Let's be honest, we've all been there: wrestling with a heavy, sloshing gas can, trying to pour fuel without spilling it everywhere. It's a clumsy, frustrating, and often messy business. The portable gas container with a pump is the modern answer to this age-old problem. Think of it not just as a better can, but as your own personal, mobile refueling station.

The End of Spills and Heavy Lifting

For too long, refueling anything away from a gas station has been a real chore. If you've ever tried to fill a boat, ATV, or generator from a standard five-gallon jug, you know the drill. You hoist that heavy thing up, try to aim the spout, and hope you get more fuel in the tank than on the ground. It's not just inefficient; it's a perfect way to waste money and contaminate the environment.

A portable gas container with a pump completely flips the script. By building a pump right into the container, the awkward act of pouring becomes a controlled, precise transfer of fuel. No more muscle and luck needed. You just put the nozzle in place and let the pump do the heavy lifting for you.

A Modern Approach to Refueling

The idea is incredibly simple but makes a world of difference. It takes a frustrating, multi-step job and turns it into a clean, simple process. It's like the difference between bailing out a boat with a bucket versus just flipping on the bilge pump—same goal, but the ease and safety are in a different league.

Think about all the classic problems with traditional gas cans:

- Spills and Drips: Awkward angles and terrible spout designs almost guarantee fuel will end up on your equipment, the dock, or in the water.

- Physical Strain: Hoisting and holding a 30-pound container steady is a recipe for back and muscle strain.

- Wasted Fuel: Overfills are common, which means you're literally pouring expensive fuel down the drain and creating a safety risk.

- Slow Glugging: The "glug-glug-glug" of a traditional can makes for an inconsistent, slow, and hard-to-manage pour.

A portable fuel system with an integrated pump is engineered to solve these exact problems. It gives you a cleaner, safer, and far more efficient way to refuel by putting you in total control of the fuel flow, from start to finish.

This guide is for anyone who is just fed up with the old way of doing things. Whether you're a boater who needs to refuel on the water, a powersports enthusiast out on the trail, or a homeowner juggling lawn equipment, you're about to see how these systems offer a genuinely better experience. We’ll break down how they work, the key features to look for, and why they can make refueling a task you no longer have to dread.

How These Smart Fuel Systems Actually Work

Have you ever found yourself wondering what makes a portable gas container with a pump so much better than your old, clunky gas can? It’s not just one single part. It’s a complete system, where every piece is designed to work together, turning the messy, awkward task of pouring fuel into a clean and controlled transfer.

The core idea is actually pretty simple. You have four key players: the container, the pump, the hose, and the nozzle. Each one has a specific job to do to get fuel from point A to point B without spills, back strain, or wasted gas.

