Understanding Marine Fuel Shut Off Valve Systems

Marine fuel shut off valves are vital safety devices for any vessel. They act as the first line of defense against fuel leaks and potential fires. These valves quickly isolate the fuel supply, preventing a small issue from becoming a major disaster. Think of them like a circuit breaker in your home. When a fault occurs, the circuit breaker cuts off the electricity to prevent damage.

A marine fuel shut off valve works similarly, stopping fuel flow during an emergency. This seemingly simple mechanism can be the difference between a minor inconvenience and a major incident.

Why Are Marine Fuel Shut Off Valves Critical?

Fuel leaks in marine environments can have devastating consequences. A small spark can ignite spilled fuel, leading to a rapidly spreading fire. Fuel leaks also pose a significant environmental threat. They pollute waterways and can harm marine life. Marine fuel shut off valves mitigate these risks. They offer a fast and reliable way to stop fuel flow, which is particularly important in situations like collisions or groundings where fuel lines might be damaged.

Fuel tank shut-off valves are critical safety components in marine vessels, effectively protecting against fuel leakage and fire hazards. They isolate fuel tanks during emergencies. The global fuel tank shut-off valve market has annual sales estimated to be in the millions of units. More detailed statistics can be found here: Fuel Tank Shut-off Valve Market Report

How Do These Valves Enhance Safety?

These valves don't just react to emergencies. They also contribute to a safer overall boating experience. They allow you to isolate your fuel tanks during maintenance, for instance. This eliminates the risk of accidental spills.

Some modern marine fuel shut off valve systems integrate with other onboard safety systems. This allows for automated responses in critical situations. This integration can significantly improve the safety of your vessel and crew.

What Boat Types Benefit from Shut Off Valves?

Nearly every type of boat, from small recreational boats to large commercial vessels, benefits from the added safety of a marine fuel shut off valve. The size and complexity of the valve system will vary depending on the vessel's size and type. However, the core principle remains the same: prevent fuel leaks and protect against fire.

Understanding these systems and their importance helps you make informed decisions about your boat's safety equipment. This knowledge empowers you to choose the right valve for your specific needs and ensure its proper installation and maintenance.

Marine Fuel Shut Off Valve Types And Technologies

Choosing the right marine fuel shut off valve for your vessel is a critical decision. From simple manual levers to sophisticated automated systems, the technology has evolved significantly. Understanding the different types available, along with their strengths and weaknesses, is crucial for making an informed choice. This means considering not only the initial cost but also factors like response time, reliability, and how much maintenance is required.

Manual Valves

Manual valves, operated by a lever or handle, are the most basic type. Generally, they are the most affordable option. However, they require a crew member to physically activate them, which results in slower response times during emergencies. In situations demanding rapid fuel shut off, this delay can be a serious concern.

Pneumatic Valves

Pneumatic valves use compressed air for activation. They offer faster response times than manual valves and can be operated remotely, enabling quicker action in emergencies. However, they add complexity and potential maintenance requirements because they depend on a compressed air system.

Electro-Hydraulic Valves

Electro-hydraulic valves combine the speed of electronic controls with the power of hydraulics. They provide the fastest response times among common valve types, which is essential for containing fires or fuel leaks. Their integration with automated systems enhances safety even further. However, this advanced functionality typically comes at a higher price.

Automated/Smart Valves

Automated, or "smart," valves represent the latest advancements in this technology. These systems use sensors and control units to automatically shut off fuel flow based on predefined parameters, such as leak detection, impact detection, or pre-programmed emergency shutdown. While these systems enhance safety and efficiency, they usually come with a premium cost. Some smart valves integrate with fuel level monitoring systems, providing real-time insights and predictive maintenance alerts. This proactive approach minimizes downtime and helps ensure peak performance. For more information about fuel tank maintenance, you can read: How to master your fuel tank cleaning.

The following table summarizes the key differences between the various marine fuel shut off valve technologies:

Marine Fuel Shut Off Valve Technology Comparison

| Technology Type | Response Time | Installation Complexity | Best Application | Maintenance Requirements |

|---|---|---|---|---|

| Manual | Slowest | Simple | Small vessels, basic applications | Low |

| Pneumatic | Moderate | Moderate | Medium-sized vessels, remote operation needed | Moderate |

| Electro-Hydraulic | Fastest | Complex | Large vessels, critical safety systems | High |

| Smart | Variable, typically fast | Complex | Advanced systems, integrated automation | Moderate to High |

This table highlights the trade-offs between response time, installation complexity, and maintenance needs. While manual valves are simple and low-maintenance, they lack the speed of more advanced options. Smart valves offer the greatest potential for automation and safety but require more complex installation and potentially higher maintenance.

