Improving your safety culture isn't about ticking boxes on a compliance checklist. It's about nurturing a deep-seated, organization-wide commitment to keeping people safe. The goal is to move away from a reactive "rules and punishment" model to a proactive culture where every single person feels ownership over safety. This shift hinges on visible leadership commitment, active employee engagement, and using the right tools to make the safe choice the easy choice.

Moving Beyond Basic Safety Compliance

Too many businesses get stuck in the "compliance trap." They think a thick safety manual and a clean paper trail automatically mean they have a safe workplace. While meeting regulations is non-negotiable, it’s just the starting line, not the finish. A binder full of rules is useless against a culture that quietly accepts shortcuts or puts speed before caution.

This compliance-only approach is why preventable incidents happen, even at companies with a perfect safety record on paper. Picture a marina where every staff member has completed their annual training, yet near-misses during fueling are shrugged off as "just part of the job." The paperwork looks great, but the actual behavior on the dock tells a much riskier story.

The Limits of a Rulebook

Real safety isn't what's written down; it's what's practiced every single day. When leaders only bring up safety during an audit or after something goes wrong, they send a clear message: compliance is the only thing that matters. This fails to build the kind of intuitive, forward-thinking mindset needed to spot and handle new or unexpected hazards.

A crucial first step is to thoroughly understand all your baseline requirements. Getting a firm grip on the essentials, like the various OSHA safety training requirements, builds the foundation for a genuine safety culture. It makes sure everyone starts from the same page with a clear understanding of the non-negotiables.

Here's the hard truth: a rulebook can't cover every situation. A strong safety culture empowers your crew to make the right call in the moment, even when there isn't a specific rule for it. It turns people from passive rule-followers into active safety partners.

The Stagnation of Safety Performance

This focus on paperwork instead of people has led to a disturbing trend. Around the world, work-related accidents cause millions of deaths and hundreds of millions of injuries each year, carrying a massive economic burden. Despite decades of regulations, safety performance in many developed countries has basically flatlined for the last 20 years. This stagnation is a clear signal that we have to move past traditional compliance and figure out how to genuinely improve safety culture.

To break this cycle, you have to shift from reactive measures to proactive engagement. This means:

- Fostering Open Communication: Create channels where employees can report hazards without fearing blame.

- Empowering Your Frontline Team: Get the people closest to the risks involved in creating the solutions.

- Investing in Engineered Controls: Use technology, like the CLiX system, to design hazards out of the process from the start.

Ultimately, getting beyond basic compliance means treating safety as a core value, not just another department. It's about creating an environment where every employee—from the newest hire to the CEO—is actively involved in protecting themselves and their teammates.

Building a Culture Starts with Visible Leadership

A real safety culture doesn't come from a memo or a mission statement tacked to the wall. It’s built on the ground, through the daily, visible actions of leadership. When your crew sees you actively putting safety first, it stops being just talk and becomes how business is done.

This means getting out of the office and onto the dock. It’s the difference between asking for a report on a near-miss and throwing on a hard hat to investigate it yourself. You have to show up. Be present. Prove that safety isn't just another box to check.

Walking the Walk Demonstrates Commitment

People are smart. They can spot the difference between what leadership says and what leadership does a mile away. A memo about new procedures gets forgotten, but the image of a supervisor stopping a fueling operation to fix an unsafe practice? That sticks. These are the moments that truly shape your culture.

Think about the message you send when you actually put money behind your words. Investing in engineered controls like the CLiX system, which is designed to physically prevent spills, speaks volumes. It tells every single person on your team, "Your safety and the health of our environment are worth this investment."

A manager who delegates all safety tasks sends the message that it's a secondary concern. But a manager who gets their hands dirty, participates in drills, and asks tough questions shows everyone that safety is a shared, top-tier responsibility.

This isn’t just about looking good; it's a proven way to drive real change. Research consistently shows that management commitment is the cornerstone of a strong safety culture. This is measured by how quickly leaders address safety issues and take proactive steps to fix them. When leaders are directly involved, it shapes the crew's belief that safety is taken seriously.

For those at the top looking to truly embed these values, there are some great playbooks out there. For a high-level perspective, resources like A CEO's Guide to Building Organizational Culture can offer solid strategies for turning abstract values into concrete actions.

From Reactive Correction to Proactive Coaching

Being a visible leader is about more than just enforcing the rules. It’s about turning every interaction into a chance to coach your team. When you see something unsafe, the goal shouldn't be to punish. It should be to understand.

A leader who asks, "What made you feel you had to take that shortcut?" will learn far more than one who just writes someone up.