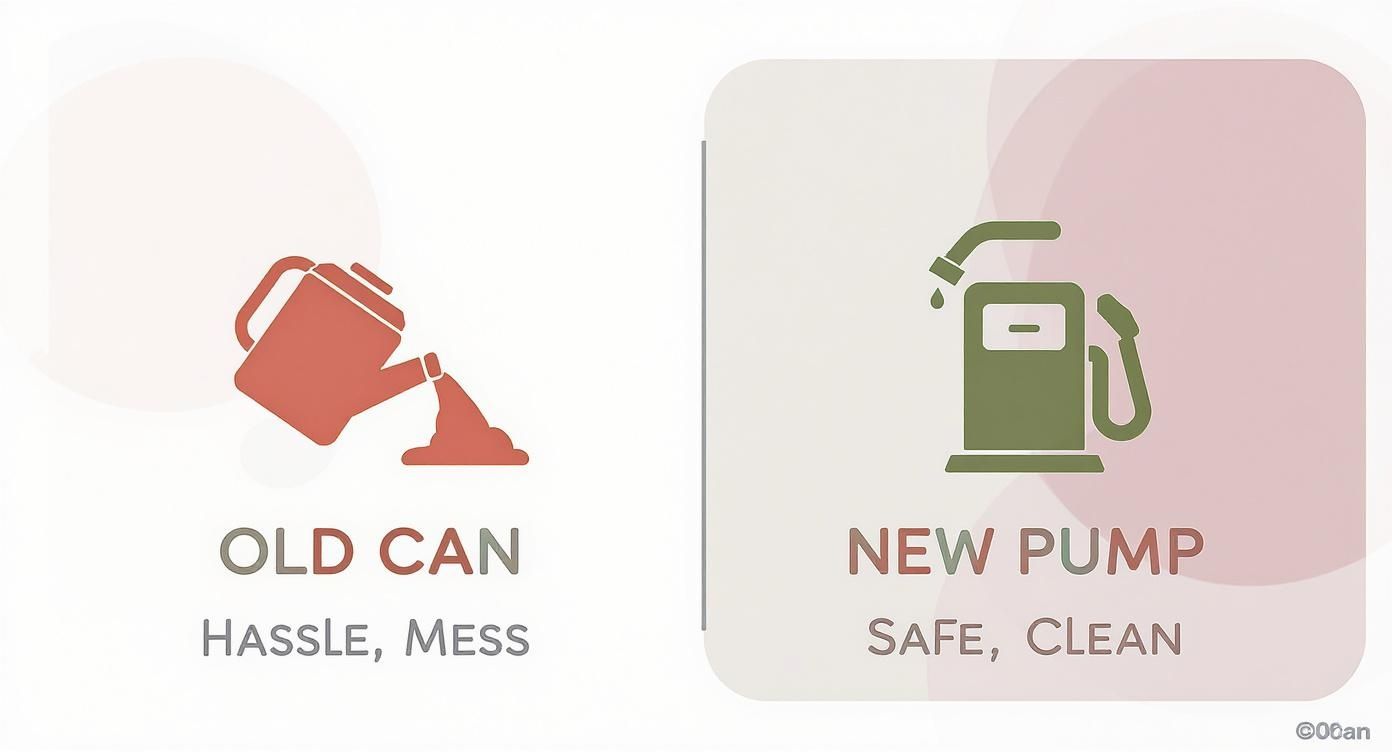

This image really highlights the jump from the old, frustrating way of fueling to the modern, controlled method.

It’s easy to see the contrast between the hassle of an old-school can and the clean, safe experience of a modern pump system.

The Anatomy Of A Modern Fuel Container

Everything starts with the container. Today’s best models are made from high-density polyethylene (HDPE), a tough plastic that stands up to corrosion and the occasional drop. The real secret weapon, though, is a proper vent system. This lets air flow into the container as fuel flows out, stopping that frustrating "glugging" and keeping the stream smooth and steady.

Next up is the pump, which is the heart of the whole operation. It provides the muscle to move fuel up and out. You'll generally find two types:

- Manual Pumps: These are all about simple mechanics, like a hand crank or a squeeze handle. Think of it as a really efficient, modern take on a siphon. Every crank or squeeze pushes a specific amount of fuel through the hose, giving you total control over the flow.

- Electric Pumps: For maximum convenience, these use battery power (often AAs) or a 12V DC connection to your boat or vehicle. Just press a button, and a small motor does all the work, delivering a steady, hands-free stream of fuel—kind of like your own personal gas station pump.

The big idea here is simple: instead of fighting gravity and straining your back, the pump creates positive pressure to push fuel exactly where you want it. This fundamental change is what makes spills a thing of the past and refueling almost effortless.

From Container To Tank: The Fuel's Journey

Once you start the pump, it pulls fuel from the bottom of the container and pushes it into a flexible, reinforced hose. A good hose is non-negotiable—it needs to be tough enough to handle gasoline without breaking down and long enough to reach your tank without you having to stretch, kink the line, or balance the container in a precarious spot.

The fuel’s trip ends at the nozzle. Just like the one at the gas station, the nozzle gives you precise, on-demand control. Squeeze the handle to start the flow, and let go to stop it instantly. This is what prevents overfilling and lets you top off a tank with confidence. The physics at play are pretty universal; for a different take, understanding various fluid dispensing mechanisms in other tools can be surprisingly insightful.

The shift toward these smarter systems isn't just anecdotal. The fuel storage container market is valued at USD 29.9 billion in 2025 and is projected to hit USD 47.3 billion by 2035. Portable fuel containers make up the biggest piece of that pie, with an expected annual growth rate of 5.4%. It’s a clear sign that people are demanding safer, more convenient ways to handle fuel.

Choosing the Right Features for Your Needs

Picking the right portable gas container isn't a one-size-fits-all deal. What works for a small generator won't cut it for a 30-foot boat. The best choice really comes down to what you need it for. Think of it like any other tool—you need to match its features to the job at hand.

The market is full of options, and it’s easy to get bogged down in the details. But if you focus on a few key areas—the container itself, the pump mechanism, and the hose—you can narrow down your choices and find a system that makes refueling simple, safe, and spill-free.

Evaluating Container Construction and Materials

Let’s start with the foundation: the can itself. Nearly every quality container you'll find is made from high-density polyethylene (HDPE). This stuff is tough, stands up to gasoline without a problem, and can take the bumps and scrapes of being hauled around a garage, a dock, or the back of a truck.

But good design goes beyond just the plastic. The little things make a huge difference in usability.

