A boat's fuel system is the lifeblood of its engine. It's a whole network dedicated to one thing: getting clean, consistent fuel from the tank into the engine's combustion chamber. If you own a boat, getting familiar with how this all works is one of the most important things you can do.

Understanding How a Boat Fuel System Works

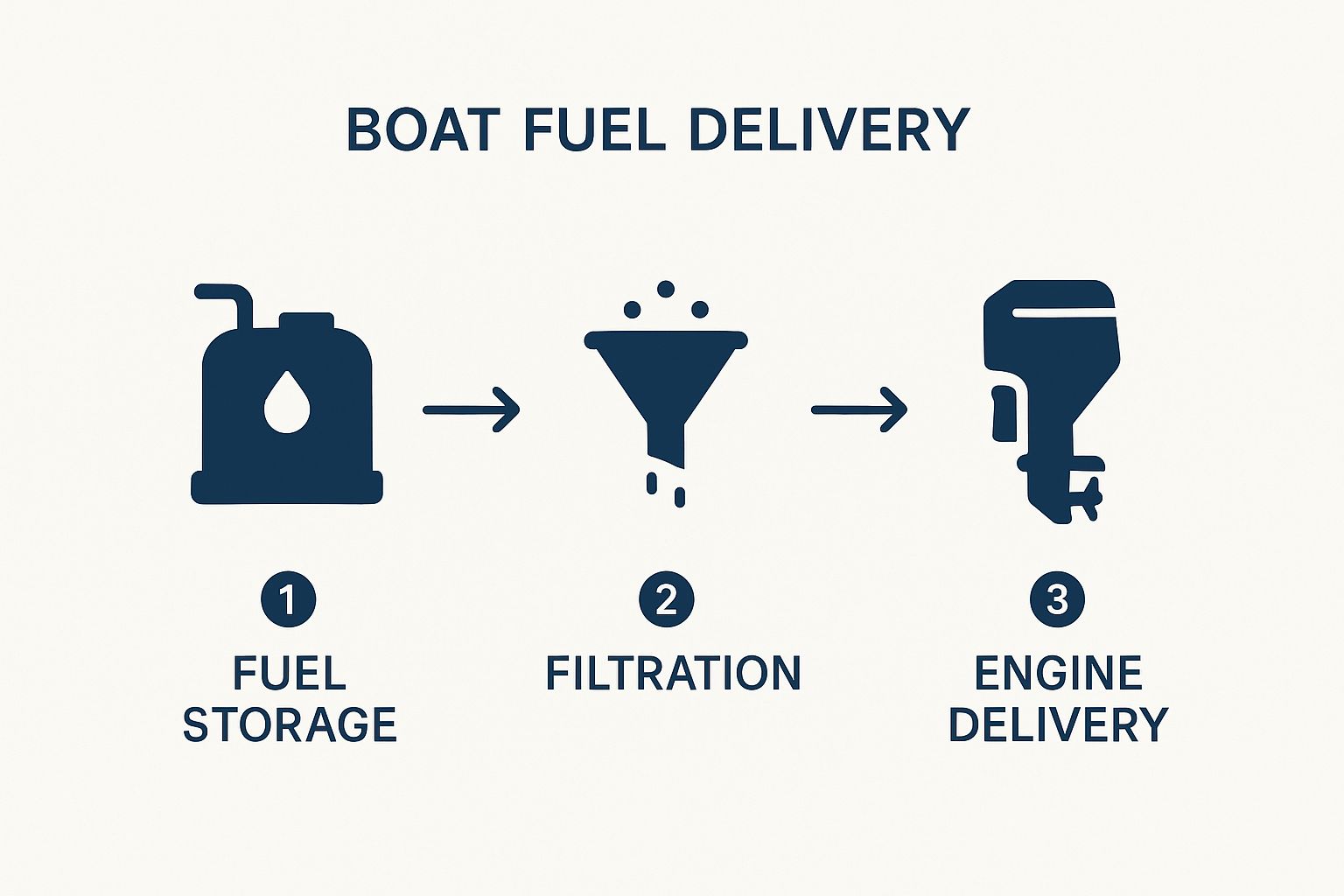

Think of your boat's fuel system as a highly specialized delivery service. Its only job is to move fuel from storage to the engine, making sure it arrives clean and ready to burn. If any part of that service breaks down, you'll feel it in your engine's performance—and it could even put your safety at risk. The whole operation depends on a few key parts working together perfectly.

