At its core, a hand fuel transfer pump is a pretty clever device that uses a simple pressure difference to move liquid from one container to another. Think of it like a heavy-duty drinking straw for fuel. You provide the muscle, and basic physics does the rest. It's this straightforward, no-frills mechanism that makes it such a lifesaver in countless off-grid and emergency situations where electricity is a luxury.

How a Hand Fuel Transfer Pump Works

So, how does it actually move the fuel? It’s all about pressure and suction. The pump doesn't just magically teleport liquid—it manipulates air pressure to get the fuel flowing. When you crank that handle, you’re creating a vacuum. Nature can't stand a vacuum, so it rushes to fill the empty space, and the only thing around to fill it is the fuel in your source container.

It's a surprisingly efficient process that hinges on a few key parts working together perfectly. The real action happens inside the pump's body, where a piston or a diaphragm moves back and forth to create that crucial pressure difference. It's a simple, elegant solution for a very common problem.

The Basic Principle: Suction and Displacement

Remember using a straw as a kid? When you suck the air out, you lower the pressure inside it. The higher atmospheric pressure outside then pushes your drink up the straw to even things out. A fuel transfer pump hand model works on that very same principle, just on a bigger, more controlled scale.

Each pump of the handle involves two main actions: the intake stroke (sucking the fuel in) and the discharge stroke (pushing it out).

- Intake Stroke: When you pull the handle up or back, a piston or diaphragm inside the pump moves, creating more space within the pump chamber. This generates a low-pressure zone, or a vacuum. The normal atmospheric pressure pushing down on the fuel in the source tank forces the liquid up the intake hose and into the pump.

- Discharge Stroke: Now, you push the handle down or forward. This shrinks the volume inside the pump chamber, which pressurizes the fuel trapped inside. This pressure forces a one-way valve to open, pushing the fuel out through the discharge hose and into your waiting tank.

