The Evolution of Marine Fuel Gauges: What You Need to Know

For years, boaters relied on rudimentary methods to check their fuel levels. Dipsticks were common, and hoping for the best was often part of the process. This led to inaccurate readings and the dreaded experience of running out of fuel far from shore. Thankfully, marine fuel gauges have come a long way, offering much-needed accuracy and peace of mind. This evolution is a direct response to the challenges of the marine environment.

One reason standard car fuel gauges don't work well on boats is the constant sloshing of fuel due to waves. This movement makes accurate readings with traditional float-based systems nearly impossible. Saltwater corrosion and electrical interference also add to the complexity. This is where specialized marine technologies are essential.

Modern Marine Fuel Gauge Technologies

Modern marine fuel gauges use several advanced technologies to overcome these challenges.

-

Resistance Sensors: These sensors use a float attached to a variable resistor. As the fuel level changes, so does the resistance, providing a reading on the gauge.

-

Capacitance Probes: These probes measure the change in capacitance between the probe and the fuel. As the fuel level varies, the capacitance also changes, giving a highly accurate measurement.

-

Ultrasonic Systems: Ultrasonic gauges send sound waves into the tank and measure the time it takes for the echo to return. This time corresponds to the distance to the fuel surface, allowing for a precise reading.

-

Pressure Transducers: These sensors measure the pressure at the bottom of the tank, which relates directly to the fuel's height and volume. This method works particularly well in irregularly shaped tanks.