- Ergonomic Handles: Look for multiple grip points. They make a world of difference when you're lifting and pouring from a full, heavy can.

- Durable Wheels: If you’re looking at a larger container (14 gallons or more), good wheels are an absolute must. They turn a potential back injury into a simple walk.

- Stable Base: A wide, low-profile design is your best friend. It keeps the container from tipping over, which is a major safety win.

These are the nuts and bolts of a good container. For a closer look at some of the best designs out there, check out our rundown of the top portable fuel pump picks for 2025.

Manual vs. Electric Pump Mechanisms

The pump is what really separates these systems from a standard gas can. Your main choice here is between manual and electric, and it’s a big one. Each has its place, depending on whether you value simplicity or speed.

A manual pump is as straightforward as it gets. Usually operated with a hand crank or a squeeze handle, it gives you direct, hands-on control over the flow. This is perfect for filling up smaller engines where you want to be precise and avoid overfilling. Plus, with no batteries or motors, they're incredibly reliable.

Electric pumps, on the other hand, are all about making life easier. Powered by common AA batteries or a 12V DC hookup to your boat or truck, they do the work for you. Just push a button and you get a steady, hands-free flow of fuel. They’re a lifesaver when you’re refueling a big tank and don't want to hold a heavy container for several minutes.

It’s no surprise that powered pumps are getting more popular. The mobile fuel pumps market is on track to hit USD 6.1 billion by 2033, and DC-powered models already make up over 44.5% of that. People are choosing convenience.

The right pump choice comes down to a simple trade-off: manual pumps offer unmatched reliability and control for smaller jobs, while electric pumps provide superior speed and convenience for larger refueling tasks.

Hose Length and Nozzle Design

Finally, let's talk about the parts you'll handle the most: the hose and nozzle. A longer hose—at least 10 feet is a great starting point—gives you a ton of flexibility. It lets you set the container on the ground or dock and still comfortably reach the fuel tank without awkward lifting or positioning.

The nozzle is just as critical. A quality nozzle with a comfortable grip and a responsive trigger gives you total control, letting you stop the flow instantly. Some of the best models even have an auto-stop feature, just like at the gas station, which cuts the flow when the tank is full. It’s the ultimate protection against messy, wasteful, and environmentally harmful spills.

Comparison of Common Pump Types

To help you sort through the options, this table breaks down the most common pump mechanisms you'll find. Each one is built for a different kind of job.

| Pump Type | Power Source | Typical Flow Rate | Best Use Case | Key Advantage |

|---|---|---|---|---|

| Manual Squeeze | Hand Power | 1-2 GPM | Small engines, topping off | Simple, reliable, excellent control |

| Manual Crank | Hand Power | 2-3 GPM | ATVs, generators, small boats | Faster than squeeze, still reliable |

| Battery Powered | AA or D Batteries | 2-4 GPM | Mid-size boats, equipment | Hands-free convenience, portable |

| 12V DC Electric | Vehicle/Boat Battery | 5-10+ GPM | Large boats, machinery, vehicles | Highest speed for large volumes |

Ultimately, whether you need the pinpoint control of a manual pump or the raw speed of a 12V DC electric model, understanding these differences will help you pick the perfect fueling system for your needs.

Safety First: How to Handle Fuel Responsibly

Let's be blunt: gasoline is serious business. It’s incredibly useful, but it's also volatile stuff. Whether you're topping off a generator for a weekend project or fueling up a boat for a day on the water, safety can't be an afterthought. It has to be the first thing on your mind.

The good news is that a portable gas container with a pump is already a huge step in the right direction, cutting down the risk of spills dramatically. But the tool is only part of the equation. True safety comes from building good habits—a simple, repeatable routine that protects you, your gear, and the environment every single time.

Set Up a Safe Refueling Zone

Before you even think about unscrewing a cap, take a look around. Gasoline fumes are sneaky. They're heavier than air, which means they can sink and travel along the ground, looking for anything that can ignite them. Your first job is to control the environment.

Always, always refuel in a well-ventilated area. Outdoors is best. This gives any vapors a chance to blow away instead of collecting in a dangerous, invisible cloud. Refueling in a closed-off garage, a cramped shed, or down in the cabin of a boat is asking for trouble.

Next, go on an "ignition source" hunt. Turn off engines, and kill any nearby electrical equipment. Put out that cigarette. Be aware of things you might not immediately think of, like pilot lights on water heaters or the potential for a static shock.

It all boils down to one simple rule: keep fuel and ignition sources far apart. It only takes one stray spark. Making sure your refueling zone is open, clear, and free of anything that could create a spark is the single most important thing you can do.

