The Hidden Dangers Behind Every Gas Spill

A gas spill isn't just an annoying mess; it's a serious hazard to both safety and the environment. Beyond the obvious fire risk, less apparent threats lurk in those shimmering puddles and invisible vapors. These hidden dangers demand a cautious and informed approach to cleanup—one that goes far beyond wiping up the visible gasoline.

Volatile Organic Compounds: The Invisible Threat

One of the most significant hidden dangers is the release of Volatile Organic Compounds (VOCs). These chemicals evaporate easily, creating a toxic atmosphere. Exposure to VOCs can cause a range of health problems, from mild headaches and dizziness to more serious respiratory illnesses and long-term neurological damage. Even small spills can have a significant impact, especially in areas with poor ventilation. In addition, VOCs contribute to the formation of ground-level ozone, a major component of smog.

Environmental Impact: Beyond the Surface

Gas spills also pose a substantial threat to the environment. When gasoline seeps into the ground, it contaminates the soil and can pollute groundwater. This affects drinking water sources and harms local ecosystems. The contamination can linger for years, impacting plant and aquatic life, and even larger animals dependent on these resources. The VOCs released also contribute to air pollution and can have long-term effects on air quality. While specific gas spill cleanup statistics are harder to find, data from oil spill responses offer some perspective. The 1991 Gulf War oil spill released 380-520 million gallons, highlighting the potential scale of environmental damage from liquid fuel spills. Learn more about oil spills and their impact: Oil Spills Statistics

Why Standard Cleaning Methods Fall Short

Common cleaning methods for gas spills, like using soap and water or letting the spill evaporate, are dangerously insufficient. These methods don't address the invisible threat of VOCs and may even worsen the problem by spreading the contamination. This highlights the need for specialized cleaning techniques and equipment that effectively contain and neutralize the spill. Proper cleanup involves removing the visible gasoline and managing the invisible vapors to prevent soil and groundwater contamination, minimizing the impact on the surrounding environment.

Life-Saving Precautions Before Tackling Any Gas Spill

The immediate aftermath of a gas spill is crucial. Your actions in the first few minutes can determine the safety of the cleanup process. Before even considering cleaning, several life-saving precautions are essential.

Initial Assessment and Response

First, secure the area. This involves eliminating all potential ignition sources. Think beyond open flames; turn off nearby appliances, extinguish pilot lights, and avoid using cell phones, which can create sparks. Understanding potential dangers requires a comprehensive risk assessment, similar to drone risk management.

Next, ventilate the area. Open doors and windows to circulate fresh air and dissipate gasoline vapors. Keep in mind that natural airflow might not be sufficient, particularly in enclosed spaces.

