Let’s talk about a simple piece of gear that solves one of the most common, frustrating problems at the fuel dock: the diesel nozzle adapter. In a nutshell, it's a connector that bridges the gap between those huge commercial fuel nozzles and the smaller fuel fill on your boat. It creates a secure, leak-proof seal, turning a potentially messy job into a clean, stress-free top-up.

The Frustrating Problem of Fuel Spills at the Dock

Every boater has been there. You pull up to the fuel dock, ready for a quick fill, and find yourself wrestling with a high-flow commercial nozzle that looks like it was made for a semi-truck, not your recreational vessel.

Trying to carefully angle that beast into your boat’s smaller deck fill is a recipe for disaster. The result is almost always the same: a sudden gush of diesel overflows, staining your deck, polluting the water, and wasting expensive fuel.

This isn't just an annoyance; it’s a real safety hazard. A slippery, diesel-coated deck is an accident waiting to happen. Plus, nobody wants to be the one responsible for that rainbow sheen spreading across the marina.

The Simple Solution to a Common Headache

This is exactly where a diesel nozzle adapter comes in. Think of it as the missing puzzle piece—a sturdy connector that creates a perfect, spill-proof seal between the oversized pump nozzle and your boat's fuel inlet. It completely eliminates the size mismatch that causes all the trouble.

The demand for practical solutions like this is booming. The fuel nozzle adapter market was valued at around USD 1.2 billion in 2023 and is expected to nearly double by 2032. That kind of growth shows just how many people are looking for safer, more reliable fueling equipment.

Key Takeaway: A diesel nozzle adapter is a small investment that prevents costly fuel waste, protects the marine environment, and makes every trip to the fuel dock safer and far less stressful.

This handy tool ensures every drop of fuel goes where it’s supposed to: your tank. It's especially crucial when dealing with older pumps that might have unreliable auto-shutoff features, where overfills are far more likely. If you're curious about how those mechanisms work, you can learn more about the mechanics of a fuel nozzle auto shut off.

At the end of the day, maintaining a safe fueling system is a core part of responsible boat ownership. Keeping your entire diesel system compliant is vital, and that includes everything from proper fueling procedures to certified appliances. You can even get official boat diesel oil appliance certificates to ensure everything is up to code. An adapter is a small but critical part of this safety-first mindset.

How a Diesel Nozzle Adapter Actually Works

Think of a diesel nozzle adapter as a universal translator. On one side, you have the high-flow, large-diameter commercial fuel nozzle found at a truck stop or marina. On the other, you have your boat’s much smaller, standard-sized deck fill. They simply don't speak the same language.

The adapter acts as the perfect go-between. It’s a precisely engineered piece of hardware that fits snugly into your boat’s fuel inlet, creating a secure port for the oversized commercial nozzle to dock into. This simple but brilliant design forms a sealed bridge, allowing fuel to flow freely without any messy spills or blow-back.

By making this perfect connection, the adapter lets you transfer fuel at incredible speeds—often up to 25 gallons per minute or even more. It safely channels that powerful flow directly into your tank, turning what could be a chaotic, frustrating mess into a quick and controlled process.

The Anatomy of a Spill-Proof Connection

The real magic of a diesel nozzle adapter is how its key components work together. Every part has a specific job, all focused on creating a leak-proof seal and a secure fit. This creates a system you can truly rely on every time you refuel.

Here’s a quick look at the critical parts:

- The Adapter Body: This is the main piece, usually made from tough materials like anodized aluminum or stainless steel. It gives the adapter the strength to handle the pressure and weight of a heavy commercial fuel nozzle.

- The Deck Fill Interface: One end is machined to the exact diameter of your boat’s fuel inlet (like 1.5" or 2"). This ensures a tight, wobble-free fit when you pop it into the deck.

- The Nozzle Receptacle: The other end is flared out to perfectly accept the high-flow nozzle. It guides it smoothly into place and provides a stable connection point.

