Understanding Your Boat's Fuel System: Common Challenges

A reliable fuel system is crucial for any boat, ensuring smooth operation and preventing unexpected disruptions on the water. This listicle dives into six common boat fuel tank problems, offering practical solutions and preventative measures. Understanding these issues will help recreational boaters, professional captains, and marina operators alike maintain their vessels effectively. From contaminated fuel to venting issues, we'll cover the key challenges that can impact your boat's performance. We'll also provide actionable advice to prevent these problems from occurring in the first place.

This guide provides clear explanations and solutions for common boat fuel tank problems, enabling you to:

- Diagnose fuel-related issues accurately: Quickly pinpoint the root cause of common problems.

- Implement effective solutions: Learn how to fix problems yourself or when to call a professional.

- Prevent future problems: Implement preventative maintenance to avoid future headaches.

- Save time and money: Avoid costly repairs and lost time on the water.

We'll explore these specific boat fuel tank problems:

- Contaminated Fuel

- Clogged Fuel Filters

- Fuel Tank Corrosion

- Fuel Pump Failure

- Fuel Line Blockage

- Tank Venting Issues

By understanding these issues, you'll be better prepared to address boat fuel tank problems, ensuring enjoyable and trouble-free boating experiences.

1. Contaminated Fuel

Contaminated fuel is a pervasive problem for boat owners, frequently causing performance issues and potentially damaging the engine. This occurs when unwanted substances like water, dirt, bacteria, or other debris find their way into your fuel tank. In the marine environment, condensation and water intrusion are particularly common culprits, making this a significant concern for boaters. This issue isn't just an inconvenience; it can lead to costly repairs and significant downtime.

Why Contaminated Fuel is a Serious Problem

Contaminated fuel affects boat engines in several ways. Water in the fuel can cause corrosion within the fuel system, leading to rust and component failure. It can also disrupt the combustion process, resulting in rough idling, reduced power, and even engine stalling. Bacteria growth, another form of contamination, can create a slimy biofilm that clogs fuel lines and filters, further hindering engine performance. Addressing fuel contamination promptly is crucial to prevent these issues from escalating into major engine damage.

Real-World Examples of Addressing Fuel Contamination

Several strategies are effective in combating fuel contamination. Yacht owners using high-quality fuel filters, like those from Racor (Parker Hannifin), report a significant reduction (up to 90%) in contamination-related issues. Commercial fishing fleets have implemented regular fuel testing protocols to identify and address contamination early, minimizing downtime and repair costs. Even at the fuel dock, marina operators use water-detecting paste to ensure the quality of fuel being delivered to boats. These examples demonstrate the importance of proactive fuel management.

Actionable Tips for Preventing and Addressing Contaminated Fuel

Here are some practical steps you can take to manage fuel contamination:

- Install a fuel/water separator filter system: This is your first line of defense against water in your fuel.

- Use fuel stabilizers and biocides: These additives help prevent fuel degradation and bacterial growth, especially during storage.

- Check for water: Use water-detecting paste monthly to monitor for water presence in your tank.

- Keep tanks full: A full tank minimizes the airspace where condensation can form.

- Drain water from fuel/water separator: Regularly drain any collected water from the separator to maintain its effectiveness.

When and Why to Implement These Strategies

These preventative measures should be incorporated into your regular boat maintenance routine. Implementing them consistently, even when no problems are apparent, is the key to avoiding costly fuel-related issues down the line. Proactive fuel management is particularly important before periods of storage, like during the off-season, to protect your engine from the damaging effects of contaminated fuel. Learn more about contaminated fuel and tank cleaning. Whether you're a recreational boater or a professional captain, understanding and addressing fuel contamination is essential for ensuring the smooth and reliable operation of your vessel.

2. Clogged Fuel Filters

Clogged fuel filters are a common boat fuel tank problem that can lead to a range of engine performance issues. These filters, designed to trap debris and contaminants, can become obstructed over time, restricting the flow of fuel to the engine. This starvation of fuel can manifest as poor performance, difficulty starting, and even engine stalling, especially when the engine is under load. This seemingly minor issue can significantly impact your boating experience and, if left unaddressed, can lead to more serious engine problems.

