When a fuel spill happens, every second is critical. Relying on a generic, off-the-shelf fuel spill response plan template is a gamble you can't afford to take. In the heat of the moment, a one-size-fits-all plan often creates more confusion than clarity, leading to operational chaos and serious environmental damage.

Why Generic Spill Plans Fail in a Crisis

A real crisis is the worst possible time to find out your response plan is just a box-ticking exercise instead of a functional, life-saving tool. I've seen it happen. Generic plans almost always fail because they are vague, missing the critical, site-specific details your team needs to act fast and effectively.

The Problem with Vague Instructions

Think about a spill at a busy construction site or a marina. A generic plan might say something like, “Deploy absorbent booms to contain the spill.” Okay, but which booms? Where are they stored? Who has the keys to the storage shed? This kind of vague instruction leaves your team scrambling for answers when they should be taking action.

When a plan is short on specifics, it forces your people to make high-stakes decisions on the fly, often with incomplete information. That hesitation can be the difference between a small, contained leak and a major environmental disaster with six-figure cleanup costs. A truly customized plan eliminates that guesswork and empowers your team to act with confidence.

A response plan's real value isn't that it exists on a shelf, but that it's actually useful in an emergency. If your team can't grab it and immediately know what to do, it’s not protecting your people, your assets, or your reputation.

Meeting Strict Regulatory Standards

Let’s not forget the regulators. Federal agencies like the EPA have very specific, non-negotiable requirements for spill prevention and reporting. A generic document you downloaded online probably won't cover the particular regulations that apply to your facility, your location, or the type of fuel you handle.

This snapshot from the EPA's website just scratches the surface of the regulations involved.

As you can see, compliance isn't a single checkbox; it covers everything from prevention measures to detailed preparedness plans. A plan tailored to your operation ensures you're meeting these specific legal duties and avoiding crippling fines. While you're building your plan, our guide on essential fuel spill cleanup procedures can give you more detailed, practical insights.

This isn't just a hunch; the market shows a growing focus on preparedness. The global oil spill management market was valued at USD 151.61 billion in 2024 and is projected to keep growing, largely because of stricter environmental laws and the sheer volume of fuel being transported worldwide. For a closer look, you can dive deeper into the trends shaping the oil spill management market.

Building Your Plan's Core Components

A good fuel spill response plan template is more than just a document that checks a box for regulators. It has to be a practical tool that anyone on your team can grab and use in the middle of a crisis. The real trick is to build something comprehensive enough to be compliant, yet simple enough to be useful under extreme pressure. Let’s get into what that looks like.

Forget long, wordy paragraphs. When fuel is spreading, nobody is going to read a novel. You need clear, direct instructions. This is where leaning on best practices for creating clear and actionable documentation can make a world of difference, turning your plan from a binder on a shelf into a genuine field guide.

Establish a Clear Chain of Command

When a spill happens, the first thing people will ask is, "Who's in charge?" Your plan needs to answer that question without a moment's hesitation. You must designate an Incident Commander—the one person who has the final say and directs the entire response.

This isn't about seniority; it's about who is trained, calm under pressure, and available. And what if they're not there? You absolutely need to name at least two alternates. Leadership gaps are where small problems spiral into disasters.

For instance, a small marina might have the dockmaster as the Incident Commander and the lead mechanic as the first backup. This simple clarity kills confusion when every second counts.

Create an Immediate Notification Tree

Once the situation is being managed on-site, who do you call? And in what order? A notification tree, often called a call-down list, is essential. It's a simple visual guide that ensures the right people get the right information quickly.

Your list should be broken down into a few key groups:

- Internal Team: Your Incident Commander, key response personnel, and company leadership. Make sure you have their 24/7 contact info, not just their office line.

- Official Agencies: This includes direct lines for the local fire department, the National Response Center (NRC), and any state or local environmental agencies you're required to notify. Don't just write "Call 911."

- Key Support: Have the numbers for your emergency cleanup contractor, your insurance agent, and even legal counsel ready to go.