- High-Quality O-Rings: These might be the most important part of the whole setup. These rubber or synthetic seals create an airtight and fuel-tight barrier, stopping any diesel from escaping around the connection points.

A well-designed adapter doesn't just connect two different sizes. It creates a pressurized, sealed system that forces every single drop of fuel exactly where it needs to go—into your tank. It takes all the guesswork and the mess out of fueling up.

From Mismatch to Perfect Match

Try to fuel without an adapter, and you know the drill. The massive nozzle rests awkwardly on the edge of the fuel fill, leaving big gaps where diesel can easily splash out. The adapter closes this gap completely. Once you insert it, it sits flush with your deck fill, and the O-rings compress to form that perfect seal.

For a deeper dive into how it all comes together, you can check out our complete guide on the diesel fuel nozzle adapter.

When you then slide the high-flow nozzle into the adapter, a second seal is formed. This double-sealed system contains the entire fuel path from the pump to your tank. Now, when you squeeze the trigger, the diesel has only one place to go: straight down. The adapter effectively turns a problematic mismatch into a flawless, custom fit every single time.

Here’s the rewritten section, designed to sound like an experienced human expert sharing practical advice.

So, Why Do You Actually Need One of These Things?

At first glance, a diesel nozzle adapter looks like a simple chunk of metal. It’s easy to dismiss it as just another gadget. But trust me, for anyone who runs a diesel boat, this little tool solves some of the biggest headaches you'll face at the fuel dock. It’s a game-changer for safety, your wallet, and the environment.

The most immediate problem it solves? Messy, expensive, and dangerous fuel spills. You know the drill: you’re trying to wrangle a high-speed commercial pump nozzle into your boat’s small deck fill, and whoosh—diesel goes everywhere. It eats away at your gelcoat, stains your teak, and creates a disgusting sheen on the water. An adapter creates a solid, sealed connection, so every single drop goes where it’s supposed to: your tank.

It’s About More Than Just a Clean Deck

By stopping spills, an adapter starts saving you money right away. Diesel isn't cheap, and those little "oops" moments at the pump add up fast over a season. With a diesel nozzle adapter, you can be sure that the fuel you're paying for is actually making it into your boat, not sloshing around on deck.

This leads directly to the most important benefit: safety. A deck slick with diesel is an accident waiting to happen. It's incredibly slippery, and a fall on a moving boat is no joke. Not to mention, fuel spills are a serious fire hazard. Keeping the diesel in the tank makes refueling a clean, predictable, and much safer routine for you and your crew.

A good adapter turns a messy, wasteful chore into a clean, efficient process. It's one of the smartest, simplest upgrades you can make to protect both your boat and the people on it.

The Freedom to Fuel Up Anywhere

Here’s the benefit most people overlook: an adapter gives you options. You’re no longer stuck paying inflated marina prices for fuel. With the right adapter, the world of commercial truck stops opens up to you.

These places almost always sell diesel for significantly less per gallon. For a boat with a large tank, the savings can be huge on a single fill-up. This flexibility means you can shop around for the best price, which is a big deal when you remember diesel packs more punch—around 36.9 MJ/liter of energy. As engine technology has improved, so have the nozzles that deliver the fuel, and an adapter is your key to connecting to them all, a trend noted in market reports on the growth of diesel nozzle technology.

When you boil it down, this small investment delivers some seriously big returns.

- You Protect the Water: No more accidental diesel spills polluting the marina.

- You Save Money: Every drop of expensive fuel goes directly into your tank.

- You Stay Safe: A clean, dry deck means no slip-and-fall hazards or fire risks.

- You Gain Freedom: Fill up at less expensive commercial truck stops, not just marinas.

How to Choose the Right Diesel Nozzle Adapter

Not all adapters are created equal, and picking the right one is the secret to a perfect, spill-free fit every time you pull up to the fuel dock. Think of it like using the right wrench for a specific bolt—the correct size and material make all the difference between a smooth job and a frustrating mess. Nailing this choice from the get-go will save you a ton of time and aggravation down the line.