Maybe the right equipment wasn't available. Maybe the pressure to refuel faster than the clock overrode a safety protocol. You'll never uncover these systemic problems from a disciplinary report. Those insights only come from real conversations that build trust and show you respect your team's on-the-ground experience.

So, how do you make this happen? Here are a few practical ways to be more present:

- Take regular safety walks. Spend time on the docks or in the yard with no agenda other than to observe and talk with the crew. Ask questions. Listen.

- Lead the post-incident debriefs. Don't make it an interrogation. Frame it as a collaborative learning session focused on "How can we improve?" instead of "Whose fault was this?"

- Celebrate safety wins. When an employee reports a near-miss or suggests a safety improvement, recognize them publicly. This shows everyone that you value proactive thinking.

Empowering Your Team Through Action

Ultimately, a leader’s most important job in building a safety culture is to empower their team. This empowerment is a direct result of the trust you build through your consistent, visible actions. When people believe you’re genuinely invested, they feel safe to speak up, take ownership, and look out for one another.

Picture this: at a busy marina, a new dockhand spots a frayed fuel hose. In a poor culture, they might stay quiet, worried about being seen as a troublemaker. But in a culture built by visible leadership, they know their manager would thank them for their sharp eyes. They report it immediately, preventing a potential spill and a serious fire hazard.

That's the goal. You want to create an environment where doing the right thing is second nature, driven by a shared belief that starts at the top. It's a constant process, but it begins with one simple rule: leaders go first. Your actions, not your words, will define your commitment to safety.

Turning Your Crew into Safety Champions

A safety culture that relies solely on orders from the top is a house of cards. It might look good on paper, but it's bound to collapse under pressure. Real, sustainable safety happens when every single person on your crew feels a sense of ownership—not just for their own well-being, but for the person working right next to them. This is the difference between simply following rules and actively championing safety.

The goal here is to move your team from a compliance mindset to one of proactive problem-solving. You want them to be the ones spotting hazards and feeling confident enough to speak up and act. This doesn’t happen overnight or by accident. It’s the result of intentionally building a culture based on trust, empowerment, and a shared commitment to getting everyone home safe.

Give Your Safety Committee Real Teeth

Let's be honest: many safety committees are just for show. They meet once a month, check a box, drink some stale coffee, and file minutes that no one ever reads. If you want to actually improve safety, your committee needs real influence. It must include people from all levels of the operation, especially the folks on the front lines.

Your dock crew and engine room technicians are the ones who see the little problems that add up to big risks. They know which valve is sticky and what corner is always slippery. Giving them a real voice in shaping safety procedures turns them from passive observers into your most powerful advocates.

An empowered safety committee doesn't just talk about problems; it solves them. It should have its own modest budget and the authority to test new gear or tweak a workflow. This is how you turn frontline insights into real-world improvements.

Think about this scenario: a dockhand on the committee mentions that the standard-issue gloves get dangerously slick when they come into contact with a specific cleaning agent. A manager sitting in an office would never know that. The committee gets the green light to trial and approve a new type of glove. Just like that, a problem is solved, and a powerful message is sent to the entire crew: your voice matters, and your feedback leads to change. That’s how you build trust.

Create a Reporting System People Actually Use

One of the biggest roadblocks to a safer workplace is fear. People see a near miss or a small spill and stay quiet because they're worried about getting blamed or facing punishment. The only way around this is to build a "just culture" with a truly blame-free reporting system.

This means that when a report comes in, the first question isn’t "Who messed up?" but "Why did this happen?" The focus immediately shifts to the system, the process, and the conditions that allowed the event to occur. Was the training unclear? Is the equipment showing its age? Was the crew under pressure to rush through the job?

This approach gives you invaluable data you would otherwise miss. It's not just a gut feeling; the research proves it. A major study found that organizations with strong safety cultures—where communication is open and employees are involved—have significantly lower injury rates. When leadership removes the fear of reporting, the entire operation gets safer.

Building this kind of psychological safety is the foundation of a resilient organization. For anyone in the marine fueling business, understanding every angle of risk is non-negotiable. For a deeper dive, you can explore our complete playbook for boat fueling safety to help secure your operations.

Get the Front Line Involved in Risk Assessments

Who knows the risks of a job better than the person doing it every single day? Bringing your frontline staff into formal risk assessments is a total game-changer. They offer a practical, hands-on perspective that you simply can't get from behind a desk. They're the ones who know which tools are frustrating to use and what shortcuts people might take when they're in a hurry.