Pro Tip: Your notification tree should be one of the very first pages. I’ve seen teams laminate it and post it in high-traffic areas. When your hands are shaking, you’ll be glad it’s easy to find and read.

Document Initial Containment Protocols

This section is all about the immediate first steps. Think simple checklists and bold instructions. Your team needs to know exactly what to do in the first 60 seconds to prevent the spill from getting worse.

Example Initial Actions:

- Stop the Source: If it's safe to do so, shut off the valve or turn the container upright. Stop the bleeding.

- Protect the Drains: This is your number one priority after stopping the source. Use drain covers, absorbent socks, or anything you have to keep fuel out of storm drains and waterways.

- Deploy Absorbents: Start surrounding the spill with booms and pads to keep it from spreading out.

- Secure the Area: Use caution tape or cones to block off the area and keep people away.

These immediate actions are arguably the most critical part of your entire plan. They are what will make the biggest difference between a minor cleanup and a major environmental incident.

Making the Plan Your Own: From Template to Reality

Grabbing a fuel spill response plan template online is a great first step, but that's all it is—a start. A generic plan won't do you much good when a real spill happens. The real work is turning that document into a practical, custom-fit guide for your specific site, one your team can actually follow when the pressure is on.

This whole process kicks off with a detailed risk assessment. I'm not talking about a quick glance around. You need to walk your entire property with a critical eye. Think about every place fuel is stored and every place it moves. Is your biggest headache a potential pinhole leak in a 55-gallon drum? Or is it a hydraulic line blowing on a forklift right next to a storm drain? For some, the main risk is an overflow during a fuel transfer at a busy loading dock. You have to know your weak spots.

Map Out Your Hot Spots

Once you've pinpointed your most likely spill scenarios, it's time to get visual. Pull out a facility blueprint or even just sketch a rough map by hand. This map will be one of the most important tools you have during an emergency.

Make sure your map clearly shows:

- Fuel Storage Locations: Every tank, drum, and mobile bowser.

- Fuel Transfer Points: Anywhere you move fuel between containers.

- Spill Pathways: Mark every single floor drain, storm sewer, and drainage ditch. These are the routes a spill will take.

- Sensitive Areas: Note any nearby streams, wetlands, or other environmentally fragile zones.

Think about it: a vehicle maintenance shop's map is going to look completely different from a bulk storage terminal's. The shop needs a plan that can handle small, quick spills from equipment near floor drains. The terminal, on the other hand, must be prepared for a massive tank failure.

Plan Your Defense Before the Spill

With your risk map complete, you can start pre-planning exactly how you'll contain a spill in each of those hot spots. Don't wait until fuel is spreading to figure out how you're going to block a particular drain. Assign specific spill kits and containment gear to each high-risk area ahead of time.

A plan that just says "contain the spill" is basically useless. A plan that says "grab the 10-foot boom from Spill Kit #3 and block the storm drain next to Bay 2" is what will save you from a fine—or a disaster. Specificity is everything.

Getting this granular is more important than ever. The global emergency spill response market is projected to grow from around USD 33.77 billion in 2025 to USD 58.80 billion by 2035. That's a huge jump, and it shows just how much regulators and industries are focusing on detailed, effective planning. You can see the latest trends in the emergency response market to get a feel for where things are headed.

