When you think about a fuel tank, you probably picture the one in your car. Now, imagine trying to power a massive cargo ship on a voyage from Shanghai to Rotterdam. That gives you a sense of the scale, but the technology inside a modern marine gas container is a whole different world.

These containers are the unsung heroes of the shipping industry's push for cleaner energy, allowing massive vessels to run on lower-emission fuels across the world's oceans.

Why Marine Gas Containers Are So Critical

Let's get one thing straight: these aren't just big metal boxes. They are highly sophisticated systems built to solve one of the toughest engineering problems out there: keeping liquefied natural gas (LNG) at a mind-numbingly cold -162°C (-260°F).

At that temperature, natural gas shrinks to 1/600th of its gaseous volume, which is the only way to carry enough of it to power a ship across an ocean. But keeping something that cold while the ship is pitching and rolling on the high seas is a massive technical challenge.

Tackling the Toughest Problems at Sea

For decades, the shipping industry has relied on heavy fuel oil, a cheap but dirty power source that contributes heavily to air pollution. LNG offers a much cleaner burn, but making the switch isn't as simple as just pouring a new fuel into an old tank.

The industry needed a completely new kind of containment system that could:

- Handle the Deep Freeze: The materials and insulation have to be perfect. If that extreme cold reached the ship's steel hull, it could become as brittle as glass.

- Survive a Storm: Imagine thousands of tons of liquid sloshing around inside a tank during rough weather. These containers are built to absorb those incredible forces without breaking a sweat.

- Be Incredibly Safe: A leak could release a huge cloud of flammable vapor, which is a non-starter. Safety isn't just a feature; it's the absolute number one priority in every single design.

This is where the engineering brilliance of marine gas containers really shines. They are designed from the ground up to handle these exact problems, making cleaner fuels a safe, reliable option for the global fleet.

The shift to cleaner fuels is more than just an environmental checkbox; it's a complete logistical and engineering overhaul. These containers are the linchpin that makes it all possible, allowing ships to carry new energy sources without sacrificing safety or efficiency.

Think of this guide as your map to understanding this vital technology. We’ll dive into the different designs, break down the strict safety rules they have to follow, and look at their role in pushing the maritime world toward a greener future. From the basics of cryogenic storage to what's next for zero-emission fuels, you'll get a clear picture of how these systems are changing the game.

Exploring Different Marine Gas Container Designs

When you’re talking about marine gas containers, there's no one-size-fits-all solution. The engineering behind these systems is a specialized field, constantly balancing space, safety, and how the ship needs to operate.

Think about it like this: you wouldn't use a delicate teacup to carry water on a long hike; you'd grab a tough, insulated canteen. It's the same principle here. The kind of gas container a ship needs depends entirely on its mission.

The design of these containers generally breaks down into two main families: Membrane tanks and Independent tanks. Each has its own set of trade-offs, which ultimately shape how a vessel works and the kind of cargo it can handle.

The Integrated Approach: Membrane Tanks

Imagine a high-tech thermos, but instead of being a separate bottle, it's built right into the ship's hull. That's the basic idea behind a membrane tank. These systems use an incredibly thin layer—the "membrane"—made of advanced materials like Invar (a nickel-steel alloy that barely expands or contracts with temperature changes) or stainless steel to hold the cryogenic liquid.

This thin primary barrier is backed by thick layers of heavy-duty insulation, which in turn is supported by the ship's inner hull. Because the tank follows the exact shape of the hull, this integrated design is fantastic for maximizing space. Virtually no room is wasted, letting the vessel carry as much cargo as possible.

The flip side? All the force from the sloshing liquid gets transferred directly to the ship's hull. This means the hull itself has to be exceptionally strong and resilient, which makes for a highly specialized and demanding construction process.

The Self-Contained Solution: Independent Tanks

Independent tanks are a different beast altogether. Think of them as giant, self-contained capsules secured deep inside the ship. They are completely separate from the hull and don’t rely on it for structural support. This separation adds an extra layer of safety, with the hull acting as a final protective shell.

These tanks come in three main varieties, each with its own specific design.