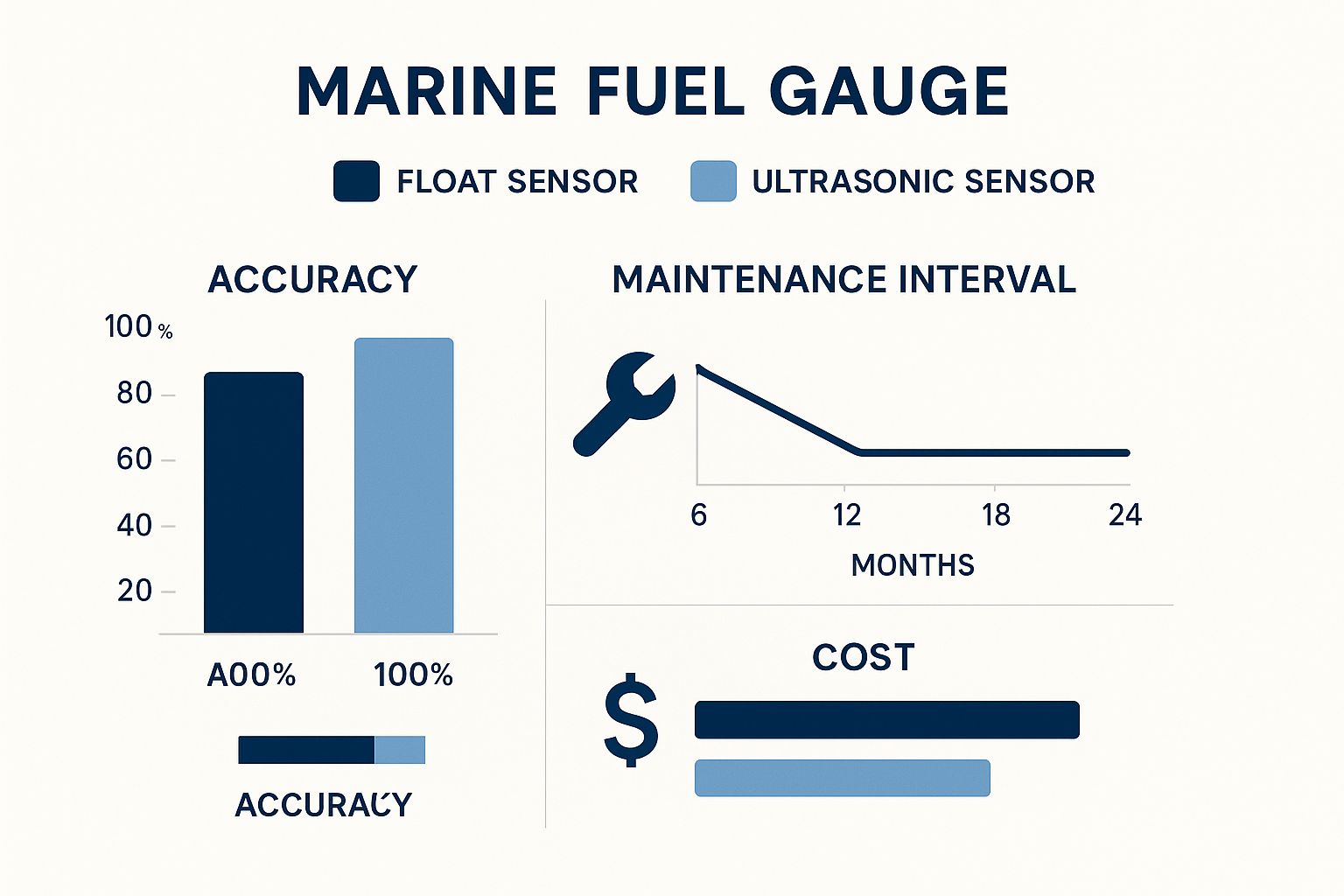

Capacitance probes are often preferred for their accuracy and resistance to fuel sloshing. However, ultrasonic systems are gaining popularity for their ability to work in tanks with complex shapes. Each technology has its own pros and cons, making it important to choose the right gauge for your boat. The marine fuel management market is growing, showing how important reliable fuel management is. The market is projected to grow from USD 3.86 billion in 2024 to USD 5.58 billion by 2030, with a CAGR of 6.33%. You can explore this further at Marine Fuel Management Market Research. This growth highlights the increasing need for accurate fuel measurement to improve efficiency and reduce costs.

Choosing the right marine fuel gauge ensures accurate readings, leading to safer and more enjoyable boating. Consider factors like tank shape, electrical compatibility, and your specific boating needs to make the best choice.

Choosing Your Perfect Marine Fuel Gauge: Beyond the Basics

Selecting the right marine fuel gauge isn't as simple as picking the cheapest one. It requires careful thought about your boating activities and the needs of your vessel. A weekend fishing trip in a small boat has different fuel monitoring needs than a long-range cruise on a yacht. A basic gauge might be fine for short trips, but a more advanced system with multiple tank monitoring and alarms is essential for longer journeys.

Matching Technology to Your Needs

Experienced boaters understand the importance of factors like tank shape, electrical system compatibility, and environmental conditions. Irregularly shaped tanks, common in many boats, pose a challenge for traditional float-based gauges. This makes ultrasonic or pressure-based gauges a better choice because they accurately measure fuel levels in complex tank shapes. Making sure the gauge is electrically compatible with your boat's systems is also vital for smooth integration and to avoid electrical interference. You can explore various fueling solutions at CLiX Fueling Solutions and Products.

Features That Matter (and Those That Don't)

Not all features are equally important. Backlighting is helpful for low-light conditions, but a fancy digital display might be an unnecessary expense if you just need basic fuel level readings. Programmable alarms, however, can be incredibly valuable, alerting you to low fuel levels and preventing the disastrous situation of running out of fuel far from shore. This brings us to the importance of the overall market when choosing a gauge. The demand for accurate fuel gauges is tied to the growth of the marine fuel market, which is expected to reach $171.494 billion by 2030, growing at a CAGR of 4.05% from 2025. This growth highlights the increasing importance of accurate fuel management. You can delve deeper into these market statistics at Global Marine Fuel Market Research.

Making the Right Choice for Your Vessel

The data chart below shows how well different marine fuel gauge technologies work for various vessel types. The chart compares resistance, capacitance, ultrasonic, and pressure-sensing technologies across small recreational boats, mid-sized cruisers, large yachts, and commercial vessels.

