At its core, a marine fuel level sensor is a device built to do one thing exceptionally well: measure the exact amount of fuel in your vessel's tank. But to call it just a gauge would be a massive understatement. This instrument is a cornerstone of modern boating, giving you the hard data you need for safety, efficient fuel use, and preventing messy, expensive spills.

Why Modern Fuel Sensors Are Essential for Your Vessel

Let's be honest. Relying on an old-school, swinging-arm fuel gauge is a bit like navigating with a map where half the details are smudged. You get a general idea of where you stand, but it’s far from the reliable information you need for making smart decisions on the water.

This is where a modern marine fuel level sensor completely changes the game for any serious mariner.

Think of it this way: a basic gauge is a rough estimate. It swings around with the boat's movement and can be wildly inaccurate. A modern sensor, on the other hand, is like a dedicated financial advisor for your fuel tank. It delivers real-time, precise data that lets you run your vessel with more confidence, safety, and efficiency. It’s the leap from approximation to precision that defines professional-grade vessel management.

The Pillars of Modern Fuel Monitoring

The true value of a quality marine fuel sensor comes down to a few core benefits that directly impact every single trip you take. These aren't just small tweaks; they fundamentally change how you manage your boat's most vital resource.

- Unwavering Safety: The most immediate payoff is ditching the constant worry of running out of fuel. Knowing your exact level means you won't get stranded at sea—a situation that can go from inconvenient to dangerous in a heartbeat.

- Significant Cost Savings: When you have precise data, you can start optimizing your fuel burn. You’ll learn your boat’s most efficient cruising speeds, spot potential fuel leaks or even theft early, and stop wasting money by overfilling at the dock.

- Environmental Responsibility: Fuel spills aren't just bad practice; they're a serious environmental hazard. Modern sensors are key to preventing embarrassing and damaging overfills, helping you protect our waterways and comply with regulations.

For any vessel operator, a modern sensor transforms fuel from a constant worry into a managed asset. It's the difference between guessing and knowing—and that's everything when you're miles from shore.

This move toward data-driven fuel management isn’t a luxury. For anyone who wants to get the most out of their time on the water while cutting down on risk and operating costs, it’s a necessity.

A quality sensor gives you a clear, constant, and reliable picture of your fuel status, so you can focus on the journey. It's this foundation that systems like CLiX Fueling Solutions build upon, adding another layer of security by automatically preventing spills before they can even happen.

Here is the rewritten section, crafted to sound more natural and human-written.

How Do Marine Fuel Level Sensors Actually Work?

Ever look at your fuel gauge and wonder how it really knows how much is left in the tank? It's not magic, but a clever bit of engineering designed to give you a reliable reading, whether you're cruising on a calm bay or navigating choppy seas.

At its core, a marine fuel level sensor acts like a translator. It takes a physical measurement—the height of the fuel in the tank—and converts it into an electrical signal your helm display can understand and show you as a simple percentage or volume.

This process starts the second the sensor is installed. The main job is to detect the surface of the fuel and how it changes. While there are a few different ways to do this, the goal is always the same: create a consistent, measurable signal that directly reflects the amount of fuel you have left.

The Signal's Journey: From Tank to Helm

Think of it as a tiny, high-speed communication network. In the blink of an eye, information travels from deep inside your tank right to the dashboard in front of you.

Here’s how that quick journey breaks down:

- Detection: First, the sensor, which sits inside the tank, uses its specific technology to find the fuel's surface. This could involve sound waves, electrical fields, or even magnetic floats.

- Conversion: That physical measurement is instantly turned into a raw electrical signal. This might be a change in resistance or capacitance that fluctuates perfectly with the fuel level.

- Processing: Onboard electronics, either inside the sensor itself or in a small connected module, clean up this signal. This is crucial for filtering out the "noise" caused by fuel sloshing around, giving you a stable, accurate reading.

- Transmission: Finally, the refined signal is sent through a wire to your gauge or multifunction display.

The whole system is built for one thing: reliability. When you're miles from shore, that little number on your screen needs to be something you can trust implicitly.