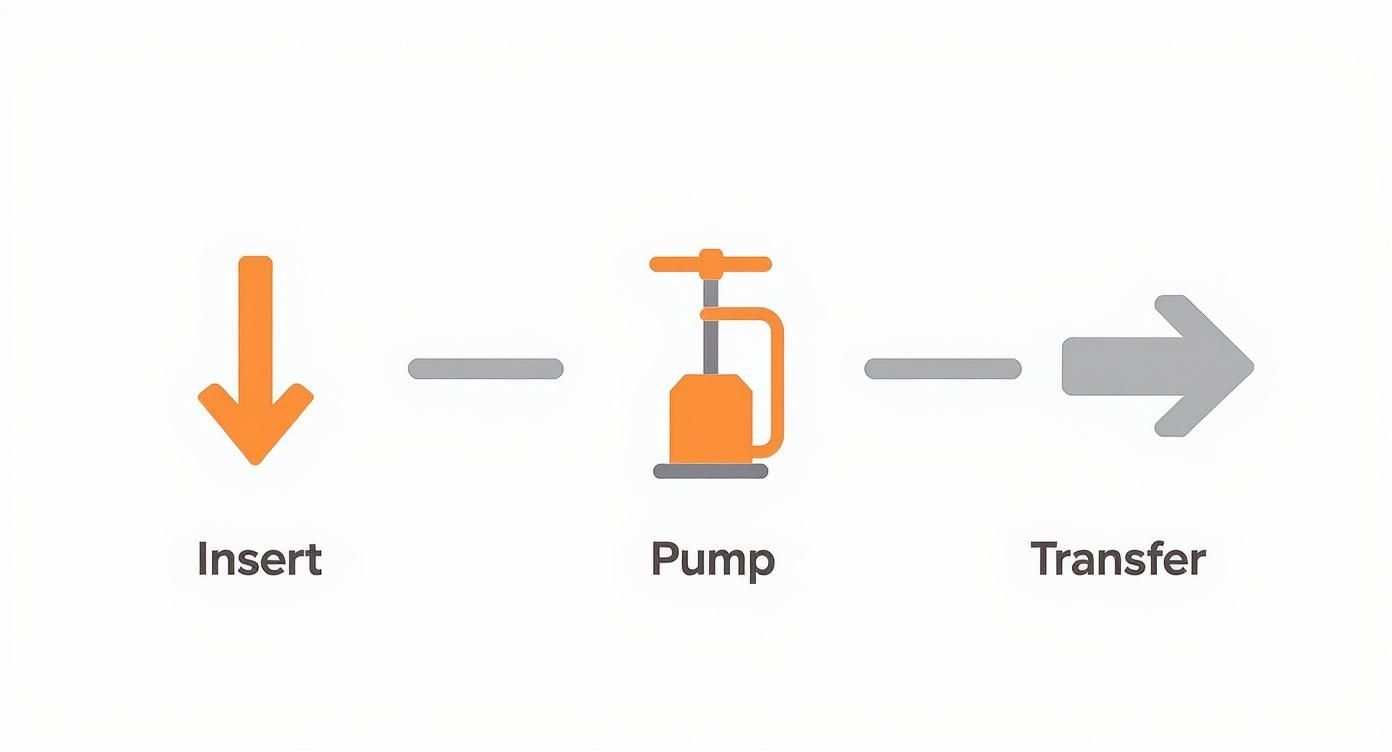

This infographic breaks down the basic operation into three simple steps.

As you can see, it’s a direct mechanical process: you put the hose in, pump the handle, and the fuel moves. No external power needed.

Key Components and Their Roles

For this mechanical dance to work, several parts have to do their jobs just right. While designs can vary a bit between models, most manual pumps are built from the same core components. Getting to know these parts helps pull back the curtain on how these pumps work so well.

Here's a quick rundown of the essential components you'll find in most hand pumps.

Key Components of a Hand Fuel Transfer Pump

| Component | Primary Function | Common Materials |

|---|---|---|

| Handle/Lever | Provides the manual force to operate the pump's internal mechanism. | Steel, Aluminum, Cast Iron |

| Pump Body | Houses the piston, diaphragm, or vanes that create suction and pressure. | Cast Iron, Steel, Polypropylene |

| Intake Hose | Draws fuel from the source container into the pump body. | Reinforced PVC, Rubber |

| Discharge Hose | Pushes fuel from the pump body into the destination container. | Synthetic Rubber, PVC |

| Piston/Seals | Creates the airtight seal needed to build a vacuum and generate pressure. | Nitrile, Viton, Teflon |

| Check Valves | Ensures fuel flows in one direction, stopping it from flowing backward. | Steel, Brass, Plastic |

The seals and check valves are the unsung heroes here. Without a tight seal, the pump could never create a strong enough vacuum. And without a reliable check valve, the fuel would just slosh back and forth instead of moving forward into your tank.

Key Takeaway: A hand fuel transfer pump is a closed system. Its success depends entirely on maintaining an airtight environment where your manual effort can successfully displace air with fuel and keep it moving in the right direction. Even a small leak can ruin its ability to create suction.

Comparing the Different Types of Manual Fuel Pumps

Picking the right fuel transfer pump hand model isn't a one-size-fits-all deal. The best tool for the job really comes down to what you need to do—how much fuel you're moving, what kind of container you're using, and how often you'll be doing it.

Getting a handle on the main designs is the first step. Generally, you'll find three types out there: the Lever-Action, the Rotary Vane, and the Siphon pump. Each one strikes a different balance between power, ease of use, and portability.

The Sturdy Lever-Action Pump

Think of the lever-action pump as the heavy-lifter of the manual pump world. You know the one—it has that long, piston-like handle. These pumps are built tough for high-volume jobs, which is why you see them everywhere on farms, construction sites, and in garages.

The way they work is beautifully simple. You pull the handle up, and it creates a vacuum that sucks fuel up from a barrel. Push it down, and that fuel is forced out the hose. This direct mechanical action can move a lot of liquid fast, often between 10 to 15 gallons per minute (GPM).

They're usually made from cast iron or steel, so they can handle thicker stuff like diesel and oil just as easily as gasoline. These pumps are built to take a beating and keep on working.

- Best For: Emptying 55-gallon drums, refueling heavy equipment like tractors and generators, and any other high-volume task.