As the data chart shows, resistance-based gauges are common in smaller boats because they are simple and affordable. Capacitance and ultrasonic gauges are more often used in larger vessels that need greater accuracy, especially those with irregularly shaped tanks. Pressure-sensing technology is the preferred choice for commercial ships and large yachts because it is robust and can handle large-scale fuel monitoring. Understanding these trends helps boat owners make smart choices based on their vessel type and how they use their boat.

To further assist in selecting the right gauge, the table below provides a detailed comparison based on vessel type.

Marine Fuel Gauge Comparison by Vessel Type This table compares different marine fuel gauge types and their suitability for various vessel categories, helping readers identify the best option for their specific boat.

| Gauge Type | Small Recreational Boats | Mid-sized Cruisers | Large Yachts | Commercial Vessels | Price Range | Key Features |

|---|---|---|---|---|---|---|

| Resistance | Excellent | Good | Fair | Poor | Low | Simple, Affordable |

| Capacitance | Good | Excellent | Good | Fair | Medium | Accurate, Irregular Tank Compatible |

| Ultrasonic | Fair | Excellent | Excellent | Good | Medium-High | High Accuracy, Complex Tank Shapes |

| Pressure-Sensing | Poor | Fair | Good | Excellent | High | Robust, High-Volume Monitoring |

This table summarizes the suitability of each gauge type for different vessel sizes, along with price range and key features. Choosing the right marine fuel gauge is an investment in safety, reliability, and peace of mind out on the water.

Installation Secrets: When To DIY and When To Call a Pro

Installing a marine fuel gauge can appear deceptively simple. Retailers often gloss over the complexities involved. So, how do you decide if you should tackle this project yourself or hire a professional? This section will guide you through that important decision-making process.

Grounding, Positioning, and Compatibility: The Trifecta of a Successful Installation

Three key elements determine a successful marine fuel gauge installation: grounding, sensor positioning, and compatibility. Proper grounding is essential. Without it, inaccurate readings or total gauge failure can occur. Think of the ground as a stable electrical pathway for your gauge. Incorrect sensor positioning can also lead to inaccurate fuel level readings. For instance, a poorly placed sensor in an irregular tank might show "empty" when it's actually half full. Finally, confirming compatibility between the gauge, sensor, and your boat's electrical system is crucial to prevent problems and expensive repairs.

Real-World Installation Disasters: Learning from Others' Mistakes

Even seemingly easy installations can go wrong. Imagine installing a new gauge only to discover wildly inaccurate readings. One common issue is an irregular tank shape, which can interfere with accurate fuel measurement. This is particularly true with older float-style gauges. Another frequent problem is signal interference from other onboard electronics. This can cause erratic readings. These examples highlight the importance of careful planning and understanding potential issues before starting. For solutions to ensure smooth, spill-free fueling, you might find CLiX Fueling and Related Products helpful.

DIY vs. Pro: Making the Right Call for Your Installation

When is DIY appropriate, and when should you call a professional? Simple installations in boats with standard tank shapes and uncomplicated wiring are often manageable for a competent DIYer. However, complex tank shapes, intricate wiring, or integration with other onboard systems often require a qualified marine technician. Consider your skills, available tools, and the installation's complexity. While professional installation might seem costly upfront, it can save you time, frustration, and potentially expensive repairs later.

Tools, Time, and Skills: Assessing Your DIY Capabilities

Before attempting a DIY installation, evaluate your tools, available time, and skills. Do you have the necessary tools, such as wire strippers, crimpers, and a multimeter? How much time can you realistically dedicate to the project without feeling rushed? Are you comfortable working with electrical systems and reading wiring diagrams? Honest self-assessment is critical. Some tasks might seem manageable, but certain installations demand specialized knowledge and experience. Choosing the right approach – DIY or professional – will ensure your marine fuel gauge provides reliable performance for years to come.