Evaluating the Spill

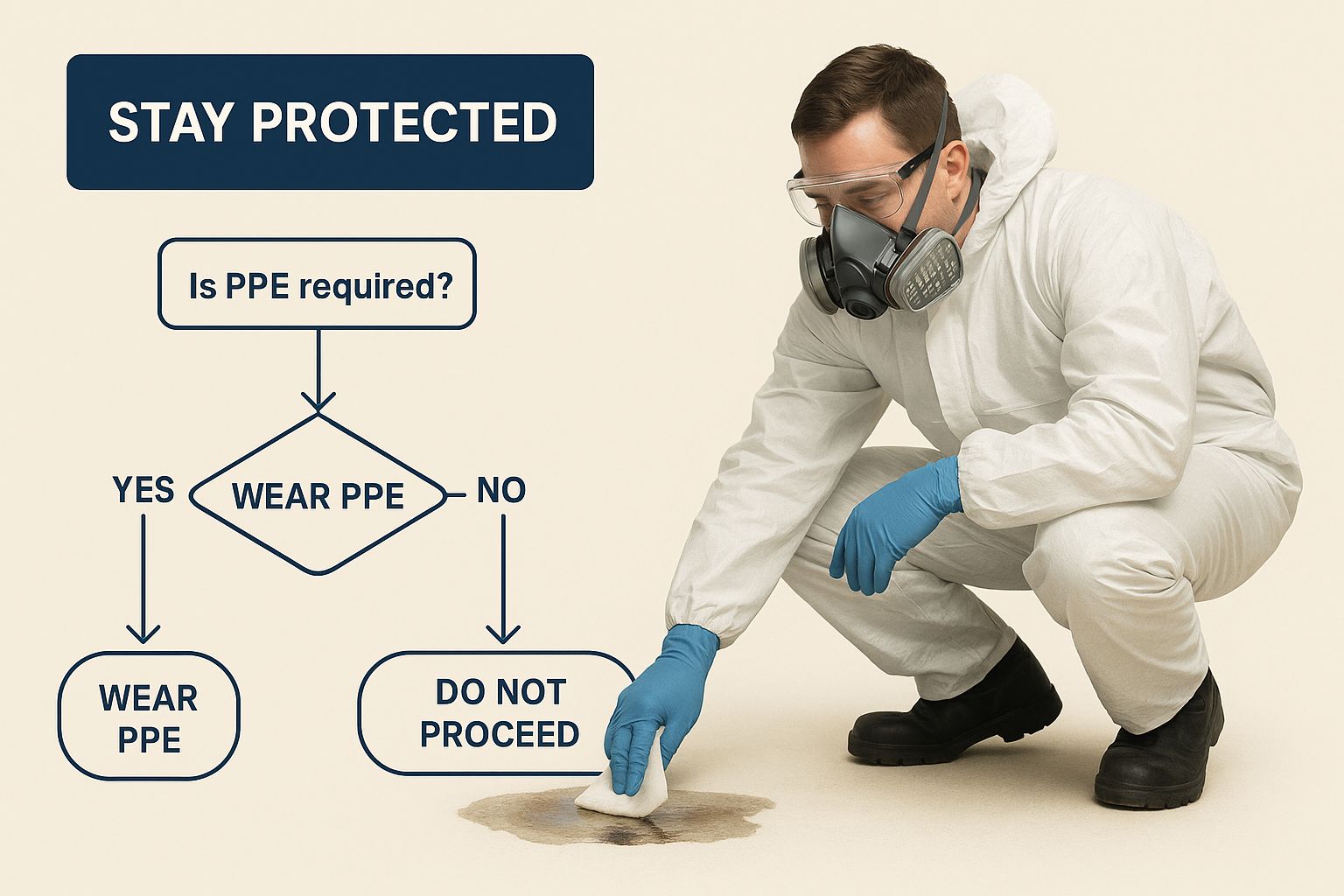

Assess the spill's size and location. A small spill on an open patio presents different challenges than a large spill inside a garage. This assessment is a crucial decision point, leading us to the decision tree infographic below. You might also be interested in: How to master...

This decision tree infographic visually represents the crucial first steps after a gasoline spill.

This infographic simplifies decision-making in a stressful situation, outlining different outcomes based on spill size, location, and the presence of ignition sources.

The decision tree helps you navigate key questions:

- Spill Size: Is it less than a quart, between 1-5 quarts, or more than 5 quarts?

- Location: Is the spill indoors or outdoors?

- Ignition Sources: Are there potential ignition sources nearby?

Each branch offers a specific action: cautious cleanup for small, contained outdoor spills; evacuation and contacting emergency services for larger or indoor spills; and prioritizing the elimination of ignition sources.

Essential Protective Gear

Always wear appropriate Personal Protective Equipment (PPE). This includes gloves made of nitrile or neoprene (avoid latex, as gasoline can degrade it), eye protection, and, for larger spills, a respirator. The necessary PPE increases with the spill size.