It all starts in the fuel tank, which is just what it sounds like: the main reservoir where your fuel lives. From there, the fuel gets pulled through fuel lines, which are basically the highways of the system. But before it gets anywhere near the engine, it has to pass a crucial quality check.

The Path from Tank to Engine

The fuel's first stop after leaving the tank is one or more fuel filters. These are the security guards of the system, designed to catch water, dirt, and any other gunk that doesn't belong. Studies on marine fuels make it crystal clear: clean fuel is everything. Even tiny particles can gum up the works in a high-performance engine, so this filtration step is absolutely critical for keeping your engine healthy.

Once it's clean, the fuel pump takes over. This component pressurizes the fuel, giving it the push it needs to travel the rest of the way to the engine. You can think of the pump as the heart of the system, pushing that lifeblood forward with steady pressure.

This visual breaks down the simple three-stage journey that fuel takes.

This process shows why just having fuel in the tank isn't enough. You need a clean, pressurized supply, and every stage is a potential weak link if it isn't maintained.

The Final Delivery Stage

The last step in the journey involves either a carburetor or, far more commonly in modern boats, fuel injectors. These are incredibly precise nozzles that spray a fine, vaporized mist of fuel directly into the engine's combustion chamber at exactly the right moment.

The precision of this final delivery affects everything—your boat's power, its fuel economy, and even its emissions. This is where the magic happens, turning the stored energy in the fuel into the mechanical power that pushes your boat through the water.

This entire sequence happens thousands of times a minute without you ever seeing it. To make it all work, a few key components have to be in sync:

- Storage and Venting: The tank not only holds the fuel but also has a vent to let air in as fuel is used, which prevents a vacuum from forming.

- Transport and Pumping: Fuel lines act as the plumbing, and the pump provides the muscle to move the fuel.

- Filtration: The filters are your engine's last line of defense against contaminants.

- Delivery: The injectors are the final gatekeepers, ensuring the perfect amount of fuel gets delivered for combustion.

Once you have a good grasp of this flow, you're well on your way to knowing how to maintain and troubleshoot any fuel system.

Choosing Between Diesel and Gasoline Fuel Systems

Picking between a diesel or a gasoline engine is one of the biggest decisions you'll make as a boat owner. It's a choice that defines your entire fuel system and goes way beyond what you pump at the dock. This decision shapes your boat's performance, what you pay upfront, your running costs for years to come, and even your safety on the water. The right answer really just depends on how you see yourself using your boat.

A good way to think about it is like choosing a car. If you want something for quick, thrilling drives, you’d probably get a high-performance sports car (gasoline). But for hauling heavy loads across the country, a tough diesel truck is the obvious choice. The same basic logic holds true for boats.

The Case for Gasoline Fuel Systems

It’s no surprise that gas-powered boats are everywhere, especially for smaller and mid-sized recreational boats. Their big draw is a great power-to-weight ratio and a much friendlier price tag to get started. A gasoline engine just gives you more horsepower for its size and weight compared to its diesel cousin.

What does that mean for you? Quicker acceleration and higher top speeds. It’s perfect for things like water skiing, wakeboarding, or just zipping across the bay. The lower upfront cost of the boat itself also opens up the world of boating to a lot more people.

But all that performance has its trade-offs. Gasoline is much more volatile than diesel, and its lower flash point means there's a higher risk of fire or an explosion from fumes building up in an enclosed space like an engine room. On top of that, gas engines are thirsty, burning through fuel at a much faster clip.

The Advantages of Diesel Fuel Systems

When it comes to long-range cruising, commercial fishing, or powering larger yachts, diesel is the undisputed king. The main reasons are simple: incredible fuel efficiency, massive torque, and sheer longevity. A well-maintained diesel engine can run for thousands of hours, often lasting two to three times longer than a similar gas engine.

That fuel efficiency is a huge deal. Diesel fuel packs more energy into every gallon, which means a diesel engine will take you much farther on a full tank. For anyone dreaming of long offshore trips or just wanting to tame their annual fuel bill, this is a massive plus.

