At its heart, a hand pump fuel transfer pump is a brilliantly simple, power-free tool designed for one crucial job: moving gasoline or diesel from one container to another, safely and cleanly. It’s the kind of reliable gear you need when you're far from any power source, making it an absolute must-have for boaters, off-road enthusiasts, and anyone serious about emergency preparedness.

Why a Manual Pump Is Your Most Reliable Fueling Tool

Picture this: you're anchored in a quiet, secluded cove, miles from the nearest fuel dock, and you notice your main tank is getting low. Or maybe it's the end of the season, and you need to drain the old fuel before putting your boat away for the winter. In moments like these, an electric pump isn't always an option. This is exactly where the rock-solid dependability of a manual fuel pump proves its worth.

Think of it as the ultimate manual override for all your fueling needs. It’s a purpose-built tool that just works, every single time, because it doesn't rely on batteries, electrical outlets, or any complex motors. The design is beautifully straightforward, typically using the simple physics of a siphon or a basic piston to get fuel flowing.

The Power of Simplicity

The real magic of a manual pump is its no-fuss operation and durable build. There are no wires to corrode, no circuits to short out, and no batteries that can die right when you need them most. That built-in simplicity is what makes it such a vital piece of safety equipment on any vessel.

For boaters, this means you can:

- Refuel on the Water: Top off your main tank from jerry cans without ever having to head back to the marina.

- Handle Emergencies: Quickly move fuel from one boat to another or drain a tank if you suspect contamination.

- Perform Maintenance: Empty tanks with ease for cleaning, repairs, or long-term seasonal storage.

A hand pump fuel transfer pump isn't just a tool; it's peace of mind. Its reliability ensures you’re never stranded due to a lack of power when you need to move fuel.

In this guide, we'll dive into how these pumps work, what to look for when you're ready to buy one, and the best practices for using them safely. Once you see just how valuable they are, you’ll understand why this simple device is a non-negotiable for any serious boater.

How a Hand Pump Actually Moves Fuel

At first glance, a hand pump fuel transfer pump looks almost too simple to get the job done. But that simple, rugged design is exactly what makes it so dependable. The secret isn't some complex bit of engineering, but a basic law of physics: creating a pressure difference. When you make the pressure inside the pump lower than the pressure outside, the fuel has no choice but to start moving.

Think about using a drinking straw. When you suck on the straw, you lower the air pressure inside it. The higher atmospheric pressure pushing down on your drink then forces the liquid up the straw. A hand pump runs on the exact same idea, just using your muscle instead of your mouth to create that pressure drop and get fuel from a jerry can into your boat's tank.

The Piston Pump: The Workhorse Design

The most common and powerful type you'll find is the piston pump. If you've ever pumped up a bike tire, you're already familiar with how this works. Inside the pump's body is a piston connected to a handle. As you pull the handle up, you create a vacuum that sucks fuel into the chamber through an intake valve.

When you push the handle down, that intake valve shuts, and the fuel you just pulled in gets forced out through a separate discharge valve into the hose. Every up-and-down stroke repeats the process, giving you a steady, controlled flow. It's a surprisingly efficient design that can move a lot of fuel fast—many models can easily hit flow rates of 7-8 liters per minute or more.

The Siphon Pump: Simplicity in Action

The other main design is the siphon pump, sometimes called a bulb pump. This one is even simpler and lets gravity do most of the work. It’s essentially a flexible hose with a rubber bulb squeezed into the middle. When you squeeze the bulb, you push air out. As it expands back into shape, it creates a vacuum that starts pulling fuel into the hose.

After a few good squeezes, the fuel starts flowing. As long as the container you're pumping from is higher than the tank you're filling, gravity takes over and keeps the siphon going. It's not as quick as a piston pump, but for smaller jobs or as a foolproof backup, its simplicity is hard to beat.

The real magic behind both pump designs is a tiny, unsung hero: the check valve. Think of these one-way valves as the traffic cops of the system. They make absolutely sure that fuel only flows in one direction—out of the can and into your tank, never the other way around.