- Key Advantage: Unbeatable durability and a seriously impressive flow rate for a manual pump.

A good lever-action pump is an investment. If you're regularly moving a lot of fuel and don't have power nearby, you just can't beat its reliability.

The Smooth Rotary Vane Pump

If the lever pump is the powerhouse, the rotary vane pump is the smooth operator. Instead of a strenuous up-and-down motion, you just turn a hand crank. It’s a much more continuous and less jarring way to move fuel.

Inside, a rotor with little sliding vanes spins around. As you crank it, these vanes trap fuel and push it from the inlet to the outlet in a nice, steady stream. This makes them perfect for jobs where a consistent, manageable flow is more important than raw speed.

Rotary pumps can move a respectable amount of fuel, usually around 7-10 GPM, but with a lot less effort on your part. They're also versatile enough to handle everything from gasoline and diesel to light oils, and their smooth operation helps cut down on splashing and spills.

Common Rotary Pump Applications

- Auto Shops: Great for precisely dispensing oils and other fluids from large barrels.

- Marinas: Perfect for refueling boats where a steady flow prevents spilling fuel into the water.

- Small-Scale Industrial: Used for transferring chemicals or lubricants where a consistent output is critical.

The only real trade-off is that their internal parts are a bit more complex than a lever pump's. This means they can be more sensitive to dirt or debris in the fuel, so using a good filter is a smart move to keep them running for years.

The Simple Siphon Pump

For small, occasional jobs, nothing beats the simplicity of a siphon pump. Usually made of lightweight plastic, it's just a flexible hose with a squeeze bulb or a small plunger. This is the tool you grab when you only need to move a few gallons.

This kind of fuel transfer pump hand model uses a bit of initial suction to get things started, and then gravity does the heavy lifting. You just put the source container up higher than the receiving one, give the bulb a few squeezes to get the fuel flowing, and the siphon effect takes over.

Sure, the flow rate is much lower—typically 1-3 GPM—but you can’t beat them for convenience and cost. They're perfect for draining a lawnmower for the winter, moving gas between cans, or for a roadside emergency.

Comparison of Manual Fuel Pump Types

To make it even clearer, let's break down how these three pumps stack up against each other. Each has its place, and seeing their strengths and weaknesses side-by-side can help you decide which one fits your needs.

| Pump Type | Mechanism | Best For | Pros | Cons |

|---|---|---|---|---|

| Lever-Action | Up-and-down piston motion | High-volume transfer from drums | High flow rate, very durable, handles thick fluids | Requires more physical effort, can be heavy |

| Rotary Vane | Circular hand-crank motion | Continuous, smooth transfer | Easy to operate, steady flow, versatile | More complex internal parts, sensitive to debris |

| Siphon | Squeeze bulb or plunger | Small-volume, occasional tasks | Highly portable, inexpensive, simple to use | Low flow rate, requires gravity assist, less durable |

In the end, it all comes down to the job at hand. A farmer refueling a combine will want the raw power of a lever pump. A boat owner will appreciate the controlled, spill-free flow of a rotary pump. And for emptying a gas can into your ATV, a simple siphon pump is all you'll ever need.

Why You Absolutely Need a Manual Pump in Your Toolkit

It’s easy to get caught up in the mechanics of how these pumps work, but their real magic is in how incredibly practical they are. A fuel transfer pump hand model isn't just another tool; it’s your get-out-of-jail-free card when you're far from a power outlet or need a solid backup when the electricity fails. Its biggest strength is that it doesn't need electricity at all.

Picture this: you're on a remote job site, way out in a farm field, or enjoying a day on the lake. Suddenly, a machine sputters to a stop, completely out of fuel. You can't just plug a pump into the wall. This is where a manual pump saves the day. It lets you move fuel right where it's needed, whenever you need it, with nothing more than a bit of elbow grease. That kind of self-reliance is invaluable.

You Can't Beat the Price

Let's talk about money. One of the best reasons to own a manual pump is how affordable it is. Electric pumps not only cost more upfront but also come with installation headaches and running costs, whether it's for electricity or batteries. A hand pump, on the other hand, is a simple, one-time purchase with pretty much zero running costs.

