Navigating Marine Gas Tank Types: What Experts Don't Tell You

Choosing the right marine gas tank isn't as simple as grabbing the first one you see. It involves considering several factors, from the tank's material and type to its size and how it's installed. Understanding these nuances can greatly impact your boating experience.

Types of Marine Gas Tanks: Portable vs. Permanent

One of your first decisions will be between a portable and a permanent tank. Portable tanks offer flexibility for smaller boats or occasional use. They're easy to transport and refill, making them ideal for short trips. However, their capacity is often limited.

Permanent tanks, conversely, are designed for larger vessels and hold more fuel. They can be divided into built-in and replaceable types. Built-in tanks are integrated into the boat's structure, maximizing space but requiring professional installation and replacement.

Replaceable permanent tanks offer a compromise between convenience and capacity. They allow for upgrades or replacements without significant structural changes.

Material Matters: Aluminum, Plastic, and Stainless Steel

Your tank's material significantly impacts its durability, performance, and safety. Aluminum tanks are lightweight and corrosion-resistant, making them a common choice.

Plastic tanks are also lightweight and rust-resistant, but may not be as durable as metal. Stainless steel tanks offer the most robustness and corrosion resistance, but they are more expensive.

This trade-off is reflected in the expanding marine fuel tank market. Valued at about $4.12 billion in 2022, the market is projected to reach $5.98 billion by 2030, with a 6.2% annual growth rate. This growth is partly due to fuel storage technology advancements for meeting emission standards. Learn more about marine fuel tank market growth.

To help you compare these materials, the following table breaks down their properties and best uses:

Marine Gas Tank Material Comparison A comparison of different marine gas tank materials highlighting their properties, advantages, and suitable applications.

| Material | Weight | Durability | Corrosion Resistance | Cost | Best For |

|---|---|---|---|---|---|

| Aluminum | Light | Good | Excellent | Moderate | General boating |

| Plastic | Light | Fair | Excellent | Low | Small boats, dinghies |

| Stainless Steel | Heavy | Excellent | Excellent | High | Offshore boating |

As the table highlights, each material offers a unique balance of cost, durability, and weight. Aluminum provides a good middle ground, while plastic prioritizes lightweight construction, and stainless steel emphasizes longevity.

Deciphering Certifications and Construction

Not all marine gas tanks are made equally. Look for certifications, like those from the American Boat and Yacht Council (ABYC), which ensure the tank meets safety and quality standards.

Quality construction features, such as double-walled designs or internal baffles, enhance safety and reduce fuel sloshing. These features are increasingly important as maritime trade expands and demands larger, more efficient tanks. For more information, check out these boating resources.

Visualizing the Impact of Material Choices

The data chart below visually compares aluminum, plastic, and stainless steel tanks across weight, durability, and corrosion resistance.

As the chart clearly shows, aluminum offers a good balance of weight and durability, while stainless steel excels in durability but is heavier. Plastic provides the lightest option, however, it has the lowest durability. The chart illustrates the trade-offs associated with each material, enabling boaters to make informed choices based on their individual needs.

