It’s easy to think of a marine fuel filler as just a fancy gas cap for your boat. But it's so much more than that. Think of it as the guardian of your entire fuel system—the one component standing between a smooth day on the water and a world of expensive, frustrating problems.

A weak or failing filler isn't just an inconvenience. It can let water into your fuel, allow dangerous fumes to escape, and lead to spills. This can result in anything from catastrophic engine damage to serious safety risks.

Why Your Marine Fuel Filler Matters More Than You Think

Let's be honest, the fuel filler is probably one of the last things you think about on your boat. It’s just a piece of hardware bolted to the deck, right? But that small part does some heavy lifting for your vessel's safety, performance, and even its legal compliance. Getting the right one isn't just a minor upgrade; it's a critical decision for the long-term health of your boat.

Your First Line of Defense

Out on the water, your boat is constantly exposed to the elements. Your fuel filler is the primary shield protecting your fuel tank from that harsh environment. Water is the number one enemy of a marine engine, and it doesn't take much to cause thousands of dollars in damage. A top-notch filler with a solid O-ring or gasket creates a perfect seal to keep rain, sea spray, and wash-down water out of your tank.

That seal works both ways, too. It keeps fuel and vapors in. Spilling fuel at the dock is messy, ruins your boat's finish, and is terrible for the marine life below. Even worse, fuel vapors escaping from a poor seal create a serious fire hazard.

A properly sealed marine fuel filler is your best defense against both water contamination and dangerous fuel leaks. It’s a small investment that protects a very expensive engine.

Keeping You Safe and Compliant

A well-designed fuel filler is also a crucial piece of safety equipment. How many boaters have fumbled and dropped a fuel cap overboard? It happens all the time. A tethered cap is a simple but brilliant feature that prevents this headache, which would otherwise leave your fuel tank wide open and exposed.

On top of that, clear labeling is non-negotiable. Fillers marked "GAS" or "DIESEL" prevent the nightmare of misfuelling—a simple mistake that can destroy an engine in minutes. This hardware is also at the heart of environmental rules that require boaters to prevent fuel spills and vapor leaks. Skimping on your fuel filler isn't just risky; it could get you in hot water with the authorities.

Choosing the Right Type of Marine Fuel Filler

Picking the right marine fuel filler goes way beyond just how it looks. It's a choice that directly affects your convenience at the pump, the security of your boat, and how smoothly refueling goes. Let's be honest, not all fillers are made the same, and what works for a small fishing skiff might not be the best fit for a large cruiser.

Let's break down the common designs out there so you can find the perfect match for your vessel and how you use it.

Standard Screw-In Caps

This is the classic, the old reliable you’ll see on most boats. The standard screw-in cap is the workhorse of the marine world for a reason—it’s simple, effective, and won’t break the bank. You’ve got a threaded fitting on your deck and a cap you twist to secure. Easy.

Thankfully, most modern screw-in caps come with a tether—usually a small chain or a plastic strap. It's a simple little feature that prevents the dreaded "cap overboard" moment, saving you a ton of frustration and keeping your fuel tank from being left wide open.

Locking Fuel Fillers for Extra Security

If you keep your boat at a busy public marina or leave it unattended for stretches of time, a locking fuel filler is a smart upgrade. On the surface, it looks just like a standard cap, but it has a key lock built right in. This gives you two major advantages:

- Fuel Theft Prevention: It makes it incredibly difficult for anyone to siphon expensive fuel from your tank.

- Vandalism Protection: More importantly, it stops someone from maliciously dumping water or other junk into your fuel system, which could destroy your engine.

That extra layer of security brings a lot of peace of mind, knowing your fuel is safe and sound when you're not around.

Sleek Flush-Mount Designs

For those who want a clean, modern aesthetic, the flush-mount marine fuel filler is the way to go. These fillers are designed to sit perfectly level with the deck, getting rid of any protruding hardware that could become a trip hazard or snag a fishing line. When it’s closed, all you see is a smooth, seamless surface.