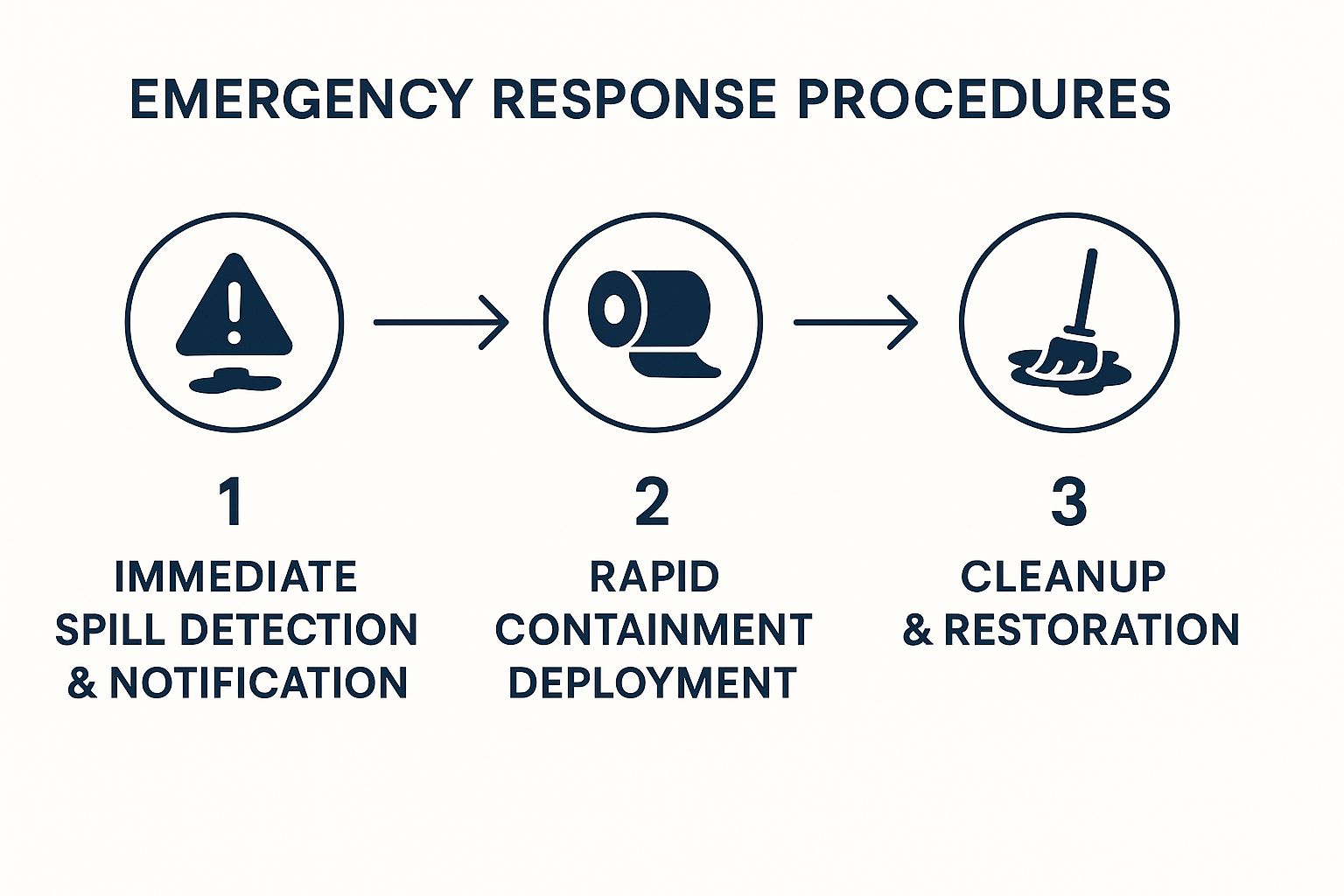

The infographic below shows the basic flow of any response. Your custom plan just fills in the critical details for each step.

As you can see, a successful response is all about moving from detection to containment as fast as humanly possible. A well-thought-out, site-specific plan is the only way to make that happen.

Navigating Your Regulatory and Reporting Duties

Once a spill is contained, the immediate physical danger might seem over. But from a legal standpoint, your responsibilities have just begun. The moment fuel hits the ground, you're on the clock with agencies like the EPA and OSHA, and they don't mess around. The fines for failing to report correctly can easily make the cleanup bill look small.

This is where your Spill Prevention, Control, and Countermeasure (SPCC) plan comes in. It's not just a good idea; it's an EPA mandate for facilities that store a certain amount of fuel and could potentially have a spill that reaches U.S. waters. Figuring out if you're required to have an SPCC plan is one of the first things you need to do.