This makes it a no-brainer for just about anyone, from small-scale farmers to weekend boaters. There are no power cords to get damaged, no batteries that die at the worst possible moment, and no complicated motors to fail. Its beautiful simplicity translates directly into long-term savings.

Key Insight: When you look at the total cost of ownership, a manual fuel pump is incredibly low. By cutting out the need for power and keeping maintenance to a minimum, it offers a reliable way to transfer fuel that won’t hit you with surprise costs down the road.

Get the Flow Just Right and Stop Spills

Another huge plus is the control you get. When you’re pumping by hand, you can actually feel the fuel moving. This direct feedback lets you manage the flow with amazing accuracy, so you can slow down as a tank gets full and avoid messy overflows.

This level of control is key to preventing spills, which are not only wasteful but also harmful to the environment. Some electric pumps can fill a small tank too fast, leading to a mess. A manual pump, however, lets you put in precisely the amount of fuel you need. This careful handling saves fuel, protects your equipment, and keeps the ground clean.

The Safer Choice Over Dangerous Shortcuts

Without a proper pump, it’s tempting to try risky methods like tipping heavy, awkward fuel cans or trying to pour directly into a tank. Honestly, that’s just asking for trouble. It’s a fast track to spills, back injuries, and a serious fire hazard. A dedicated fuel transfer pump hand model takes all that danger out of the equation.

It creates a sealed, secure path from the fuel can to the tank, making sure the fuel goes exactly where it's supposed to. This controlled transfer dramatically cuts down the risk of accidents, making the whole job safer for everyone. The growing need for these reliable tools is clear from market data. The global fuel transfer pump market was valued at USD 2.6 billion in 2025 and is expected to hit USD 4.7 billion by 2035, thanks to high demand in farming and industry. You can dive deeper into these trends in the full report from Future Market Insights.

How to Choose the Right Hand Fuel Transfer Pump

Picking the right hand fuel transfer pump isn't just about grabbing the first one you see. It’s about finding the perfect match for your specific job to make sure everything is safe, efficient, and built to last. With so many different materials, flow rates, and designs out there, a little homework upfront can save you a world of frustration later.

Let's break down what really matters so you can make a smart choice.

The absolute first thing to check is material compatibility. Fuel is nasty stuff—it can eat through the wrong kind of plastic or rubber in no time. If your pump's seals and body aren't designed for the liquid you're moving, you're setting yourself up for leaks, damage, and a potentially dangerous mess.

Evaluate Material Compatibility and Durability

Different fuels demand different materials, period. For instance, Nitrile (Buna-N) seals are workhorses for diesel and oils, but they'll swell and fail if you run gasoline or ethanol through them. On the other hand, Viton seals are tougher and can handle a much wider range of chemicals, making them a far safer bet for all-around use.

The pump’s body tells you a lot about its toughness, too. You’ll see heavy-duty cast iron and steel pumps that are practically bulletproof—perfect for getting banged around on a farm or construction site. But if you need to carry it around, a well-made pump from a chemical-resistant polymer or aluminum might be the smarter, lighter choice.

Crucial Tip: Never guess. Always double-check the manufacturer's spec sheet to see what fuels the pump is rated for. Using the wrong pump for a volatile fuel like gasoline isn't just a bad idea; it's a serious safety hazard that can cause seals to fail and spill fuel everywhere.

Determine Your Required Flow Rate

Next up, how fast do you need to move that fuel? This is all about flow rate, usually measured in gallons per minute (GPM). If you're filling up a big tractor tank, a high-volume lever pump that can push 10-15 GPM will get the job done quickly.

But if you're just topping off a lawnmower or an ATV, a simple siphon pump that moves 1-3 GPM is a much better tool. The slower speed gives you far more control, preventing those annoying and wasteful overflows. Think about your most common task and pick a rate that balances speed with precision. If you want to see how different models stack up, our guide on the top portable fuel transfer pumps is a great place to start.

The need for good fuel transfer equipment is huge worldwide. The Asia Pacific region, for example, accounted for about 35.9% of the global market revenue in 2021, driven by explosive growth in its industrial and agricultural sectors. You can dig deeper into these trends in the full fuel transfer pump market analysis on MarketResearchFuture.com.