Making Sense of the Tech: Two Simple Analogies

Technical concepts can get a little dense, so let’s break down two popular sensor types with some real-world comparisons.

A great marine fuel sensor is designed to be the most trustworthy voice on your vessel, giving you unwavering accuracy in an environment of constant motion, vibration, and corrosive fuel.

Ultrasonic Sensors: The Bat in Your Tank

You know how a bat navigates in total darkness? It sends out a high-frequency chirp and listens for the echo. By timing how long it takes for the sound to bounce back, it builds a precise map of its surroundings.

An ultrasonic fuel sensor does the exact same thing.

- It’s mounted at the very top of the tank, pointing down.

- It sends out a quick pulse of sound that travels through the air gap, hits the surface of the fuel, and bounces right back up.

- The sensor’s internal clock measures the round-trip time of that echo.

Since we know the speed of sound, the sensor can calculate the distance to the fuel with incredible accuracy. Subtract that distance from the tank’s total height, and voilà—you have a precise fuel level. Best of all, there are no moving parts to get stuck or wear out.

Capacitive Sensors: The Invisible Ruler

This one is a bit more abstract, but stick with me. Imagine two metal tubes, one inside the other, running the full height of your tank. A capacitive sensor sends a tiny, safe electrical charge through them, creating an electrical field in the space between.

Now, fuel and air affect this electrical field differently. Fuel has what’s called a higher dielectric constant than air.

As your fuel level rises, it pushes the air out from between the tubes. This changes the overall electrical properties of that space, which the sensor measures as a change in capacitance. The sensor's electronics read that change and translate it into a super-precise fuel level. It's like an invisible ruler measuring your fuel from top to bottom.

Comparing the Different Types of Fuel Sensors

Choosing the right marine fuel level sensor isn't about grabbing the most expensive one off the shelf. It’s about finding the right tool for the job—matching the technology to your boat, your tank, and your needs. Not all sensors are built the same, and understanding what makes each one tick is the key to investing wisely in your vessel's safety and reliability.

Let's look at the most common types you'll find on the market. Think of this as a quick guide to help you find the perfect match.