The Clock is Ticking: Understanding Your Reporting Timeline

When a spill occurs, you don't have the luxury of time. You need to know exactly who to call, and you need to know it now. Your fuel spill response plan template absolutely must have a section dedicated to emergency contacts and the precise triggers for making those calls.

For instance, any spill that leaves a visible sheen on a nearby waterway requires an immediate call to the National Response Center (NRC). On top of that, states have their own rules, which are often even tougher. Here in my state, a spill of just 25 gallons of petroleum means you're on the phone with the state environmental agency right away.

These timelines are not suggestions. Your plan needs to spell this out with zero ambiguity:

- What information to provide: The type of fuel, a solid estimate of the quantity, the exact location, and the potential impact on the surrounding area.

- Who to contact: A clear, prioritized list with names and direct phone numbers for federal, state, and local authorities.

- When to make the call: The specific spill amounts or conditions that trigger a report, along with the time limits for doing so.

A critical tip I've learned over the years: as soon as a spill happens, assign one person to do nothing but handle notifications. While one team focuses on containment, this person's sole job is to work down that contact list. This way, your physical response and your legal reporting happen at the same time, not one after the other.

The Paper Trail: Managing Post-Spill Documentation

The job isn't finished once the last of the absorbent material is picked up. The paperwork you file afterward is your official legal record, proving you did everything by the book. This documentation is your best defense against future liability claims.

Make sure you're prepared to complete and file these key documents:

- Internal Incident Report: This is your detailed story of what happened, the root cause, and the immediate actions you took.

- Waste Disposal Manifests: Think of these as receipts. They are the legal proof that you handed over contaminated materials to a licensed hazardous waste company.

- Corrective Action Plan: This is where you formally state what you're going to do to make sure this kind of spill never happens again.

Governments are pouring more money into spill response technology and enforcing stricter rules. This puts a lot of pressure on businesses, especially smaller operations, to have their act together. It's a financial reality that makes a rock-solid response plan a must-have for balancing your compliance duties with your budget. You can read more about these growing international efforts to stay informed. If your operations are near the water, you might also find our guide on how to prevent marine pollution helpful.

Keeping Your Team Trained and Ready

Let's be honest. A perfectly written fuel spill response plan template is completely useless if it just gathers dust in a binder on a shelf. The real value comes alive when your team can actually execute it under pressure. This is where consistent, hands-on training turns that document from a simple compliance checklist into a core part of your safety culture.