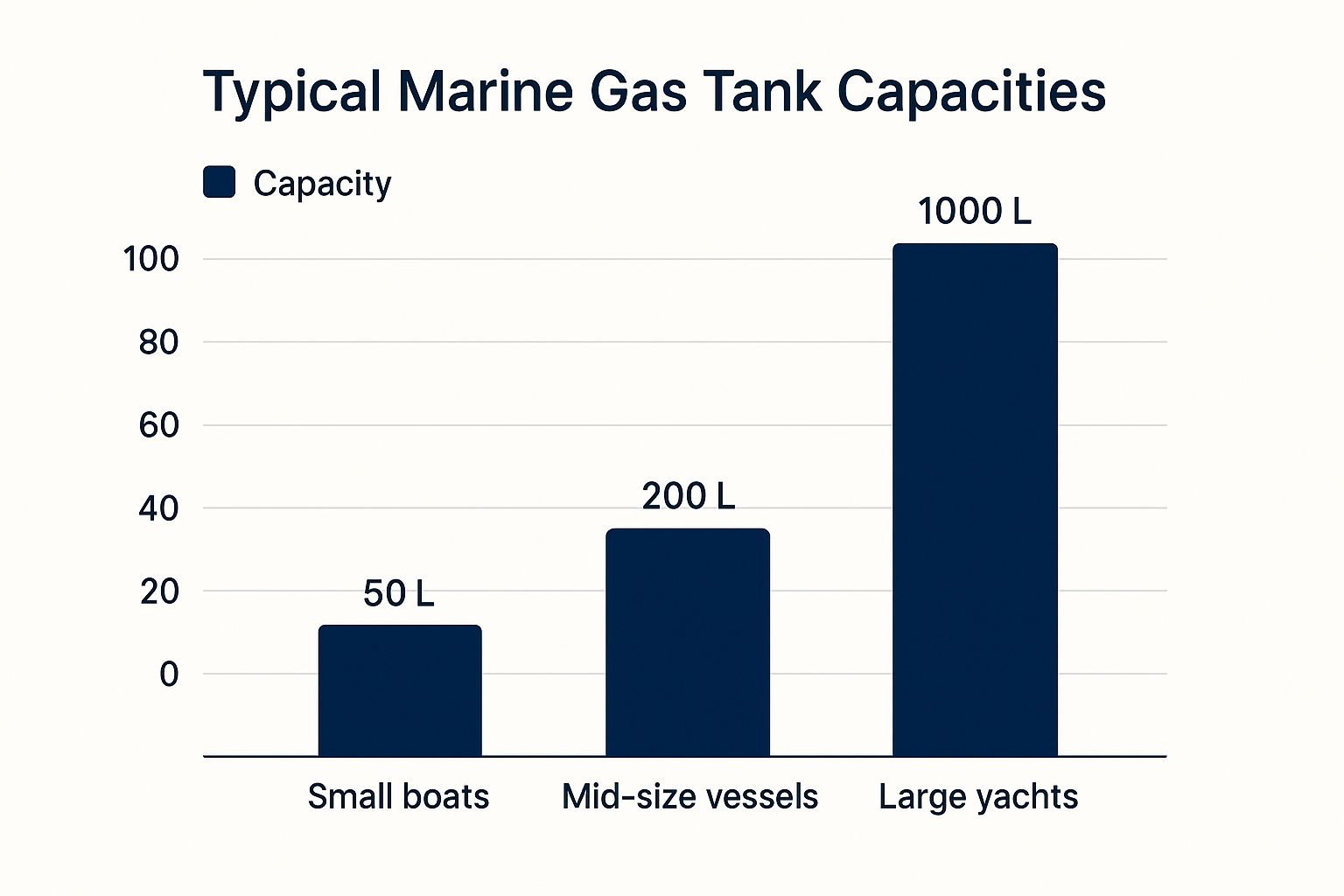

Sizing Your Marine Gas Tank: Beyond the Basic Calculations

Figuring out the right marine gas tank size is about more than just crunching numbers. Manufacturer recommendations offer a good starting point, but they don't always reflect how you'll actually use your boat. This often leads boaters to choose tanks that are either too big, wasting precious space, or too small, restricting their time on the water.

Why Bigger Isn't Always Better

Many boaters assume that the largest tank is the best choice. However, an oversized tank adds extra weight, which can impact fuel efficiency, performance, and even boat stability. This is especially true for smaller vessels. Plus, fuel left sitting unused can break down over time, potentially causing engine issues.

Matching Tank Size to Boating Style

Think about your typical boating trips rather than simply maximizing capacity. How far do you usually travel? Are you a day tripper or do you prefer longer voyages? A smaller tank might be sufficient for someone who mainly fishes close to shore. On the other hand, offshore anglers or those who enjoy extended cruises will need a greater fuel capacity.

Fuel Consumption: A Key Factor

Knowing your boat's fuel consumption rate is essential for selecting the right tank size. This rate depends on things like engine size, hull design, and speed. Keep track of your fuel usage on several trips to get a realistic estimate. This will help you choose a tank that gives you plenty of range without being unnecessarily large.

Global marine fuel consumption trends also play a role in tank design and capacity. The marine fuel market is expected to grow significantly due to increased maritime trade and the move towards alternative fuels. This growth requires bigger and more efficient tanks to meet the demands of the shipping industry.

Innovative Tank Configurations

Modern tank designs provide smart solutions for making the most of available space. Saddle tanks, for example, are designed to fit the shape of the hull, saving space in tight areas. Bladder tanks are flexible and can be placed in unconventional locations. These options allow you to optimize fuel storage without sacrificing other design features.