The marine fuel shut-off valve plays a vital role within the larger context of marine actuators and valves. This market reached a size of USD 2.8 billion in 2022 and is projected to grow to USD 3.6 billion by 2027, expanding at a CAGR of 5.3%. For a deeper dive into these market trends, see: Marine Actuator and Valve Market Research. This growth reflects the increasing use of advanced technologies like electro-hydraulic, pneumatic, and smart valve systems. Understanding how marine fuel shut off valves work with other fuel system components is essential for overall system performance.

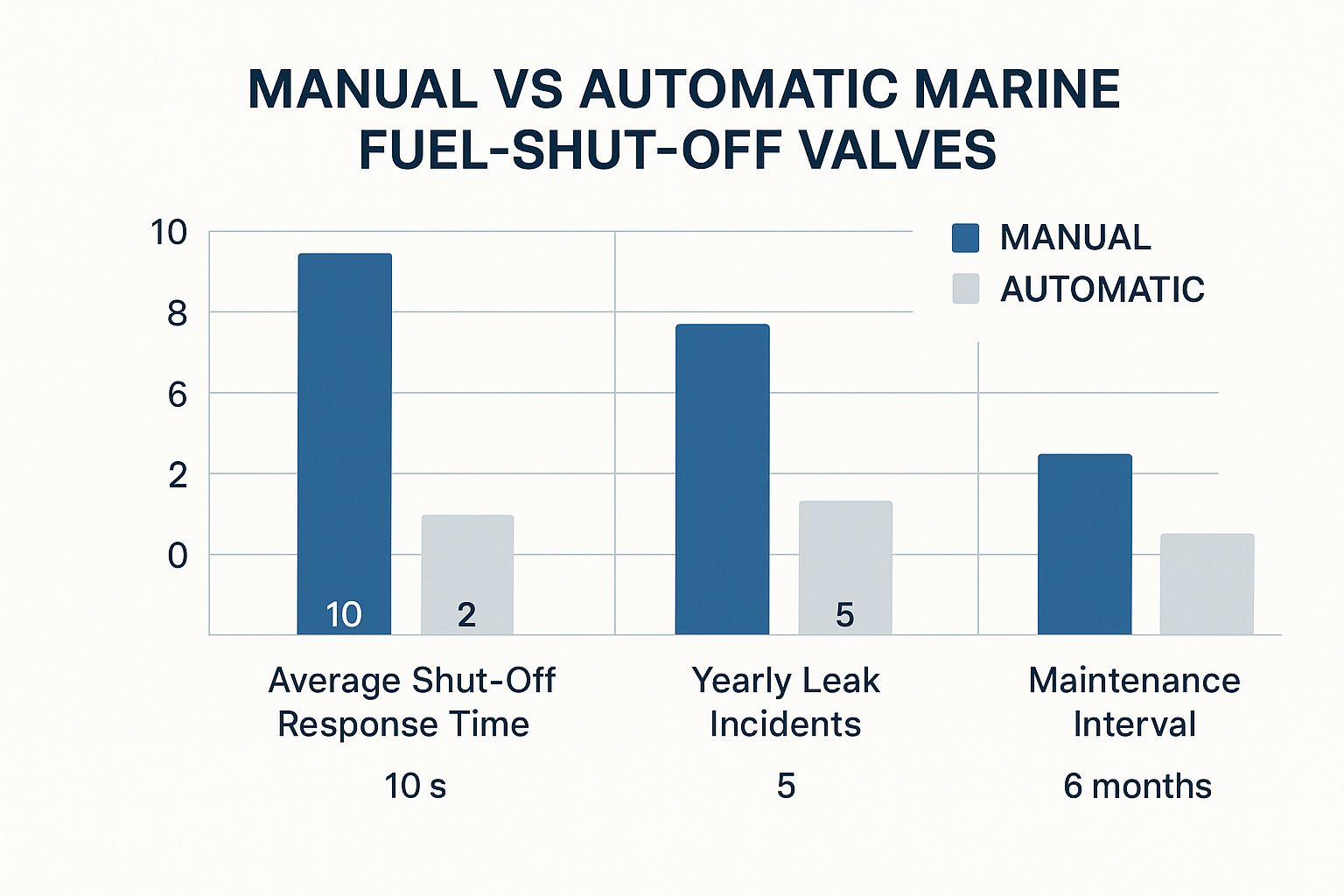

The infographic above visually compares the performance of manual and automatic marine fuel shut off valves. It focuses on key metrics: average shut off response time, yearly leak incidents, and required maintenance intervals. The data clearly shows that automatic valves outperform manual valves in response time and leak prevention, while also needing less frequent maintenance. This highlights the safety and operational advantages of investing in advanced valve technologies.