Calibration Mastery: Ensuring Your Marine Fuel Gauge Reads True

Accurate fuel readings are essential for every boater. They offer not just convenience, but also contribute significantly to peace of mind and on-the-water safety. Knowing your precise fuel level prevents the dreaded scenario of being stranded far from shore. This, however, hinges on a correctly calibrated marine fuel gauge. Let's explore the crucial process of calibration, highlighting its importance and explaining how to achieve it.

Why Factory Calibration Is Often Insufficient

Many boaters assume their new marine fuel gauge is perfectly calibrated from the factory. Unfortunately, factory settings rarely account for unique tank configurations, especially in boats with irregularly shaped tanks. This means even a brand-new gauge might not accurately reflect your true fuel level. Proper installation technique is also paramount. This helpful guide on valve installation offers valuable insights into proper techniques. Furthermore, factors such as fuel movement, temperature fluctuations, and even the ethanol content in the fuel can influence the accuracy of your readings.

Factors Influencing Fuel Gauge Readings

Several variables can affect the readings displayed on your marine fuel gauge. Fuel sloshing, a constant in a marine environment, causes fluctuating readings, making it difficult to obtain a consistent measurement. Temperature changes also influence fuel density, leading to slight variations in readings. Moreover, the increasing use of ethanol in fuel blends can affect how the sensor interacts with the fuel, impacting accuracy.

For example, consider a boat with a long, narrow fuel tank. The sloshing within such a tank is amplified, hindering the gauge's ability to settle on an accurate reading. This highlights the critical need for proper calibration.

Practical Calibration Techniques

Calibrating your marine fuel gauge establishes a precise correlation between the displayed reading and the actual fuel level in your tank. This typically involves adding measured amounts of fuel to the tank and noting the corresponding gauge readings. Some modern gauges offer convenient electronic calibration features, enabling finer adjustments and compensation for tank shape and fuel type. While methodical, it's a worthwhile investment for reliable fuel information. This is particularly important in light of the technological advancements being driven by the growing demand for accurate measurement. The global level gauge market, for instance, is predicted to reach $2.1 billion by 2028, exhibiting a CAGR of 6% from 2023 to 2028. You can find more detailed statistics here.

Achieving Reliable Readings Through Calibration

Proper calibration transforms your marine fuel gauge from a rough approximation into a precision instrument. This accuracy is essential for informed decisions regarding range, refueling, and fuel consumption. You can accurately estimate your travel distance based on remaining fuel and avoid running out unexpectedly. Furthermore, accurate readings facilitate precise fuel consumption tracking, aiding in the identification of potential engine problems or inefficiencies. Ultimately, mastering calibration empowers you with confidence on the water, knowing your fuel gauge provides reliable information when it matters most.

Troubleshooting Marine Fuel Gauges: Solve Problems Like a Pro

Even the best marine fuel gauges can have problems. Knowing how to troubleshoot these issues can save you money on repairs. This section will help you understand and fix common fuel gauge problems. You’ll learn which problems you can fix yourself and which ones need a professional. Interested in more boating tips? Check out our collection of blog posts related to boating and fuel.

Common Fuel Gauge Problems and Their Causes

Marine fuel gauges can have all sorts of issues. They might give erratic readings, suddenly stop working, or slowly become less accurate over time. Here are some of the most frequent causes:

-

Sensor Corrosion: Saltwater can corrode fuel sensors. This leads to inaccurate or intermittent readings. Older sensors without good seals are especially vulnerable.

-

Grounding Issues: A bad ground connection can stop the gauge from working. It’s like a broken link in a chain, stopping the flow of electricity.

-

Wiring Degradation: Exposure to weather, vibrations, and just plain aging can damage wiring. This causes intermittent or total signal loss. Damaged wiring is like a weak radio signal – it can't send the information clearly.

-

Fuel Sender Issues: The fuel sender itself can break down from wear and tear. This can lead to incorrect readings or a completely unresponsive gauge.