Why Clogged Fuel Filters are a Serious Problem

The restriction of fuel flow caused by a clogged filter puts a strain on the entire fuel system. It forces the fuel pump to work harder, potentially shortening its lifespan. Furthermore, a lack of sufficient fuel can lead to improper combustion, resulting in reduced power, increased fuel consumption, and excessive exhaust smoke. In severe cases, a completely clogged filter can cause the engine to stall, leaving you stranded on the water. This not only disrupts your trip but can also create a safety hazard.

Real-World Examples of Addressing Clogged Fuel Filters

Many boaters proactively manage fuel filter issues. Caterpillar marine engines often utilize dual Racor 500 series filters, allowing for a quick changeover if one becomes clogged, ensuring continuous operation. Recreational boaters often carry spare filter elements and the necessary tools to perform a change on the water, minimizing downtime. Charter boat operators, prioritizing reliable operation, frequently perform weekly filter inspections and replacements to avoid unexpected issues during client trips. These practices highlight the importance of prioritizing fuel filter maintenance.

Actionable Tips for Preventing and Addressing Clogged Fuel Filters

Here are some practical tips for managing your boat's fuel filters:

- Install fuel pressure gauges: Gauges placed before and after the filter allow you to monitor filter performance and identify clogging before it becomes critical.

- Carry spares: Keep spare filter elements and the required tools on board for quick replacements when needed.

- Regular replacements: Adhere to the manufacturer's recommended filter replacement intervals.

- Weekly inspections: Inspect filter bowls weekly for signs of contamination, such as water or debris.

- Dual filter systems: Consider installing a dual filter system with a changeover valve for uninterrupted fuel supply.

When and Why to Implement These Strategies

Integrating these strategies into your regular boat maintenance routine is crucial. Regular checks and timely replacements are essential for optimal engine performance and reliability. Implementing these practices, even when no problems are apparent, will help you avoid potential breakdowns and ensure a smooth boating experience. Proactive fuel filter management is particularly important before extended trips or periods of heavy use, minimizing the risk of fuel-related issues while on the water. Addressing clogged fuel filters is a simple yet effective way to protect your engine and enjoy uninterrupted boating.

3. Fuel Tank Corrosion

Fuel tank corrosion is a significant problem for boat owners, potentially leading to costly repairs, fuel contamination, and even environmental hazards. This degradation occurs when the metal of your fuel tank reacts with water, air, or other substances, gradually weakening and compromising its integrity. In the harsh marine environment, where moisture and salt are ever-present, this is a particularly pressing concern for boaters. Aluminum and steel tanks are especially susceptible to corrosion, but even less reactive materials can be affected over time.

Why Fuel Tank Corrosion is a Serious Problem

Corrosion creates several issues for boaters. Perhaps most obviously, it can lead to leaks in the fuel tank, resulting in fuel loss and potential environmental pollution. Rust and other corrosion byproducts can also contaminate the fuel itself, leading to clogged filters, reduced engine performance, and even engine damage. Similar to water filters, boat fuel filters require regular maintenance and replacement. For a reliable and efficient water purification system, check out this High Flow Water Filter. Addressing corrosion early is crucial to prevent these problems from becoming major headaches.

Real-World Examples of Addressing Fuel Tank Corrosion

Various strategies are employed to mitigate and repair fuel tank corrosion. Many recreational boats now use rotationally molded polyethylene tanks from manufacturers like Moeller, which are highly resistant to corrosion. Commercial vessels often utilize epoxy-lined steel tanks for enhanced protection in demanding environments. For older metal tanks, restoration using specialized coatings like Por-15 can effectively seal and protect against further corrosion. These examples highlight the diverse approaches available for dealing with this issue.

Actionable Tips for Preventing and Addressing Fuel Tank Corrosion

Here's how you can protect your boat's fuel tank from corrosion:

- Inspect tanks annually: Look for signs of rust, pitting, or discoloration, especially around fittings and seams.