Navigating Regulatory Compliance and Safety Standards

The maritime industry faces growing pressure to lessen its environmental footprint. This means stricter regulations for vessel operators, especially regarding fuel systems and emissions. Understanding and following these evolving standards is now crucial for staying competitive and avoiding penalties. Investing in compliant marine fuel shut off valve systems is becoming increasingly essential.

IMO MARPOL Annex VI and Its Impact

One key regulation affecting the maritime sector is the International Maritime Organization (IMO) MARPOL Annex VI. This annex aims to prevent air pollution from ships, setting limits on sulfur oxide and nitrogen oxide emissions. It also regulates volatile organic compounds (VOCs) and ozone-depleting substances. These regulations significantly influence how marine fuel shut off valves are designed, installed, and operated.

For instance, Annex VI requires ships to use low-sulfur fuels, impacting the material compatibility of certain valve components. The regulations also outline requirements for fuel system integrity to prevent leaks and spills, which directly affects shut-off valve performance standards. This highlights the need for strong, reliable valve systems that can handle these fuels and ensure leak-free operation.

As frameworks like MARPOL Annex VI tighten, there's a growing focus on combining safety and sustainability. Vessel operators now want valve technologies that not only provide emergency fuel shut-off but also help meet emission targets. This combined focus is boosting the demand for advanced marine shut-off valves. Learn more about this trend at Marine Fuel Injection System Market.

Preparing for Future Regulations

Regulatory compliance is an ongoing process. New rules and updates are constantly being developed and implemented. Vessel operators must keep up with these changes and prepare their vessels accordingly.

Practical Steps for Compliance

-

Regular Inspections: Frequent inspections of your marine fuel shut off valve system are vital. This involves checking for leaks, corrosion, and proper operation.

-

Maintenance and Documentation: Keep detailed maintenance records. This shows your commitment to compliance and helps identify potential problems early.

-

Professional Consultation: Working with a qualified marine surveyor can provide valuable guidance on meeting specific regulatory requirements, including selecting and installing compliant valve systems.

By proactively addressing regulatory compliance, vessel operators avoid penalties, improve operational efficiency, and protect their investments. A well-maintained, compliant fuel system contributes to a safer, more sustainable maritime environment. This means fewer risks, less downtime, and a stronger commitment to environmental stewardship.

Installation And Maintenance Best Practices That Work

Proper installation and diligent maintenance are vital for the reliability and lifespan of your marine fuel shut off valve. This section offers practical guidance on these essential processes, incorporating insights from experienced marine technicians. We'll explore everything from choosing the right valve location to employing connection techniques built to resist harsh marine conditions.

Installation Best Practices

The effectiveness of your marine fuel shut off valve depends heavily on correct installation. Selecting the ideal location ensures easy access during emergencies. Meanwhile, proper connection techniques prevent leaks and guarantee reliable performance in demanding situations.

-

Strategic Placement: Position the valve in a readily accessible spot near the fuel tank. This facilitates quick shut off in emergencies.

-

Secure Connections: Employ suitable fittings and sealants to create leak-proof connections. Carefully check all connections for security.

-

Corrosion Protection: Safeguard the valve and its components from corrosion, particularly vital in saltwater environments. Consider using marine-grade materials and protective coatings.

-

Adherence to Manufacturer's Instructions: Strictly follow the manufacturer's installation guidelines. This guarantees proper function and often preserves the valve's warranty.

Common Installation Mistakes To Avoid

Certain installation errors can compromise safety and even invalidate warranties. Using incorrect fittings or improper sealing can result in leaks. Likewise, neglecting corrosion protection significantly reduces the valve's lifespan.

-

Using Incompatible Materials: Confirm all components are compatible with your fuel type. This includes the valve, fittings, and sealants.

-

Overtightening Fittings: Overtightening can damage the valve or create vulnerabilities to leaks. A torque wrench can ensure correct tightness.