When you start shopping for a diesel nozzle adapter, you'll find they're usually made from one of two materials: anodized aluminum or stainless steel. Each has its pros and cons in a harsh marine setting, so figuring out which is best for you is the first step.

Material Matters for Durability

Anodized aluminum is a popular choice because it's lightweight, strong, and generally easier on the wallet. The anodizing process adds a tough, protective layer that fights off corrosion from salt spray and diesel fuel, making it a great all-around option for most boaters.

On the other hand, stainless steel is the top-of-the-line, premium choice. It's heavier and will cost you more, but its ability to resist corrosion is second to none. If you spend most of your time in saltwater or just want the toughest, longest-lasting solution possible, stainless steel is often worth the extra investment. It's built to take years of abuse.

Pro Tip: Whatever material you choose, make sure the adapter has high-quality, fuel-resistant O-rings. These little seals are what actually prevent leaks, so their quality is absolutely critical for a reliable connection.

Comparing Diesel Nozzle Adapter Materials

To make the decision a bit easier, it helps to see how these two common materials stack up against each other in the real world. This table breaks down their strengths and weaknesses to help you pick the right one for your boat and how you use it.

| Material Type | Pros | Cons | Best For |

|---|---|---|---|

| Anodized Aluminum | Lightweight, corrosion-resistant, and more affordable. | Can be more susceptible to scratches and dings over time. | Most recreational boaters in freshwater or mixed environments. |

| Stainless Steel | Extremely durable and offers superior corrosion resistance. | Heavier and more expensive than aluminum options. | Boaters in harsh saltwater environments or for heavy commercial use. |

Ultimately, both are solid choices, but stainless steel offers that extra peace of mind for those who demand the absolute best in a saltwater environment.

Finding the Perfect Fit for Your Boat

Material is only half the battle; you also have to match the adapter to your boat's specific deck fill. The most important measurement is the diameter of that fill. Most recreational boats in North America have either a 1.5-inch or a 2-inch deck fill, so grab a ruler and measure yours before you buy. An adapter that’s too loose will just wobble and leak, while one that’s too tight won't fit at all.

Beyond the perfect fit, look for a couple of key features that separate a good adapter from a great one. A built-in tether or a spot to attach a lanyard is a must-have. You'd be surprised how many adapters end up at the bottom of the marina. This simple feature can save you the headache and cost of buying a replacement.