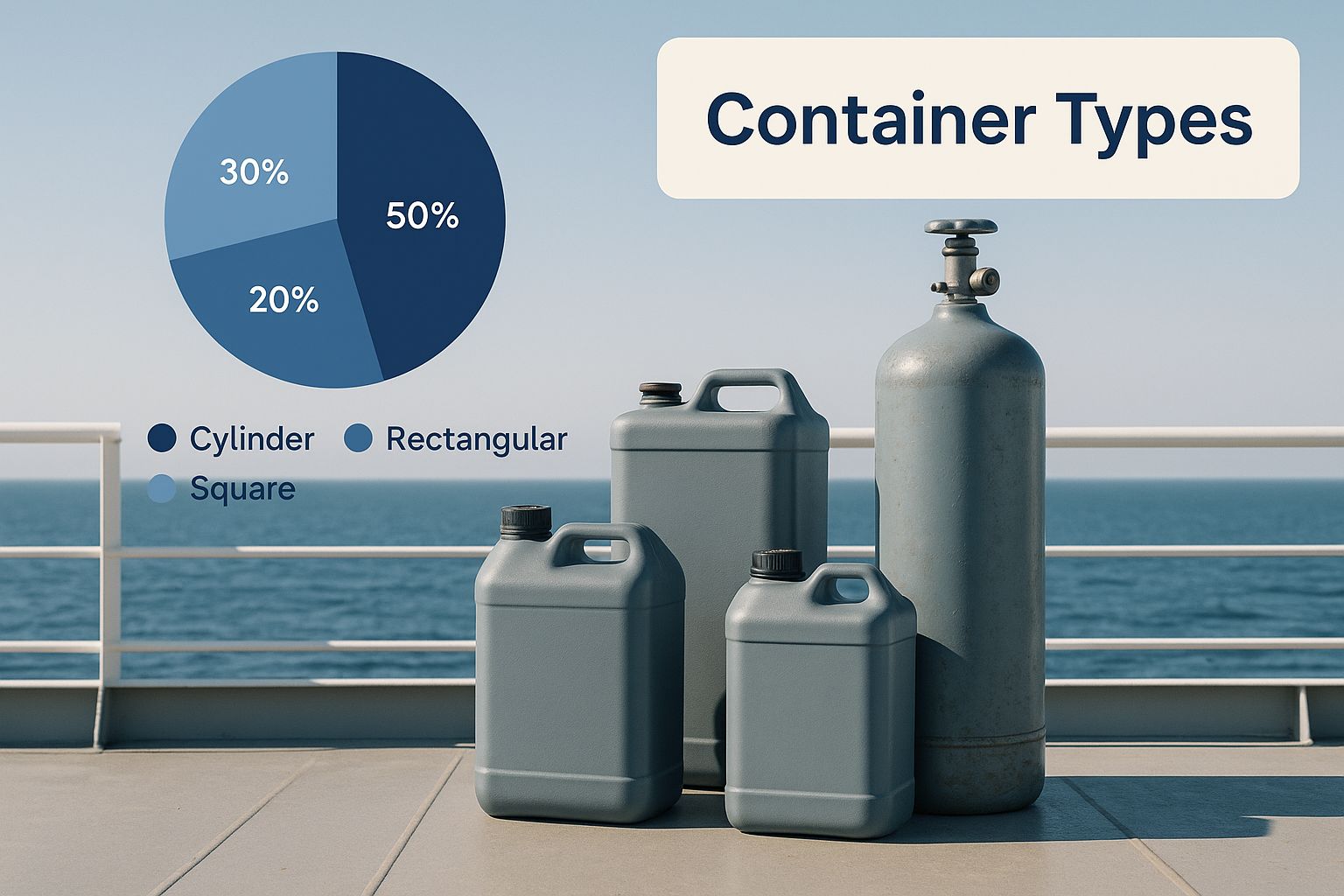

The image above really shows how the different shapes—from massive spheres to boxy prisms—are selected to fit a ship's design and its specific job out on the water.

To give you a clearer picture, let's break down the main types you'll find on the water.