-

Ignoring Grounding Requirements: Proper grounding is critical for electrical systems, particularly for electronically controlled valves.

Essential Maintenance Practices

Regular maintenance is just as crucial as correct installation. A well-maintained valve offers greater reliability in emergencies and enjoys a longer lifespan, saving you money in the long run.

-

Regular Inspection: Visually inspect the valve for signs of wear, corrosion, or damage. Check for leaks, loose connections, and any other issues.

-

Operational Testing: Regularly test the valve's operation to confirm it functions correctly when needed.

-

Cleaning and Lubrication: Maintain valve cleanliness and lubrication as per the manufacturer's recommendations.

-

Professional Servicing: Consider professional servicing for complex systems, particularly those with electronically controlled valves.

You might be interested in: How to master your boat's fuel tank maintenance. This guide offers additional valuable advice on ensuring the safety and longevity of your fuel system.

DIY vs. Professional Maintenance

Understanding when to handle maintenance yourself and when to call a professional is key. Boat owners can usually perform simple tasks like visual inspections and operational tests. However, complex procedures like repairs or servicing electronically controlled systems are best left to qualified technicians.

By adhering to these installation and maintenance best practices, you can ensure your marine fuel shut off valve offers reliable protection and contributes to a safer boating experience. This proactive approach not only enhances safety but also protects your investment and minimizes the risk of costly future repairs.

Maximizing Fuel Efficiency and Environmental Protection

Modern marine fuel shut off valves are more than just safety devices. They are essential for optimizing fuel efficiency and minimizing environmental impact. Choosing the right valve and maintaining it properly directly impacts fuel consumption and creates a cleaner emissions profile. This leads to significant cost savings for vessel operators while also promoting responsible environmental practices.

For instance, the precise flow control offered by advanced valves reduces fuel waste during normal operations. These valves also prevent leaks, which further lowers fuel consumption and the risk of pollution. By investing in high-quality marine fuel shut off valves, vessel operators can see real improvements in how efficiently their vessels operate.

Environmental Benefits of Modern Valve Technology

Modern valve technologies significantly reduce fuel waste thanks to precise engineering and advanced features. Preventing leaks is a crucial benefit, protecting marine ecosystems from damaging fuel spills. For safe and effective upkeep, refer to detailed guides like the Solenoid Valve Installations And Maintenance Instructions. This proactive approach helps create a cleaner and healthier marine environment.

Furthermore, some marine fuel shut off valve systems include sensors that track fuel flow and identify any issues. This allows for real-time adjustments and predictive maintenance, optimizing fuel efficiency and reducing the chance of leaks. This type of proactive maintenance further lessens environmental impact and supports sustainable boating.

Fuel shut-off valves are vital for achieving fuel efficiency and environmental compliance in the marine industry. The global marine fuel injection system market is projected to reach USD 8.3 billion by 2034, growing at a 3.6% CAGR from 2025. Learn more about the growing Marine Fuel Injection System Market. This growth highlights the increased focus on valves designed to minimize fuel leakage and improve combustion. For further information on protecting our oceans, you can explore resources like How to prevent marine pollution.

Case Studies and Real-World Examples

Many vessel operators have seen significant improvements in fuel efficiency and emissions reduction after installing advanced marine fuel shut off valve systems. These real-world examples demonstrate the tangible advantages of modern valve technology. The progress being made emphasizes the importance of fuel efficiency and environmental protection in the marine industry. By adopting these strategies, vessel operators show their dedication to sustainable boating and environmental responsibility.

Choosing The Right Marine Fuel Shut Off Valve For Your Vessel

Selecting the right marine fuel shut off valve is critical for any boat owner. It's not just a safety checklist item; it's a smart investment. It protects your vessel, crew, and the marine environment. This involves balancing upfront costs with long-term reliability and maintenance. It also means understanding how the valve works with your current fuel system and performs in different conditions.

Factors To Consider When Choosing A Valve

Several factors influence your choice. Understanding them helps you make an informed decision:

-

Vessel Type: A small recreational boat has different needs than a large commercial vessel. Size and type play a significant role.

-

Fuel Type: Compatibility between the valve and your fuel is essential. Ensure the valve can handle your fuel type, whether gasoline or diesel.

-

Environmental Conditions: Where you boat matters. Saltwater requires valves with better corrosion resistance.

-

Integration With Existing Systems: Seamless integration with your current fuel system simplifies installation and improves performance.

-

Budget: Safety is paramount, but budget matters. Balance cost, features, and long-term value.