A Methodical Approach to Troubleshooting

Finding the cause of a fuel gauge problem requires a step-by-step approach. Begin by visually checking all the wiring and connections. Look for obvious damage or corrosion, such as loose connections, frayed wires, or corrosion on the sensor.

Next, test the gauge’s ground connection. Use a multimeter to check the ground. A good ground ensures a stable electrical path.

If the ground is fine, test the sensor. You might check its resistance or capacitance, depending on the sensor type. This makes sure the information is flowing correctly.

Finally, if the sensor and wiring are working, the gauge itself might be the problem. Test the gauge with a known good sensor to be sure. This methodical process helps you find the exact issue.

Saltwater-Specific Challenges

Saltwater is tough on marine electronics. Corrosion is always a threat. Electrical interference can also disrupt signals. The constant movement and vibration on a boat can loosen connections and cause wear and tear.

This is why you need strong, marine-grade parts and regular maintenance. It’s worth investing in quality marine fuel gauges. They might cost more than car gauges, but a replacement is much cheaper than the problems caused by inaccurate fuel readings.

Troubleshooting Table:

The following table provides a quick guide for troubleshooting common marine fuel gauge issues.

| Symptom | Possible Causes | DIY Checks | Solutions | Prevention Tips |

|---|---|---|---|---|

| Gauge reads empty | Faulty sender, Wiring issue, Empty tank | Check wiring, Inspect sender | Replace sender, Repair wiring, Fill tank | Regular inspections, Corrosion protection |

| Gauge reads full | Stuck float, Wiring short | Manually move float, Check wiring continuity | Replace sender, Repair wiring | Regular inspections |

| Erratic readings | Loose connection, Intermittent wiring fault, Fuel slosh | Tighten connections, Check wiring for breaks | Clean and tighten connections, Replace wiring, Install a baffle in the tank to reduce slosh | Regular inspections, Secure wiring |

| Gauge doesn't move | Blown fuse, Faulty gauge, Broken wiring | Check fuse, Test gauge | Replace fuse, Replace gauge, Repair wiring | Check and clean fuse connections |

By understanding the typical causes of marine fuel gauge problems and using a systematic troubleshooting method, you can fix many issues yourself. This knowledge helps make frustrating gauge problems easier to solve, ensuring your time on the water is safe and enjoyable.

Smart Integration: Connecting Your Marine Fuel Gauge to Modern Systems

Integrating your marine fuel gauge with other onboard systems is no longer a luxury, but a key component of modern boating. This interconnected approach provides boaters with a comprehensive information network, significantly improving both safety and efficiency on the water. By transforming basic fuel data into usable insights, smart integration empowers boaters to make better decisions.

The Power of NMEA 2000 and Other Protocols

NMEA 2000 is a standardized communication protocol specifically designed for marine electronics. It’s one of the most important tools for system integration. This protocol allows various devices, like your marine fuel gauge, GPS, chartplotter, and engine management system, to seamlessly share data. Imagine your chartplotter displaying fuel consumption alongside navigation information, or your engine management system optimizing performance based on fuel levels. This kind of data sharing is the power of NMEA 2000. It's important to remember, however, that not all communication protocols offer the same capabilities. Proprietary systems can sometimes lead to compatibility issues, so choosing systems that adhere to open standards like NMEA 2000 is essential.

Beyond Basic Fuel Readings: The Benefits of Integration

Integrating your marine fuel gauge goes far beyond simply knowing how much fuel is left. Integrated systems can calculate real-time range based on your current speed and fuel consumption, providing a more accurate estimate of how far you can travel. These systems can also track fuel efficiency over time, helping you identify potential engine problems or adjust your boating habits for better fuel economy. Some advanced systems can even predict maintenance needs based on fuel consumption patterns, letting you address issues proactively. If you’re having difficulty editing images for your boat, consider using tools like a car background remover to enhance your photos.