Consider Ergonomics and Ease of Use

Don't forget about comfort, especially if you'll be using the pump often. A well-designed tool can be the difference between a quick, easy job and a sore arm.

Here are a few things to look out for:

- Comfortable Handle: Is the grip cushioned or shaped to fit your hand? A good handle makes a huge difference during long pumping sessions.

- Smooth Operation: If you can, give it a test run. A quality rotary pump should turn smoothly, and a lever pump shouldn't stick or feel jerky.

- Weight and Balance: If you have to lug it from one drum to another, a lighter pump will be your best friend. Less weight means less strain.

Assess Hoses and Included Accessories

Finally, look at the whole package. The pump is the heart, but the hoses and accessories are just as important. The intake hose needs to be long enough to hit the bottom of your tank, and the discharge hose should reach its destination without being stretched taut.

Also, check for those little extras that add a ton of value and safety:

- Nozzle: A good nozzle gives you control right where you need it, preventing spills.

- Filter: A strainer on the intake hose is a simple but brilliant feature. It keeps gunk out of your pump and out of your engine.

- Grounding Clamp: This is non-negotiable for flammable fuels. An anti-static grounding clamp prevents static sparks that could ignite fumes.

Essential Safety Practices for Transferring Fuel

Let's be clear: handling flammable liquids like gasoline or diesel demands your full attention. Using a fuel transfer pump hand model is worlds safer than trying to pour from a heavy can, but it doesn't magically erase the risks. You still need to follow a strict safety checklist to protect yourself, your gear, and the environment.

The number one rule? Always, always work in a well-ventilated area. Fuel vapors are sneaky—they're heavier than air and can pool in garages or sheds, creating a ticking time bomb. Transfer fuel outside whenever possible, or at the very least, in a garage with the main door wide open. You need that airflow to carry the fumes away.

Preparing Your Workspace and Gear

Before you even touch the pump, take a minute to set the stage. A little prep work up front is the best way to stop an accident before it even starts.

First, kill any potential ignition sources. We all know about cigarettes and lighters, but don't forget the less obvious culprits. Turn off nearby engines, space heaters, or anything else that could create a spark. That's all it takes to ignite fuel vapor.

Next, give your equipment a quick but thorough inspection. Check the pump and hoses for cracks, leaks, or any signs of brittleness. A worn-out hose is a disaster waiting to happen. Make sure every connection is tight and secure to prevent drips during the transfer.

Safety First: That pre-transfer check takes less than 60 seconds, but it can prevent a total system failure. Never just assume your gear is good to go—always check it before you start.

Mastering Safe Pumping Techniques

Once your area is prepped and safe, it's time to focus on the actual pumping. A crucial step that many people skip is grounding the equipment. As fuel moves through a hose, it can build up a surprising amount of static electricity. One tiny spark from that static discharge is enough to ignite the fumes.

If your pump is equipped with one, use an anti-static grounding clamp. Connect it to a clean, bare metal spot on both the fuel can and the vehicle or tank you're filling. This gives any static charge a safe path to ground. It's what the pros do for a reason.

Here are a few other must-do practices while you're transferring fuel:

- Wear Proper PPE: At a minimum, you need safety glasses and fuel-resistant gloves. Nitrile gloves are perfect for protecting your skin from harsh chemicals.

- Maintain Control: Keep a solid grip on the nozzle the entire time. Never, ever walk away from a pump while it’s running.

- Avoid Overfilling: Watch the tank level closely. As it gets near the top, slow down your pumping speed to prevent a messy, dangerous spill.

When you're working with fuel, it’s critical to follow all established safety standards, including specialized ones for marine use like boat diesel oil appliance certificates. To learn even more, check out our guide with expert tips for the safe use of your fuel transfer hand pump. Turn these steps into habits, and you'll make every fuel transfer a safe one.

Where You’ll Find Hand Fuel Pumps in Action

A hand fuel transfer pump is so much more than a gadget you keep in the garage. It’s a real workhorse, showing up in all sorts of industries and hobbies. The beauty of these pumps is their simplicity and adaptability, giving you a way to move fuel when there’s no power outlet in sight.