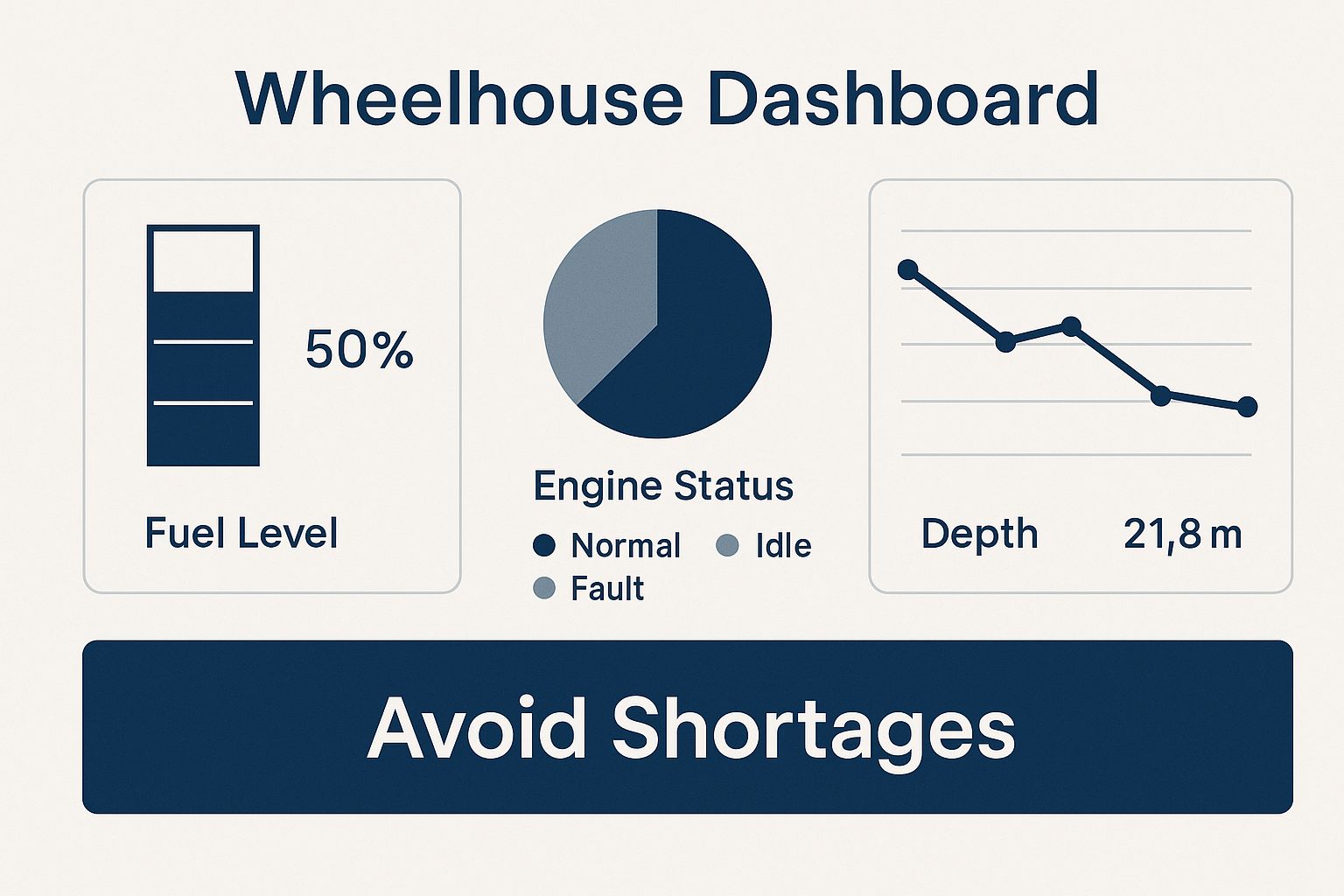

This kind of real-time dashboard data is exactly what separates guessing from knowing. It’s the difference between a great day on the water and a preventable headache.

The Modern Workhorse: Ultrasonic Sensors

Just like a bat using echolocation, ultrasonic sensors send out a sound wave from the top of the tank. They measure the time it takes for the echo to bounce off the fuel's surface and return. This non-contact approach is their biggest superpower.

Because there are zero moving parts, nothing can physically break, wear out, or get gunked up by fuel sludge. This makes them incredibly durable, especially in the rough-and-tumble marine world. For boaters who want a "set it and forget it" solution, these are tough to beat.

The Precision Instrument: Capacitive Sensors

Capacitive sensors are another excellent option with no moving parts, known for their pinpoint accuracy. Imagine two probes running through the tank. The fuel between them acts as a dielectric, and as the level rises or falls, it changes the sensor's electrical capacitance. This change is then translated into a very precise reading on your gauge.

Their strength is delivering steady, continuous measurements that don't get thrown off by fuel sloshing around. It's crucial, however, to maintain a clean boat fuel system, as debris and water can sometimes interfere with their readings.

Comparison of Marine Fuel Sensor Technologies

To make the choice clearer, here’s a straightforward comparison of the main sensor technologies. This table lays out what each type does best, so you can quickly see which one aligns with your priorities, whether that's unmatched accuracy, rugged durability, or a budget-friendly price point.

| Sensor Type | Operating Principle | Key Advantage | Best For |

|---|---|---|---|

| Ultrasonic | Measures distance to fuel surface using sound waves. | Non-contact, no moving parts, extremely durable. | Harsh environments; boaters prioritizing reliability and long life. |

| Capacitive | Measures changes in electrical capacitance as fuel level changes. | High precision, no moving parts, stable readings. | Applications needing top-tier accuracy; works with various fuel types. |

| Reed Switch | A magnetic float moves up and down a sealed tube, activating switches. | Electronics are sealed away from fuel; good durability. | Recreational boats looking for a reliable, cost-effective upgrade. |

| Resistive | A float arm moves a wiper across a variable resistor. | Very low cost, simple and traditional design. | Basic or older setups where budget is the primary concern. |

Ultimately, the best sensor is the one that gives you peace of mind. By understanding these core differences, you can select the technology that provides the right balance of performance and value for your vessel.