Safety is another major point in diesel's favor. Diesel fuel is far less flammable than gasoline, making it a much safer thing to have sloshing around in your tanks. Its higher flashpoint dramatically lowers the risk of an accidental fire from a stray spark or leaking fumes.

Diesel engines are built for the long haul. While you’ll definitely pay more for them initially, their lower fuel burn, less frequent maintenance needs, and better safety profile make them the go-to for serious cruisers and commercial skippers.

Diesel vs. Gasoline Fuel Systems: A Quick Comparison

To really see how these two systems stack up, it helps to put them side-by-side. This table breaks down the key differences that matter most to boat owners.

| Feature | Diesel Fuel System | Gasoline Fuel System |

|---|---|---|

| Upfront Cost | Higher initial investment | Lower initial investment |

| Fuel Efficiency | Excellent, burns less fuel per hour | Lower, higher fuel consumption |

| Safety | Safer, less volatile fuel | More volatile, higher fire risk |

| Longevity | Very durable, long lifespan | Shorter lifespan than diesel |

| Performance | High torque, steady power | High horsepower, faster acceleration |

| Maintenance | Generally less frequent but can be more complex | More frequent but often simpler |

| Weight | Heavier engine for its power output | Lighter engine for its power output |

| Best For | Long-distance cruising, trawlers, large yachts | Sport boats, day cruisers, smaller vessels |

As you can see, there’s no single "best" option—just the best option for a specific type of boating.

Making the Right Decision for Your Boat

At the end of the day, the right choice comes from being honest about your boating lifestyle. Don't get fixated on the sticker price; think about how you're really going to be spending your time on the water.

Start by asking yourself a few simple questions:

- What will I be doing most of the time? Are you a weekend warrior pulling a tube, or are you planning to cross an ocean?

- What's my real budget? Think beyond the purchase price and consider your annual fuel and maintenance costs.

- Do I care about resale value? A well-cared-for diesel boat often holds its value much better over the years.

- How comfortable am I with engine work? While incredibly reliable, diesel systems can feel a bit more intimidating to a DIY mechanic.

By thinking through these points, you can pick the fuel system that truly fits your needs, setting you up for countless hours of fun and worry-free time on the water.

Getting to Know the Key Players in Your Fuel System

To really get a feel for a boat's reliability, you need to look past the shiny hull and the powerful engine. The real workhorse is the fuel system, a specialized team of components working in harmony. Each part has a critical job, and if one stumbles, the whole operation can grind to a halt.

Think of it as a journey, with the fuel traveling from the tank all the way to the engine in a series of carefully managed steps. Let's walk through the essential players in this process and see what makes them so important for your boat's performance.

The Fuel Tank: Where It All Begins

Every drop of fuel starts its journey in the fuel tank. You'll typically find modern boat tanks made from either high-density polyethylene (plastic) or aluminum, and each has its perks. Plastic tanks are incredibly tough and won't corrode, while aluminum tanks are prized for their strength and the ability to be custom-built for a perfect fit.

No matter the material, every marine fuel tank must have a solid venting system. As your engine sips fuel, the vent lets air in, preventing a vacuum that could choke off the fuel supply. It's a non-negotiable safety feature that also allows fuel vapors to escape safely instead of building up.

Fuel Lines and Pumps: The Delivery Network

From the tank, fuel travels through a network of fuel lines. These aren't just any hoses; they are the arteries of the system, built to survive the harsh marine environment and resist breaking down from fuel additives. A loose fitting or a cracked line is more than just a nuisance—it’s a serious fire hazard.

Pushing the fuel through these lines is the fuel pump. It's the heart of the whole operation, creating the steady pressure needed to feed the engine. Some engines use a low-pressure mechanical pump, while others rely on a high-pressure electric one. Either way, its job is the same: keep the fuel flowing so the engine never starves.

A boat's fuel system is only as strong as its weakest link. A cracked fuel line, a clogged filter, or a failing pump can bring an otherwise perfect day on the water to a sudden halt.

Multi-Stage Filtration: The Engine's Bodyguard

Before fuel can be ignited, it needs to be squeaky clean. That's the job of the filtration system, which acts as the engine's personal bodyguard, stopping dirt, debris, and water from getting through. Most boats use a multi-stage approach for the best protection.

