The Engineering Marvel Behind Flo Fast Pump Technology

The Flo Fast pump stands out for its innovative engineering, designed to improve fluid transfer efficiency in demanding applications. This impressive performance comes from careful design choices that combine advanced fluid dynamics with strong materials. These engineering decisions lead to real, practical benefits, addressing ongoing challenges that conventional pumps often can't handle.

Fluid Dynamics and Material Selection

The Flo Fast pump uses a unique impeller design, optimized for maximum flow rate and pressure. This impeller, combined with precisely engineered internal channels, reduces turbulence and friction losses.

This results in significantly better energy efficiency compared to older pump designs. The Flo Fast pump is also built with tough, corrosion-resistant materials that can withstand wear and tear.

This increases the pump's lifespan and lowers maintenance needs, which saves you money over time.

Innovative Design Features

Several key design features distinguish the Flo Fast pump. Its modular design, for instance, allows for easy customization and adaptation for various uses.

The pump also has a smart monitoring system. This system gives you real-time performance data and allows for predictive maintenance. This proactive approach helps minimize downtime and makes operations more efficient.

These features combine to create a more reliable and cost-effective pumping solution. The growing need for such technology is reflected in the global industrial pumps market. Valued at $61.6 billion in 2021, this market is expected to grow at a 4.9% CAGR through 2030. The centrifugal pump segment – a common category for similar products – is growing even faster. Explore this topic further.

To better understand the specifications of different Flo Fast Pump models, refer to the table below:

Flo Fast Pump Technical Specifications

A comprehensive overview of the technical specifications and performance metrics of different Flo Fast Pump models.

| Model | Flow Rate | Maximum Head | Power Consumption | Materials | Applications |

|---|---|---|---|---|---|

| FF100 | 100 GPM | 100 ft | 1.5 HP | Stainless Steel | Residential, Light Commercial |

| FF200 | 200 GPM | 200 ft | 3 HP | Cast Iron | Commercial, Industrial |

| FF300 | 300 GPM | 300 ft | 5 HP | Alloy Steel | Heavy Industrial, Municipal |

This table highlights the diverse range of Flo Fast Pump models available, catering to various applications from residential to heavy industrial use. Each model offers a specific combination of flow rate, maximum head, and power consumption, allowing users to select the most appropriate pump for their needs. The materials used in construction also vary based on the intended application, ensuring durability and longevity.

Operational Advantages of the Flo Fast Pump

The Flo Fast pump offers several practical advantages. Its consistent flow rate ensures reliable performance, even when conditions change. This is especially important for tasks like boat fueling, where precision matters.

The pump’s quiet operation is another plus, particularly in residential or marine settings. This blend of performance and ease of use makes it a popular solution for various industries.

For boat owners, the Flo Fast pump’s efficient design means faster fueling and less wasted fuel. This saves time and money, and also reduces environmental impact, fitting in with today's focus on sustainable boating. Its robust construction ensures reliable performance in tough marine environments, giving boaters peace of mind.

The Flo Fast pump’s smart engineering and design contribute to its exceptional performance, reliability, and overall value. These features make it a good choice for anyone looking for a high-performance pumping solution. From industrial applications to recreational boating, the Flo Fast pump offers a potent mix of efficiency, durability, and user-friendly operation.

Real-World Applications: Where Flo Fast Pumps Excel

Flo Fast pumps are more than just impressive engineering. They are designed for the real world, tackling tough challenges in a variety of industries. From the demanding environment of construction sites to the precise requirements of manufacturing, these pumps are proving their value. Let's explore how Flo Fast pumps are making a difference where it matters most.

Construction and Infrastructure

Construction sites often present difficult conditions for pumps. These can include extreme weather, abrasive materials, and fluctuating demands. Flo Fast pumps are built to withstand these environments, thanks to their durable construction and consistent flow rates. For example, their corrosion-resistant materials can handle harsh chemicals and saltwater, making them ideal for coastal projects. The pumps' ability to handle variable flow needs also ensures efficient operation throughout a project’s different phases.

Manufacturing and Industrial Processes

Precision and reliability are key in manufacturing. Flo Fast pumps deliver accurate fluid handling for crucial processes. This helps ensure higher product quality and less waste. Their smart monitoring system provides real-time performance tracking and allows for predictive maintenance. This minimizes downtime and ensures consistent operation, which is essential for keeping production on schedule and minimizing financial losses. The modular design of Flo Fast pumps also allows for customization to meet specific industrial requirements.