The Time-Tested Choice: Reed Switch Sensors

Reed switch sensors offer a clever and dependable float-based design. A float containing a magnet slides up and down a sealed central tube as the fuel level changes. Inside that tube, a series of tiny sealed switches (the "reed switches") are lined up. As the float's magnet passes by, it closes a switch, which tells your gauge what the fuel level is.

Because all the delicate electronics are safely sealed away from the corrosive fuel, this design is quite robust. It strikes a great balance between durability and affordability, making it a very popular choice for all kinds of recreational boats.

The Traditional Option: Resistive Sensors

You’ll find resistive sensors in many older or more basic boats—they’ve been the standard for a long time. They work with a float on a swinging arm, which is connected to a variable resistor. As the float moves, the arm sweeps across the resistor, changing the electrical signal sent to the gauge.

While they are certainly the most budget-friendly option, their main weakness is the exposed mechanical parts. The wiper arm is in constant contact with the resistor, and over time, this friction causes wear and tear. That mechanical contact can lead to jumpy readings or outright failure, which is why many boat owners today are upgrading to more modern, non-contact sensors for better long-term reliability.

The Real-World Benefits of Accurate Fuel Monitoring

Upgrading your boat's fuel monitoring system isn't just about swapping out an old gauge. When you invest in a modern marine fuel level sensor, you're getting tangible benefits that pay you back in improved safety, real cost savings, and much easier environmental compliance. Think of it as a single piece of gear that transforms how you manage your most vital resource on the water.

The most immediate and critical payoff is a huge boost in safety and peace of mind. Out at sea, guesswork is your enemy, especially when it comes to fuel. An old, unreliable gauge that swings wildly with every wave forces you to constantly second-guess your range, creating a lot of unnecessary stress and risk.

Knowing your true fuel level is everything. It helps you avoid the kind of trouble that leaves you searching for answers on what to do if you run out of gas at sea. With precise, real-time data, you can plan your voyages with confidence, knowing exactly how much fuel you have and how far you can really go. This lets you focus on enjoying the journey, not obsessing over your tank.

Drive Down Costs and Boost Efficiency

Beyond safety, a high-quality fuel sensor is a serious financial tool. For any vessel, fuel is one of the biggest operating expenses, and the only way to get a handle on those costs is with accurate data.

When you know exactly how much fuel is in your tank at all times, you open up a few smart ways to save money:

- Optimize Fuel Burn: Tracking your real-time usage helps you dial in your boat's most efficient cruising speed and RPM. You'll end up saving fuel on every single trip.

- Prevent Fuel Theft: Sudden, unexpected drops in your fuel level become glaringly obvious. This helps you spot potential siphoning or a hidden leak before it turns into a major loss.

- Perfect Your Refueling: Stop playing the overfill-and-spill game at the fuel dock. An accurate reading tells you exactly how much fuel you need, preventing costly spills and making sure you only pay for what your tank can actually hold.

Whether you're a weekend boater or a commercial captain managing a whole fleet, these small savings add up fast. The sensor gives you the hard data you need to make smarter financial decisions.

Meet Environmental Regulations with Ease

We all share the responsibility of protecting our marine environments, and modern fuel sensors are a surprisingly big part of that effort. Fuel spills are not just messy and destructive; they can also lead to steep fines and cleanup bills.

A precise fuel level sensor is your first line of defense against accidental overfills. It turns what was a risky guessing game into a controlled, spill-free process.

Systems like CLiX Fueling Solutions take this protection a step further by automatically shutting off the fuel nozzle the moment the tank is full, creating a nearly foolproof barrier against spills.

This proactive approach to spill prevention is becoming more critical across the industry. In fact, in 2023, the market for marine sensors focused on fuel and propulsion systems held the second-highest share by application. This shows just how much pressure there is to improve efficiency and reduce environmental harm. An accurate fuel sensor is the foundation for hitting both of those goals, making it easier than ever to be a good steward of the water.