Think about huge farms or chaotic construction sites. In places like these, manual pumps are absolute game-changers. Because they don't need electricity, they're the go-to solution for refueling in remote spots where lugging heavy equipment back to a central tank just isn't an option.

Keeping Farms and Construction Sites Running

In farming, every minute counts. When a tractor runs out of fuel in a far-flung field, work grinds to a halt. A simple hand pump lets a farmer refuel right there from a drum on their truck, turning a major delay into a minor pit stop.

It's the same story on construction sites. These pumps are constantly used to top off everything from generators to excavators. They offer a fast, safe, and no-fuss way to handle fuel on a rugged job site, keeping the whole project on track.

The growing need for these handy tools is pretty clear from the numbers. The global market for fuel transfer pumps was valued at around USD 124 million in 2025 and is expected to climb to USD 176 million by 2032. This isn't surprising when you see how much industries like agriculture and construction rely on them. You can check out more details about the fuel transfer pump market's growth on intelmarketresearch.com.

A Must-Have for Boaters and Car Buffs

Anyone who spends time on the water or in the garage knows the value of a manual pump. For boaters, it’s the perfect way to get fuel from a jerry can into the boat’s tank without spilling a drop into the water. It’s cleaner, safer, and just plain smarter.

And for the car enthusiast? It's an essential piece of kit. Whether you need to drain old gas from a project car, fill up an ATV for a weekend ride, or get the lawnmower ready for winter, a hand pump makes the job a thousand times easier.

Picture This: You're stuck on the side of the road, and the fuel gauge is on empty. That small siphon pump you tossed in your trunk suddenly becomes your best friend. It lets you easily transfer gas from a spare can and get yourself to the next station, no tow truck needed.

To make sure the fuel you're transferring is as clean as possible, pairing your pump with the right accessories is a smart move. Check out our guide on the top fuel funnels with filters to find one that works for you.

Frequently Asked Questions

Even with a tool as straightforward as a hand pump, questions pop up. Let's walk through some of the most common ones so you can use your pump safely and get the job done right.

Can I Use the Same Pump for Gasoline and Diesel?

The short answer is: you really shouldn't. While some pumps claim to handle multiple fuels, the best and safest approach is to have a dedicated pump for each.

Mixing fuels, even in tiny amounts, can lead to cross-contamination and engine trouble down the road. More importantly, gasoline and diesel have different chemical properties. Gasoline can be harsh on the seals inside a pump built for diesel, causing them to wear out, swell, or crack, which can lead to dangerous leaks. Always stick to the manufacturer's guidelines for your specific pump.

What Should I Do If My Pump Is Not Creating Suction?

This is the number one problem people run into, but it's almost always an easy fix. If you're not getting any suction, it means air is getting into the system somewhere.

Here’s a quick troubleshooting checklist:

- Check Your Connections: Make sure every fitting—from the pump itself to the hoses—is snug and airtight. A loose connection is the most common cause.

- Inspect the Hoses: Take a close look at both hoses for any tiny cracks, splits, or holes that could be letting air in.

- Look at the Seals: If your pump has seen a lot of use, the internal seals might be worn down and need to be replaced.

- Prime the Pump: Sometimes, a new pump just needs a little help to get started. You can often kickstart the suction by pouring a small amount of fuel into the intake hose to create that initial vacuum.

How Do I Properly Clean and Store My Fuel Pump?

A little bit of care goes a long way in making your pump last for years. When you're done using it, run a small amount of light oil through the system. This lubricates all the moving parts and clears out any leftover fuel residue.

Give the outside a quick wipe-down to get rid of any grime or fuel spills. Store your fuel transfer pump hand model somewhere cool and dry, and keep it out of direct sunlight, which can make the hoses brittle over time. And when you put it away, coil the hoses loosely—avoiding any sharp bends or kinks that could cause them to crack.

Stop wasting time and fuel with messy, unreliable methods. Upgrade to a spill-free, stress-free fueling experience with CLiX Fueling Solutions. Discover the difference at https://clixfueling.com.