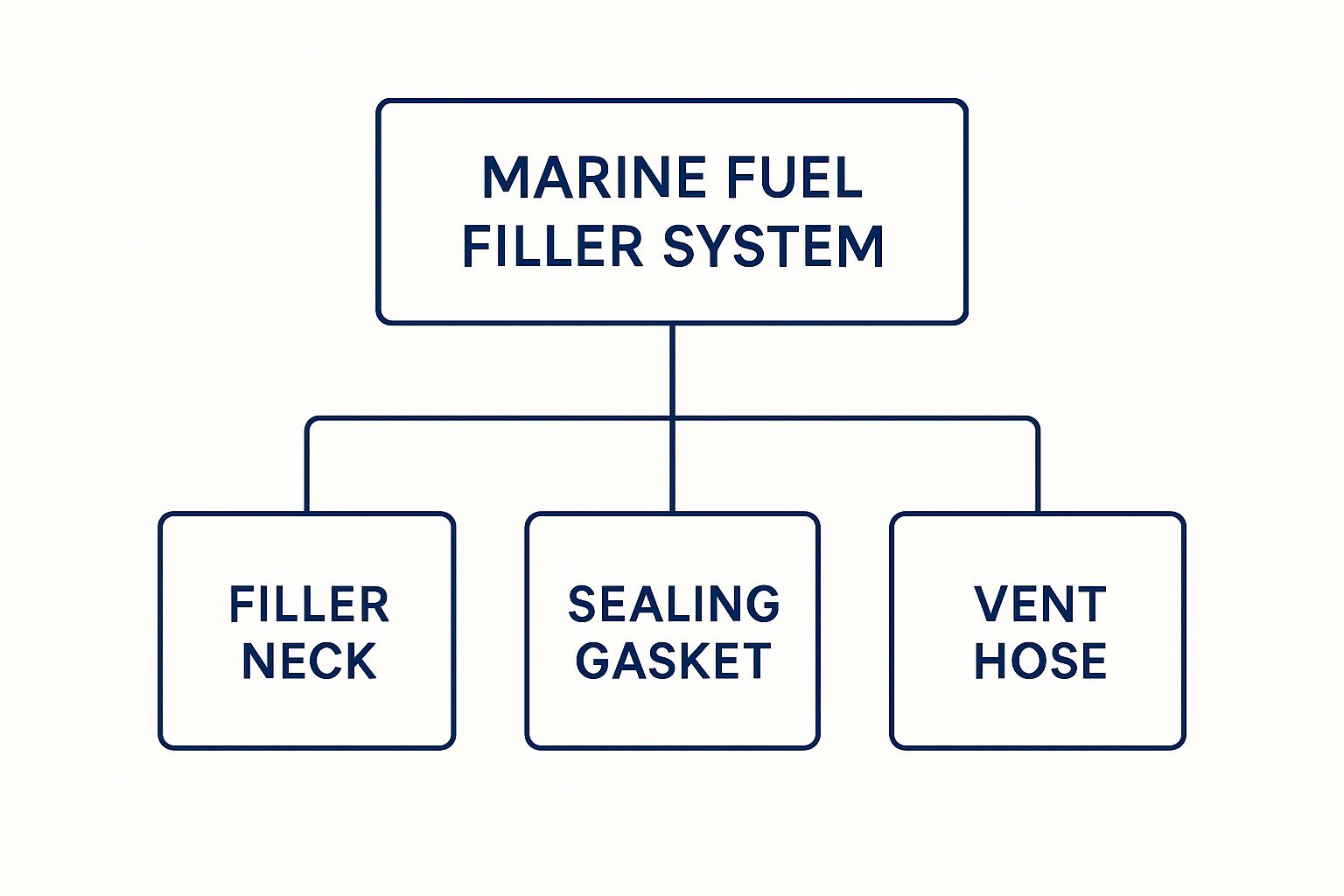

No matter which style you choose, remember that a fuel filler is more than just the cap you see on deck. The hidden components—the filler neck, gasket, and vent hose—are what truly make the system work safely and reliably.

The image below gives you a clear picture of how these parts come together.

