Think of an automatic fuel shut off valve as the ultimate emergency brake for your boat's fuel line. If a fire breaks out in the engine room or a major leak occurs, this critical device instantly cuts the fuel supply from the tank. It’s what stops a small problem from turning into a full-blown disaster. For any modern boater, this isn't just an accessory; it's an absolute necessity.

Understanding This Critical Safety Device

Your boat’s fuel tank is a reservoir of power, but let's be honest—it's also a significant risk, especially with gasoline. An automatic fuel shut off valve acts as the vigilant gatekeeper between that tank and your engine. Its job is simple: make sure fuel only gets through when everything is safe.

Without one, a fire in the engine compartment has a direct, open line to the fuel tank. That’s a recipe for a terrifying situation on the water, turning a manageable fire into an uncontrollable inferno in seconds.

Why It’s More Than Just a Switch

It's easy to look at this valve and think of it as a simple on/off switch, but that misses the point entirely. This is an automated failsafe. Unlike a manual valve you have to remember to turn in a moment of sheer panic, this one is wired to your boat's ignition or a fire suppression system. It takes human error out of the equation when you need it most.

The entire purpose of an automatic fuel shut off valve is to prevent or minimize a few key dangers:

- Engine Fires: It immediately chokes off the fuel supply, starving the fire. This dramatically boosts the effectiveness of your fire extinguisher and buys you precious time to get everyone to safety.

- Fuel Leaks: If a fuel line breaks, the valve can be triggered to stop the flow. This prevents gallons of flammable liquid from pooling in your bilge, which averts both a fire hazard and an environmental mess.

- Post-Accident Risks: After a collision or another incident that kills the engine, the valve automatically ensures the fuel supply is cut, securing the boat from a secondary fire.

Think about it this way: industrial safety systems, which operate on similar principles, have shown that the ability to remotely shut down a system is crucial. One study noted that failing to control fuel flow can have "disastrous consequences." That warning is just as true on a 30-foot boat as it is in a massive factory.

At its core, this one component offers constant, tireless protection. It doesn’t wait for you to react. It acts the instant it's triggered, making it one of the most important safety upgrades any responsible boat owner can install.

Absolutely. Here is the rewritten section, crafted to sound like it was written by an experienced boater and marine expert.

How These Essential Safety Valves Work

So, what's really happening inside one of these valves to keep your boat safe? It’s actually a pretty clever and simple system. The whole thing is built around a single, non-negotiable principle: shut off the fuel instantly when something goes wrong, without you having to do a thing.

Think of it like an electric gatekeeper for your fuel line. This gatekeeper—the valve itself—is wired directly into your boat's ignition. When you turn the key, you're not just getting the engine ready to start; you're also sending a small electrical current to the valve. This current powers a little electromagnet, called a solenoid, which pulls back a plunger and opens the gate. Fuel can now flow freely to the engine.

The magic happens the moment the power is cut. Turn the key off, and that electrical signal vanishes. The electromagnet deactivates, and a spring instantly shoves the plunger back into place, slamming the gate shut. The fuel flow stops dead in its tracks.

The Fail-Safe in Action

This "normally closed" design is what makes it a true safety device. Its natural, unpowered state is shut. It has to be actively told to open and needs a constant electrical current to stay that way.

This is a game-changer in an emergency because it automatically handles the most common disasters:

- Engine Fire: If a fire breaks out and melts the wiring, the power to the valve is cut. The valve slams shut, starving the fire of more fuel.

- Electrical Short: A sudden short or a dead battery also cuts the power, closing the valve and preventing fuel from flooding a non-running engine.

- You in a Panic: Even just turning the ignition off in a hurry is enough. The system is secured without a second thought.

In short, if anything interrupts the power from the ignition, the fuel supply is automatically cut off. You don't have to remember to flip a switch or turn a handle when every second counts.

The demand for this kind of safety-first engineering is growing everywhere. The fuel outlet valve market, which is a close cousin to what we're talking about, was valued at around $2.5 billion and is expected to grow by 5% each year. This is all driven by a worldwide push for safer, more efficient systems. If you're curious about the numbers, you can read the full market report to see the trends.