To help you choose the right PPE, refer to the table below:

Personal Protective Equipment for Gas Spill Cleanup This table outlines the essential safety equipment needed when cleaning different sizes of gas spills, with recommendations based on spill volume and location.

| PPE Item | Small Spills (<1 quart) | Medium Spills (1-5 quarts) | Large Spills (>5 quarts) |

|---|---|---|---|

| Nitrile/Neoprene Gloves | Required | Required | Required |

| Eye Protection | Recommended | Required | Required |

| Respirator | Optional | Recommended | Required |

| Full Body Protection | Optional | Optional | Required |

| Boots | Recommended | Recommended | Required |

This table highlights the increasing need for protection as the spill size increases. While small spills may only require gloves and eye protection, larger spills necessitate respirators and full body protection to minimize exposure to hazardous fumes and liquids.

Knowing Your Limits

Finally, know when to call the professionals. If the spill is large, indoors, or near a sensitive area (like a drain or water source), don't attempt to handle it yourself. Contact your local fire department or a hazardous materials cleanup service. Their expertise ensures safe and effective remediation, protecting both you and the environment.

Surface-Specific Techniques for Cleaning Gas Spills

Cleaning up a gasoline spill isn't as simple as it might seem. Different surfaces require different approaches, and understanding these nuances is key to a safe and effective cleanup. Factors like material porosity and temperature play a significant role, as does the cleaning method itself.

Concrete and Asphalt

For non-porous surfaces like concrete and asphalt, containment is the first step. Use absorbent materials such as commercial spill pads, or even dry sand or kitty litter if that's what you have on hand, to stop the spill from spreading.

Gently work the absorbent material into the gasoline, letting it soak up as much as possible. Once saturated, sweep up the contaminated material and dispose of it properly according to local regulations. For any remaining residue, use a degreaser designed for fuel spills, followed by a thorough rinse with water.

Soil

Porous surfaces like soil present a more difficult challenge. Gasoline can quickly seep deep into the ground, so acting fast is essential. Contain the spill as you would on concrete, but absorption alone won’t suffice. The contaminated soil needs to be removed.

Excavate the affected area to a depth that corresponds with the level of gasoline penetration. This soil then requires specific disposal procedures, often involving professional environmental remediation services.

Absorbent Materials: A Closer Look

Choosing the right absorbent material is crucial. While common household items can be used in a pinch, commercial absorbents offer significantly higher absorption capacity and are designed for safer handling. Some can absorb 10-20 times their weight in liquid.

These commercial products are also designed for easier and safer disposal, reducing the risk of spreading contamination. We’ll discuss specialized cleanup tools and products in more detail later in this post.

Carpet, Clothing, and Vehicles

Fabric and upholstery require special care. For carpets and vehicle interiors, blot the spill repeatedly with a clean cloth and a mixture of mild detergent and water. Don't rub, as this can spread the stain.

For clothing, pre-treat the affected area with a stain remover before washing. Allow all items to air dry completely to remove lingering gasoline fumes. For heavy contamination, professional cleaning might be necessary.

Detecting Residual Contamination

Sometimes, gasoline can remain even after a seemingly thorough cleanup, especially in porous materials. Professionals utilize specialized equipment to detect these invisible traces, ensuring complete decontamination and preventing lingering health and environmental risks.

Neutralizing Odors and Residues

The strong smell of gasoline can linger even after cleaning. Products designed with odor neutralizers can eliminate these persistent smells without introducing additional hazards. These often involve applying a chemical solution that breaks down the remaining volatile organic compounds (VOCs), effectively neutralizing the odor.

The growing use of natural gas globally highlights the serious challenges of cleaning gas spills and leaks, which contribute significantly to methane emissions. The 2015 Aliso Canyon blowout in California released 97,100 metric tons of methane, resulting in a costly cleanup and displacement of residents. For more statistics on the impact of such incidents, see Oil Spills Statistics.

Addressing gas spills effectively requires a multi-pronged approach, adapting techniques to each specific surface. Understanding these varied approaches and knowing when to call in professional help are critical for effective cleanup and minimizing environmental damage.

The Ultimate Toolkit for Handling Gas Emergencies

Cleaning up a gas spill isn't as simple as grabbing some paper towels. It requires specific tools and products designed to handle the inherent dangers. A well-stocked spill response kit is absolutely essential.