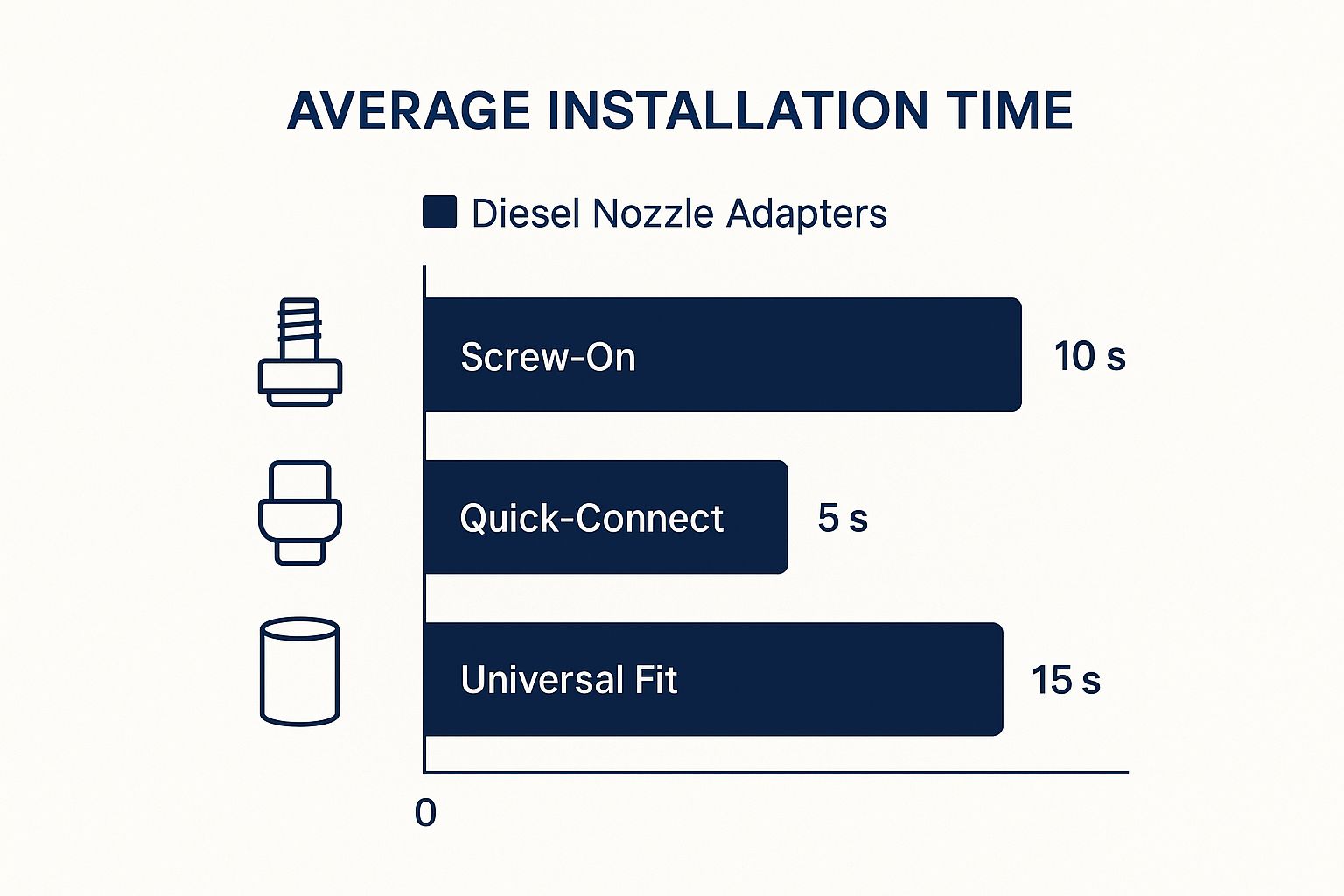

As you can see, the time difference isn't huge, but every second counts when you're trying to get back out on the water. By keeping material, size, and these handy features in mind, you can confidently choose the perfect diesel nozzle adapter for your vessel.

Getting it Right: Using and Maintaining Your Adapter

Having a great diesel nozzle adapter is only half the battle. To truly get a clean, spill-free fill-up every time, you need to use it correctly and give it a little TLC. A few simple habits will ensure this handy tool remains a reliable part of your boating gear for years.

The most important thing to check? The O-rings. Before you even head to the pump, give those little rubber seals a quick once-over. Look for any cracks, nicks, or signs that they’re drying out. A damaged O-ring is almost always the culprit behind a messy fuel leak.

Your Pre-Fueling Checklist

Taking a few seconds to prep at the dock can save you from a major cleanup headache. Think of it as your pre-flight check for fueling.

- Check the O-Rings: Make sure they're in good shape and pliable. A quick wipe with a clean rag gets rid of any dirt or grit that could compromise the seal.

- Get a Snug Fit: Firmly insert the adapter into your boat’s deck fill. It should sit flush against the opening and feel secure—no wobbling allowed.

- Ease Into It: Even with a perfect fit, don't just jam the fuel nozzle in and squeeze the handle full-throttle. Start the flow slowly, watch for any drips, and then ramp up the speed once you're sure everything is sealed tight.