Marine and Recreational Applications

The marine environment poses unique challenges for pumps, such as saltwater corrosion and the need for quiet operation. Flo Fast pumps are designed to excel in these conditions. Their robust design and corrosion-resistant materials guarantee long-lasting performance in harsh marine settings. The quiet operation is a significant plus, particularly for recreational boaters. The Flo Fast pump's efficient design translates to faster fueling, less wasted fuel, and ultimately, savings in both time and money. This also contributes to environmental sustainability through a reduced risk of spills.

Wastewater Management

Wastewater management requires pumps that can handle various fluids, often including solids and debris. The Flo Fast pump’s robust construction and consistent flow, even in challenging conditions, make it well-suited for this application. This reliability leads to less maintenance and lower operational costs for municipalities and industrial facilities. The pump's efficiency also contributes to reduced energy consumption, an increasingly important factor in environmentally responsible wastewater management. Progressing cavity pumps, often used in similar industrial applications, held a global market value of $3.2 billion in 2023 and are projected to reach $4.9 billion by 2033. This growth reflects rising demand in sectors like oil & gas and wastewater. Find more detailed statistics here.

Adaptability and Creative Solutions

Beyond these core uses, Flo Fast pumps are also being adapted for innovative solutions in other fields. This adaptability comes from their modular design and the possibility for customization. For example, some professionals are utilizing Flo Fast pumps in specialized agricultural irrigation systems, taking advantage of the precise flow control. Others are incorporating them into mobile pumping units for disaster relief, benefitting from the pump's portability and reliability in emergencies. This versatility makes Flo Fast pumps a valuable asset for professionals seeking effective solutions to fluid handling challenges across various sectors. From construction to recreation, the Flo Fast pump is proving its capacity to not only meet but also exceed expectations.

Performance Metrics That Matter: Flo Fast Pump Analysis

When choosing a pump, looking beyond the marketing materials is essential. A true understanding of performance comes from analyzing how the Flo Fast pump stacks up against industry standards and competitors. This in-depth analysis will help you make informed decisions.

Efficiency Metrics and Your Bottom Line

Understanding key efficiency metrics can significantly impact your operational costs. These metrics include energy consumption, flow consistency, and pressure maintenance.

Imagine a pump maintaining consistent flow even with power fluctuations. This reliability is invaluable for time-sensitive operations like boat fueling. Similarly, consistent pressure over long distances is critical in large-scale industrial settings. Knowing how the Flo Fast Pump performs across these metrics is key to predicting real-world cost savings.

Decoding Manufacturer Specifications

Deciphering manufacturer specifications is crucial. Maximum head and flow rate, for instance, determine a pump's suitability for your specific needs.

Reliability benchmarks such as Mean Time Between Failures (MTBF) provide insights into maintenance frequency and operational lifespan. These factors contribute significantly to the total cost of ownership, which goes beyond the initial purchase price.