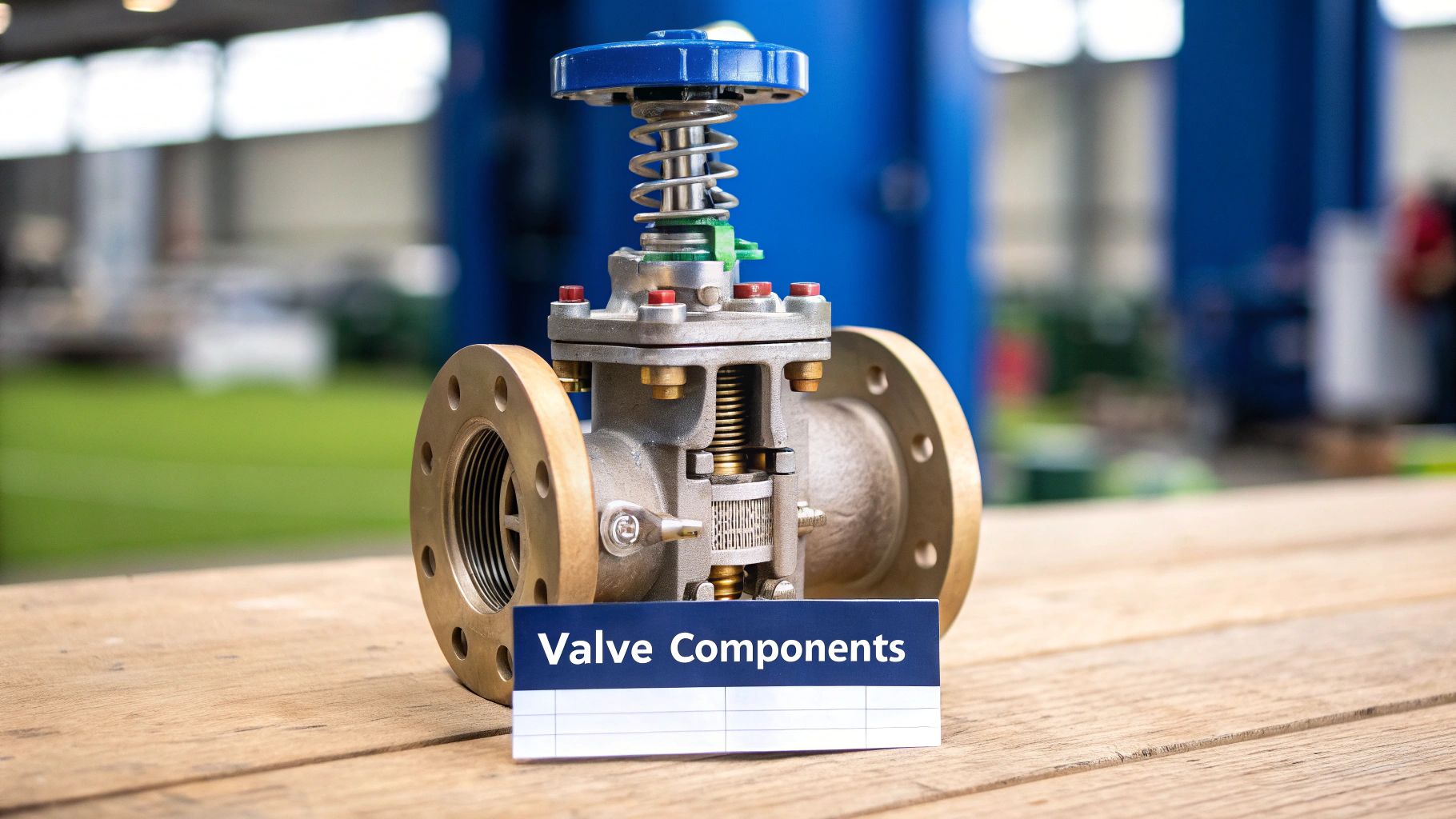

The Two Parts That Make It Work

It helps to know the two main components to really get it.