This careful approach is well worth it. Diesel is incredibly energy-dense, packing about 15% more energy per liter than gasoline. That’s a key reason diesel engines are so efficient, and it’s what drives the demand for high-quality fueling gear, as shown in reports on global diesel injector nozzle markets.

Post-Fueling Care and Storage

Once the tank is topped off, you’re not quite done. What you do next is just as important as the prep work.

After pulling the adapter out, wipe it down with a dedicated rag to remove any leftover diesel. This simple step keeps fuel from dripping on your beautiful deck or stinking up a storage locker. Tuck it away in a clean, dry place—a small pouch or case is perfect for protecting it from dings and dirt. This also prevents you from accidentally introducing contaminants into your fuel tank next time.

For more on keeping your fueling process clean, take a look at our guide on choosing the right fuel funnel for your boat.

Key Maintenance Tip: If an O-ring ever looks brittle or damaged, replace it right away. They’re cheap and easy to find. This tiny bit of upkeep is the secret to keeping your adapter working like new and guaranteeing a spill-free experience for the long haul.

Got Questions? We've Got Answers

Even with all the info, you probably still have a few questions rolling around in your head. That's perfectly normal. To make sure you feel totally comfortable, we’ve gathered the most common questions we get from boaters just like you.

Let’s clear up those last few details so you can head to the fuel dock with confidence.

Is There a "One-Size-Fits-All" Diesel Nozzle Adapter?

Great question, but the short answer is no. While the whole point is to fit any standard high-speed diesel nozzle, the adapter itself has to be a perfect match for your boat’s deck fill. Most boats out there have either a 1.5-inch or a 2-inch fuel inlet, and your adapter needs to match that size exactly.

Think of it like a socket wrench—you need the right size socket for the bolt. A good, snug fit is what creates that leak-proof seal. Before you buy anything, take a quick measurement of your deck fill. It's the only way to guarantee a solid, wobble-free connection.

Can I Use a Diesel Adapter with a Gasoline Nozzle?

Definitely not. This is a huge safety issue. Diesel nozzle adapters are built specifically for diesel systems and the larger nozzles you find at diesel pumps. Gas nozzles are designed to be smaller for a very important reason: to stop you from accidentally pumping gasoline into a diesel tank.

Safety First: Don't ever try to force a gas nozzle into a diesel adapter. Misfuelling isn't just a simple mistake; it can destroy your engine and create a serious fire risk. The two systems are incompatible by design to keep you safe.

What if the Fuel Nozzle Feels Too Loose or Too Tight?

If the connection doesn't feel right, don't force it. A loose fit is just asking for a spill, and a super-tight fit could damage the pump nozzle or your adapter. It’s not common, but you can run into this with older equipment at the dock.

Here’s what to do:

- Check for Grime: Take a look at the pump nozzle and inside your adapter. Is there any dirt or debris gumming things up? Sometimes a quick wipe is all it takes.

- Inspect the O-Rings: A worn-out O-ring on your adapter can cause a sloppy fit. If it looks cracked, brittle, or flattened, it’s time for a new one.

- Try Another Pump: If you've checked everything else, the issue might just be that specific nozzle. If there's another pump available, give that one a try instead.

How Often Should I Replace the O-Rings?

There's no hard-and-fast rule here, since it really depends on how often you're fueling up. The best habit to get into is giving the O-rings a quick visual check every time you use the adapter. You're looking for any signs of cracking, brittleness, or wear.

As a good rule of thumb, just plan on replacing them at the start of each boating season. O-rings are cheap and take seconds to swap out. A little bit of proactive maintenance is the best way to make sure your diesel nozzle adapter is always ready to give you a perfect, spill-free seal.

Ready to make fueling your boat simpler, cleaner, and safer? CLiX Fueling Solutions offers a premium diesel nozzle adapter designed for durability and a perfect fit, ensuring every drop of fuel goes where it belongs.

Discover the CLiX difference and end fuel spills for good at clixfueling.com