Ever wonder how your boat's fuel tank "breathes"? It's all thanks to a simple but absolutely essential part: the marine fuel vent. This little device is basically the lungs of your fuel system, letting air out as the tank fills and letting air in as your engine drinks fuel. Without it, you’re looking at a world of trouble, from dangerous pressure buildup to a vacuum that could literally crush your tank.

Why Your Boat's Fuel Tank Needs to Breathe

Think about trying to pour a can of soda into a narrow bottle. If you don't leave a little space for the air to escape, the liquid glugs, splashes, and makes a mess. Your boat’s fuel tank is no different. A properly working fuel vent is the secret to keeping your boat safe and running smoothly.

The Two-Way Street: Pressure and Vacuum Relief

When you're at the fuel dock, the vent provides an escape route for the air inside the tank as gasoline or diesel rushes in. This prevents that messy, dangerous splash-back and lets you fill up quickly and safely. That's the pressure relief side of its job.

But it also works in the other direction. As your engine sips fuel, something has to take its place inside the tank. The vent allows air to flow in, equalizing the pressure. Without this vacuum relief, the fuel pump would struggle, and a powerful vacuum would start to build.

That vacuum isn't just a small problem. It can be strong enough to starve your engine of fuel, causing it to sputter and die. In a worst-case scenario, it can actually deform or even collapse the walls of your fuel tank.

A good fuel vent keeps the pressure neutral, ensuring a steady, reliable flow of fuel to the engine. The health of your entire fuel system really hinges on this constant, simple exchange of air. To get the full picture, check out our in-depth guide to boat fuel tanks.

A Critical Safety Guard

A fuel vent isn’t just about performance—it’s one of your boat’s most important safety devices. It handles the natural expansion and contraction of fuel caused by temperature swings, which is a constant reality out on the water. This is crucial for all kinds of fuel, from heavy fuel oil (HFO) to marine diesel oil (MDO), protecting the tank from the stress of pressure changes.

A vent that’s clogged, kinked, or poorly installed is a serious hazard. Here’s what can go wrong:

- Fuel Spills: Pressure can force fuel back up the fill pipe during refueling, causing a dangerous and environmentally damaging spill right at the dock.

- Fire Risk: Fuel vapors are highly flammable. If they can't vent properly, they can concentrate in the bilge or other enclosed spaces, creating a huge risk of fire or explosion.

- Tank Damage: Over time, constant pressure or vacuum cycles can warp, crack, or even rupture a fuel tank, leading to expensive repairs and a major safety crisis.

It’s a small part, for sure, but the marine fuel vent plays a massive role in making sure your boat runs right and your trips stay safe.

How Marine Fuel Vents Actually Work

To really get why this little part is so crucial, you need to picture what's happening inside your fuel tank. The whole system runs on a very simple law of physics: air displacement.

For every gallon of fuel you pump in, a gallon of air has to get out. Later, when you're out on the water, for every gallon of fuel your engine sips, a gallon of air has to find its way back in.

The fuel vent is the gateway that makes this two-way street of airflow possible. It’s a simple idea, but getting it right involves a few key parts working together perfectly. Let’s walk through the two main jobs it has.

Scenario 1: At the Fuel Dock

When you start fueling up, the gasoline or diesel fills your tank from the bottom. As the fuel level rises, it squeezes the air trapped above it, building up pressure. Without a way for that air to escape, it would literally push back, causing the pump to click off constantly or, worse, spit fuel right back at you.

That’s where the vent line comes in. It acts as an escape hatch, giving that compressed air a safe path out of the tank and into the open air. This allows you to fill up smoothly without any "glugging" or dangerous overflows.

Scenario 2: While Running the Engine

Now, let's say you're cruising along. Your engine’s fuel pump is constantly pulling fuel from the tank. As the fuel level drops, it creates a void—a vacuum.

If air can't get in to fill that void, the vacuum becomes surprisingly powerful. This "vacuum lock" can starve your engine of fuel, causing it to sputter and die at the worst possible moment. In extreme cases, the outside atmospheric pressure can even be strong enough to crush or collapse the tank itself.