This visual shows how the filler neck channels fuel into the tank, the gasket creates that all-important seal, and the vent hose allows air to escape, preventing dangerous pressure buildup. Getting the style right on deck is important, but making sure these behind-the-scenes parts can do their job properly is what gives you a system that’s both functional and good-looking.

Essential Features of a High-Quality Fuel Filler

When you’re looking at marine fuel fillers, it’s the little things that separate a good one from a great one. A cheap filler might seem like a bargain at the store, but out on the water, it can become a real headache. The best models are defined by a few key features that stand up to the tough marine environment.

Think of it like a checklist. If a fuel filler has all these things, you can trust it to protect your boat and make fueling a little less stressful. Let's break down exactly what to look for.

A Robust O-Ring or Gasket

The seal is arguably the most critical part of any marine fuel filler. It's the only thing standing between your clean fuel and all the stuff you don't want in it—rain, salt spray, and water from a deck washdown. A quality filler will have a thick, beefy O-ring or gasket made from a material like nitrile or Viton that won't break down when exposed to fuel.

This little ring does two vital jobs: it keeps water out and fuel vapors in. A flimsy seal will dry out, crack, and fail, which can lead to anything from water-contaminated fuel wrecking your engine to dangerous flammable vapors escaping onto your deck.

A premium O-ring isn’t just a nice-to-have; it's the gatekeeper that guarantees a watertight, vapor-tight seal, protecting both your engine and everyone on board.

The Indispensable Tethered Cap

Ask any seasoned boater, and they’ll have a story about dropping something important overboard. Losing a fuel cap isn't just a minor inconvenience—it’s a real problem that leaves your tank wide open to contamination until you can track down a replacement. A simple tethered cap prevents this from ever happening.

Usually just a small chain or a durable plastic strap, the tether connects the cap right to the filler housing. It’s a beautifully simple fix for a potentially serious issue. If you're looking at a fuel filler and it doesn't have a tether, that should be a major red flag.

Durable, Marine-Grade Materials

The materials used in a fuel filler dictate how long it will last. A boat deck is a harsh place, constantly bombarded with salt, intense sun, and corrosive fuel. The right materials are an absolute must.

Here’s a quick rundown of the best options:

- 316 Stainless Steel: This is the gold standard for any hardware on a boat. It’s incredibly resistant to rust and corrosion, especially from saltwater, making it the perfect choice for a fuel filler you can count on for years.

- Advanced Composite Polymers: Don't overlook modern, high-strength plastics. They offer fantastic durability, will never corrode, and are engineered to withstand both fuel and UV damage. They provide a lightweight yet incredibly tough alternative to metal.

Choosing a filler made from one of these materials means it won’t pit, crack, or fail when you need it most. It's a smart decision that pays dividends every time you head out on the water.

Matching Your Filler to Gas, Diesel, or Future Fuels

https://www.youtube.com/embed/Xu9VycNsnIU

Putting the wrong fuel in your boat isn't just a mistake; it's a catastrophic and expensive one. Think of it as accidentally giving your engine poison. Your marine fuel filler is the very first line of defense against this disaster. It’s a simple piece of hardware doing a vital job every single time you're at the fuel dock.

This is exactly why clear and permanent labeling isn't just a nice feature—it's non-negotiable. Fillers absolutely must be marked "GAS" or "DIESEL," often with the industry-standard color coding: red for gasoline, yellow for diesel. This simple visual cue can be the one thing that stops a momentary lapse in judgment from turning into a multi-thousand-dollar engine rebuild.

On top of that, many diesel fillers are designed with a larger diameter opening. This isn't a random choice. It acts as a physical barrier, making it difficult, if not impossible, to shove a smaller gasoline nozzle into a diesel tank by mistake. It’s a smart, practical design that adds another crucial layer of protection.

Beyond Gas and Diesel

Today’s boats almost exclusively run on gasoline or diesel, but the entire marine industry is standing on the edge of a major shift. To hit long-term environmental targets, the sector is deep into exploring cleaner, next-generation fuels. Getting a handle on these trends helps you see where boating technology is headed.

The most critical job of a fuel filler is preventing you from putting the wrong fuel in the tank. A clearly marked and correctly sized filler isn't just a convenience; it's essential hardware that protects your engine from irreversible damage.