- Use sacrificial anodes (for metal tanks): These attract corrosive elements, protecting the tank itself.

- Ensure proper electrical grounding: This minimizes galvanic corrosion caused by stray currents.

- Keep tanks full: A full tank reduces the airspace where condensation, a major contributor to corrosion, can form.

- Consider tank coatings or liners: These provide a protective barrier against corrosive elements.

When and Why to Implement These Strategies

Integrating these preventative measures into your regular boat maintenance routine is essential. Consistent implementation, even when no visible corrosion is present, is the best way to safeguard your fuel tank and avoid costly repairs down the line. Pay extra attention before and after periods of storage, as fluctuating temperatures and humidity can accelerate corrosion. Whether you're a weekend sailor or a seasoned captain, addressing fuel tank corrosion is crucial for the long-term health and safety of your vessel.

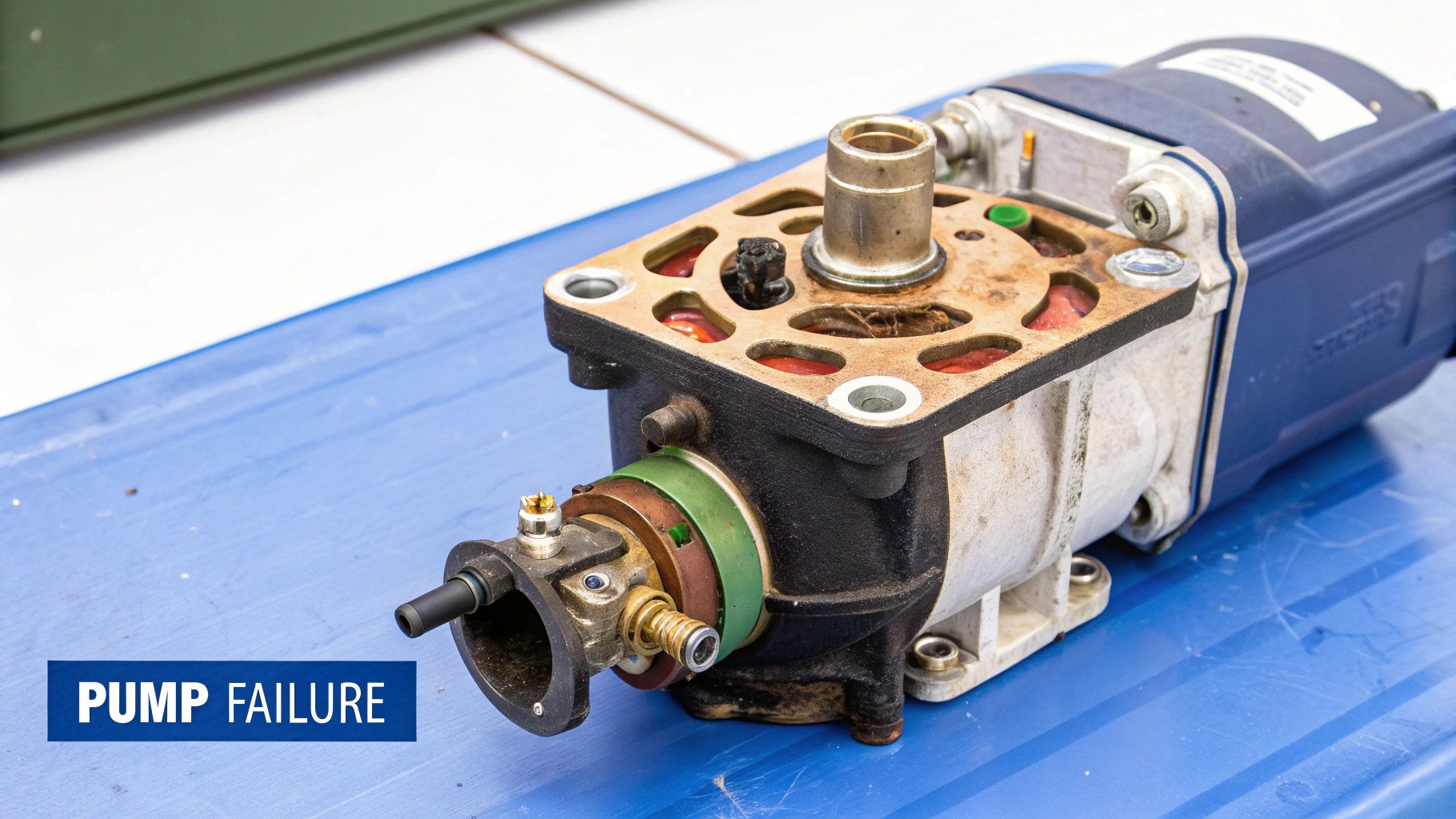

4. Fuel Pump Failure

Fuel pump failure is a common and frustrating problem that can leave you stranded on the water. Several factors contribute to this issue, including contaminated fuel, overheating from low fuel levels, electrical problems, and simple mechanical wear. The marine environment, with its inherent moisture and vibration, adds further stress to these essential components. This makes understanding fuel pump issues and their prevention crucial for any boat owner.

Why Fuel Pump Failure is a Serious Problem

A failing fuel pump manifests in several ways. You might experience difficulty starting the engine, especially after it's been sitting for a while. Engine stalling, particularly under load, is another telltale sign. You might also notice a loss of power or a decrease in fuel efficiency. Ignoring these symptoms can lead to complete engine failure, requiring costly repairs and significant downtime.

Real-World Examples of Addressing Fuel Pump Issues

Different boat types often use specific fuel pump systems. High-performance boats frequently utilize Walbro high-pressure fuel pumps to meet their demanding power requirements. Johnson/Evinrude outboards often feature the VRO (Variable Ratio Oiling) pump system, which combines fuel and oil delivery. Larger vessels, powered by engines like the Caterpillar C7.1, have robust fuel pump assemblies designed for heavy-duty operation. Understanding the nuances of your specific system is crucial for proper maintenance.