Commercial Absorbents: A Safer and More Effective Solution

While household items like kitty litter or sand might seem like easy solutions, they're far less effective than commercial absorbents. Products designed specifically for absorbing gas, often made from materials like polypropylene or vermiculite, can absorb a surprising amount – sometimes up to 20 times their weight in gasoline. This means faster cleanup and less waste.

You might be interested in: How to master...

Essential Non-Sparking Tools: Preventing Ignition

Safety is the top priority during cleanup. Regular metal tools can create sparks, which can ignite gasoline vapors and lead to an explosion. Using non-sparking tools made from brass, bronze, or plastic is critical. This includes shovels, brooms, and containers for the contaminated absorbent materials.

Containment and Disposal: Protecting the Environment

Containing a spill isn't just about stopping it from spreading; it’s also about preventing environmental damage. Using containment vessels made from chemically resistant materials keeps the gasoline from seeping into the surrounding ground. Proper disposal is also essential. Contacting a local hazardous waste disposal facility ensures safe and responsible handling of the contaminated materials.

Detection Equipment: Ensuring Complete Decontamination

Even after the visible gasoline is gone, unseen dangers can remain. Gas detection meters, while more commonly found in professional settings, can be invaluable for ensuring complete decontamination. These devices detect lingering volatile organic compounds (VOCs), highlighting areas that need further cleaning and preventing long-term health risks.

The following table summarizes the pros and cons of different absorbent products you can include in your gas spill kit.

Comparison of Gas Spill Absorption Products

| Product Type | Absorption Capacity | Cost Range | Environmental Impact | Best For |

|---|---|---|---|---|

| Polypropylene Pads/Rolls | High (up to 20x their weight) | Moderate to High | Low (can be incinerated) | Large spills, industrial settings |

| Vermiculite | Moderate to High | Moderate | Low (natural mineral) | Small to medium spills, general use |

| Clay-Based Absorbents | Moderate | Low | Low | Small spills, home use |

| Sand | Low | Low | Moderate (can be contaminated) | Emergency use, temporary containment |

| Kitty Litter | Low | Low | Moderate (can be contaminated) | Emergency use, very small spills |

This table highlights the importance of choosing the right absorbent for the job. While cost is a factor, the effectiveness and environmental impact should also be considered.

Building Your Spill Response Kit: Be Prepared

Having a pre-assembled spill response kit can make all the difference. It should include:

- Commercial absorbents: For quickly soaking up spilled gasoline.

- Non-sparking tools: For safely handling contaminated materials.

- Containment vessels: For preventing the spread of the spill.

- PPE (Personal Protective Equipment): This includes gloves, eye protection, and a respirator.

- Disposal bags: For containing contaminated absorbents and other waste.

- Gas detection meter (optional): For detecting any residual contamination, especially important for larger spills.

Having these items on hand ensures a swift and efficient response, minimizing the impact of the spill and protecting both people and the environment.

Protecting Your Environment When Cleaning Gas Spills

Cleaning up a gas spill isn't just about addressing the immediate danger. It's also about protecting our environment. Even small amounts of gasoline can significantly impact local ecosystems, polluting water, harming soil, and endangering wildlife. Understanding this environmental impact is key to effectively cleaning gas spills.

The Ripple Effect of Gas Spills

Gasoline contains many harmful substances, including benzene, toluene, ethylbenzene, and xylene (BTEX). These compounds can rapidly contaminate soil and water. If gasoline reaches groundwater, it can make it unsafe to drink and threaten aquatic life. Contaminated soil can also harm plant growth and disrupt the food chain.

Identifying High-Risk Scenarios

Some spills present a greater environmental threat than others. Spills near drains, storm sewers, or bodies of water require immediate professional attention. These situations carry a high risk of extensive contamination. Spills on porous surfaces like soil or sand also need quick action to prevent deep penetration and lasting damage. For more information, check out the CLiX Fueling Collections.

Remediation Techniques: Minimizing Environmental Impact

The right remediation approach is essential for minimizing long-term environmental harm. Bioremediation, using microorganisms to break down contaminants, can be effective in some situations. Phytoremediation, using plants to absorb and remove pollutants from the soil, is another approach.