The fuel vent prevents all that drama by letting fresh air flow back into the tank, keeping the pressure balanced and ensuring your engine gets the steady stream of fuel it needs.

Think of it like drinking from a juice box. If you don't let any air in, the box just collapses, and you can't get the last drops out. Your fuel vent is that little air hole that lets you finish your drink.

The Key Parts of the System

A fuel vent isn't just one piece; it's a small system. While the exact setup can vary, you'll almost always find these three components:

- The Vent Line: This is simply the hose that runs from a high point on the fuel tank to the vent fitting on the hull. It has to be a specific, marine-grade hose (look for USCG Type A2) that won't break down from constant contact with fuel fumes.

- The Vent Fitting: This is the part you actually see on the outside of your boat. It might be a small stainless steel mushroom cap or a louvered plastic piece. Its job is to let air move freely while blocking splashing water from getting into your fuel tank.

- The Flame Arrestor: Tucked inside the vent fitting is a fine mesh screen. This tiny part has a massive job: it prevents an outside spark from traveling down the vent line and igniting the explosive fuel vapors in your tank. It also does a great job of keeping bugs and debris out.

Choosing the Right Fuel Vent for Your Boat

Picking the right marine fuel vent is more than just a cosmetic choice. It’s one of those small but critical decisions that directly affects your boat's safety, its performance, and whether it meets regulations. Not all vents are created equal, and the best one for you hinges on your boat's design, how you use it, and the waters you navigate.

Think of it like choosing the right tires for a car. You wouldn't put racing slicks on an off-road truck, right? In the same way, a sleek, low-profile vent that looks great on a ski boat could be a terrible choice for an offshore fishing boat that’s constantly getting hammered by spray and green water.