Actionable Tips for Preventing and Addressing Fuel Pump Failure

Here are several proactive steps you can take:

- Maintain adequate fuel levels: Keeping your tank above 1/4 full helps prevent fuel pump overheating, a major cause of premature failure.

- Install a fuel pressure gauge: This allows you to monitor fuel pump performance and identify potential issues early on.

- Carry spares: Having a spare fuel pump and the necessary installation tools on board can save you a tow and get you back on the water quickly.

- Regular testing: Test your fuel pump pressure annually to ensure it's operating within specifications.

- Clean fuel pickup screens: Regularly cleaning the fuel pickup screens prevents debris from clogging the system and stressing the pump.

When and Why to Implement These Strategies

Integrating these preventative measures into your regular maintenance routine is essential. Even if you haven't experienced any issues, proactive maintenance can significantly extend the life of your fuel pump and prevent unexpected breakdowns. Learn more about fuel pump selection and maintenance. Understanding your boat's fuel system and taking preventative steps is a small investment that can save you significant time, money, and frustration on the water.

5. Fuel Line Blockage

Fuel line blockage is a common yet often overlooked boat fuel tank problem that can lead to significant engine trouble. This occurs when the fuel lines, responsible for carrying fuel from the tank to the engine, become obstructed. Several factors contribute to blockages, including debris, gum deposits from old fuel, collapsed hoses, and even ice formation in cold weather. The marine environment, with its inherent exposure to UV rays and constant vibration, further exacerbates these issues, making fuel line maintenance crucial for boat owners.

Why Fuel Line Blockages are a Serious Problem

A blocked fuel line restricts the flow of fuel to the engine, starving it of the necessary energy to operate effectively. This can manifest as a variety of performance issues, from rough idling and reduced power to complete engine stalling. In severe cases, a blocked fuel line can cause permanent engine damage, necessitating costly repairs. Furthermore, fuel starvation can occur unexpectedly, leaving boaters stranded on the water.