Comparing Marine Gas Container Designs

This table breaks down the primary types of marine gas containers, highlighting their core features, advantages, and common use cases in the shipping industry.

| Container Type | Key Feature | Primary Advantage | Common Application |

|---|---|---|---|

| Membrane Tank | Integrated with the ship's hull. | Maximum space efficiency. | Large LNG carriers where cargo capacity is paramount. |

| Independent Type A | Prismatic (box-like) shape. | Good space utilization for an independent tank. | LPG carriers and smaller LNG vessels. |

| Independent Type B | Spherical "Moss" tank design. | Excellent stress distribution and safety. | Large LNG carriers requiring robust, proven designs. |

| Independent Type C | Pressurized cylindrical or spherical shape. | Simple, robust, and doesn't need a secondary barrier. | LNG-fueled ships (as fuel tanks) and smaller gas carriers. |

As you can see, the choice between these designs isn't arbitrary—it’s a calculated decision based on the vessel's specific role and operational needs.

Breaking Down the Independent Types

Let's dive a little deeper into those independent tanks, as they are categorized by their shape and how they manage pressure.

- Type A Tanks: These are usually prismatic (box-shaped) and are built to hold liquid at or near atmospheric pressure. Since they can't handle much pressure buildup, they must have a full secondary barrier that can contain any potential leaks for a specified amount of time.

- Type B Tanks: Often spherical, these are engineered to a much higher standard. Their design uses sophisticated modeling to predict and prevent issues like fatigue and cracks. Because of this, they only need a partial secondary barrier, like a drip tray. That classic spherical shape is brilliant at distributing stress evenly across the structure.

- Type C Tanks: These are fully pressurized tanks, basically like the propane tanks you'd see on land, just on a mind-boggling scale. Typically cylindrical or spherical, they can withstand serious internal pressure. Their sheer strength and "leak-before-failure" design mean they don't need a secondary barrier at all. This makes them a popular choice for smaller vessels or as fuel tanks on ships running on LNG.

The move toward cleaner fuels is really shaking up the maritime market. The global ship gas tank market is growing fast, mostly because more and more ships are adopting LNG. In 2025, the market value is expected to be around $2.5 billion, and experts predict a compound annual growth rate (CAGR) of 7% through 2033. You can explore the full research about these market trends to see what's driving this shift.

Choosing a container design is a fundamental decision that impacts everything from a ship's initial cost to its long-term operational flexibility. A membrane design might offer more cargo space, but a Type C tank could provide simpler, more robust fuel storage for a different kind of vessel.

Ultimately, picking the right design comes down to a careful analysis of the vessel’s job. Things like the intended cargo, typical trade routes, and the type of fuel all play a huge part in deciding whether an integrated membrane tank or a self-supporting independent tank is the best tool for the job.

How Global Safety Standards Keep Ships and Their Crews Safe

When you're dealing with cryogenic fuels like LNG, "safety first" isn't just a catchy phrase—it's the entire foundation of the maritime industry. A single problem with a marine gas container could lead to a disaster. That’s why a complex web of global standards dictates every single detail, from how these tanks are designed and built to how they’re used on the open water.

These aren't just arbitrary rules someone dreamed up. They're the product of decades of hard-won engineering lessons, all designed to manage enormous risks and protect the crew, the ship, and the fragile marine environment.

The Watchdogs of International Maritime Safety

At the center of it all is the International Maritime Organization (IMO), a special UN agency that sets the global benchmark for safety and environmental performance in shipping. The IMO's rules aren't just recommendations; they are legally binding for member nations, creating a high, consistent standard of safety across the globe.

For any ship running on gas fuels, the rulebook that matters most is the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code). This code was created specifically to handle the unique challenges of fuels like LNG, which are kept at incredibly cold temperatures and behave very differently from old-school marine diesel.

The IGF Code leaves no stone unturned. It covers everything from where fuel tanks can be located on the ship to the specific materials used to build them and the emergency systems that must be in place. It’s the definitive guide for making sure these advanced fuel systems work safely, no matter the conditions.

Engineering Safety From the Ground Up

The IGF Code is built on a "safety-by-design" philosophy. This means that protection isn’t just bolted on at the end; it's woven into the very fabric of every marine gas container. It’s a lot like a modern car—you have airbags, crumple zones, and stability control all working together to prevent accidents and protect the people inside.

Here are a few of the critical safety features required by these codes:

- Pressure Relief Valves: Think of a gas container as a high-tech pressure cooker. As the cryogenic fuel naturally warms up a tiny bit, it creates "boil-off" gas, which builds pressure. These valves are essential safety releases that automatically vent that excess pressure, preventing it from ever reaching a dangerous level.