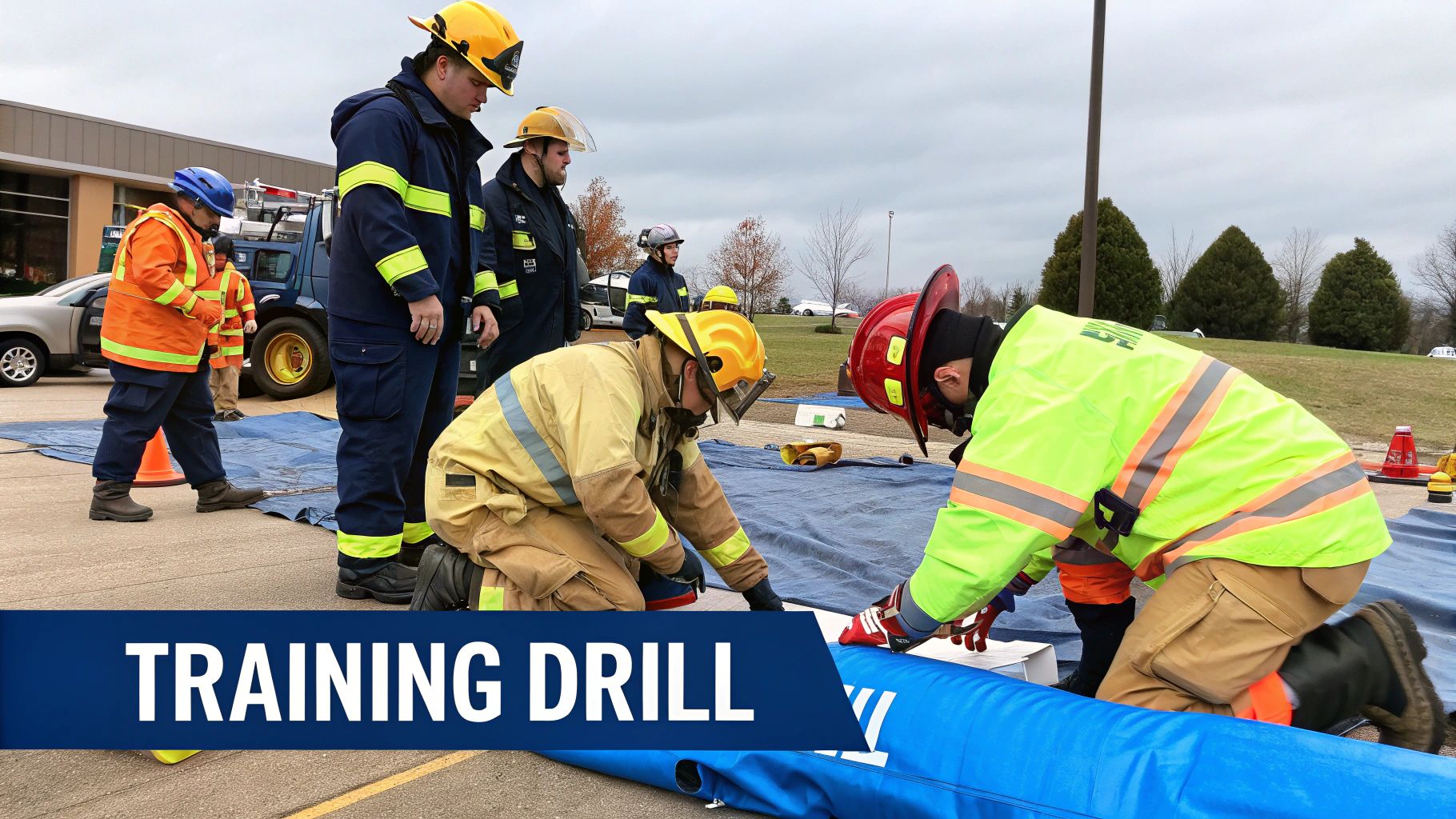

Good training is so much more than just handing someone the plan and telling them to read it. It's about building muscle memory. In a real emergency, you want your people grabbing the right spill kit, deploying containment booms, and communicating clearly without hesitation. That kind of confidence only comes from practice.

Designing Practical Training Drills

The best way to poke holes in your plan—and find those weaknesses before a real spill does—is to test it. You don't have to shut down operations for a massive drill every month. The trick is to run different types of drills on a regular basis to keep skills sharp and spot areas for improvement.

- Tabletop Exercises: Think of these as low-stress, "what-if" discussions. Get your key people in a room, give them a spill scenario, and have them talk through the plan. It’s a fantastic way to make sure everyone knows who to call and what their specific job is.

- Walkthroughs: This one's simple but effective. Take your team on a tour. Physically point out where the spill kits are, identify high-risk spots like storm drains, and show them the assembly points. It connects the words on the page to the world they work in every day.

- Full-Scale Drills: At least once a year, you need to simulate the real thing. This means actually rolling out booms, throwing down absorbent pads, and making mock phone calls. It’s the ultimate test of your plan, your equipment, and your team's readiness.

After every single drill, even the small ones, hold a debrief. Ask your team what worked, what was confusing, and what could be better. That feedback is pure gold. Use it to fine-tune your plan right away.

Creating a Living Safety Culture

A spill response plan isn't a "set it and forget it" task. It needs constant attention to stay effective. The best way to do this is to create a simple, repeatable schedule for review and maintenance. This keeps both your team and your equipment ready to go at a moment's notice.