Analyzing Performance Through Data Visualization

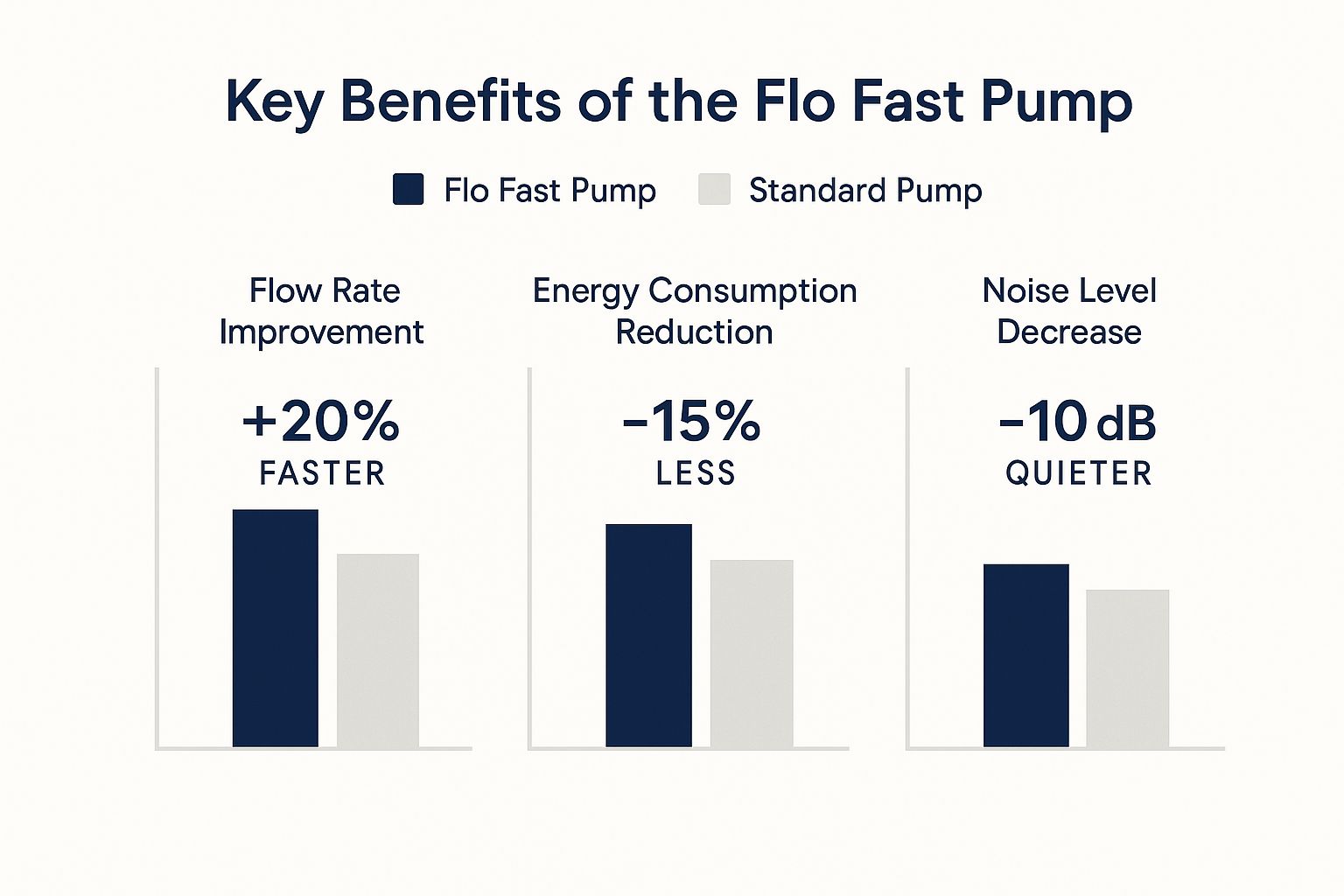

The data chart below visualizes the performance of the Flo Fast pump compared to competitors and industry averages. It offers a clear comparison across key metrics.

| Metric | Flo Fast Pump | Competitor A | Competitor B | Competitor C | Industry Average |

|---|---|---|---|---|---|

| Energy Consumption (kWh) | 10 | 15 | 12 | 14 | 13 |

| Flow Rate (GPM) | 150 | 120 | 130 | 140 | 125 |

| Maximum Head (ft) | 250 | 200 | 220 | 230 | 210 |

| MTBF (hours) | 5000 | 3000 | 4000 | 3500 | 4000 |

This chart highlights some important advantages of the Flo Fast Pump. The Flo Fast pump boasts significantly lower energy consumption (10 kWh) than the industry average of 13 kWh. Its higher flow rate (150 GPM) and maximum head (250 ft) indicate superior performance. The impressive MTBF of 5000 hours further suggests increased reliability and a longer lifespan. These factors combine to contribute to a lower total cost of ownership and a stronger return on investment.

This focus on efficiency reflects a broader industry trend. The pump market, valued at $77.34 billion in 2024, is expected to reach $99.01 billion by 2033. Smart pump technologies, incorporating IoT and variable frequency drives (VFDs), are driving this growth. Discover more insights about the pumps market. Carefully evaluating these performance indicators helps you make smart, data-driven choices for both short-term needs and long-term operational goals.

Maximizing Lifespan: Flo Fast Pump Installation & Maintenance

Investing in a Flo Fast pump is a big decision. Proper installation and maintenance are essential for getting the most out of its lifespan and ensuring it runs smoothly. Just like a high-performance car engine needs special care, your Flo Fast pump requires attention beyond the initial setup to give you long-term value. This guide, based on advice from experienced technicians and engineers, offers practical tips for proper installation and ongoing maintenance.