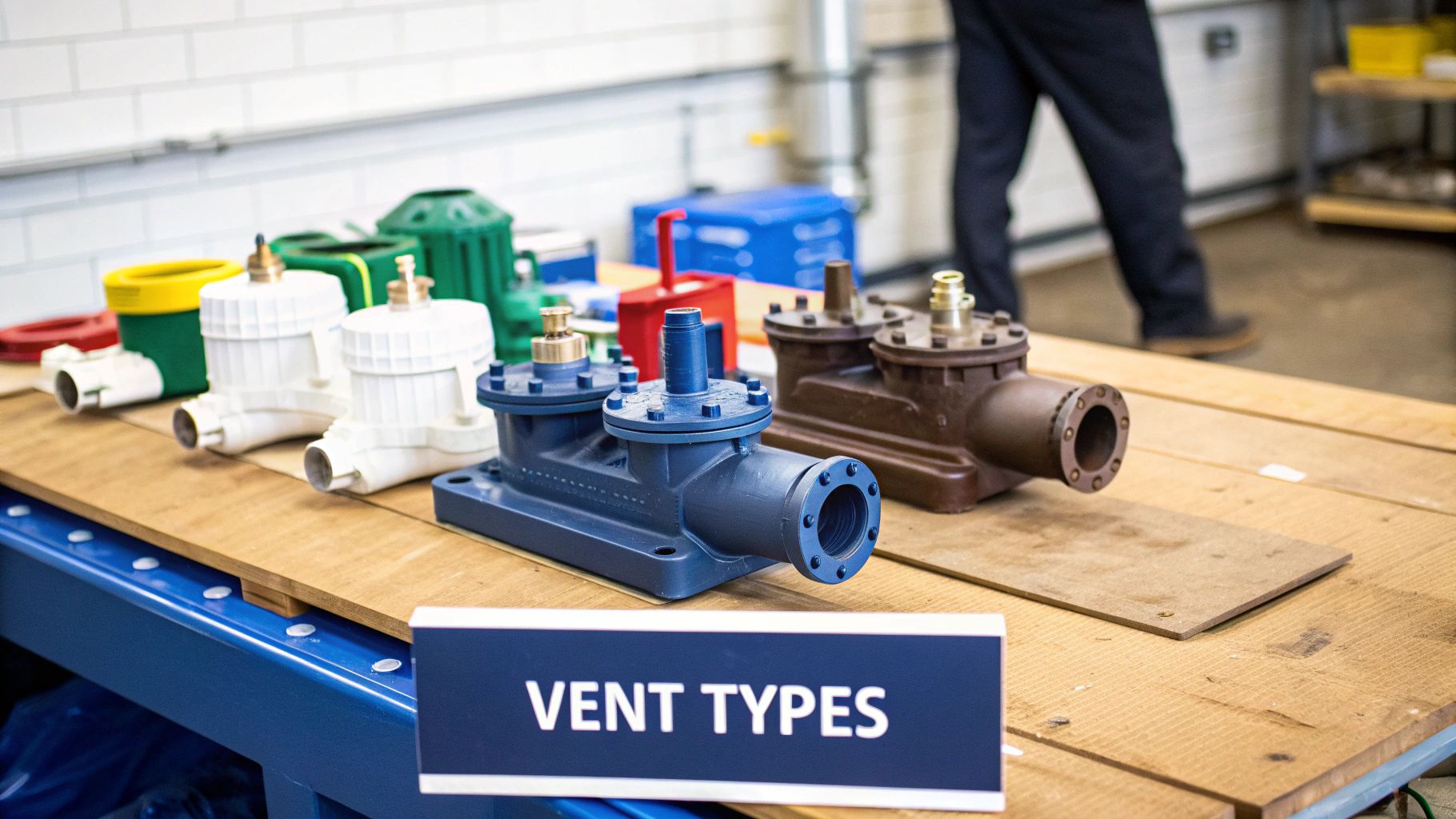

Comparing Common Fuel Vent Designs

Most fuel vents you'll find fall into a few common categories. Each has its own strengths and is built for specific applications. Figuring out what you've got or what you need for an upgrade starts with knowing the basic types.

- Traditional Gooseneck Vents: You can spot these a mile away. Their classic U-shaped "gooseneck" design is fantastic at keeping water from sloshing down into the vent line. They are a time-tested, reliable choice, especially for boats that spend a lot of time in rough water where deflecting spray is a constant battle.

- Flush-Mount Vents: For boaters who are all about clean lines and a modern look, flush-mount vents are the go-to. They sit perfectly flush with the hull, so there's nothing to snag a fishing line or a stray piece of clothing on. The trade-off? Their low profile can make them a bit more prone to taking on water in heavy seas if they aren’t installed just right.

- Combination Fill-and-Vent Units: These are pretty slick. They combine the fuel fill port and the vent into a single, tidy unit. This makes installation a breeze—you only have to cut one hole in the hull—and it keeps things looking uncluttered. You'll often see these on smaller recreational boats where simplicity is king.

To help you sort through the options, we've put together a simple comparison of these common marine fuel vent designs.

Comparison of Common Marine Fuel Vent Types

This table compares the key features, advantages, and disadvantages of the most common types of marine fuel vents to help vessel owners make an informed choice.

| Vent Type | Primary Use Case | Key Advantage | Potential Drawback |

|---|---|---|---|

| Gooseneck | Offshore and rough water boats | Superior water resistance | Bulkier design, can snag lines |

| Flush-Mount | Ski boats, modern cruisers | Sleek, low-profile appearance | More vulnerable to water intake |

| Combination Unit | Smaller boats, simple setups | Simplified installation, clean look | Can be complex to service |

Choosing the right design is a big step, but there’s one more crucial factor to consider: what it's made of.

Material Matters: Durability and Longevity

The material your fuel vent is made from will determine its lifespan and how well it holds up. The marine environment is famously unforgiving—saltwater, blistering sun, and constant temperature swings will test any component.

Stainless steel is pretty much the gold standard for marine hardware. It’s incredibly resistant to corrosion, it's strong, and it keeps its polished look for years. It costs more upfront, but its durability often makes it the cheapest option in the long run, especially if your boat lives in saltwater.