- Secondary Barriers: For many tank designs, the rules demand a second line of defense. If the main tank were somehow to leak, this secondary barrier is designed to contain the cryogenic liquid long enough for the crew to get the situation under control.

- Gas Detection and Shutdown Systems: Modern vessels are outfitted with highly sensitive detectors that can sniff out the tiniest gas leak. If a leak is found, these systems can sound alarms and trigger an automatic emergency shutdown, cutting off the fuel supply before the problem can get worse.

The whole system is designed with layers of redundancy. The idea is that if one part fails, multiple backup systems are ready to take over and keep everyone safe.

The Human Side of Safety

Great engineering is only half the battle. These safety standards also demand strict operational rules and specialized training for the crew. Anyone working on a gas-fueled ship has to know the specific properties of the fuel and the precise procedures for handling it.

These protocols cover everything from routine fueling—known as bunkering—to practicing emergency drills. This human element is every bit as important as the steel and sensors. For anyone curious about the day-to-day best practices, our guide on boat fueling safety offers a complete playbook with principles that apply to vessels of all sizes.

Together, this combination of tough regulations, smart engineering, and rigorous training creates an incredibly strong safety culture. It’s what makes marine gas containers some of the most secure and dependable fuel systems in the world, giving the global fleet the confidence to embrace cleaner fuels.

Driving the Maritime Industry's Green Transition

The move toward cleaner fuels isn’t just a passing trend—it's a complete reinvention of global shipping. At the very center of this shift, you’ll find marine gas containers. These specialized tanks are the technology making it possible for massive vessels to ditch heavy, dirty fuel oil for cleaner options like Liquefied Natural Gas (LNG).

For decades, the default fuel for shipping was a thick, sulfur-heavy bunker fuel that was a major source of air pollution. By making the switch to LNG, the industry is seeing some incredible environmental victories. LNG-powered ships can slash sulfur oxide (SOx) emissions by over 99% and cut nitrogen oxide (NOx) emissions by up to 85%.

These aren't minor tweaks. They represent a huge leap forward in cleaning up the air around busy ports and shipping routes. And it's the clever engineering of modern marine gas containers that makes it all happen, allowing cryogenic fuel to be stored and delivered safely to a ship’s engines.

Addressing the Methane Challenge Head-On

But the journey to LNG isn't without its own hurdles. The biggest one is something called "methane slip." This happens when a tiny amount of unburned methane, the main component of natural gas, escapes into the atmosphere. Since methane is a powerful greenhouse gas, figuring out how to control it is crucial for LNG's future.

This is where innovation really shines. Advanced engine designs, like high-pressure dual-fuel engines, are built to burn natural gas much more completely, cutting methane slip by over 50% compared to older, low-pressure engines.

At the same time, the marine gas containers themselves have gotten smarter. Modern systems are designed to capture the "boil-off" gas that naturally evaporates. Instead of just letting it escape, they redirect it to be used as fuel, turning what was once a waste product into a source of energy.

The goal is to create a closed-loop system where every bit of fuel is used for propulsion, not released into the environment. This constant cycle of identifying a problem and engineering a solution is what drives progress in the maritime sector.

A Gateway to Zero-Emission Fuels

While LNG is a fantastic transitional fuel, the industry's ultimate goal is total decarbonization. This is where the real long-term value of investing in gas infrastructure comes into focus. The expertise and supply chains we're building for LNG today are directly transferable to the zero-carbon fuels of tomorrow, like green hydrogen and ammonia.

These next-generation fuels bring even tougher storage challenges, needing either extremely cold cryogenic temperatures or special handling to manage toxicity. The hard-won lessons from designing and operating today's marine gas containers are paving the way for the systems we'll need for these future fuels.

- Hydrogen: Needs to be kept at an incredibly cold -253°C (-423°F), which requires next-level insulation and materials.

- Ammonia: Can be stored at a more manageable -33°C (-27°F), but it's corrosive, demanding specialized tank materials and strict safety protocols.

This forward-thinking approach ensures that today's investments aren't a dead end but a critical stepping stone. To understand the bigger picture of protecting our oceans, it’s worth learning more about the essential steps to prevent marine pollution and act now.