1. The Solenoid: This is the electrical trigger. It's a coil of wire that, when juiced up by your ignition, creates a magnetic field. That magnetic force is what pulls the plunger back and opens the valve, fighting against a spring that's trying to keep it closed.

2. The Valve Body: This is the physical gate. It’s the sturdy metal housing (usually brass or stainless steel) that contains the plunger and spring assembly. This is the part that actually blocks the fuel.

Put them together, and you have a beautifully simple system. The solenoid gets the "go" signal from the ignition, and the valve body does the heavy lifting. The instant that signal disappears—for any reason at all—the entire system snaps back to its safest state: closed.

Key Benefits for Every Boat Owner

When you install an automatic fuel shut off valve, you're not just bolting on another gadget. You're making a serious upgrade to your boat's safety and reliability. The payoff goes well beyond the valve itself—it brings peace of mind, helps you meet regulations, and can even make your boat more valuable.

The biggest benefit, without a doubt, is proactive fire prevention. An engine room fire is every boater's nightmare. If a fire starts, an open fuel line acts like a fuse, feeding the flames directly from your tank. What could have been a small, manageable fire can quickly become a full-blown catastrophe.

An automatic shut off valve instantly cuts off that fuel supply at the source. It starves the fire, buying you and your crew critical time to deploy extinguishers or, if necessary, abandon ship safely.

More Than Just Fire Safety

But it's not all about worst-case scenarios. These valves offer some really practical advantages that you'll appreciate during routine ownership. They give you a new layer of control over your entire fuel system.

Here are a few of the key perks:

- No More Spills: Ever tried to change a fuel filter and ended up with a bilge full of stinking, hazardous fuel? With this valve, you can shut the fuel off right from the helm before you even pick up a wrench. No mess, no fumes, no environmental harm.

- Stay Compliant (and Save Money): Many marine insurance companies and safety bodies, like the American Boat and Yacht Council (ABYC), either require or strongly recommend these valves, especially for inboard gasoline engines. Being compliant can often lead to lower insurance premiums.

- Boost Your Resale Value: When it's time to sell, a boat loaded with modern safety features really stands out. An automatic fuel shut off valve shows a potential buyer that the boat was owned by someone who cared and didn't cut corners on safety.

Think of this device as an investment in proactive safety. It turns your fuel system from a simple set of pipes and tanks into a smart network that can protect itself—and you—when every second counts.

A Growing Standard in Safety Technology

The idea of automatically stopping the flow of a dangerous substance in an emergency isn't new. It’s a proven safety concept used across many industries, especially as power systems get more complex.

For example, look at the market for hydrogen shut-off valves. They do the same job for highly flammable hydrogen gas. That market is expected to more than double, hitting $2.5 billion. This trend shows just how vital automated safety tech has become.

Ultimately, a reliable automatic fuel shut off valve is a non-negotiable part of a well-run boat. It works quietly in the background, giving you a layer of protection every time you leave the dock. To learn more about how this fits into the bigger picture, check out our complete modern guide to boat fuel management systems.

Choosing the Right Fuel Shut Off Valve

Picking the right automatic fuel shut off valve isn't just about grabbing a part off the shelf. It's about finding the perfect safety match for your boat's specific fuel system. They aren't all the same, and knowing what to look for is key to getting reliable, long-term protection on the water.

Your first major decision comes down to how the valve works. You'll run into two main types: normally open (NO) and normally closed (NC). Just think about what the valve does when it has no electrical power. An NO valve is open by default and needs power to close it, while an NC valve is closed by default and needs power to open.

For any marine fuel system, a normally closed (NC) valve is the only safe choice. This design is what we call "fail-safe." If there's an electrical fault, a wire gets cut, or you simply turn off the ignition, the power is lost. When that happens, the valve instantly snaps shut, stopping the fuel flow right in its tracks. An NO valve would do the exact opposite, which is the last thing you want in an emergency.

Matching the Valve to Your Fuel System

Okay, so you know you need a normally closed valve. The next step is making sure it's a perfect fit for your boat. An improperly matched valve can cause all sorts of headaches, from restricting fuel flow and starving your engine to just not sealing properly.