Chrome-plated brass or Zamak gives you a similar look to stainless steel but for less money. The catch is that the chrome plating can eventually start to pit or flake off, exposing the metal underneath to corrosion. They're a solid budget-friendly choice but expect to replace them more often.

Durable polymers and plastics are the most affordable option. They're lightweight, totally corrosion-proof, and won't rust. Modern UV-stabilized plastics are a world away from the brittle plastics of the past. They're a fantastic choice for freshwater boats or for anyone looking for a low-maintenance, cost-effective solution.

Your choice of material directly impacts how well your vent will withstand the elements. For a boat that lives in a saltwater slip, investing in high-grade 316 stainless steel is one of the smartest decisions you can make for long-term reliability and safety.

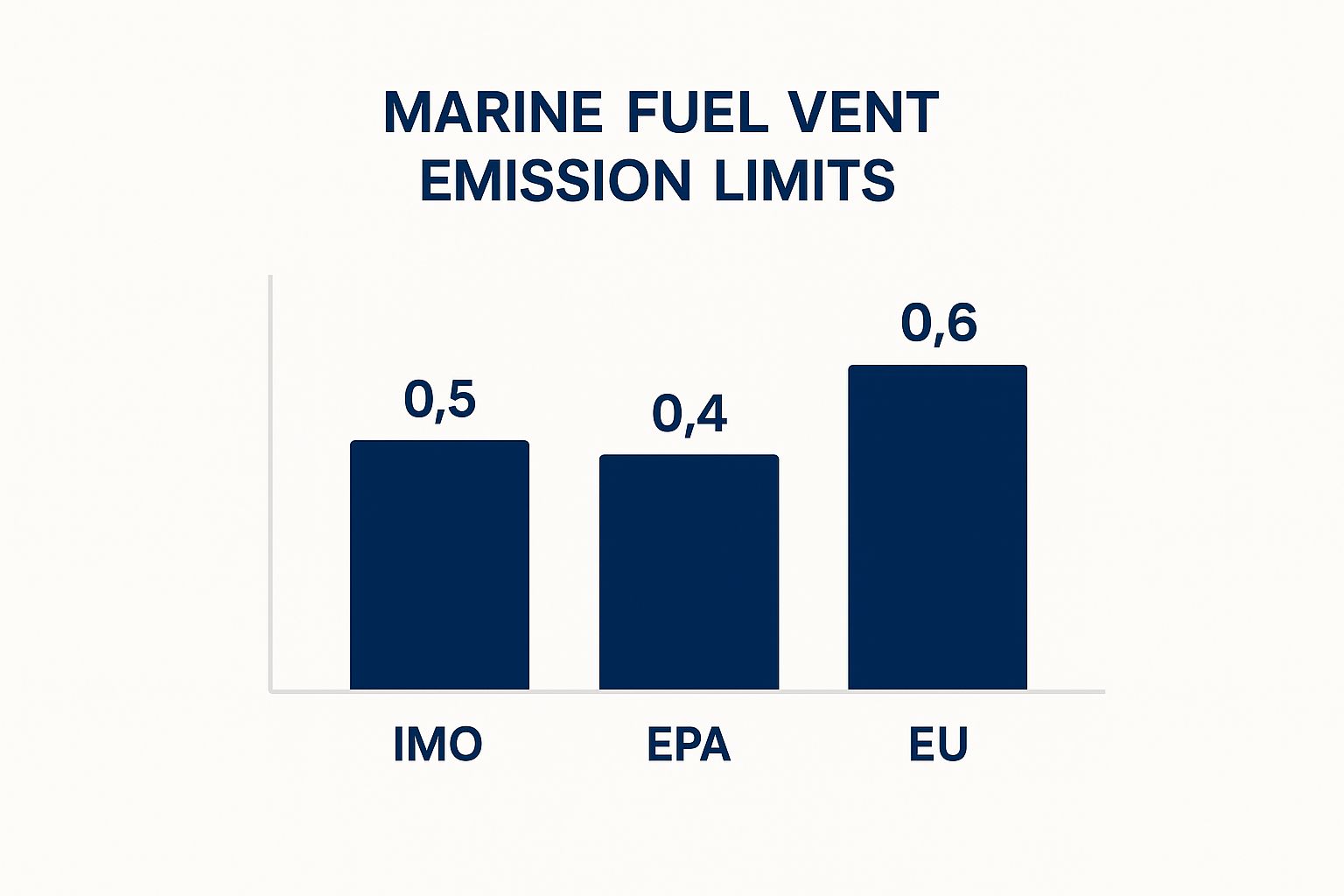

On top of design and material, you also need to think about regulatory standards. The chart below shows how different international bodies are cracking down on emissions, which is a big driver in how these components are being designed today.

As you can see, the standards vary quite a bit, with the EPA currently setting the tightest limits. This reflects a growing global focus on reducing fuel vapor emissions. Picking a vent that meets or exceeds these standards is a good way to ensure your boat is both safe and environmentally responsible.

Proper Installation and Maintenance You Can Do

Knowing how to install and look after your marine fuel vent isn’t just about ticking boxes—it's about taking charge of your boat's safety and reliability. A proper installation is what keeps water out of your fuel and prevents dangerous spills before they ever have a chance to happen.

Think of routine maintenance as your first line of defense against the most common failures. This hands-on knowledge lets you spot trouble early and keep your fuel system breathing easy, giving you peace of mind on every single trip.

Best Practices for Fuel Vent Installation

Installing a fuel vent might seem straightforward, but the details are what count. Where you place the vent fitting and how you run the hose can mean the difference between a safe, dry fuel tank and one that’s always at risk. The goal is to create a foolproof path for air that’s designed to keep everything else out.

For a professional-grade installation, these rules are non-negotiable:

- Always Run Uphill: The vent hose must always travel uphill from the tank to the vent fitting on the hull. This simple gravity-fed design makes it incredibly difficult for liquid fuel to slosh up and out of the vent.

- Create a High Loop: The hose needs a high loop, sometimes called a P-trap, that rises well above both the fuel tank and the vent fitting. This loop is your best defense against water siphoning back into your tank, especially in rough seas or during a heavy washdown.

- No Dips or Sags: Check that the vent hose has a continuous, gradual slope. Any low spots or sags create a place for fuel or condensation to pool, forming a blockage that's just as bad as a wasp nest.

Following these steps is fundamental. For boaters who want an extra layer of security, installing an Attwood 1675 Fuel Vent Line Surge Protector is a great move. It helps stop fuel from burping out of the vent when you're refueling or bouncing around in choppy water.

Your Simple Maintenance Checklist

Checking your marine fuel vent is one of the easiest and most important jobs you can do on your boat. It only takes a few minutes but can prevent huge headaches, from engine trouble to dangerous fuel spills. A clogged vent is a silent problem that can escalate quickly.

Use this simple checklist to catch issues before they get serious. Try to run through these steps at least once a season—more often if you're in saltwater or dusty areas.

Step 1: Inspect the Vent Opening and Screen

The exterior vent fitting is the most common trouble spot. Insects, especially mud daubers, absolutely love building nests in these little openings, which can create a total blockage. Salt crystals can also build up and clog the screen.

- Look closely at the opening for any debris, nests, or corrosion.

- Gently clean the flame arrestor screen with a soft brush and fresh water to wash away any salt or grime.

- Never poke a wire or anything sharp into the screen. You could easily damage the fine mesh, which would compromise its ability to stop a flame.

Step 2: Examine the Vent Hose

The hose running from your tank to the vent is just as important. A cracked, kinked, or old hose can leak flammable vapors into your bilge or even collapse on itself, causing a blockage from the inside.

- Trace the hose all the way from the vent fitting back to the tank. Feel for any cracks, soft spots, or signs of fuel weeping.

- Make sure there are no kinks or sharp bends that could restrict airflow.

- Check that all hose clamps are tight and free of rust. If you see any corrosion, replace the clamp immediately with a marine-grade stainless steel one.