Regulatory Frameworks: Reporting and Compliance

Understanding regulations for reporting gas spills is important. Different regions have specific procedures and limits for notifying authorities. Knowing these requirements is crucial for compliance and avoiding penalties. This usually means contacting your local environmental agency and giving them details about the spill. Failure to report can lead to hefty fines and legal action.

Technology is constantly improving our ability to deal with gas spills. Satellite monitoring, initially used for tracking oil spills, now helps detect methane plumes from gas leaks. Between 2019 and 2022, these systems identified over 1,800 ultra-emitter events. More statistics are available from the Pipeline Incident 20-Year Trends report.

Containment and Disposal: Preventing Further Spread

Containing a spill is essential to prevent further environmental damage. This involves using absorbent materials to soak up the gasoline and setting up barriers to stop it from spreading. Proper disposal of contaminated materials is also critical. This generally requires contacting a licensed hazardous waste disposal company. They have the right expertise and equipment to handle these materials safely and according to environmental regulations.

Assessing the Need for Professional Remediation

While some small spills can be cleaned up with DIY methods, larger spills or those in environmentally sensitive locations often require professional soil remediation. Professionals can assess the extent of the contamination and implement specific remediation strategies, ensuring thorough cleanup and minimizing long-term environmental harm. This could involve soil excavation, chemical treatments, or other specialized techniques.

Never Clean Again: Gas Spill Prevention Mastery

Preventing gas spills isn't just about avoiding big mistakes. It's also about understanding the smaller things that can cause accidents. This includes recognizing container problems, dispelling handling myths, and considering the weather.

Choosing the Right Container: Design Matters

The design of your gas container can significantly impact spill risk. Look for containers with strong seals and sturdy construction. Avoid flimsy plastic that can crack or leak. Vented containers reduce pressure buildup, lowering spill risk during pouring. Consider containers with built-in anti-spill features like automatic shut-off nozzles. These are especially important in marine environments where spills can be disastrous.

Handling Habits: Avoiding Common Misconceptions

Many spills come from simple handling errors. Overfilling is a common mistake. Always leave room in the container for expansion due to temperature changes. Another misconception is that gas can be stored anywhere. Temperature changes can cause pressure buildup, increasing spill risk. Store gasoline in a cool, well-ventilated area, away from heat and sunlight.

Environmental Factors: Adapting to the Conditions

Weather affects spill risk. Wind makes pouring difficult and increases splashing. Rain creates slippery surfaces, making containers harder to control. Adjust your fueling techniques accordingly. Find a sheltered spot when it's windy.

Professional-Grade Precautions: Thinking Like an Expert

Fuel professionals use specific techniques to minimize spills. Slow and steady pouring is key. Fast pouring increases splashing and overfilling. Secondary containment is another strategy. Place a larger container or tray underneath to catch spills. This prevents small spills from becoming major hazards. For more on environmental protection during cleaning, see Easy Eco-Friendly Swap-Outs.

The Psychology of Errors: Understanding Human Factors

Even with the best intentions, mistakes happen. Fatigue, distraction, and complacency contribute to accidents. A pre-fueling checklist can help. This checklist should include checking ventilation, inspecting the container, and confirming the correct fuel type.

Seasonal Considerations: Adapting to Changing Temperatures

Temperatures change throughout the year, requiring different precautions. In hot weather, gasoline expands, needing more container space. In cold weather, gasoline thickens, making it harder to pour. Adjust your techniques accordingly.

Implementing Professional Precautions at Home

Professional principles apply at home, too. Choosing the right containers, using secondary containment, and developing personal fueling protocols can virtually eliminate spills. By using these precautions, you can ensure safer fueling and protect your environment.

Tired of worrying about gas spills? CLiX Fueling Solutions offers a spill-free approach to boating. Our automatic shut-off nozzles prevent overfilling and spills, protecting your boat and the environment. Learn more and order yours at https://clixfueling.com.