Here are the key things you need to look at:

- Valve Size and Fuel Line Diameter: The valve's size has to match the inner diameter of your fuel line. A valve that's too small creates a bottleneck and restricts fuel. One that's too big won't seal correctly. Always measure your fuel line before you buy.

- Material Compatibility: The material the valve is made of really matters. Brass is a solid, common choice that works well for both gasoline and diesel. But if you're in a harsh saltwater environment, stainless steel is the superior option for maximum corrosion resistance.

- Ignition Protection Rating: This one is absolutely non-negotiable. Any electrical part installed in an engine compartment with a gasoline fuel system must be "ignition protected." This means it’s built to prevent any internal sparks from igniting fuel vapors in the air.

Choosing a valve without an ignition protection rating for a gasoline engine bay is an extremely dangerous mistake. It introduces a source of ignition right where you need to prevent one, defeating the entire purpose of the device.

To get a better handle on how this all fits together, our guide to the complete boat fuel system can give you a deeper look into how all the components work in harmony.

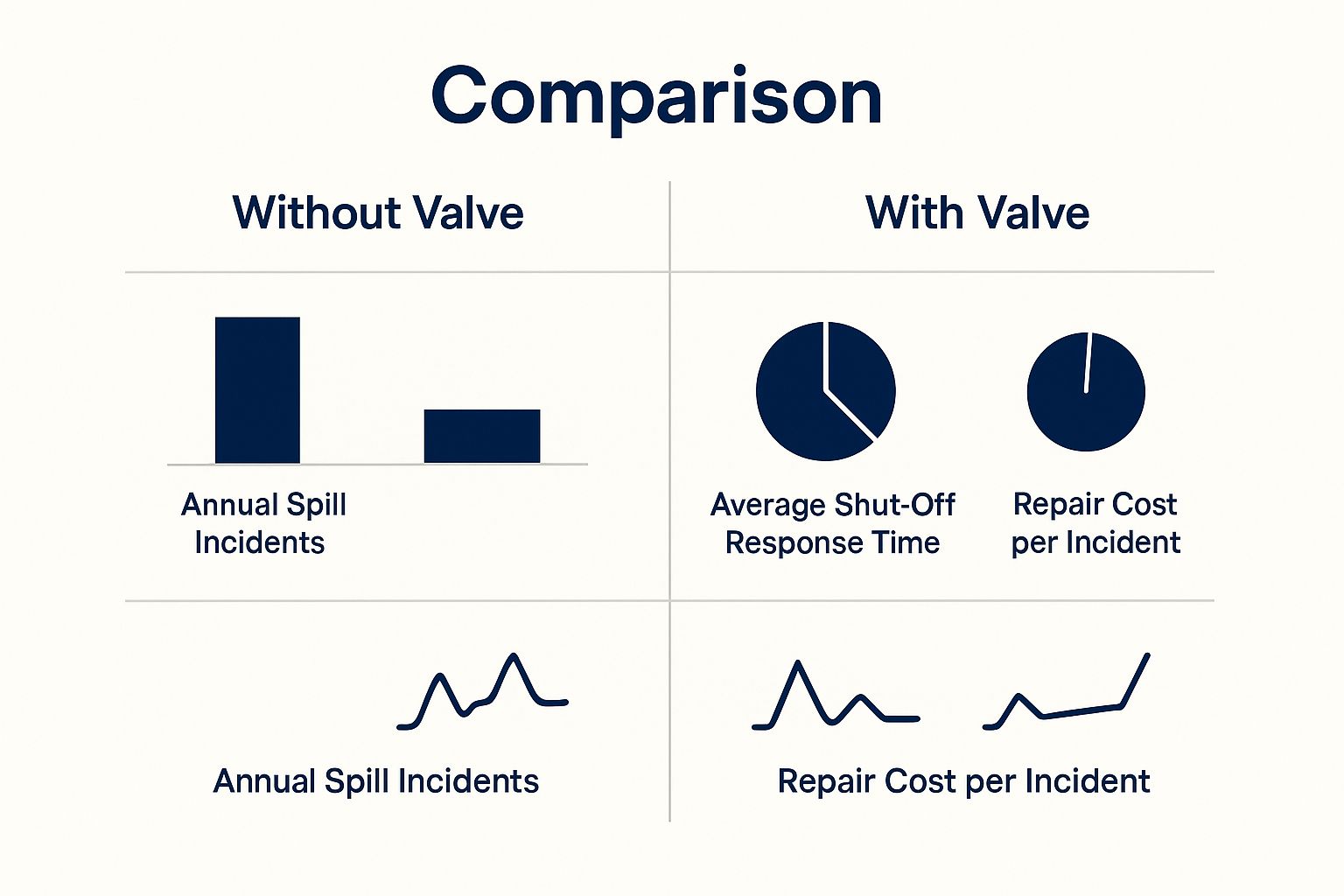

This image below really drives home the safety improvements an automatic valve brings to the table. It compares some key metrics for boats with and without this simple but vital piece of equipment.

As you can see, the data is pretty clear. Installing a valve makes a huge difference in reducing incident rates and the overall financial sting of any fuel-related accident.

Comparison of Automatic Fuel Shut Off Valve Types

To make sense of the options, it helps to see them compared directly. The table below breaks down the common types of automatic fuel shut off valves based on how they work and where they fit best in a marine setting.

| Valve Type | Operating Principle | Best For | Key Consideration |

|---|---|---|---|

| Normally Closed (NC) Solenoid | Uses an electric current to hold the valve open; closes when power is cut. | All marine fuel systems. This is the standard for safety. | Fail-safe design is critical for preventing fuel leaks during power loss or emergencies. |

| Normally Open (NO) Solenoid | Uses an electric current to close the valve; opens when power is cut. | Industrial processes where flow is needed during a power failure. | Unsafe for boats. It would allow fuel to flow freely in an emergency. |

| Motorized Ball Valve | A small electric motor physically turns a ball valve to open or close it. | Larger fuel lines or systems where slow, controlled closure is desired. | Slower to operate than a solenoid, which might be a factor in a fast-developing emergency. |