Here’s how it usually works:

- Primary Fuel Filter/Water Separator: This is your first line of defense, sitting between the tank and the engine. It catches the big stuff and, crucially, separates out any water that’s found its way into your fuel.

- Secondary On-Engine Filter: This finer filter is mounted directly on the engine. It’s the final checkpoint, snagging any smaller particles that got past the primary filter right before the fuel enters the engine.

Checking and changing these filters is easily one of the most important maintenance jobs you can do. For a more complete picture of the whole setup, take a look at our guide on the essential parts of a boat fuel system.

Fuel Injectors: The High-Tech Gatekeepers

In modern marine engines, the final hand-off goes to the fuel injectors. These aren't your grandfather's carburetors. They are incredibly precise nozzles that spray a fine, atomized mist of fuel directly into the combustion chamber. This precision is what dictates your engine's efficiency, power, and emissions.

The injector’s role is so critical that the global marine fuel injection system market was valued at around USD 5.8 billion and is expected to climb to USD 8.3 billion by 2034. In fact, the injector component alone makes up a massive 31.1% of that market, which really drives home how vital it is for engine performance.

By perfectly timing and measuring the fuel spray, modern injectors squeeze more power out of every single drop. This doesn't just save you money at the pump; it ensures a cleaner, more complete burn, which is essential for meeting today’s tough emissions standards.

Troubleshooting Common Fuel System Problems

Even the most well-kept boat can run into trouble, and when your engine starts acting up, the fuel system is almost always the first place to look. That sputtering sound, a sudden loss of power, or an engine that just won't turn over—more often than not, it’s a fuel issue. Knowing what to look for can save you a world of frustration and the dreaded call for a tow.

Most of these headaches trace back to a single villain: bad fuel. Think of contaminated fuel as a poison working its way through your boat's veins, and it’s behind countless engine performance problems.

Identifying and Fixing Fuel Contamination

Fuel contamination isn't just one thing; it's a catch-all term for several nasty problems that can plague your tank. Each one looks a little different.

- Water Contamination: Water is sneaky. It can get in through a bad fuel cap seal, form from simple condensation, or even come straight from the pump at the fuel dock. Since water is heavier than fuel, it sinks to the bottom of your tank, right where the fuel pickup sits. An engine that sputters and struggles to hold a steady RPM is a classic sign you're sucking up water.

- Debris and Sludge: Over the years, rust, sediment, and all sorts of gunk settle at the bottom of your tank. In calm water, it might not be a problem, but as soon as you hit some chop, that nasty sludge gets stirred up and pulled right into your fuel lines.

- Microbial Growth: This is the infamous "diesel algae." In reality, it’s microbes that thrive at the point where water and diesel meet. They form a thick, slimy mess that can clog your entire system—filters, lines, and injectors—in a surprisingly short amount of time.

If you think you've got contaminated fuel, your first move should be to check the primary fuel filter/water separator. Is the clear bowl full of water? Does it look like dark, muddy coffee? That's your smoking gun. Draining it is just a temporary patch; the real fix involves getting the tank professionally cleaned and having the fuel "polished."

Uncovering Clogged Filters

A clogged fuel filter is the number one consequence of bad fuel. It's the most common breakdown point for a reason—it’s doing its job! But when it gets clogged, it’s like a pinched straw. The fuel flow gets restricted, and your engine starts gasping for what it needs to run.

The symptoms are textbook. The engine starts up fine at the dock, but when you push the throttle down to get on plane, it bogs down and just won't give you the power you need. The solution couldn't be simpler: change the filter. This is exactly why every boater should have at least two spare filters on board, no exceptions. For more on this, check out our guide on how to diagnose and prevent common boat fuel problems.

A sputtering engine under load is the number one symptom of fuel starvation. Before you suspect a major engine problem, always check your fuel filters first. It's the simplest, cheapest, and most common solution.

Addressing Other Common Failures

While dirty fuel and clogged filters cause the vast majority of problems, other parts of the system can give up the ghost, too.