A surprisingly common mistake is forgetting about the hose material itself. Safety regulations are clear: only specific marine-grade fuel hoses, like USCG Type A2, should be used for vent lines. Using a non-rated hose is a serious fire hazard because it will break down quickly when exposed to fuel vapors.

The importance of a well-maintained fuel system really can't be overstated. Even tiny efficiency gains from a clear vent contribute to better fuel management. On a global scale, total marine fuel sales are projected to grow by about 2% between 2023 and 2030, and efficiency improvements are a key factor in keeping that number from being higher. As the Asia Pacific region expands its market share, these best practices become even more critical for a growing global fleet.

Understanding New Fuel Vent Regulations and Technology

The world of boating never stands still, and even the humble marine fuel vent is getting a serious upgrade. Thanks to stricter environmental rules and new tech, how these essential parts are built and what we expect from them is changing fast. It's not just about letting a tank breathe anymore; it’s about doing it cleanly and smartly.

This whole shift is part of a bigger global push to cut down on harmful emissions from everywhere—including our boats. That simple act of venting fuel vapor, which we once took for granted, is now rightly seen as a source of pollution. Because of this, marine fuel vents are becoming much more sophisticated.

The Rise of Vapor Recovery Systems

One of the biggest leaps forward is the move to vapor recovery systems. If a traditional vent is like an open window letting fumes drift out, a vapor recovery system is more like a high-tech air purifier for your fuel tank.

Instead of just releasing flammable, polluting hydrocarbon vapors into the air, these systems are designed to capture them. They usually work with charcoal canisters or other absorbent materials that trap the vapors on their way out. This is a double win: it's better for the environment and makes your boat safer by cutting down on explosive fumes.

New Fuels Demand New Solutions

The growing use of alternative marine fuels is also shaking things up. Fuels like Liquefied Natural Gas (LNG) behave completely differently from standard gasoline or diesel, so they need specialized equipment.

Venting systems for these fuels have to handle things like extreme cold and unique pressure changes. This has spurred the creation of advanced pressure/vacuum relief valves and emergency vents built specifically for the challenges of next-gen fuels, keeping everything safe and running smoothly.

The basic idea is the same—manage the pressure—but the execution has to be incredibly precise. For these advanced fuels, the vent isn't just a simple tube; it's a highly engineered safety valve.

This trend toward cleaner fuel management isn't just a good idea; it's becoming law. Take the EU’s FuelEU Maritime regulation, which kicks in during 2025. It demands major cuts in greenhouse gas emissions. In 2023 alone, over 13,000 vessels visiting EU ports produced a whopping 97.9 million tonnes of greenhouse gases. To hit these new targets, boats will need to adopt technologies like better fuel vents that stop fugitive emissions during fueling and operations. To see how the industry is gearing up, check out the explainer on Zero Carbon Shipping.

Smart Technology and Real-Time Monitoring

The next step for marine fuel vents is all about smart technology. Modern boats are loaded with sensors and digital displays giving you a live look at every system, and the fuel system is always front and center.

The latest vents are being built with integrated sensors that can keep an eye on:

- Tank Pressure: This can warn you about a potential blockage before it turns into a real danger.

- Vapor Flow: You'll know if the system is working as it should and not leaking.

- Overfill Prevention: These sensors work with other parts of the fuel system to stop messy and dangerous spills.

These smart systems give you a whole new level of control and peace of mind. They can pop up an alert on your helm display or even ping your phone. Getting that real-time data means you can fix small problems before they become big ones. You can learn more in our guide on how a fuel tank overfill alarm is a game-changer for safety. This kind of digital oversight is making boating safer and cleaner for everyone.

Your Marine Fuel Vent Questions, Answered

Even after getting the basics down, you're bound to have a few specific questions about your fuel vent. This section tackles the most common things boaters ask, serving as a quick reference guide. Think of it as your go-to spot for troubleshooting or just double-checking something before you make an upgrade.

How Can I Tell if My Fuel Vent Is Blocked?