Resale Value: Thinking Long-Term

The size and type of your marine gas tank can influence your boat's resale value down the line. While a huge tank may not be necessary for you now, it could appeal to future buyers who plan on longer trips. A well-chosen tank can be a real selling point, demonstrating both practicality and extended range. This makes proper tank sizing not just a matter of current needs, but also a smart long-term investment.

Installation Secrets: Making Your Marine Gas Tank Truly Secure

Proper installation of your marine gas tank is crucial for both performance and safety. It's not just about following the basic instructions; it's about understanding the nuances that prevent fuel system issues. This means thinking beyond the manufacturer's recommendations and applying techniques used by experienced professionals.

Positioning Your Marine Gas Tank for Optimal Performance

Where you place your marine gas tank impacts weight distribution and how easily you can access it. Incorrect placement can create instability, reduce fuel efficiency, and make maintenance a real headache. Ideally, position the tank low in the boat near the centerline. This improves stability and minimizes rocking.

Accessibility is also key. The tank should be easy to reach for inspections, refills, and any necessary repairs. This might involve custom solutions, depending on your boat's layout.

Mounting Methods That Withstand Rough Seas

Securing your marine gas tank is critical, particularly in rough conditions. If the tank isn't mounted correctly, it can move around, stressing fuel lines and potentially causing leaks. Use sturdy mounting brackets and straps specifically designed for marine use.

Over-tightening straps can damage the tank, while loose straps allow movement. Finding the right balance requires careful attention and regular checks. It's similar to securing cargo – too tight can cause damage, too loose and it shifts during transport.

Ventilation Strategies to Prevent Vapor Buildup

Proper ventilation is essential to prevent the buildup of flammable fuel vapors, a serious safety hazard. Good ventilation also regulates pressure inside the tank, which prevents leaks and ensures proper fuel flow. This requires installing vents that allow air to circulate while keeping water out.

Think about the airflow around the tank. Obstructions can restrict ventilation and increase the risk of vapor buildup. Experienced installers often design custom ventilation systems tailored to the boat's design.

Electrical Grounding: Eliminating Ignition Risks

Electrical grounding is crucial to prevent sparks that can ignite fuel vapors. A correctly grounded system directs stray electrical currents away from the tank, reducing the risk of fire. This involves connecting the tank to the boat's grounding system with marine-grade wiring and connectors.

The importance of a strong grounding system can't be overstated. It's a critical safety measure protecting against potentially disastrous outcomes. It's like a lightning rod on a building, providing a safe path for electrical discharge.

Learning from Installation Disasters

Real-world examples of faulty installations demonstrate the importance of these principles. Improperly secured tanks have broken free in rough seas, causing significant damage and posing safety threats. Inadequate ventilation has also led to explosions from ignited fuel vapors.

By understanding these potential problems and following the recommended installation procedures, you can ensure a safe and dependable fuel system. This proactive approach protects your investment and ensures safe and enjoyable boating for years to come. Take your time and pay attention to the details – don't rush the installation process. A properly installed marine gas tank is the foundation of a safe and enjoyable boating experience.

Building a Bulletproof Marine Fuel System Around Your Tank

A marine gas tank is just one component of a larger, more complex fuel system. Building a reliable and robust system requires careful consideration of each part, from the tank itself to the fuel lines, filters, and monitoring systems. This is precisely how professional boat builders design fuel systems capable of withstanding the harsh marine environment for years to come.

Choosing the Right Fuel Lines: Material and Diameter

Fuel lines are essential; they're the arteries of your fuel system. Selecting the correct material is critical. Standard rubber fuel lines deteriorate quickly when exposed to ethanol-blended fuels. This often leads to cracks and leaks. Marine-grade fuel hose, designed for ethanol resistance, offers better durability and a longer lifespan.

The diameter of your fuel lines also significantly impacts engine performance. A fuel line that's too narrow restricts fuel flow, which can starve the engine and decrease performance. On the other hand, a line that’s too wide can cause pressure drops and inefficient fuel delivery. Choosing the correct diameter is essential for optimal engine operation.

Water Separators and Fuel Filters: Essential Protection

Water separators and fuel filters are the kidneys of your fuel system, removing contaminants and water that can harm your engine. Water separators extract water from the fuel, preventing corrosion and engine damage. Fuel filters trap dirt and debris that can clog injectors and affect engine efficiency.

Quality varies across water separators and fuel filters. Some offer minimal protection, providing a false sense of security. High-quality filters with a fine micron rating offer the best protection. Investing in high-quality filtration is a wise decision for the long-term health of your engine.