Evaluating Manufacturers And Their Track Records

Researching manufacturers is essential. Look for proven reliability and quality. Consider:

-

Manufacturer’s Reputation: A solid track record and positive reviews show a commitment to quality.

-

Warranty and Support: A good warranty and responsive support provide peace of mind.

-

Material Quality And Construction: Durable, marine-grade materials are key for harsh environments.

-

Testing And Certification: Independent testing verifies performance and safety standards.

Understanding Value Vs. Marketing Hype

Focus on practical features, not marketing jargon. A sleek design is nice, but it doesn't necessarily improve safety. Prioritize features like fast response times, reliable sealing, and corrosion resistance. These directly affect safety and how long the valve lasts.

Making Informed Decisions

The table below helps you compare valve options:

To help you navigate the options, take a look at this comparison table:

Marine Fuel Shut Off Valve Selection Criteria

| Vessel Type | Recommended Valve Type | Key Features | Typical Price Range | Installation Complexity |

|---|---|---|---|---|

| Small Recreational Boat | Manual or Basic Electric | Simple operation, easy installation | $50 - $200 | Low |

| Medium-Sized Boat | Electric or Pneumatic | Remote operation, faster response times | $200 - $500 | Moderate |

| Large Commercial Vessel | Electro-hydraulic or Smart | Automated shut off, integrated safety systems | $500+ | High |

This table is a starting point. Talking with marine professionals is crucial. They can provide expert advice. Open communication with suppliers also helps you get the right valve at a fair price.

By carefully considering these factors and doing your research, you can choose a marine fuel shut off valve that offers lasting protection. This proactive approach ensures your vessel and crew are protected against potential fuel-related issues, giving you peace of mind on the water.

Key Takeaways For Marine Fuel Shut Off Valve Safety

Implementing robust fuel valve safety practices is crucial for every vessel owner. This involves understanding the components, regular maintenance, and knowing what to do in emergencies. This section provides an action plan based on industry best practices, focusing on practical steps you can take right away.

Regular Inspection and Testing

Regularly inspecting your marine fuel shut off valve is your first line of defense. Make it a routine part of your vessel maintenance.

-

Visual Inspection: Look for signs of corrosion, wear, or damage. Check for leaks, loose connections, and any other visible issues.

-

Operational Test: Regularly test the valve's functionality to confirm it operates correctly and will perform as expected in an emergency.

-

Frequency: Aim for monthly inspections and tests, or more often depending on usage and environmental conditions.

Understanding Warning Signs

Knowing the warning signs of a potential fuel system issue allows for quick action. Early detection can prevent small issues from becoming major problems.

-

Fuel Smell: A persistent fuel odor requires immediate investigation. It could point to a leak or another issue.

-

Slow Response: If your valve responds slowly or struggles to shut off completely, it needs attention.

-

Visible Leaks: Any fuel leakage, no matter how small, demands immediate action.

-

Unusual Engine Performance: Problems with engine performance, such as sputtering or difficulty starting, could be related to fuel system issues.

Emergency Response Procedures

A clear plan for fuel-related emergencies is essential for minimizing potential damage and ensuring the safety of your vessel and crew.

-

Shut Off Fuel Supply: Your first action in any fuel-related emergency should be to shut off the fuel supply using the marine fuel shut off valve.

-

Contain the Spill: If a spill occurs, take steps to contain it and prevent spreading.

-

Ventilate the Area: Ensure adequate ventilation to prevent fuel vapor buildup.

-

Contact Authorities: Report the incident to the appropriate authorities as required.

Maintenance Scheduling and Professional Support

Create a realistic maintenance schedule and stick to it. This is vital for long-term valve reliability. Knowing when to seek professional help is equally important.

-

Scheduled Maintenance: Include valve inspection and testing in your regular vessel maintenance schedule. Check the manufacturer's recommendations for service intervals.

-

Professional Assistance: Contact a qualified marine technician for complex repairs or if you are unsure about any part of your fuel system. A relationship with a trusted technician is a smart investment.

-

Record Keeping: Maintain detailed records of all inspections, tests, and maintenance performed. This documentation helps with troubleshooting and shows your commitment to safety.

Staying informed about evolving safety standards and working with a qualified marine technician are vital for a safe and reliable fuel system.

Upgrade your vessel’s safety and fuel efficiency with CLiX Fueling Solutions. Their innovative, spill-free system offers peace of mind on the water.