify Compliance

Let's be honest: trying to manage environmental compliance training with a filing cabinet and a spreadsheet is asking for trouble. It's not just clunky; it’s a surefire way for critical details to slip through the cracks. This is where specialized software comes in, completely changing how you handle the administrative side of compliance.

Platforms like CLiX Fueling Solutions centralize your entire program. Imagine having all your training records, certifications, and compliance documents in one organized, easy-to-access place. No more digging through folders for a lost certificate or guessing who needs a refresher course.

This isn't just about going paperless. It's about having solid, data-driven proof of your efforts. When an auditor pays a visit, you won't need to spend days frantically gathering paperwork. Instead, you can pull up a complete, audit-ready report in just a few clicks.

From Manual Tracking to Automated Management

The real beauty of using technology here is how it automates the tedious, repetitive tasks that eat up your team's time. It helps you shift from putting out fires to preventing them in the first place.

Take a look at how software stacks up against the old-school manual approach. It quickly becomes clear which method gives you more control and less risk.

Manual vs. Software-Assisted Compliance Management

| Task | Manual Approach | Software-Assisted Approach (e.g., CLiX) |

|---|---|---|

| Tracking Completion | Someone manually checks names off a list. It’s slow, and the risk of human error is high. | Completion is logged automatically for each employee, creating a verifiable digital record. |

| Sending Reminders | Depends on calendar alerts or someone’s memory to chase down staff for refresher training. | Automated email or text reminders are sent to employees and managers when certifications are about to expire. |

| Reporting Status | Involves digging through physical files or multiple spreadsheets to get a sense of where you stand. | A real-time dashboard gives you an instant, at-a-glance view of your entire team's training status. |

This kind of real-time visibility is a game-changer. You can spot potential gaps—like an employee whose spill response certification is lapsing—and address them long before they become a real violation.

The Growing Role of Compliance Software

The move toward technology isn't just a fleeting trend. As environmental regulations get stricter, more and more companies are realizing they need better tools. The global Environmental Compliance Software market is expanding quickly because this software is essential for tracking, reporting, and navigating the complex web of environmental rules. You can read more about this market's growth and importance over at Cognitive Market Research.

Using dedicated software for environmental compliance isn't about adding another tool—it's about removing points of failure from your system. It ensures that critical tasks are handled consistently and correctly, freeing your team to focus on safe operations.

Ultimately, these tools provide the backbone for a much stronger, more resilient program. They make sure all your hard work in training and spill prevention is properly documented and supported. Protecting marine life is a major reason we do this, and you can learn how to prevent marine pollution with our essential steps in our detailed guide.

How Do You Know If Your Training Is Actually Working?

So you've rolled out your environmental compliance training. Great. But how do you know if it's actually making a difference? Just checking off a box to say someone completed a course doesn't cut it. The real proof is in what happens out on the dock or at the fuel pump—seeing behaviors change and risks genuinely go down.

To truly gauge success, you need to look beyond completion rates and start tracking specific Key Performance Indicators (KPIs). These metrics give you hard data, turning your training from an expense into a measurable investment.

What to Measure: The KPIs That Matter

Instead of guessing, let's look at some practical metrics you can start tracking right away:

- A drop in near-misses. Are you seeing fewer reports of minor drips or overfills that were caught just in time? That's a huge win and a clear sign your team is more vigilant.

- Better inspection scores. Keep an eye on scores from both your own internal audits and official regulatory visits. Seeing those numbers climb is solid proof that protocols are being followed consistently.

- Quicker incident response. Time how long it takes your team to grab a spill kit and get a situation under control. When those response times get shorter, you know your training is sinking in, potentially saving you from a much larger problem.

- Fewer mistakes with equipment. Track errors tied to handling gear, like using the wrong nozzle or failing to make a secure connection. A decrease here points directly to effective hands-on training.

Collecting this kind of data gives you a real-world snapshot of your program's impact. It’s the same logic behind using data to optimize other parts of your operation. For example, our guide on a boat fuel management system explores how tracking metrics can boost both efficiency and safety on the water.

Never Stop Improving: The Feedback Loop

A great training program isn't a "one-and-done" deal. It's a living thing that needs to adapt and evolve. The final, and perhaps most important, step is creating a feedback loop to keep your training sharp.

Start by talking to your employees. They’re the ones on the front lines, and they know what's practical and what's not. Anonymous surveys or even informal chats can uncover blind spots you never would have seen otherwise. Combine their feedback with your KPI data to pinpoint exactly where you need to make improvements.

The best training programs are never truly "finished." They are constantly updated based on new rules, changes in operations, and real-world lessons learned. This is what sets a genuinely compliant operation apart from one that's just checking boxes.

This cycle—measure, get feedback, and refine—is what continuous improvement is all about. The idea is to build a safety culture that gets stronger and more resilient over time. You can explore various strategies for implementing continuous improvement to keep your program from getting stale. By embracing this mindset, you ensure your team is always ready for what's next.

Ready to build a spill-free, stress-free fueling operation? CLiX Fueling Solutions provides the innovative technology that prevents overfills and protects your boat and the environment. Discover how our automatic shut-off system can make every fueling experience safer and cleaner by visiting https://clixfueling.com today.