Real-World Examples of Addressing Fuel Line Blockages

Various techniques are used to address fuel line blockages. Ski boat owners sometimes clear minor blockages using compressed air to dislodge debris. Commercial fishing vessels, given the critical nature of their operations, often employ fuel line blow-back systems for routine maintenance. These systems reverse the flow of fuel to flush out contaminants. Sailboat owners with auxiliary engines often install removable fuel pickup tubes, allowing for easy inspection and cleaning to prevent blockages. These examples highlight the proactive approach many boaters take to avoid fuel line problems.

Actionable Tips for Preventing and Addressing Fuel Line Blockages

Preventing and addressing fuel line blockages involves a combination of regular maintenance and preventative measures:

- Use fuel line antifreeze in cold weather: This prevents ice formation within the fuel lines, a common problem in colder climates.

- Replace fuel lines every 10 years or per manufacturer schedule: Aging fuel lines are prone to cracking and collapsing, increasing the risk of blockage. Adhering to a replacement schedule minimizes this risk.

- Install accessible fuel line connections for maintenance: Easy access to fuel line connections simplifies routine checks and cleaning.

- Carry spare fuel line and fittings: Having spares on board allows for quick repairs in case of unexpected blockages.

- Use fuel additives to prevent gum formation: These additives help prevent the buildup of gum and varnish deposits that can clog fuel lines.

When and Why to Implement These Strategies

Implementing these strategies should be a regular part of boat maintenance. Regular checks and preventative measures are essential, especially before extended trips or periods of storage. Addressing fuel line issues proactively, even before symptoms appear, helps prevent more significant and costly problems down the line. This preventative approach not only ensures the smooth and reliable operation of your vessel but also enhances safety on the water. Fuel line products from brands like Tempo and Gates Marine, along with maintenance kits from companies like Racor, offer solutions for various boat types and operating conditions.

6. Tank Venting Issues

Tank venting issues are a common source of frustration for boat owners, often leading to engine performance problems and potential safety hazards. A properly functioning vent system allows air to enter the tank as fuel is consumed, preventing a vacuum. It also allows expanding fuel vapors and air to escape, preventing pressure buildup. When the vent system malfunctions, it can disrupt fuel delivery and even damage the fuel tank. This makes understanding and addressing tank venting issues crucial for any boat owner.

Why Tank Venting Problems are a Serious Issue

A blocked vent line can create a vacuum in the fuel tank as the engine draws fuel. This vacuum restricts fuel flow, causing the engine to sputter, stall, or lose power. Conversely, a blocked vent can also lead to pressure buildup, especially in warm weather as fuel expands. This pressure can stress the tank, potentially leading to leaks or even rupture. Furthermore, improperly designed vent systems can allow water intrusion into the tank, contaminating the fuel and causing further problems.

Real-World Examples of Addressing Tank Venting Issues

Many production boats utilize ABYC-compliant venting systems, incorporating features like vent loops and anti-siphon valves to prevent water intrusion. Experienced sailboat owners often customize their vent line routing to accommodate unique tank placements and prevent blockages. The use of high-quality fuel tank vents with check valves, such as those from Perko, is a common practice among boaters to ensure reliable venting. These real-world examples highlight the various approaches to maintaining a properly functioning vent system.

Actionable Tips for Preventing and Addressing Tank Venting Issues

Here are some practical tips for managing your boat's fuel tank venting system:

- Inspect vent lines annually: Check for kinks, blockages, and deterioration. Replace any damaged sections.

- Install vent line loops: This prevents water from entering the tank through the vent line.

- Use proper vent valve designs: Ensure valves are appropriate for marine applications and allow proper airflow.

- Ensure vent outlets are above potential water levels: This prevents water from entering the vent during rough seas or heavy rain.

- Test tank venting: Check for vacuum formation by running the engine and observing fuel flow.

When and Why to Implement These Strategies

These strategies should be part of your regular boat maintenance schedule. Inspecting and maintaining the vent system annually, preferably before the start of the boating season, can prevent many common venting problems. Addressing these issues promptly, even when they seem minor, can avoid more significant problems down the line. Proactive maintenance is essential for ensuring a safe and reliable boating experience. Learn more about Tank Venting Issues. Proper tank venting is crucial not just for engine performance, but also for the safety and longevity of your fuel system.