Real-World Examples of Smart Integration

Consider a long-range cruiser with an integrated fuel management system. The captain can monitor fuel levels across multiple tanks, receive alerts for low fuel or unusual consumption, and calculate precise range estimations based on current conditions and planned routes. This level of control offers invaluable peace of mind and enables proactive decision-making. Another example is a fishing boat with a system that integrates fuel consumption with GPS data. This allows the captain to track fuel usage at specific fishing locations, maximizing efficiency and minimizing environmental impact while saving money.

Enhancing Safety and Convenience Through Connectivity

These examples show how integrated systems improve both safety and convenience. Real-time range calculations and low-fuel alerts contribute significantly to safer boating by preventing potentially hazardous situations far from shore. The convenience of having all vital information in one place simplifies the boating experience, allowing the captain to focus on navigation and enjoyment. Furthermore, the insights into fuel consumption and engine performance provided by integrated systems can lead to better decisions that potentially reduce long-term operating costs.

Marine Fuel Gauge Longevity: Protecting Your Investment

Marine environments are notoriously tough on electronics. Saltwater, humidity, and constant vibrations can quickly wear down even the sturdiest equipment. But, with the right care, your marine fuel gauge can provide reliable service for years to come. This means consistent performance and fewer surprise repair costs.

Preventative Maintenance: The Key to Long-Term Reliability

Just like your boat’s engine, your marine fuel gauge needs regular preventative maintenance. Simple checks and cleaning can greatly extend its life. For example, regularly inspecting the wiring for corrosion and loose connections can prevent bigger issues later on. This is especially important in saltwater, where corrosion is a constant concern. Checking the sensor for any signs of damage or buildup is also essential. A little preventative maintenance can save you a lot of trouble (and expense) in the future.

Seasonal Inspection: Catching Problems Early

A seasonal inspection routine can help you find potential problems before they turn into expensive repairs. At the beginning of each boating season, inspect the gauge’s wiring and connections. Look for corrosion, loose wires, and any damage. Also, test the gauge's functionality and accuracy to make sure it’s providing correct readings. It's much like checking your boat’s engine before you head out – a quick check can prevent major issues.

Winterization Techniques: Protecting Your Gauge From Freeze Damage

Winterization is essential to protect your marine fuel gauge from freeze damage. If you live in an area with freezing temperatures, proper winterization is a must. One key step is making sure your fuel tank is either completely filled or emptied to prevent condensation, which can cause corrosion. Using a fuel stabilizer helps prevent fuel degradation and protects the sensor. Finally, disconnect the gauge's wiring and store it in a dry, protected area to minimize exposure to the elements. These winterization steps will ensure your gauge is ready for the next boating season.

Cleaning Best Practices: Avoiding Corrosion

Cleaning your marine fuel gauge may seem straightforward, but using the wrong products can actually worsen corrosion. Avoid harsh chemicals and abrasive cleaners, as they can damage the gauge’s protective coatings. Instead, use a mild soap and water solution, rinsing thoroughly to remove any salt residue. Applying a corrosion inhibitor after cleaning adds an extra layer of protection against the harsh marine environment. Similar to how you’d avoid using harsh chemicals on your boat’s gelcoat, gentle cleaning products help preserve your fuel gauge's protective finish.

Recognizing the Early Warning Signs of Failure

Knowing the early warning signs of fuel gauge failure can prevent you from getting stuck out on the water. Erratic readings, slow response times, and dimming backlights could point to a problem. For instance, if your gauge suddenly starts fluctuating or responds slowly to changes in fuel level, it’s time to take a closer look. Think of these early warnings like the check engine light in your car – they alert you to potential issues before they get serious. Addressing these issues early can often prevent more extensive failures and costly repairs, helping to keep you informed and safe on the water.

Ready for a truly stress-free fueling experience? CLiX Fueling Solutions offers an innovative approach to fueling, eliminating spills and ensuring accurate fuel management. Visit CLiX Fueling Solutions to learn more and transform your fueling process.