The Soaring Market for Sustainable Fuels

The push for sustainability isn't just about doing the right thing for the planet; it's also a powerful economic force. The sustainable marine fuels market, which is tied directly to the adoption of advanced marine gas containers, is set for explosive growth. Valued at roughly $13.22 billion in 2024, the market is projected to rocket to nearly $648.79 billion by 2034. That's a massive compound annual growth rate of 47.60%. You can explore these figures in detail in the full sustainable marine fuels market research.

This incredible financial forecast shows just how serious the industry is about making a change. In the end, marine gas containers are so much more than simple storage tanks. They are the active, dynamic technologies at the heart of shipping’s decarbonization journey, helping make cleaner oceans and clearer skies a reality.

What to Consider When Selecting a Gas Container

Choosing the right marine gas container is one of the biggest calls a ship owner or operator has to make. This isn't just about buying a tank. You're essentially defining the vessel’s operational future—its efficiency, its routes, and its ability to stay relevant in a fast-changing industry. It’s a classic balancing act between what it costs today and how it will perform for decades to come.

Think of it like picking an engine for a new truck. You wouldn't just grab the biggest one off the shelf. You’d think about what you're hauling, your fuel budget, and how long you plan to run it. It's the exact same logic here, just on a much, much bigger scale.

Analyzing Your Vessel's Mission

First things first: what is this ship actually going to do? A vessel's core purpose and its typical sailing routes are the starting point for everything.

Get to the bottom of these questions:

- What are the primary trade routes? A ship making long hauls across the ocean needs all the fuel capacity it can get, making a space-saving membrane tank a strong contender. On the other hand, a vessel doing shorter, regional runs might be better off with the rugged simplicity of a Type C tank.

- Is the bunkering infrastructure there? The global network for LNG and other new fuels is still a work in progress. Your container choice might be dictated by what's available at the ports your ship will call home.

- How will the tank affect cargo capacity? Every cubic meter taken up by fuel is a cubic meter you can't fill with paying cargo. For huge container ships and bulk carriers, that trade-off is a critical piece of the profitability puzzle.

Once you have answers, you'll have a clear operational profile that starts to point you toward the right container solution. A ship built for the Pacific Northwest to Alaska Green Corridor, for example, has entirely different needs than one crossing the Atlantic.

Balancing Costs and Future Fuel Flexibility

Of course, budget is always a huge factor, but you have to look past the initial sticker price. The real cost—the total cost of ownership—includes maintenance, operational efficiency, and the system's lifespan. A cheaper tank today could end up costing you more in the long run if it's less efficient or needs constant upkeep.

Even more importantly, the fuel landscape is shifting under our feet. A vessel built today will likely still be sailing in 2050, by which time fuels like green methanol, ammonia, or hydrogen could be the new normal.

Selecting a gas container isn't just a decision for today; it's a strategic bet on the future of marine fuel. The ideal system offers a pathway to adapt to next-generation energy sources without requiring a complete vessel overhaul.

This is where future-proofing becomes so critical. Some designs are inherently more flexible, making it easier to convert to other cryogenic or low-flashpoint fuels down the road. That adaptability could add years to a vessel's profitable service life. For a closer look at the nuts and bolts of fuel storage, our comprehensive boat fuel tank guide provides great insights on selection and upkeep that are relevant for vessels of all sizes.

The Advantage of Integrated Fuel Systems

Finally, you have to decide: are you buying just a container, or are you investing in a complete, integrated fuel system? Trying to piece it all together yourself—a tank from one supplier, controls from another, and safety gear from a third—can turn into a real headache of mismatched parts and compatibility issues.

A holistic, "plug-and-play" solution, like those from CLiX Fueling Solutions, bundles everything into one cohesive package. This approach ensures every component is engineered to work together flawlessly from day one.

Benefits of an Integrated System:

- Superior Reliability: All parts are pre-tested as a single unit, which drastically reduces the risk of unexpected failures at sea.

- Enhanced Safety: The safety features aren't an afterthought; they're built-in and calibrated to work together seamlessly.

- Streamlined Installation: A single, complete package takes a lot of the complexity out of the installation process, saving valuable time and labor costs.