Ultimately, for most recreational boats, the Normally Closed (NC) solenoid valve is the go-to choice. It's fast, reliable, and provides the essential fail-safe protection every boater needs.

By carefully checking these points—solenoid type, size, material, and ignition protection—you can confidently pick the perfect automatic fuel shut off valve. This small step ensures the device will work flawlessly when you need it most, giving you true peace of mind on the water.

Safe Installation and Simple Maintenance Tips

Knowing how an automatic fuel shut-off valve works is great, but installing it correctly is what really counts. This is where you turn safety theory into a practical reality on your boat. Whether you're a hands-on boater or hiring a pro, getting the installation right is crucial for the valve to do its job when an emergency strikes. A proper setup, followed by easy, routine maintenance, is your ticket to long-term peace of mind on the water.

Getting the Installation Right

The single most important decision you'll make during installation is placement. The valve needs to be installed on the fuel line as close to the fuel tank as you can possibly get it. Why? This drastically shortens the length of unprotected fuel line. If a leak or break happens anywhere downstream, the valve can stop the flow right at the source.

Another detail that's easy to miss but absolutely critical is the fuel flow direction. Look closely at the body of the valve—you'll see a small arrow. This arrow shows the direction fuel needs to travel, from the tank toward the engine. If you install it backward, your engine won't get a drop of fuel. Always double-check this before you tighten things down.

Critical Safety Measures Before You Begin

Anytime you work with your boat's fuel and electrical systems at the same time, you have to be extra cautious. Before you even think about touching a wire or a fitting, follow these non-negotiable safety steps.

- Disconnect All Power: The very first thing to do is disconnect the boat's battery completely. This removes any chance of a stray spark igniting fuel fumes.

- Ensure Good Ventilation: Work in an open, well-ventilated space. Pop open all the hatches and consider using a fan to keep the air moving and clear out any vapors.

- Have a Fire Extinguisher Ready: Keep a Class B fire extinguisher within arm's reach. You have to be prepared.

A study on automated tank systems highlighted that vulnerabilities can lead to disastrous consequences, including physical damage and environmental hazards. This is a stark reminder of why a flawless installation is so vital—it’s your first and best defense against system failure.