So, instead of just creating a Job Safety Analysis (JSA) and handing it down, build it with them. This collaboration not only produces a more accurate and realistic plan but also creates instant buy-in. When people help write the safety rules, they believe in them. They're far more likely to follow them and to encourage their peers to do the same.

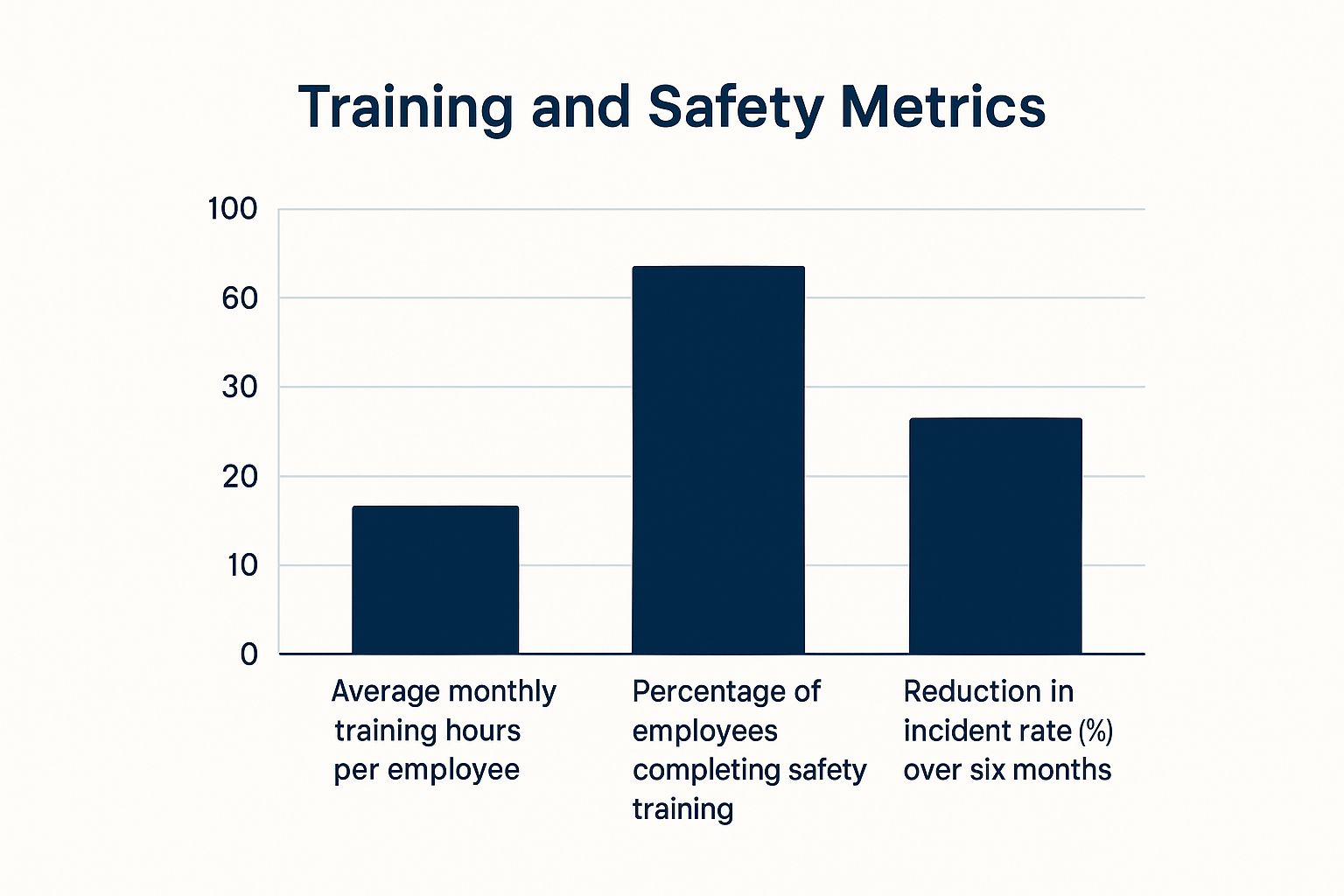

The chart below shows exactly why this investment in your people pays off.

As you can see, higher rates of training and employee engagement lead directly to a sharp drop in safety incidents. It’s clear proof that a well-trained, engaged crew is your single best defense against accidents.

Using Technology to Engineer Safer Workflows

A genuinely strong safety culture isn't just about rules and training. It's about designing your workplace so that the safe way to do a job is also the easiest and most obvious way. This is where smart technology comes in, helping you build safety right into your day-to-day operations and drastically cutting down on the potential for human error.