In the end, an integrated system almost always delivers better performance and, frankly, more peace of mind. By carefully weighing the vessel's mission, the long-term costs, and the need for future flexibility, you can select a marine gas container that's not just another piece of equipment, but a true strategic asset.

Where Marine Fuel Storage is Headed

The story of marine gas containers is still being written. As the shipping world pushes hard for a zero-emission future, these essential systems are getting a complete rethink to handle the next generation of clean fuels. The hurdles are massive—fuels like liquid hydrogen and ammonia come with their own unique and demanding storage rules.

Take liquid hydrogen, for instance. To keep it stable, you need to maintain a bone-chilling -253°C (-423°F). That's a huge ask, pushing cryogenic insulation and materials science to their absolute limits. Ammonia is a bit easier at -33°C (-27°F), but it’s corrosive, meaning you need special tank materials to keep everything safe and sound for the long haul. These aren't just minor tweaks; we're talking about major engineering breakthroughs.

Tanks That Think for Themselves

It's not just about the materials, though. The future of marine fuel storage is also digital. The old-school gas tank is evolving into a smart, self-monitoring system, all thanks to a network of Internet of Things (IoT) sensors built right into the containers.

These sensors are constantly chattering, sending a live feed of data on things like:

- Temperature and pressure inside the tank

- Stress on the container walls

- Gas detection to catch even the smallest leak in a heartbeat

All this information gets crunched by AI-driven predictive maintenance software. Instead of reacting to a problem, these systems can see a potential failure coming weeks ahead of time, letting crews make proactive repairs. This kind of digital watchfulness is a game-changer for safety and reliability out on the water.

The next generation of marine gas containers won't just hold fuel; they will actively manage it. This shift from passive storage to an active, intelligent system is a critical step toward making zero-emission shipping a safe and practical reality.

This jump in technology has big money implications for the entire marine fuel world. The global bunker fuel market—the folks who supply the fuel for these containers—was worth around $125 billion in 2024 and is expected to hit $161 billion by 2030. You can dig deeper into the dynamics of this growing market to see just how much is at stake. At the end of the day, innovation in fuel storage isn't just an engineering puzzle—it's the key to unlocking a sustainable and profitable future for global shipping.

Got Questions? We've Got Answers

When you start digging into marine gas containers, a few common questions always seem to pop up. Let's tackle some of the most frequent ones to clear things up.

How Long Do These Containers Actually Last?

You can expect a marine gas container to last the entire working life of the vessel, which is usually somewhere between 20 and 30 years. These aren't your average tanks; they're built to endure.

Manufacturers use incredibly tough materials like stainless steel or specialized nickel-steel alloys. These metals are specifically chosen because they can handle the brutal, cryogenic temperatures and the constant motion of life at sea. To make sure they hold up, they go through regular, strict inspections required by maritime classification societies—think of them as the quality control enforcers of the shipping world.

What Happens to the Gas That Evaporates?

Even with the best insulation, a tiny bit of the liquefied natural gas (LNG) will naturally warm up and turn back into a gas. This is called "boil-off gas," or BOG, but modern ships don't let it go to waste.

The smartest and most common approach is to simply use it. The boil-off gas is piped straight to the ship's engines, providing a bit of free fuel to help power the vessel.

Some ships have more advanced systems, like an onboard re-liquefaction plant that captures the gas, cools it back down into a liquid, and returns it to the tank. If for some reason the gas can't be used as fuel, it can be safely burned off in a special combustion unit to keep the tank pressure stable.

Are These Containers Safe in a Collision?

Absolutely. Safety is the number one priority, and these containers are designed with multiple layers of protection to handle even severe impacts.

They're typically placed deep inside the ship's double-hulled structure, which acts as a protective shell. The independent tanks are essentially a tank within a tank, shielded by secondary barriers designed to catch any potential leaks. Membrane tanks are built right into this reinforced hull.

Every design has to meet demanding international safety codes that require collision-resistant structures, extra reinforcements, and automated shutdown systems. It's all about making sure the gas stays contained, no matter what.

Ready to make your own fueling experience safer and spill-free? CLiX Fueling Solutions offers a simple, effective way to prevent costly overfills and protect the marine environment. Discover how it works.