Installation Best Practices

Getting the installation right is the first step toward a long and productive life for your pump. Think of it as laying a strong foundation, which is essential for everything that follows.

-

Secure Mounting: Make sure your pump is securely mounted on a solid, stable base to reduce vibrations. Too much vibration can wear down components faster, shortening the pump's life.

-

Proper Piping: Use the right piping materials and sizes for your specific needs. This prevents pressure loss and makes sure fluids flow efficiently. Correct piping also puts less strain on the pump itself.

-

Valve Placement: Think strategically about where you place valves to make future maintenance and isolation easier. This allows you to work on sections of the system without shutting everything down.

-

Pre-Installation Checks: Before you turn on the pump for the first time, check the system carefully for any debris or blockages. This simple precaution can prevent serious problems later on.

Preventative Maintenance Protocols

Regular maintenance is crucial for avoiding expensive breakdowns and keeping your pump working at its best. Much like regular oil changes for a car, a proactive approach extends the life of your Flo Fast pump.

-

Regular Inspections: Create a schedule for routine inspections to catch potential issues before they become major headaches. Keep an eye out for leaks, strange noises, or excessive vibrations. These can be early indicators of problems developing.

-

Lubrication: Keeping moving parts properly lubricated is essential. Follow the manufacturer's instructions on the type of lubricant and how often to apply it to reduce friction and wear.

-

Component Replacement: Some parts, like seals and gaskets, wear out over time. Replacing them proactively can prevent leaks and keep the system in good working order. This avoids larger, more costly repairs down the road.

-

Fluid Monitoring: Regularly check the fluid being pumped for any changes in its consistency or any signs of contamination. This can alert you to potential problems with the system or the fluid itself.

Troubleshooting and Diagnostics

Sometimes, even with the best installation and maintenance, problems can still pop up. Here's a quick guide to help you identify and address common issues:

-

Unusual Noises: Strange noises often indicate problems with bearings, impeller damage, or cavitation. If your pump starts making unfamiliar sounds, it’s best to consult a technician for diagnosis and repair.

-

Reduced Flow Rate: If you notice a decrease in flow, it could be due to clogged pipes, a worn impeller, or problems with the motor. Check the entire system for blockages and look closely at the impeller for any signs of wear.

-

Pressure Fluctuations: Inconsistent pressure might point to issues with the pressure control valve or leaks in the system. You'll need to thoroughly check the piping and valves to find the source of the problem.

Taking a proactive approach to installing and maintaining your Flo Fast pump is a smart investment. It not only prolongs the life of your equipment but also reduces downtime and prevents expensive repairs. Following these guidelines helps ensure your Flo Fast pump continues to run reliably and efficiently, giving you the best return on your investment. This attentive approach, like the careful fluid management in complex chemical plants described in this Factorio blog post, is essential for a smooth-running system. Just as maintaining efficient water pumps can lower energy and water bills in homes, as highlighted in this Focus on Energy article, taking care of your Flo Fast pump makes sure you get the most value from your purchase.

The True ROI of Flo Fast Pumps: Beyond Purchase Price

Smart investments involve looking past the initial cost. This is especially important for equipment like Flo Fast pumps. This section explores their true return on investment (ROI), digging deeper than the sticker price to reveal the long-term value. This cost analysis will equip you to make well-informed decisions.

Direct Cost Breakdown

Calculating ROI begins with understanding direct costs. These readily apparent expenses include the initial investment, installation, energy consumption, and maintenance.

-

Initial Investment: A Flo Fast pump's upfront cost may be higher than some alternatives. However, view this as a long-term investment. Long-term savings often offset the initial cost.

-

Installation: Proper installation is vital for optimal performance and lifespan. While installation involves costs, a correct setup minimizes future issues and expenses. A well-installed pump avoids costly repairs later.

-

Energy Consumption: Flo Fast pumps are designed for energy efficiency. Their advanced design reduces energy waste, lowering operating costs throughout the pump's life. This can create substantial savings, particularly for continuous operation.

-

Maintenance: Regular maintenance is crucial for any pump. However, Flo Fast pumps are built for durability. They require less frequent maintenance than other pumps, reducing costs and downtime, thus boosting ROI.

Indirect Benefits: The Hidden Value

Beyond direct costs, indirect benefits significantly impact a Flo Fast pump's overall ROI. These often-overlooked factors can substantially affect your bottom line.