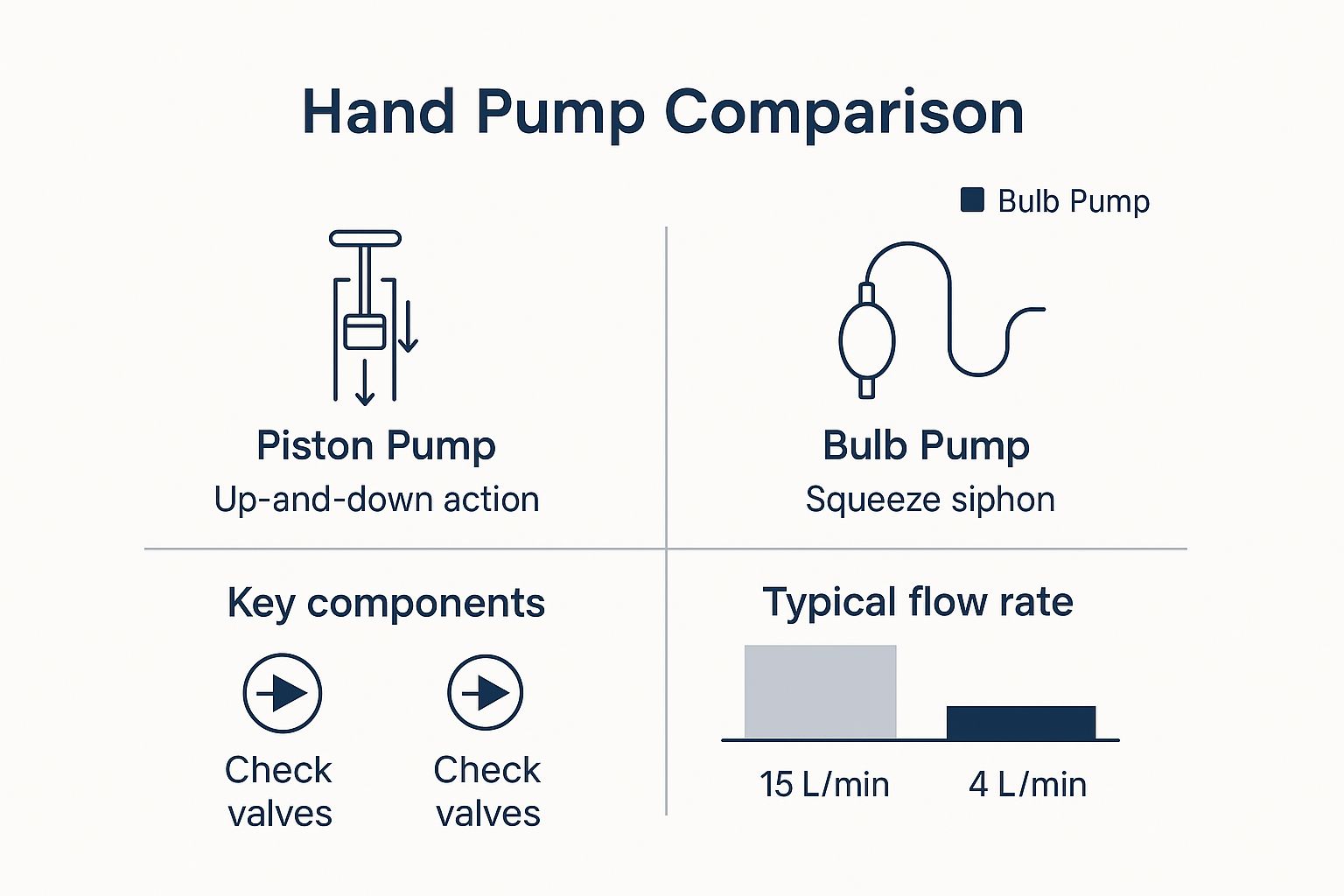

This infographic breaks down the key differences between these two go-to hand pump styles.

As you can see, piston pumps give you a much higher flow rate when you need to move a lot of fuel, while bulb pumps offer a dead-simple mechanism for transfers where you can let gravity help out.

Manual pumps have been critical tools for ages in places like farms and construction sites, especially where there's no power grid to rely on. The global market for them was valued at around USD 500 million in 2023 and is expected to climb to about USD 800 million by 2032. This isn't some flash-in-the-pan trend; it just shows how valuable these simple, reliable tools continue to be. You can dive deeper into these numbers in this detailed manual fuel pump market report.

Choosing the Right Hand Pump for Your Needs

Picking the perfect hand pump fuel transfer pump isn't as complicated as it might seem. It really just comes down to asking a few simple questions about how you plan to use it. When you get the right tool for the job, your fueling tasks become safer, faster, and a whole lot less messy.

The first thing to check, and it’s a big one, is fuel compatibility. Not all pumps can handle all fuels. The seals, gaskets, and hoses are made from different materials, and using a pump with the wrong fuel can be a recipe for disaster. A pump built for diesel might quickly break down if you run gasoline through it, leading to dangerous leaks. Always, always check the manufacturer's specs to make sure the pump is rated for your specific fuel type.

Matching the Pump to the Task

Next up, think about how much fuel you're moving and how often you're doing it. Are you just topping off a small kicker motor from a 5-gallon jug, or are you transferring 50 gallons from a drum on the dock? The answer will point you toward the right kind of pump.