Common Fuel System Failure Points

| Component | Common Symptoms | Typical Solution |

|---|---|---|

| Failing Fuel Pump | Engine cranks but won't start; sudden loss of power while running. | Test pump pressure; replacement is usually required. |

| Air Leaks in Fuel Lines | Engine runs rough, surges, or stalls; visible bubbles in a clear filter bowl. | Inspect all fuel line fittings and hoses for cracks or loose connections. |

| Vapor Lock | Engine dies after running for a while and refuses to restart until it cools down. | Check for fuel lines routed too close to hot engine parts; ensure proper ventilation. |

Figuring these out requires a bit more detective work. You always want to start with the easy stuff—the filters—before moving on to more complex parts like the fuel pump. Knowing your limits and when to call in a professional marine mechanic is just as important as knowing how to change a filter.

Don't Wait for Trouble: Keep Your Fuel System in Top Shape

When it comes to your boat's fuel system, an ounce of prevention is worth a pound of cure—and a hefty tow bill. A reliable system isn't something you buy; it's something you build through consistent, simple maintenance.

Forget waiting for a problem to pop up. A proactive routine is your best bet for keeping things running smoothly, saving you a world of frustration, time, and money. It's all about small, smart habits that protect everything from your fuel tank to your engine.

Your Go-To Maintenance Checklist

Sticking to a simple checklist turns good intentions into rock-solid reliability. Make these steps a regular part of your boating life.

- Eyeball Your Fuel Lines: Give your fuel lines a quick once-over every month or so. Look for any cracking, stiffness, or spots where they might be rubbing against something. Don't forget to check the fittings and connections—they should be tight and completely dry.

- Check Filters Before Every Trip: Think of your main fuel filter and water separator as your first line of defense. Take a peek at the clear bowl before you head out. See any water or gunk? Drain it. It’s that simple.

- Always Use a Fuel Stabilizer: Every single time you fill up, add a quality marine-grade fuel stabilizer. This is non-negotiable, especially with ethanol-blended gasoline. It stops fuel from going bad and prevents phase separation, a real trip-ender.

A few minutes spent on these tasks will pay you back with performance you can count on.

A reliable fuel system isn’t bought; it’s maintained. A few minutes of inspection before you leave the dock is far better than hours of troubleshooting offshore when something goes wrong.

Habits for Long-Term Health

Beyond your regular checks, a couple of key practices will keep your system healthy for the long haul. The goal here is to defeat the two biggest enemies of any marine fuel system: water and dirt.

The foundation of a healthy system is a clean tank. For a much deeper look at tank care, check out our boat fuel tank guide to choose and maintain one easily.

Why a Schedule Matters

It's easy to forget these things, which is why a schedule is your best friend. Consistency ensures nothing falls through the cracks.

Seasonal Fuel System Tasks

| Timing | Action Required | Why It's Important |

|---|---|---|

| Every 100 Hours or Annually | Replace primary and secondary fuel filters. | This guarantees your engine gets the clean fuel it needs to perform, especially when you're pushing it hard. |

| During Winterization/Storage | Fill the tank to 90% full and add stabilizer. | A full tank leaves less room for air, which means less condensation and less water getting into your fuel. |

| Every 3-5 Years | Have your fuel tank professionally inspected and cleaned. | Even the best filters can't stop all sludge and sediment from building up over the years. This gets it all out. |

Just think about the size of the marine engine market—valued at USD 13.31 billion and expected to climb to USD 17.46 billion by 2032. As engine technology gets more advanced, it demands cleaner fuel than ever before. Staying on top of maintenance isn't just good practice; it's essential for keeping up with modern boating. This hands-on approach will make sure your boat is ready to go whenever you are.

Where Marine Fuel Systems Are Headed

The world of marine fuel systems is changing fast. It's not just about tiny adjustments here and there; we're seeing a real push driven by the need for better efficiency and cleaner oceans. As international regulations get stricter, engine builders are being forced to get a lot more creative.

This pressure is moving some pretty advanced tech from the world of big commercial ships into the boats we use every day. The whole game is about getting the absolute most out of every single drop of fuel.

Smarter Fuel Management is Here

One of the biggest leaps forward is the widespread use of Electronic Control Units (ECUs). You can think of the ECU as the engine's brain. It's constantly taking in information from sensors—things like engine speed, how hard it's working, and even the air temperature—and using that data to fine-tune the fuel delivery on the fly.