The Hidden Danger of Static Electricity

Static electricity is the invisible threat here. As fuel flows through a hose or from a can, it can generate a static charge—the same kind of energy that makes a balloon stick to a wall. If that charge builds up and discharges as a spark near gas fumes, you've got a fire.

That's where grounding comes in. Grounding is just a way to give that static electricity a safe path to escape. The easiest way to do this when filling up a boat or vehicle is to keep the nozzle of your pump in constant contact with the metal opening of the fuel tank. This keeps both the container and the tank at the same electrical potential, so a spark can't jump between them.

For a more detailed breakdown of safe filling practices, check out our guide on where portable gasoline fuel tanks should be filled.

How to Handle Spills (Just in Case)

Even with the best gear, spills can happen. A quality portable gas container with a pump makes them far less likely, but it's always smart to be ready. Keep some absorbent pads or even a bag of kitty litter nearby just in case.

If a small spill occurs, don't panic. Just follow these steps:

- Stop the flow immediately.

- Contain the mess. Use your absorbent material to keep it from spreading.

- Clean it up by letting the material soak up the gasoline.

- Dispose of it correctly. Seal the used material in a fire-safe container. Don't just toss it in the garbage—check with your local waste management service for their rules on hazardous material disposal.

Why Those Official Labels Matter

You've probably noticed all the labels on modern fuel cans from agencies like the Environmental Protection Agency (EPA) or the Department of Transportation (DOT). They aren't just for show. They're proof that the container meets critical safety and environmental rules.

An EPA certification means the container is built to minimize how many harmful gas vapors escape into the air. This led to smarter designs like self-venting spouts and special plastics that don't let fuel permeate through. A DOT-approved container is tough enough to be transported without cracking or leaking.

When you choose a container that meets these standards, you’re not just following the rules. You’re making a responsible choice that protects you, prevents air pollution, and keeps fuel from contaminating our soil and water.

Real-World Uses for Boaters and Outdoor Enthusiasts

This is where the rubber meets the road—or in this case, where the hull meets the water. For anyone who spends time on a boat or exploring the backcountry, a portable gas container with a pump isn't just a minor upgrade. It completely changes the game. It turns a chore that used to be all about heavy lifting, messy spills, and frustration into something clean, controlled, and surprisingly easy.

Think about it. You’re moored in a quiet cove, miles from the nearest fuel dock. Instead of wrestling a couple of heavy gas cans and hoping you don't spill a drop into the water, you just set your container on the dock. You run the hose to your boat’s fuel intake, and the pump does all the heavy lifting. No back strain, no awkward balancing act, and no environmental damage.

Transforming Marine Fueling

For boat owners, the usual headaches of refueling are magnified. A spill isn’t just a stain on the driveway; it’s a serious threat to the very water you're there to enjoy. This is where a portable gas container with a pump really shines, offering real solutions to common problems.

- Dockside Efficiency: Why waste time at a crowded fuel dock? You can top off your tank quickly without the struggle of lifting and pouring.

- Remote Refueling: Extend your trips with confidence. Knowing you can safely transfer reserve fuel while anchored out gives you incredible freedom.

- Reduced Physical Strain: Say goodbye to hoisting containers that weigh 30 pounds or more over the side of your boat—a classic recipe for a back injury.

- Environmental Protection: You drastically lower the risk of fuel spills, which helps protect the water and keeps you from facing hefty fines.

A controlled pump system gives you peace of mind. It ensures every drop of fuel goes right where it’s supposed to—into your tank—protecting your boat, your back, and the marine environment.

For a deeper look at how these systems are designed specifically for boaters, you can find more information on specialized solutions like gas caddies for boats.

Beyond the Marina and Onto the Trail

The perks don't stop at the shoreline. Outdoor enthusiasts who depend on ATVs, UTVs, or generators will find that a portable fueling system brings a whole new level of convenience and safety to the middle of nowhere. Imagine you're deep in the woods and your ATV is running on fumes. Instead of trying to pour from a standard can on uneven ground (which almost guarantees a spill), you can refuel in minutes without a mess.

This push for safer, smarter fueling is happening everywhere. The global portable fuel tank market was valued at USD 1.2 billion in 2023 and is expected to hit USD 2.1 billion by 2032. That's a huge jump, and it shows a clear trend toward better fueling systems. This growth proves that whether you’re on the water, on the trail, or on a remote job site, everyone is looking for a better way to handle fuel.