How to Choose and Install Your New Fuel Sensor

So, you’re ready to upgrade to a better, more reliable fuel sensor. Good call. Moving from an old, guesswork-prone gauge to a modern sensor isn't just a minor tweak—it’s about gaining real confidence on the water. It gives you the accuracy you need for safer, more efficient boating right from the start.

But choosing the right sensor isn't a one-size-fits-all deal. A few key factors come into play, and getting them right ensures you end up with a device that works perfectly for your vessel for years to come. Think of it as a quick pre-flight check before you buy.

Let's walk through what to look for when selecting your new sensor and then take a high-level look at what the installation involves.

Selecting the Perfect Sensor for Your Vessel

Before you click "buy," take a minute to think about your boat's specific setup. The best marine fuel level sensor is one that fits seamlessly into your current system and can handle the unique conditions of your tank.

Here are the big things to consider:

- Tank Material and Shape: What’s your tank made of? Aluminum, stainless steel, or plastic? Is it a simple rectangle or a funky, irregular shape? Some sensors, like capacitive types, really shine in metal tanks. Ultrasonic sensors, on the other hand, are more versatile and can be calibrated for odd shapes and work with almost any material.

- Fuel Type: Most modern sensors handle both gasoline and diesel just fine, but it never hurts to double-check. The sensor's construction needs to stand up to whatever fuel you use without breaking down over time.

- Connectivity: How does the sensor talk to your helm? A lot of modern boats run on an NMEA 2000 network, which lets all your electronics chat with each other. Make sure the sensor you choose can connect to your display, whether that's a classic gauge or a slick multifunction display (MFD).

The goal here is simple: pick a sensor that feels like it was designed specifically for your boat. Matching these details up front will save you a world of installation headaches and make sure you get the accurate, trustworthy data you’re paying for.

Once you have these answers, you can confidently pick a technology—ultrasonic, capacitive, or reed switch—that matches what you care about most, whether it’s pinpoint accuracy or just rugged, long-lasting durability.

A High-Level View of the Installation Process

We always recommend following the manufacturer's instructions to the letter or hiring a certified marine tech to do the job. That said, understanding the basic steps can make the whole process feel less intimidating. This is for the seasoned DIY boater or anyone who just wants to know what’s going on.

First and foremost, a successful installation is a safe one. You're working around fuel, so you have to be extremely careful.

Key Safety Steps:

- Disconnect All Power: Before you touch anything, kill the power. Disconnect the boat's battery completely. This prevents any chance of a spark, which is the last thing you want near fuel.

- Ensure Maximum Ventilation: Open every hatch, port, and window you can. If you have a fan, use it to get fresh air circulating and clear out any fuel vapors. Those fumes are highly flammable.

- Prepare for Spills: Keep absorbent pads and a fire extinguisher right there with you. Even if you're careful, small drips can happen.

The installation itself involves pulling out the old sending unit, cleaning up the mounting surface, and carefully fitting the new sensor. You’ll need to get a perfect seal with the gasket to prevent any leaks. After that, it's a matter of wiring the new sensor to your display according to the manual. For a deeper dive, our guide on boat fuel sending unit setup and troubleshooting offers more detailed tips to get it just right.

In the end, a proper installation is the final piece of the puzzle, ensuring your new marine fuel level sensor gives you the performance and peace of mind you expect.

The Future of Fuel Management with Smart Technology

The humble marine fuel level sensor is undergoing a pretty incredible transformation. For decades, it was just a simple gauge showing you what was left in the tank. Now? It’s becoming the data-gathering heart of a smarter, more connected vessel.

This shift turns a passive dial into an active part of your boat's nervous system. It's the key that unlocks the future of intelligent marine operations, all powered by integrating that raw fuel data with advanced software like AI and machine learning. Instead of just telling you what you have now, these systems look ahead. They learn your boat’s specific fuel burn in different conditions—your speed, the choppiness of the water, the load you're carrying—to make some seriously accurate predictions.