Scheduling these activities builds a proactive safety culture instead of a reactive one. A great example of this mindset is in the marine world, where constant vigilance is just part of the job. For anyone working on or near water, our guide on boat fueling safety provides a complete protection playbook, which is a perfect companion to any spill plan.

Here’s a sample schedule you can adapt for your own facility:

| Frequency | Task | Purpose |

|---|---|---|

| Monthly | Inspect all spill kits and response equipment. | Makes sure everything is fully stocked, easy to get to, and works properly before an emergency. |

| Quarterly | Conduct a tabletop exercise or walkthrough. | Keeps the procedures fresh in everyone's mind without a major disruption to the workday. |

| Annually | Perform a full-scale deployment drill. | Provides a real-world test of your team's hands-on skills and the plan's overall effectiveness. |

| As Needed | Update the plan after facility or personnel changes. | Guarantees your plan reflects reality, from new staff to different equipment or site layouts. |

When you commit to this cycle of training, testing, and reviewing, your fuel spill response plan becomes more than just a document. It becomes the safe way you do business.

Answering Your Top Questions About Fuel Spill Plans

Even with the best template in hand, you're bound to have questions when putting together something as critical as a fuel spill response plan. It's only natural. I get calls all the time from facility managers, fleet operators, and boat captains with similar queries.

Let's clear up some of the most common points of confusion so you can finalize your plan with confidence.

How Often Should I Be Updating This Thing?

Think of your plan as a living document, not a "set it and forget it" task. You absolutely must review the entire plan at least annually. Mark it on your calendar.

But that's just the minimum. You need to pull it out and make updates anytime there's a significant change. Did you reconfigure your fuel storage area? Did your primary Incident Commander leave the company? Are you now using a new type of fuel? All of these demand an immediate plan update.

And most importantly, you must revise the plan after every single spill or drill. That's when you learn what really works and what doesn't. Those lessons are invaluable.

What's the Single Most Important Part of the Plan?

That's a tough one, because a good plan works as a complete system. But if you twisted my arm, I’d say the immediate action steps and the emergency contact list are the most critical. Why? Because these are the pages your crew will frantically flip to in the first five minutes of a crisis, and those initial moments are everything.

This section has to be dead simple. Your team needs to know, without a second of hesitation, how to stop the spill at its source and who to call first. No ambiguity allowed.

I’ve seen complex, 100-page plans fail because the first two pages were confusing. If the initial actions aren't crystal clear and instantly actionable, the rest of the plan might as well not exist.

Do I Need Different Plans for Different Kinds of Fuel?

It depends, but often, yes. The fundamental framework of your plan—things like the chain of command and notification procedures—will likely stay the same. However, the hands-on response tactics can change dramatically depending on the fuel.

Gasoline, for example, is highly volatile and gives off flammable vapors, demanding far different safety measures than a diesel spill. Your plan needs to account for this.

A great way to handle this is with specific sections or appendices for each fuel type you handle. Be sure each one includes:

- Specific response procedures for that particular fuel.

- A copy of the correct Safety Data Sheet (SDS).

- Personal Protective Equipment (PPE) requirements that match the fuel's specific hazards.

Where Do I Need to Keep Copies of the Plan?

Your plan is useless if no one can find it. Keep physical, hard copies in several strategic, easy-to-access spots where spills are most likely to occur. Good examples include the fuel storage shed, the maintenance bay, and inside the cab of any vehicle that transports fuel. The worst thing you can do is lock the only copy in a manager's office.

It's also a smart move to have a digital version saved on a shared drive or cloud service. This gives key leaders access from anywhere on their phone or laptop. But please, don't rely only on the digital copy. A dead battery or a network outage could make it disappear right when you need it most.

Of course, the best response plan is the one you never have to use. CLiX Fueling Solutions offers a brilliantly simple way to prevent overfill spills before they can even start, automatically shutting off the fuel flow when a tank is full. To protect your equipment, the environment, and your bottom line, check out the details at CLiX Fueling Solutions.