Common Issues Comparison of 6 Boat Fuel Tank Problems

| Issue | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Contaminated Fuel | Medium – requires filters & testing | Moderate – fuel stabilizers, filters | Improved engine performance, fewer repairs | Marine environments prone to water intrusion | Prevents costly engine damage; extends fuel system life |

| Clogged Fuel Filters | Low to Medium – filter replacements | Low – spare filters, gauges | Maintains fuel flow, avoids stalling | Boats with frequent operation and long trips | Protects fuel system; cost-effective maintenance |

| Fuel Tank Corrosion | High – inspection & possible coating | High – coatings, anodes, grounding | Prevents leaks, fuel contamination | Metal tanks in saltwater or humid areas | Prolongs tank life; reduces environmental hazards |

| Fuel Pump Failure | Medium – pump monitoring & replacement | Moderate to High – pumps, tools | Reliable fuel delivery, avoids engine stalls | Critical performance and commercial vessels | Improved pump reliability; diagnostic monitoring |

| Fuel Line Blockage | Low to Medium – line checks & cleaning | Low – replacement hoses, additives | Restores fuel flow, prevents engine failure | Boats in cold climates or long-term storage | Often clearable without replacement; symptom indicators |

| Tank Venting Issues | Medium – inspection & vent upgrades | Low to Moderate – vent fittings | Prevents vacuum/pressure problems | Any boat fuel systems to ensure proper venting | Ensures consistent fuel flow; prevents tank damage |

Keeping Your Boat Fueled and Ready: Preventative Measures and CLiX Fueling Solutions

This guide has explored several common boat fuel tank problems, from contaminated fuel and clogged filters to corrosion, pump failure, line blockage, and venting issues. Each problem presents unique challenges, but they all share a common thread: prevention is key. Addressing these issues proactively not only saves you time and money but also ensures a safer and more enjoyable boating experience.

Key Takeaways for Preventing Boat Fuel Tank Problems

By understanding the causes and solutions for each problem, you can take targeted preventative measures. Here are some of the most crucial steps:

- Regular Fuel Treatment: Prevent contaminated fuel by using fuel stabilizers and biocides. This keeps your fuel clean and prevents microbial growth, a leading cause of clogged filters.

- Fuel Filter Maintenance: Regularly inspect and replace your fuel filters, the first line of defense against contaminants.

- Inspect and Clean Your Tank: Periodically inspect your fuel tank for signs of corrosion. Professional cleaning can remove sediment and water buildup.

- Proper Fuel Storage: Store fuel in approved containers, away from direct sunlight and extreme temperatures.

- Maintain Proper Tank Ventilation: Ensure your tank vent is clear and functioning correctly. Addressing tank venting issues often requires ensuring proper radio communication; for this, explore options such as the GME GX700 VHF Marine Radio with 1m Antenna. This helps maintain proper pressure and prevents vacuum buildup.

- Check Fuel Lines and Pumps: Inspect fuel lines for cracks or leaks and test your fuel pump regularly to ensure proper function.

Why Proactive Maintenance Matters

Taking these preventative steps can significantly reduce the risk of encountering fuel tank problems. This translates to fewer on-the-water breakdowns, lower repair costs, and increased safety for you and your passengers. Ultimately, proactive maintenance allows you to spend more time enjoying your boat and less time dealing with frustrating and potentially dangerous issues.

The Added Protection of CLiX Fueling Solutions

Beyond these preventative measures, consider further enhancing your fuel system's safety and reliability. Overfilling your fuel tank can lead to spills, harming both your boat and the environment. Preventing this is where CLiX Fueling Solutions provides a crucial advantage.

Want to prevent fuel spills and overfilling, protecting your boat and the environment? CLiX Fueling Solutions offers innovative technology to safeguard your vessel and simplify the fueling process. Learn more and protect your investment by visiting CLiX Fueling Solutions.