Think of it as moving from simply trusting people to remember safety protocols to building a system where those protocols are an automatic part of the process. You start by looking at your riskiest tasks and asking a simple question: "How can we make this process foolproof?"

Instead of just training someone on how to avoid overfilling a fuel tank, you give them a tool that makes overfilling impossible. This is the whole idea behind engineered controls—physical changes to the environment that get rid of hazards at the source.

Moving from Human Oversight to Systemic Safeguards

Let's be honest: relying only on human diligence is a gamble. People get tired, distracted, or have a momentary lapse in judgment. It happens. A well-designed system, on the other hand, performs its function perfectly every single time. By bringing in tools that automate safety checks or sound the alarm in real-time, you create a powerful safety net that has your team's back.

This can look different depending on your operation. Some industries, for example, are using advanced Driver Monitoring Systems to track operator fatigue and prevent accidents before they happen. No matter the specific tool, the objective is always the same: use technology to build a more forgiving and resilient workplace.

The most effective way to improve safety culture is to design hazards out of the system entirely. When the safe way is also the easiest and most efficient way, compliance becomes automatic.

Taking this approach sends a powerful message. It shows your crew that leadership is genuinely committed to their well-being and is willing to invest in the right tools to prove it. This builds trust far more effectively than any poster or memo ever could.

A Real-World Example in Marine Fueling

Fueling a boat is a classic high-stakes job that has historically depended on little more than a keen ear and a bit of guesswork. Anyone who's been at the fuel dock knows the routine: you listen for that change in sound from the vent, hoping you can stop the flow before fuel comes gushing out. All too often, it results in a messy, dangerous spill that damages the boat, pollutes the water, and creates a serious fire hazard.

This is exactly the problem that CLiX Fueling Solutions was created to eliminate. It's a perfect example of an engineered control that fundamentally changes the fueling process for the better.

Here’s how it transforms a high-risk task:

- No More Guesswork: The CLiX system automatically shuts off the fuel nozzle the moment the tank is full. The operator doesn't have to guess or listen for anything.

- Zero Spills: It creates a secure, sealed connection between the nozzle and the fuel intake, preventing overflows onto the deck or into the water.

- Human Error is Minimized: The system removes the most common point of failure—the human element—from the most critical part of the process. You get a safe, complete fill every time.

A tool like CLiX is more than just a clever gadget; it's a physical commitment to a better safety culture. When a marina or boat owner adopts it, they're not just buying a product. They're actively engineering risk out of their operations and making the safest method the only method. It turns a stressful chore into a simple, clean, and worry-free task.

How to Measure and Sustain Your Safety Culture

https://www.youtube.com/embed/UmILLmaBLz0

Improving your safety culture isn't a project with a neat finish line. It’s a living, breathing part of your operation that needs constant attention. Once you've laid a stronger foundation, the real work begins: sustaining that momentum. The only way to do that is to measure what actually matters and let that data show you the way forward.

You can't manage what you don't measure. Gut feelings about whether things are "getting better" just don't cut it in a high-risk environment. You need solid, objective data to see if your efforts are truly taking hold. This means looking beyond simple incident rates and digging into the proactive behaviors that stop accidents before they ever happen.

Using Leading Indicators to Track Progress

Instead of only reacting to accidents after they occur (what we call lagging indicators), a truly mature safety culture focuses on leading indicators. Think of these as the forward-looking metrics that give you a real-time pulse on the health of your safety program. They signal what's likely to happen down the road, giving you the chance to make adjustments before something goes wrong.

Here are a few powerful leading indicators you can start tracking today:

- Near-Miss Reporting Rates: An increase in near-miss reports is actually a great sign. It shows your crew trusts the system and feels safe speaking up without any fear of blame.

- Safety Observations: This involves regularly observing tasks in action, noting both safe practices and at-risk behaviors. The point isn't to "catch" people doing something wrong, but to spot trends and identify coaching opportunities.

- Safety Training Completion: Don't just track who finished the training. Follow up with observations and simple quizzes to see if the knowledge is actually being applied on the dock.

- Action Item Closure Rate: How quickly does your team fix hazards found during inspections or from employee reports? A fast closure rate is proof that management is listening and responsive.

The Measure-Analyze-Act-Review Cycle

To keep your safety culture from getting stale, you need a simple, continuous loop of improvement. This framework keeps you learning and adapting.

- Measure: Use a mix of tools to gather your data. This includes the leading indicators we just talked about, but also regular, anonymous safety culture surveys. These surveys are your direct line into what the crew is really thinking and feeling.

- Analyze: Start connecting the dots. Are near-miss reports clustered around a particular piece of equipment or time of day? Do the surveys show one team feels less empowered than another? This is where you'll find your biggest opportunities for improvement.