How CLiX Fueling Systems Redefine Fuel Transfer

Let's be honest, just adding a pump to a gas can doesn't solve the core problems of refueling. Many systems simply move fuel from point A to point B, but they completely ignore the fundamental weak points that make the process messy and frustrating. CLiX isn't just another pump; it's a complete system engineered from the ground up to fix these issues at their source.

The real magic is in the connection. Think about it: where do most drips and spills happen? Right at the nozzle. Traditional hoses and connectors are notorious for small leaks, especially as they get older. CLiX tackles this with a patented, leak-proof connector that creates a fully sealed link. This simple but critical change stops messy spills before they even have a chance to start.

More Than Just a Pump

Sure, a pump can move fuel, but that doesn't mean it's a smooth or reliable process. Have you ever had a pump sputter and stop, even when the can is full? You've likely experienced vapor lock—air bubbles getting trapped in the line, which stalls the flow. It’s a lot like how a clogged filter can cause your home's furnace to shut down by disrupting the airflow.

The CLiX system is specifically designed to prevent this by maintaining a consistent, air-free draw from the container.

- Consistent Flow Rate: Because the connection is sealed and air pockets are eliminated, you get a smooth, uninterrupted stream of fuel every single time.

- Ergonomic Design: The whole system is built for human hands. Comfortable grips and easy-to-use controls mean less hand fatigue and no more wrestling with awkward equipment.

- Built-in Safety: The entire design philosophy is about preventing problems, not just reacting to them. This makes the whole process feel safer and far less stressful.

The real innovation isn't just adding a motor; it's re-engineering the entire connection to be smarter and more reliable. This focus on why fueling fails is what truly sets the CLiX system apart.

A Real Solution to Old Problems

Think about the classic headaches that come with a standard portable gas container with pump. Leaky connections, a slow or sputtering flow, and clumsy designs are practically a given. The CLiX system was born from identifying and solving each of these pain points one by one.

Instead of just forcing fuel through a hose, it delivers an integrated solution that makes refueling cleaner, safer, and worlds less frustrating. By paying attention to the details other systems miss—like the integrity of the connection and the consistency of the fuel flow—it offers a genuinely better way to handle fuel.

Frequently Asked Questions

Getting your hands on a new piece of gear always comes with a few questions. That's a good thing. We’ve put together some straightforward answers to the questions we hear most often about portable gas containers with pumps, so you can feel confident and safe every time you refuel.

Can I Use My Container for Diesel or Other Fuels?

That's a great question, and the short answer is almost always no. Most portable containers and their pumps are built specifically for gasoline.

Diesel has a different consistency and chemical makeup that can chew through the pump's internal seals and components, leading to leaks and pump failure. Always read the manufacturer’s label. While a few heavy-duty models might be rated for multiple fuel types, you should never mix fuels in the same can or use a pump for something it wasn't designed for.

What Is the Safest Way to Store the Container?

Storing fuel correctly is all about preventing accidents. The best place is a well-ventilated area, like a detached shed or garage, far away from any ignition sources. Think water heaters, furnaces, or even a tiny spark.

Keep it out of direct sunlight, which can cause pressure to build up inside the container. And it should go without saying, but never store fuel inside your car's passenger area or in your home. Make sure the caps are screwed on tight and the container is sitting on a flat surface where it won't get knocked over.

How Fast Do These Pumps Actually Transfer Fuel?

Pump speed—or flow rate—can vary quite a bit, and it really depends on the type of pump you're using. Knowing the difference helps you pick the right tool for the job.

- Manual Pumps: These are your slowest option, moving about 1-2 gallons per minute (GPM). They give you a ton of control, which is perfect for filling up small engines without making a mess.

- Battery-Operated Pumps: These are a nice step up, offering a good balance of speed and convenience. You can expect them to transfer fuel at around 2-4 GPM.

- 12V DC Electric Pumps: When you need to move a lot of fuel quickly, these are the way to go. They hook up to a car or boat battery and can pump 5-10 GPM or even more, making short work of filling larger tanks.

The biggest factor in speed is the power source. A simple hand pump is great for precise, smaller jobs, while a beefy 12V pump is built for serious refueling.

Are There Any Legal Rules for Transporting Fuel?

Absolutely. There are both federal and state regulations for moving fuel around safely. First, make sure your container is approved by an agency like the DOT (Department of Transportation) or EPA. This certification means it's been tested to be durable and to limit harmful vapor emissions.

There are also limits on how much fuel you can legally carry in a personal vehicle. When you're on the road, always make sure your portable gas container is secured in an upright position to keep it from tipping and spilling.

Ready to make your fueling experience safer and completely spill-free? See how CLiX Fueling Solutions offers a smarter, engineered approach to fuel transfer. Visit us at clixfueling.com to see the difference for yourself.