A blocked fuel vent will absolutely let you know something is wrong, and the signs are usually pretty hard to ignore. If you run into any of these, a clog is your number one suspect.

The most common place people notice a problem is right at the fuel dock. You stick the nozzle in, and it clicks off constantly, even though you know the tank is nowhere near full. That's because the air trapped inside has nowhere to go, creating back pressure that tricks the pump into shutting off.

You might also see the tank itself looking strange. A plastic or aluminum tank that's swollen or looks distorted is a telltale sign of pressure building up. Alternatively, when you open the fuel cap, you might hear a loud whoosh as air rushes in—a clear sign that a vacuum has formed.

When it comes to performance, a blocked vent can literally starve your engine. You might notice the engine sputtering, losing power, or even stalling out, especially when you're running at higher speeds. This is a classic symptom of a vacuum preventing fuel from being drawn out of the tank.

Your best bet is to get in the habit of checking the vent screen for the usual suspects:

- Bugs: Mud daubers and other insects find these little openings to be perfect for building nests.

- Salt: In a saltwater environment, salt crystals can easily form and clog the fine mesh of the flame arrestor.

- Gunk: Simple things like dust, dirt, or even dried wax from polishing the hull can seal the vent shut.

Can I Just Grab a Hose From the Hardware Store?

This is a big one, and the answer is a firm absolutely not. Using a standard, off-the-shelf hose from a hardware store for a fuel vent line is a shortcut to disaster.

Think about it: a garden hose or a simple vinyl tube isn't designed to be in constant contact with gasoline or diesel fumes. Those vapors are incredibly corrosive and will break down the hose material surprisingly quickly. The hose will get brittle, start to crack, and eventually leak.

Once that hose fails, it will start spewing flammable fuel vapors into a closed space like your bilge or engine compartment. All it takes is a single spark from a wire or a piece of equipment to ignite those fumes, leading to a catastrophic fire or explosion. It’s just not worth the risk.

Always use a hose that is specifically rated for marine fuel vent applications. You're looking for something that meets USCG Type A2 or ISO 7840 standards. These are made with materials that can handle the job safely, year after year.

What Size Fuel Vent Line Do I Need?

Picking the right size vent line is simpler than you might think—it just needs to be correctly matched to your fuel fill hose. The golden rule is that air needs to get out just as fast as fuel is going in. If the vent line is too small, it becomes a bottleneck, causing all sorts of fueling headaches.

The American Boat and Yacht Council (ABYC) has a clear standard here. For the common 1.5-inch (38mm) diameter fuel fill hose, the vent line needs to have an inside diameter of at least 5/8 inch (16mm).

Using a vent line that's too small is one of the main reasons fuel "burps" back out of the fill during fueling. Not only is it messy, but it's also an environmental and safety hazard. If you're ever replacing parts of your fuel system, take a moment to confirm your vent line is properly sized for your fill line.

Why Does My Fuel Vent Hose Have a Big Loop in It?

That high loop you see in the vent hose isn't a mistake or a sloppy installation—it’s a critical safety feature. Sometimes called an "anti-siphon loop," it serves two very important jobs.

First, it stops fuel from sloshing out of the vent opening when the boat is rolling around in rough seas. Without that loop, every time the boat pitches, a little bit of fuel could get pushed overboard, leaving a sheen on the water and wasting your money.

Second, and perhaps more importantly, it acts as a barrier to keep water out of your fuel tank. When a wave crashes over the side and dunks the vent fitting, the loop prevents that water from making a direct run down the hose and contaminating your fuel. Water in your fuel is a surefire way to cause serious engine problems.

For the loop to work correctly, it has to be positioned as high as possible—well above both the top of the fuel tank and the vent fitting on the hull. This simple bit of plumbing uses gravity to keep fuel and water where they belong while letting air and vapor move freely.

Ready to eliminate fueling spills for good? CLiX Fueling Solutions offers a patented system that automatically stops the fuel flow when your tank is full, preventing dangerous overfills and protecting your boat and the environment. Discover a smarter, safer way to fuel up at https://clixfueling.com.