- Act: Based on your analysis, create targeted action plans. If communication is a weak point, start holding more frequent pre-shift "toolbox talks." If a specific procedure is causing confusion, get the crew who actually does the work involved in rewriting it.

- Review: Finally, circle back and see if your actions made a difference. Did the next survey show better communication scores? Did near-misses in that problem area go down? This last step is what ensures your efforts are actually paying off.

Sustaining a safety culture is all about creating a feedback loop where learning never stops. Every report, every observation, and every piece of feedback is a gift—an opportunity to get better and reinforce that safety is a shared journey.

Celebrate Wins and Learn from Setbacks

Keeping the momentum going requires a two-pronged approach: positive reinforcement and resilient learning.

When your crew hits a safety milestone—like 100 days without an incident or a 100% completion rate on a new training module—celebrate it! Public recognition reinforces the right behaviors and shows you value their hard work. In fact, one recent report found that 47% of workers said just getting recognized for their efforts would improve their relationship with management.

Just as important is how you handle setbacks. When an incident inevitably happens, it must be treated as a learning opportunity, not a chance to point fingers. A blame-free investigation focused on system failures builds trust and encourages the honesty you need to prevent it from happening again. Understanding the fine details of risk management is critical here, and you can learn more by exploring our comprehensive marina safety guidelines for a secure boating experience.

By consistently measuring, acting, and celebrating progress, you turn your safety culture from a temporary project into a permanent, defining feature of how you do business.

Common Questions About Safety Culture

When you start getting serious about improving your safety culture, you’ll find certain questions and challenges pop up again and again. It’s one thing to talk about safety in theory; it's another to put it into practice on the deck. Let's tackle some of those common questions head-on.

Getting clear answers is the first step. It helps you know what to expect and where to focus your energy for the best results.

How Long Does It Take to See a Real Change?

This is usually the first thing everyone wants to know. The honest answer? It varies. But with consistent effort, you can absolutely see early, positive signs within three to six months. This usually looks like more people reporting near-misses or actively participating in safety huddles instead of just standing in the back.

But for a truly mature safety culture—where thinking proactively about safety is just how everyone operates—you're looking at a longer game. Realistically, it takes anywhere from one to three years. Progress really comes down to a few things:

- Leadership Commitment: Is management just talking the talk, or are they walking the walk every single day?

- Crew Buy-In: How quickly does your team start to trust the process and get involved?

- Your Starting Point: Are you starting from a place of simple indifference, or are you fighting against a culture that actively resists change?

Think of it as a marathon, not a sprint. The key is to aim for steady, consistent progress and make sure to celebrate the small victories.

What Is the Difference Between Safety Climate and Culture?

I hear these terms used interchangeably all the time, but they’re not the same. Getting the distinction right is crucial if you want to make changes that actually stick.

Think of safety climate as a snapshot in time. It's the current mood—the shared feeling your crew has about safety right now. A new safety policy or, unfortunately, a recent incident can shift the climate almost overnight.

Safety culture, on the other hand, is much deeper. It’s the collection of shared values and ingrained behaviors that have built up over years. It’s simply "the way we do things around here." Culture is far more stable and, frankly, harder to change.

You can't change the culture directly. Instead, you improve the culture by consistently fostering a positive climate. Every time you handle a safety concern properly, you're laying another brick in the foundation of the culture you want to build.

How Do You Get Employees to Report Near Misses?

This is one of the biggest hurdles, and overcoming it is a true sign of a healthy safety culture. If you want people to report near-misses without fear, you have to build what’s known as a "just culture."

It starts at the top. Leadership has to make it crystal clear—repeatedly—that the purpose of reporting is to learn, not to point fingers. When someone reports a close call, the investigation should immediately focus on what went wrong with the system, not the person. Was the equipment acting up? Was the procedure unclear? Was everyone under pressure to work too fast?

Next, you have to follow through. When your crew sees that their reports actually lead to positive changes, like getting new equipment or updating a confusing process, you build trust. That trust is everything. It's especially true for tasks where having the right gear is non-negotiable; using something like a boating safety equipment checklist can help spot these gaps before they cause a problem.

Finally, make reporting a celebrated act. A simple, public "thank you" to an employee for speaking up sends a powerful message to everyone: we value your honesty, and it’s safe to raise your hand here.

Ready to engineer spills out of your fueling process for good? With CLiX Fueling Solutions, you make the safest choice the only choice. Learn how our spill-free, automatic shut-off system can protect your boat, the environment, and your peace of mind. Explore CLiX today.