- Piston Pumps: These are the workhorses of the manual pump world. Their simple up-and-down action can move a lot of fuel quickly—often 7-8 liters per minute or more. If you're dealing with larger volumes on a regular basis, a piston pump is going to save you a ton of time and elbow grease.

- Siphon (Bulb) Pumps: These little guys are perfect for smaller, less frequent jobs. They're incredibly simple—a few good squeezes get the flow started, and gravity takes over from there. They’re so compact and reliable that it’s smart to keep one on board as a backup, no matter what.

The demand for these power-free fueling solutions is growing, too. The global fuel transfer pump market was valued at a whopping USD 1.71 billion in 2021 and is on track to hit nearly USD 2.47 billion by 2029. Manual pumps are a huge piece of that pie, mainly because they're so easy to carry and use anywhere. You can discover more insights about the fuel transfer pump market here.

Key Features to Compare

Once you've settled on a type, look at the smaller details like the hose. A longer hose can be a lifesaver when you're reaching into an awkward spot on a bigger boat, but it can also be a pain to store. I’m a big fan of clear hoses because they let you see the fuel flowing, so you know it’s working and can spot any air bubbles or gunk in the line.

Choosing the right hand pump is an investment in safety and convenience. A pump that matches your fuel type, volume needs, and environment will perform reliably for years.

To make it even simpler, let's break down the two main types of manual pumps you'll find for boating.

Comparing Hand Pump Types for Boating

This quick comparison should help you decide which pump design is the best fit for your boat and your routine.

| Feature | Piston Pump | Siphon (Bulb) Pump |

|---|---|---|

| Best For | High-volume, frequent transfers | Small-volume, occasional transfers |

| Flow Rate | High (e.g., 7-8 L/min) | Low (e.g., 2-4 L/min) |

| Operation | Manual up-and-down pumping | Squeeze bulb to start siphon |

| Effort | More physical effort required | Less physical effort required |

| Portability | Generally larger and heavier | Very lightweight and compact |

By thinking through these points, you can pick a pump with confidence. If you want to see our top picks, check out our guide on the top manual transfer pumps for fuel in 2025 for a detailed look at some of the best models out there.

A Step-by-Step Guide to Safe Fuel Transfer

Let's be honest, handling fuel requires your full attention. While a hand pump fuel transfer pump makes the job a whole lot easier, there's no room for cutting corners on safety. Following a simple, consistent routine is the key to getting it right every time.

Before you even touch a hose, take a minute to look things over. Check your pump and hoses for any cracks, kinks, or brittleness—anything that could spell trouble. Give all the connections a quick wiggle to make sure they're tight and secure.

Next, glance around your workspace. You need plenty of ventilation to keep fumes from building up, so working on deck is perfect. Also, make sure you have a fire extinguisher within arm's reach and you know how to use it. A little prep work goes a long way.

Executing the Perfect Transfer

Once your gear is inspected and the area is safe, you're ready to get started. Just follow these steps for a smooth, spill-free transfer.

- Position Your Containers: If you're using a siphon pump, put the fuel can on a surface higher than the tank you're filling. This lets gravity do most of the work for you. For piston pumps, just make sure both containers are on a stable, flat surface.

- Secure the Hoses: Push the intake hose deep into the fuel can so it reaches the bottom—you want to get every last drop. Then, place the outlet hose securely into the opening of the tank you're filling. For more tips on this, check out our guide to marine fuel fill systems.

- Start Pumping: Begin with slow, steady strokes. You should see fuel moving through the clear hose right away. With a siphon pump, a few good squeezes of the bulb is all it takes to get things flowing.

- Monitor the Flow: This is where your focus is crucial. Never walk away during a fuel transfer. Keep your eyes glued to the fuel level in the receiving tank to prevent a messy and dangerous overfill.

The golden rule of fuel transfer is constant vigilance. A spill not only wastes fuel and damages your boat's finish but also poses a serious environmental and fire hazard. Your full attention is the best safety tool you have.

Critical Safety Warnings to Remember

Finally, a couple of rules are absolute musts. If your pump has an anti-static grounding clamp, use it—especially when moving a lot of fuel. This little clip prevents static electricity from building up and causing a spark.

And before you even think about transferring fuel, make sure your storage setup is safe. It all starts with the right containers. You can learn more about choosing the right chemical storage tank for your facility to ensure you're starting on the right foot. Following these simple procedures makes every transfer a safe one.

Keeping Your Hand Pump Ready for Action

A hand pump fuel transfer pump is a brilliantly simple tool, but that doesn't mean you can just toss it in a locker and forget about it. Like any piece of essential boating gear, a little bit of care goes a long way. Proper maintenance is what turns a good pump into a great, reliable one that's ready to work the moment you need it.