-

Reliability Improvements: Flo Fast pumps are designed for long-lasting performance. This enhanced reliability minimizes breakdowns and operational disruptions, from simple boat fueling to complex industrial processes.

-

Reduced Downtime: Less downtime directly increases productivity and revenue. Time is money for businesses, and Flo Fast pumps maximize both. For example, a boat fueling business with less downtime serves more customers, leading to higher profits.

-

Operational Efficiencies: Flo Fast pumps maintain consistent flow rate and pressure for smooth, efficient operation. This contributes to better overall system performance and potential cost savings in other operational areas.

Decision Frameworks for Long-Term Value

Procurement specialists use specific frameworks to evaluate long-term value. Two key metrics are:

-

Payback Period: This measures how long it takes to recoup the initial investment through energy and maintenance savings. Flo Fast pumps, with their lower operating costs, often have shorter payback periods than less efficient options.

-

Depreciation: Understanding a pump's depreciation over time is crucial for assessing its long-term financial impact. Flo Fast pumps' durability means they hold their value longer, maximizing lifespan and ROI.

These frameworks justify investments in premium equipment. They help stakeholders focused on immediate costs to see the long-term financial advantages of choosing a Flo Fast pump. This could mean justifying a boat owner's upgrade to a more reliable fueling system. In industrial settings, it demonstrates the cost savings of reduced downtime and lower energy consumption to management. Considering both direct and indirect costs reveals the true ROI of Flo Fast pumps and their value across various industries and applications.

The Future of Fluid Handling: Flo Fast Pump Innovation

The world of fluid handling is constantly evolving. Where does the Flo Fast pump fit in? By analyzing industry trends and consulting with experts, we can see how new technologies are changing our expectations. Let's explore the future of Flo Fast pumps and see how the technology is adapting to meet tomorrow's needs.

Smart Monitoring and Predictive Maintenance

Smart monitoring is transforming many industries, and fluid handling is no exception. Flo Fast pumps are integrating these advancements by offering predictive maintenance. Imagine sensors in your pump relaying real-time performance data, allowing you to address potential problems before they lead to downtime.

This proactive approach maximizes operational efficiency and reduces maintenance costs, extending the lifespan of your equipment. This is especially valuable for industries with continuous operation, such as wastewater treatment plants.

Sustainability-Focused Design

Sustainability is a major focus across industries. Flo Fast is incorporating this into its pump designs by developing energy-efficient models and exploring eco-friendly materials.

Some Flo Fast pumps utilize variable frequency drives (VFDs), which optimize energy consumption based on actual demand. This results in lower electricity bills and a reduced carbon footprint, a significant benefit for environmentally conscious businesses and boat owners.

Adapting to Evolving Demands

As industries require greater efficiency and remote capabilities, Flo Fast systems are evolving. They now include features like remote monitoring and control, enabling management from anywhere with an internet connection. This is particularly useful in remote locations or for overseeing multiple pump systems.

Enhanced process integration allows Flo Fast pumps to seamlessly connect with other industrial systems, creating a more automated and efficient workflow.

Development Roadmaps for the Future

Flo Fast has a clear vision for the future. Their development roadmap includes ongoing investment in smart technologies, improved energy efficiency, and advanced materials. These innovations will benefit current users and pave the way for new applications.

For instance, Flo Fast is researching the integration of artificial intelligence (AI) to further improve predictive maintenance and optimize pump performance based on real-time conditions. This commitment to innovation positions Flo Fast pumps as a leader in the fluid handling industry. By staying ahead of the curve, Flo Fast aims to provide solutions that meet the changing needs of industries, businesses, and individuals.

Separating Hype From Real Value

The constant influx of new technologies can make it difficult to discern real value. When evaluating pump technologies, focus on metrics that directly affect your bottom line.

This means looking beyond marketing and analyzing data on energy efficiency, reliability, and maintenance requirements. Consider the total cost of ownership, including energy consumption, repairs, and downtime. Understanding the long-term financial implications helps you make informed decisions. Whether for a boat or a complex industrial process, choosing the right pump can significantly influence your success.

Ready to experience the future of fluid handling? Learn more about how CLiX Fueling Solutions, powered by Flo Fast pump technology, can transform your boating experience by visiting CLiX Fueling Solutions.