The Rise of the Predictive Vessel

Imagine your boat not just reporting numbers, but actively helping you make better decisions on the water. That's exactly where this technology is headed. A modern fuel sensor, when hooked up to an intelligent platform, gives you powerful tools that used to be reserved for massive commercial fleets.

- Predictive Fuel Analytics: The system can forecast your fuel burn for an entire trip with impressive accuracy. No more range anxiety. You can plan your refueling stops with total confidence.

- Optimized Route Planning: By mixing fuel data with live weather and sea condition feeds, the system can suggest small tweaks to your route or speed that add up to big fuel savings.

- Proactive Maintenance Alerts: An intelligent system can spot subtle changes in fuel consumption that could signal an engine problem or a dirty filter, warning you about a potential issue long before it ruins your day.

This connected ecosystem turns your vessel from a collection of separate parts into a single, smart unit. Your fuel sensor is no longer just a gauge; it’s a critical data source powering a safer, more efficient, and more enjoyable boating experience.

Investing in a Connected Future

This isn't just a fleeting trend; it’s a major market shift. The global marine sensors market, which includes the marine fuel level sensor, was valued at USD 35.81 billion in 2024. It’s projected to rocket to USD 59.45 billion by 2034. A huge driver behind that growth is the push to integrate AI with sensor data to make boating more efficient and even autonomous.

Putting a modern, network-ready sensor on your boat today is a smart, strategic move. It gets your vessel ready for the next wave of tools that are becoming more accessible every year. By tapping into these technologies, you gain a level of control and insight that makes boating not only more fun but also more sustainable.

To get a head start, you can check out our expert strategies that cut costs in marine fuel management. It's the perfect way to position yourself for the future of highly efficient navigation.

Your Top Fuel Sensor Questions Answered

Diving into marine electronics can feel a bit overwhelming, and that's especially true when you're dealing with something as crucial as your fuel sensor. Getting straight answers is key to making the right choice for your boat. Let’s clear up some of the most common questions we hear from boat owners.

Think of this as your quick guide to understanding sensor tech, installation, and what to expect in terms of performance. Nailing these details means more confidence and less stress on the water.

What Is the Most Accurate Type of Fuel Sensor?

If you're looking for pinpoint accuracy, your best bet is either a capacitive or an ultrasonic sensor. These are a major leap forward from the old-school resistive-arm sensors, which are notorious for getting "jumpy" or just plain wrong as their mechanical parts wear out.

- Capacitive sensors work by measuring changes in an electrical field, giving you a smooth, continuous, and highly precise reading of your fuel level.

- Ultrasonic sensors take a different approach, using sound waves to measure the fuel from above without ever touching it. This makes them totally unaffected by sludge or corrosion.

While the perfect choice depends on your specific boat and budget, for pure, reliable accuracy, these two non-contact technologies are the leaders of the pack.

Can I Install a New Fuel Sensor Myself?

If you’re a seasoned DIY boater who’s comfortable with marine wiring and knows the safety rules for fuel systems like the back of your hand, then yes, you can probably handle the installation yourself. But it’s a job that demands your full attention.

Your absolute priorities are to kill all power to the boat, make sure the area is completely ventilated to clear out any fumes, and have a fire extinguisher within arm's reach. A mistake here could lead to a dangerous fuel leak or an electrical spark—two things you never want on a boat.

Honestly, if you have even the slightest doubt, hiring a certified marine technician is the smartest and safest move you can make.

How Long Does a Marine Fuel Level Sensor Last?

A sensor's lifespan really comes down to its type and the quality of its construction. A traditional resistive-arm sensor, with its moving float and arm, might only give you a few good years before wear and tear lead to unreliable readings.

On the other hand, modern sensors with no moving parts, like ultrasonic or capacitive models, are built to go the distance. With no mechanical components to rub, stick, or break, they can easily last for 10 years or more. They’re specifically designed to handle the tough marine environment—the constant vibration, saltwater, and temperature changes. It’s an investment that pays off in long-term reliability.

Ready to eliminate fuel spills and gain complete peace of mind at the dock? CLiX Fueling Solutions offers a stress-free, automatic shut-off system that prevents costly overfills. Protect your boat and the environment by exploring CLiX today.