The industry is already looking at alternatives that could one day find their way into recreational boats. These aren't just drop-in replacements; they require entirely new infrastructure and handling procedures.

- Green Methanol: This fuel is produced from renewable sources and is a liquid at normal temperatures, which makes it easier to store than some other options. The catch? It's corrosive and demands specialized materials for tanks and fuel systems.

- Ammonia and Hydrogen: These are often called near-zero emission fuels, but they come with huge storage challenges. They have to be kept under intense pressure or at incredibly low temperatures, which means completely different filler and tank technology.

The Fuel Filler of the Future

As these new fuels eventually become more common, the design of the humble marine fuel filler will have to evolve right along with them. Fillers of the future will likely need smart technology, specialized connectors, and advanced materials to handle these different substances safely. For now, this evolution is mostly happening in the world of commercial shipping.

One recent analysis from Wood Mackenzie projects that conventional fuel use will peak soon, with marine LNG and, down the road, synthetic e-fuels like ammonia and methanol playing a much bigger role. While your current boat almost certainly runs on traditional fuel, this industry-wide transition underscores the timeless importance of a safe and reliable boat fuel system.

For boaters today, the main takeaway is simple. Your fuel filler is a critical safety device. Making sure it’s correctly labeled and properly sealed is the best thing you can do to protect your investment for years to come, no matter what fuel you use. To learn more about all the parts that create a secure system, you can check out our guide on the boat fuel system.

Getting Installation and Maintenance Right

Even the best marine fuel filler is useless if it’s installed poorly. Getting the installation right from the start gives you a secure, leak-proof connection that will protect your boat for years to come. And when it comes to maintenance, think of it less as a chore and more as cheap insurance against very expensive engine problems down the road.

Proper installation really begins with picking the perfect spot. You want the filler on deck where it’s easy to get to for refueling, but it needs to be far from any hatches, windows, or potential ignition sources. The last thing you want is fuel fumes getting into the cabin. It’s also smart to place it where any small spills won’t stain your beautiful teak or non-skid deck.

After you've picked the location, the seal is everything. This is not the place to cut corners. Using a top-shelf, marine-grade sealant like 3M 5200 is non-negotiable. It creates a tough, waterproof bond between the filler’s flange and the deck, stopping water from seeping into your hull or—even worse—your fuel tank.

Your 5-Minute Pre-Season Check

Before that first trip of the season, a quick once-over can save you a world of headaches. This little check-up only takes a few minutes, but it's amazing at catching small issues before they become catastrophic failures on the water.

- Inspect the O-Ring: Take a close look at the O-ring or gasket inside the cap. Is it cracked, brittle, or flattened? A worn-out O-ring is the number one reason for a leaky fuel cap seal.

- Check the Cap Tether: Give the tether a gentle tug. Make sure it's secure and not frayed. A broken tether is just an invitation to lose your cap overboard.

- Clean the Threads: Grab a rag and wipe down the threads on the cap and the filler neck. Get rid of any salt, sand, or gunk. Clean threads are the only way to ensure the cap tightens properly for a perfect seal.

Honestly, this simple 5-minute check is one of the most powerful bits of preventative maintenance you can do. It's the first line of defense for your fuel tank, which is basically the heart of your boat’s entire fuel system.

Sticking to these simple routines for installation and upkeep will keep your fuel filler working like a champ. It’s how you guarantee your hardware does its one critical job: keeping fuel in and water out. Taking good care of it not only makes the filler last longer but also shields your engine from the devastating (and costly) damage that water in your fuel can cause.

To get a better picture of how the filler fits into the bigger system, our guide to choosing and maintaining your boat fuel tank is a great next step.

Safe Refueling and Preventing Environmental Spills

Your marine fuel filler does a lot more than just give you a place to stick the fuel nozzle. It's one of the most important pieces of environmental protection gear on your boat. Every time you head to the fuel dock, you're handling a substance that can do real harm if it gets loose. A high-quality filler with a solid seal is your number one defense against spills and dangerous vapor leaks.