This level of control is a game-changer. Older mechanical systems were pretty blunt instruments, but an ECU can create the perfect fuel-and-air mix for any situation. What does that mean for you? Better fuel economy, more power when you need it, and a huge cut in nasty emissions.

Another piece of tech making waves is common rail injection. In these systems, fuel is kept under incredibly high pressure in a single tube (the "common rail") that feeds all the injectors. With that pressure always on tap, the ECU can tell the injectors to open and close with pinpoint accuracy. This creates a super-fine mist of fuel that burns way more completely.

The future of marine fuel is intelligent. By pairing advanced electronics with high-pressure delivery, modern engines can constantly adjust themselves for the best performance while leaving a much smaller footprint on the environment.

The Slow But Steady Move to Alternative Fuels

Let's be clear: diesel and gasoline aren't going anywhere overnight. But the marine industry is seriously looking at cleaner options. It’s going to be a gradual shift, but the foundation is being built right now. Groups like the International Maritime Organization (IMO) are setting some big goals for cutting emissions, which is lighting a fire under the research and development of new power sources.

Here are a few of the most promising fuels on the horizon:

- Green Methanol: This stuff is made from renewable sources and burns way cleaner than fossil fuels. It dramatically cuts down on pollutants like sulfur oxides and soot.

- Hydrogen: As a true zero-emission fuel, hydrogen's only byproduct is water. Storing it on a boat and finding a place to fill up are still big challenges, but it points to a truly clean future for boating.

- Advanced Biofuels: Made from organic materials, these can often be used as direct "drop-in" replacements for diesel. That means you get a lower-carbon fuel without needing a whole new engine.

This industry-wide push for cleaner tech is showing up in the numbers. The global market for marine fuel injection systems, currently valued around USD 5.94 billion, is expected to grow to USD 8.38 billion by 2035. That's a steady growth rate of 3.5% a year, driven almost entirely by the demand for more efficient engines that can meet tough environmental standards. You can dig deeper into these market trends with this report from Future Market Insights.

All signs point in one direction: the fuel systems of tomorrow will be smarter, more flexible, and a whole lot friendlier to our waters.

Your Top Questions About Boat Fuel Systems, Answered

Even after you get the hang of your boat's fuel system, questions inevitably come up. Think of this as your go-to guide for quick, clear answers to the stuff boaters ask about most.

How Often Should I Change My Boat's Fuel Filters?

The general rule of thumb is to change your fuel filters at least once a year or every 100 hours of engine time, whichever comes first. But always defer to what your engine manufacturer recommends—that’s the golden rule.

That said, if your engine starts sputtering or loses power when you accelerate, a clogged filter is the most likely suspect. Don't wait; change it right away. This is exactly why you should always have a few spares tucked away on board.

What Is the Best Way to Prevent Water in My Fuel Tank?

The single best thing you can do is keep your fuel tank as full as you can, especially when you’re not using the boat for a while. A full tank leaves very little room for air, which means less space for condensation to form and settle as water.

For extra protection, get into the habit of adding a good marine fuel stabilizer with a water-absorbing agent every time you fill up. Your last line of defense is your water-separating fuel filter. Make it a habit to check and drain its little collection bowl as part of your routine before heading out.

Keeping your tank topped off is the easiest and cheapest insurance against water contamination. Less air in the tank means less opportunity for water to condense and settle at the bottom.

Is It Safe to Use Gasoline with Ethanol in My Boat?

Honestly, using ethanol-blended gasoline (like E10) in a boat is playing with fire. Ethanol loves water—it literally pulls moisture out of the air. This can lead to a nasty problem called phase separation, where a mix of ethanol and water sinks to the bottom of your tank.

That sludge can cause serious damage to your engine. Ethanol is also notorious for eating away at older rubber fuel lines and gaskets. If you can, always choose ethanol-free gasoline. If you're stuck with an ethanol blend, double-check that your fuel system parts can handle it and use a marine fuel additive specifically made to combat its nasty effects.

Ready to eliminate fuel spills and the guesswork of filling up? With CLiX Fueling Solutions, you can refuel with confidence, knowing the nozzle will shut off automatically when your tank is full. Protect your boat, the environment, and your peace of mind by visiting the official CLiX Fueling website to learn more.