The best habit you can form is cleaning the pump after every use, especially if you ever switch between different fuel types. Just run a small amount of clean fuel or a compatible solvent through it to flush out any gunk or leftover residue. This simple step prevents buildups that can cause clogs or damage the internal seals down the road.

Routine Inspection and Smart Storage

Once it's clean, take a minute to give your pump a quick visual inspection. Think of it as a pre-flight check for your fueling equipment. Look for any signs of wear and tear, paying close attention to the hoses and seals—these are almost always the first things to go.

Here's what to look for:

- Hoses: Check for cracks, brittleness, or kinks. A damaged hose is just a fuel spill waiting to happen.

- Seals and Gaskets: Look for any hint of a leak or wear and tear around the connections.

- Pump Body: Make sure there are no visible cracks in the housing or handle.

When you're done, store the pump in a cool, dry place away from direct sunlight. UV rays are brutal on plastic and rubber components, and they'll definitely shorten the life of your pump. Keeping it coiled neatly in a dedicated bag or box also prevents the hoses from getting kinked or crushed. For a more organized approach, you can even adapt a preventive maintenance checklist template to fit your specific pump.

Quick Troubleshooting for Common Hiccups

Even with the best care, you might occasionally run into a minor issue. Don't worry, the fixes are usually pretty simple.

Pump Won't Prime: This is almost always caused by an air leak somewhere. Double-check that all your connections are hand-tight and that the intake hose is completely submerged in the fuel.

Minor Leaks: If you spot a drip, it’s typically a worn-out seal or a loose connection. Try tightening the fittings first. If the drip persists, it’s time to pop in a new gasket.

Staying on top of this basic maintenance ensures your pump remains a dependable workhorse. And that's becoming more important than ever. The market for fuel transfer solutions is projected to grow from USD 6.49 billion in 2024 to over USD 10.1 billion by 2035, which just goes to show how critical reliable fuel handling is. You can read more about these fuel transfer pump market trends if you're curious.

Common Questions About Hand Fuel Pumps

Even with the best guides, questions always pop up once you start using a new piece of gear like a hand pump fuel transfer pump. We’ve pulled together the most common questions we hear from fellow boaters to give you clear, straightforward answers. This should help clear up any lingering doubts and get you handling fuel with total confidence.

Think of this as your quick-reference guide for those "what if" moments on the dock or out on the water.

Can I Use the Same Hand Pump for Gasoline and Diesel?

This is a big one, and getting it wrong can cause real headaches. While many pumps are made from materials that can handle both gasoline and diesel, you absolutely must check the manufacturer’s specs first. The real weak points are the internal seals and hoses.

If you use a pump not rated for gasoline, the gas can eat away at the seals, leading to dangerous leaks. Even if your pump is compatible with both, you've got to clean it out completely between uses to avoid cross-contamination. A little bit of gasoline in your diesel engine is not something you want to deal with.

For peace of mind and your engine's health, the best approach is to have two separate pumps: one for gas, one for diesel. It completely removes any risk of a mix-up.

What Is the Best Way to Start a Siphon with a Hand Pump?

Getting a good siphon going is all about making gravity your friend. Start by placing your fuel source container higher than the tank you're filling. That height difference is what will keep the fuel moving once you prime it.

Push the intake hose all the way to the bottom of the source container. Then, secure the outlet hose inside the receiving tank. Give the primer bulb a few firm, steady squeezes until you see fuel flowing consistently through the hose. Once it's moving, gravity will do the rest of the work. Just make sure the little arrow on the bulb is pointing in the direction you want the fuel to go.

How Do I Prevent Spills When the Tank Is Almost Full?

Preventing that last-second overflow is all about paying close attention. Never, ever walk away from a fuel transfer. This is where a pump with a clear hose really shines—you can see exactly what’s happening and judge the flow.

As the fuel level gets close to the top, slow down your pumping. When you're ready to stop, don't yank the outlet hose out. The cleanest and safest way to stop the flow instantly is to lift the intake hose completely out of the source container. This breaks the siphon immediately and prevents any messy drips.

Are Electric Pumps a Better Alternative for Boating?

Electric pumps are fast and convenient, no doubt about it. But they have some serious downsides on a boat. They cost more, need a power source, and bring the risk of an electrical spark into a vapor-filled area—which is a scary thought. That means more wiring and more things to worry about.

The beauty of a hand pump fuel transfer pump lies in its bulletproof simplicity and reliability. There's no motor that can burn out and zero chance of an electrical spark. It's a must-have tool for any boater, and many seasoned captains keep one onboard as a reliable backup, even if they have a primary electric pump.

Ready to make your fueling experience safer and completely spill-free? The innovative system from CLiX Fueling Solutions automatically stops the flow when your tank is full, protecting your boat and the environment. Discover how simple safe fueling can be at https://clixfueling.com.