Marine Fuel Monitoring Systems: Staying Ahead of Problems

Modern marine fuel monitoring systems are more than just simple fuel gauges. They provide real-time data on fuel levels, consumption rates, and potential contamination problems. These systems help prevent unexpected fuel shortages and provide early warnings of issues requiring attention.

This technology is increasingly important as global marine fuel consumption trends influence tank design and capacity. The Asia-Pacific region, for instance, accounts for the largest share of marine fuel tank demand. This is driven by its position as a global manufacturing hub. In 2020, the region handled 532.7 million TEU (twenty-foot equivalent units) in container throughput, representing 65% of global volume. Investments in LNG-compatible tanks, designed to meet increasingly strict emissions regulations, further reinforce this regional dominance. Learn more here.

Troubleshooting Fuel Delivery Problems: An Insider’s Guide

Even well-maintained fuel systems can experience problems. Understanding how to troubleshoot these issues is critical for every boater. Clogged filters, faulty fuel pumps, and air leaks in the fuel lines are common issues.

Many boaters misdiagnose these problems, which leads to unnecessary repairs and wasted time. Learning to identify the root cause saves time and money. This involves checking fuel pressure, inspecting fuel lines for leaks, and testing electrical connections. A systematic approach to troubleshooting ensures quick, effective solutions.

Keeping Your Fuel System in Top Shape: Best Practices

Maintaining your entire fuel system, not just the tank, is vital for reliable performance. This involves regular inspection and cleaning of fuel lines, filters, and other components. It also means using high-quality fuel and additives to prevent corrosion and keep the system clean.

By understanding your marine fuel system and following these guidelines, you can build a reliable setup that will keep you on the water, not in the repair shop. This translates to fewer headaches, more time enjoying your boat, and peace of mind knowing your fuel system is ready for anything.

Marine Gas Tank Maintenance That Actually Prevents Problems

Maintaining your marine gas tank is more than just a routine chore. For experienced boaters, proactive maintenance is the key to avoiding costly and time-consuming issues. This involves specific cleaning and inspection procedures based on your tank's material and the type of fuel you use. Doing so maximizes the tank's lifespan and ensures safe operation.

Seasonal Maintenance: A Proactive Approach

Just like your car, your boat's fuel system needs seasonal attention. Before you launch for the season, inspect all fuel lines and connections for leaks or cracks. This is particularly critical with ethanol-blended fuels, which can damage standard rubber fuel lines. Also, check your marine gas tank for any signs of corrosion or damage.

Mid-season, add a fuel stabilizer to prevent fuel degradation and maintain a clean system. For more information, check out this resource: more information on marine gas tank maintenance and fuel systems. At the end of the season, fill your marine gas tank completely. This minimizes condensation and helps prevent rust. It also reduces the chance of phase separation if you’re using ethanol blends.

Cleaning Techniques for Different Tank Materials

Cleaning your marine gas tank requires the right approach for the specific material. Aluminum tanks, for instance, can react poorly with certain cleaning products, while plastic tanks need gentler methods. Harsh chemicals can damage seals and gaskets, leading to leaks.

To help guide your cleaning process, take a look at the maintenance schedule below:

Marine Gas Tank Maintenance Schedule Recommended maintenance intervals and tasks for marine gas tanks based on usage frequency and environment

| Maintenance Task | Pre-Season | Mid-Season | Post-Season | Every 2-3 Years | Special Conditions |

|---|---|---|---|---|---|

| Inspect fuel lines and connections | X | X | X | If fuel smell detected | |

| Check tank for corrosion/damage | X | X | After grounding or collision | ||

| Add fuel stabilizer | X | If storing fuel long-term | |||

| Fill tank completely | X | Before long periods of non-use | |||

| Clean tank (see material-specific instructions) | X | X | If contaminated fuel suspected | ||

| Inspect/replace fuel filter | X | X | If engine sputtering or slow fuel flow |

This table summarizes the recommended maintenance tasks for different times of the year and under special conditions. Remember to consult your owner's manual for specific recommendations for your boat and tank.

Early Warning Signs and Simple Inspection Routines

Catching potential issues early saves you time and money in the long run. Be alert for signs like slow fuel flow, a sputtering engine, or a strong fuel smell. These could point to a leak, a clogged filter, or a failing fuel pump. Regularly checking fuel lines, filters, and connections can prevent minor problems from escalating.