Wiring the valve is the final step. You’ll want to wire the valve’s solenoid to a circuit that only gets power when the ignition is in the "On" position. This ensures the valve opens when you start the boat and closes the second you turn the key off or if the boat loses electrical power. For more in-depth advice, check out our guide with more marine fuel shut off valve safety installation tips.

A Simple Maintenance Checklist

Your automatic fuel shut-off valve doesn't ask for much, but a little regular attention will keep it ready for action. Think of this quick check as part of your pre-departure routine. It only takes a minute.

-

Listen for the "Click": With the engine off, turn your ignition key to the "On" position (don't start the engine). You should hear a clear, sharp click as the solenoid opens the valve. Turn the key back to "Off," and you should hear it click shut. No click? That's your cue to check the wiring.

-

Inspect for Leaks: Give the valve and the fittings around it a good look. Do you see any dampness, weeping, or fuel stains? Even a tiny leak is a big problem that needs to be fixed immediately.

-

Check Electrical Connections: Take a peek at the wiring connected to the valve. Make sure it's snug and free of corrosion. The saltwater environment is tough on electrical parts, so clean off any gunk with a wire brush and protect the terminals with a little dielectric grease.

Answering Your Top Questions

Even after getting a good handle on how these valves work, it's normal to have a few more questions pop up. Let's dive into some of the most common things boaters ask about these vital safety devices. Getting these details sorted out will help you feel confident about keeping your vessel safe on the water.

We'll cover everything from legal requirements and DIY installation to troubleshooting tips. The goal is to give you the practical knowledge you need to make smart decisions for your boat's safety and reliability.

Is an Automatic Fuel Shut Off Valve Required on My Boat?

This is easily one of the most common questions, and the short answer is: it depends. While there isn't always a universal law, major safety organizations like the American Boat and Yacht Council (ABYC) have standards that pretty much make them a requirement for inboard gasoline engines. For any inboard engine, including diesel, they're considered an essential best practice for preventing fires.

Your best bet is to check your local marine regulations. Just as important, pull out your insurance policy. Many insurance companies understand what a huge safety upgrade these valves are and will often offer premium discounts for boats that have one properly installed.

Can I Install a Fuel Shut Off Valve Myself?

If you're genuinely skilled with both marine fuel lines and electrical systems, you could tackle this yourself. But this is one job where you need to be extremely careful. A small mistake during installation can cause a dangerous fuel leak or an electrical short—the exact problems the valve is designed to stop.

Because this is such a critical piece of safety equipment, we strongly recommend hiring a certified marine technician. A pro install gives you peace of mind that the valve will work flawlessly when you need it most. When you're talking about fire prevention, your safety is worth the investment.

A study on automated industrial systems found that vulnerabilities can lead to disastrous consequences, including physical damage and environmental hazards. This is a powerful reminder that for any automated safety device, a flawless, professional installation is your best defense against failure.

What Does "Normally Closed" Mean for a Valve?

This term simply describes the valve’s default state when it has no power. A "normally closed" (NC) valve is shut, blocking any fuel from flowing, until electricity is sent to open it. This is the gold standard for marine fuel safety because it’s a true fail-safe design.

Think of it like this: if your boat loses all electrical power, or if you kill the ignition in an emergency, the power to the valve is cut. It instantly snaps back to its natural "closed" position, immediately stopping fuel from leaving the tank.

How Can I Test If My Valve Is Working?

Testing your valve should be a quick, regular part of your pre-departure checklist. It's easy to do.

- With the engine completely off, turn your ignition key to the "On" position (but don't crank the engine).

- Listen carefully. You should hear a distinct "click" from the engine compartment as the solenoid gets power and opens the valve.

- Now, turn the key back to "Off." You should hear another "click" as the power cuts and the spring closes the valve.

If you don't hear those clicks, the first thing to check is the electrical connections for corrosion. If they look clean and the valve still isn’t working, it’s a good sign the valve itself needs to be replaced.

For a truly stress-free and spill-free fueling experience, look no further than CLiX Fueling Solutions. Our innovative system automatically stops the nozzle when your tank is full, preventing dangerous and costly overfills. Learn more about how you can protect your boat and the environment.