Think of the gasket inside your fuel cap. It’s like a silent guardian for your boat and the water around it. This small part creates a tight seal that stops fuel from sloshing out when the water gets rough and keeps flammable vapors from escaping into the air. It’s a simple component, but it plays a massive role in keeping our waterways and the air we breathe clean.

Tips for a Spill-Free Refueling

Clean refueling is a skill every boater should master, and having the right equipment makes it that much easier. A few simple habits can protect your boat’s finish, save you money on wasted fuel, and keep the environment pristine.

- Use Absorbent Pads: Before you even unscrew the cap, place an absorbent pad or a "fuel bib" around the filler opening. It's a cheap and easy way to catch any drips that might otherwise stain your deck or end up in the water.

- Don't Overfill the Tank: Pay attention to the sound as your tank gets close to full. You'll hear a distinct gurgling or change in pitch—that's your signal to slow down. Stopping before the nozzle's automatic shut-off kicks in is the best way to prevent that messy "fuel burp."

- Maintain a Slow, Steady Flow: It can be tempting to squeeze the fuel nozzle at full blast, but a slower, more controlled flow is much safer. It dramatically reduces the chance of backsplash and gives you more time to react as the tank fills up.

Responsible refueling is the hallmark of a great boater. It's a commitment to protecting the marine ecosystem from preventable pollution, one fuel-up at a time. Using the right techniques ensures our favorite spots stay pristine for years to come.

This push for cleaner boating is part of a much bigger industry movement. The sustainable marine fuel market is expected to grow from USD 13.1 billion in 2024 to an astonishing USD 823.5 billion by 2034, showing a massive commitment to reducing the environmental impact of boating and shipping. You can read more about this trend in the sustainable marine fuel market news.

At the end of the day, a reliable marine fuel filler is at the heart of this effort. To learn more about how a well-designed marine fuel fill helps you do your part, check out our detailed guide.

Common Questions About Marine Fuel Fillers

Even if you know your boat inside and out, practical questions always pop up. When you're dealing with something as crucial as a marine fuel filler, getting clear answers can be the difference between a minor inconvenience and a major headache. Let's tackle some of the most common questions we hear from fellow boaters.

Think of this as a practical guide to help you handle common issues and make smart choices for your boat's fuel system. From quick pre-trip checks to knowing what to do when things go sideways, these answers are here to keep you safe and confident on the water.

What Should I Do If I Lose My Fuel Cap?

It happens to the best of us—the dreaded "plop" of a fuel cap hitting the water. It’s frustrating, but the absolute first thing you need to do is get a proper replacement. Don't even think about using a rag as a temporary plug. That's a huge fire hazard and an open invitation for water and gunk to get into your fuel tank, which can spell disaster for your engine.

When you buy a replacement, make sure it’s the right size for your filler and made for your boat's specific fuel type, whether it's gas or diesel. You can find universal and model-specific caps at most marine supply stores.

If you catch a strong whiff of fuel near your filler, don't ignore it. That's a classic sign of a failing seal. A persistent smell means flammable vapors are escaping, which is a serious safety risk you need to fix right away.

How Often Should I Inspect My Fuel Filler?

A good rule of thumb is to give your fuel filler a thorough inspection at the start of every boating season. After that, a quick glance before each refueling is all it takes to catch problems early.

- Check the O-Ring: Is the gasket cracked, brittle, or flattened? If so, it’s time for a new one.

- Test the Tether: Give it a gentle tug. You want to make sure it's still secure and not about to snap.

- Clean the Threads: A quick wipe-down to remove salt and grit helps ensure you get a perfectly tight seal every time.

Can I Install a Locking Fuel Filler on Any Boat?

For the most part, yes. Locking fuel fillers are usually designed as direct, drop-in replacements for standard non-locking ones, as long as the diameter matches. It’s still a good idea to double-check the dimensions and mounting hole pattern to make sure it will fit your boat's deck before you purchase. It’s a simple and effective security upgrade for any boater.

Tired of fuel spills and the guesswork of refueling? CLiX Fueling Solutions offers a stress-free, automatic shut-off system that prevents overfills every time. Discover a safer, cleaner way to fuel your boat at https://clixfueling.com.