A simple inspection, taking just a few minutes, can prevent thousands of dollars in repairs. This is especially true for newer boats with complex fuel injection systems. It’s similar to regularly checking your car’s tire pressure—a small, proactive step that can avoid major issues down the line.

Ethanol-Blended Fuels and Changing Maintenance Requirements

Ethanol-blended fuels are now commonplace, but they require adjustments to your maintenance routine. Because ethanol attracts water, it increases the risk of corrosion in your marine gas tank. It can also degrade fuel system components faster than pure gasoline. This means more frequent filter changes and using ethanol-compatible fuel lines and fittings.

DIY vs. Professional Service

Many maintenance tasks are manageable for the average boater. However, some jobs, like repairing a leaky tank or replacing a fuel pump, need specialized skills and equipment. Knowing when to call a professional is essential. Attempting complex repairs beyond your ability can worsen the damage and create more problems. Just like home repairs, you can handle basic tasks, but major projects often call for a qualified professional.

By following these maintenance tips, you can extend the life of your marine gas tank, prevent costly repairs, and ensure years of safe and enjoyable boating. While this proactive approach requires some effort, it’s a worthwhile investment that keeps your boat on the water and out of the repair shop.

Navigating Environmental Regulations for Marine Gas Tanks

Environmental compliance is more than just avoiding penalties; it's about protecting our waterways and the future of recreational boating. This means understanding the sometimes complicated rules surrounding marine gas tanks and adopting practices that minimize our impact on the environment.

Understanding the Regulatory Landscape

Regulations for marine gas tanks vary by location and the type of vessel you own. These rules often focus on preventing fuel spills and reducing emissions. For instance, some regions have strict requirements for tank materials and ventilation systems, while others emphasize spill prevention and response procedures. Staying informed about these regulations is a key part of responsible boat ownership.

Adapting to Evolving Standards

Environmental regulations are always changing, and they generally tend to become stricter over time. Boaters who think ahead are proactively adapting to these changes, viewing them as opportunities to improve their boat's performance and value. This might involve upgrading to more eco-friendly tank materials or investing in advanced fuel systems that minimize emissions.

Emerging Tank Technologies: Reducing Environmental Impact

New tank technologies are constantly being developed to reduce the environmental impact of boating. Double-walled tanks, for example, offer an extra layer of protection against leaks, while vapor recovery systems capture fuel vapors that would otherwise be released into the air. These advancements benefit both the environment and boat owners.

You can find more information about marine gas tank maintenance and other related topics at: Additional information about marine gas tank maintenance and related topics.

Preventing and Managing Fuel Spills: Best Practices

Even with the latest technology, accidents can still occur. Being prepared for a fuel spill is essential. Smart boaters always have absorbents, spill containment booms, and a fuel spill kit readily available on board. Knowing how to use these tools quickly and effectively can significantly limit environmental damage from a spill.

Regular maintenance and inspection are your first line of defense. Checking for leaks, ensuring proper ventilation, and keeping the tank clean can prevent spills before they happen. Just like regular car maintenance prevents breakdowns, regular boat maintenance prevents environmental hazards and keeps your boat running smoothly.

Alternative Fuels: Changing Tank Requirements

The growing use of alternative fuels, such as biodiesel and propane, is changing tank requirements. These fuels often require specialized tanks made from materials compatible with the specific fuel. Understanding these requirements is essential for boaters considering a switch to alternative fuels.

Modifications for alternative fuels should be done carefully, taking into account your vessel type and how you use it. For example, converting a large diesel engine to run on biodiesel could require significant changes to the fuel system, including the tank. Likewise, using propane for a smaller outboard motor will need a different type of tank and fuel delivery system.

Choosing Modifications That Make Sense

Not every modification is necessary or beneficial for every boat. The best approach depends on several factors, including the size and type of your vessel, how you use it, and the specific regulations in your area. A small recreational boat used for day trips on a lake, for example, may not need the same level of environmental protection as a large commercial fishing vessel operating in sensitive coastal waters.

Talking with marine professionals can help you choose the most suitable modifications for your needs. They can evaluate your current setup, suggest appropriate upgrades, and ensure that any changes comply with regulations. This personalized approach helps you avoid unnecessary costs while maximizing the environmental benefits of your modifications.

Make fueling effortless and eco-friendly with CLiX Fueling Solutions! Eliminate spills, protect your boat, and contribute to a healthier marine environment. Learn more at CLiX Fueling Solutions.