Understanding Today's Marine Fuel Management Reality

The marine industry is at a crossroads. Rising fuel costs, stricter environmental regulations, and increasingly complex operations are pushing vessel operators to rethink their approach to marine fuel management. It's no longer just about keeping vessels moving; it's about optimizing a core business aspect that directly impacts profitability and sustainability.

Traditional methods, often relying on manual logs and reactive approaches, are no longer adequate. For instance, depending solely on spot-buying fuel can expose operators to unpredictable price fluctuations, significantly impacting budgets. Overlooking factors like vessel speed and weather patterns can also result in excessive fuel consumption and wasted resources.

This means forward-thinking companies are taking a more strategic approach. They’re adopting new technologies, exploring alternative fuels, and using data-driven decision-making to gain a competitive advantage. The global marine fuel market is also changing rapidly. Between 2025 and 2030, the market is projected to expand from $140.62 billion to $171.49 billion, with a CAGR of 4.05%. This consistent growth is fueled by the continued dependence on maritime trade, which handles about 90% of global trade by volume, highlighting the sheer scale of fuel use in this sector. Find more detailed statistics here

The Impact of Inefficient Fuel Management

The consequences of ineffective marine fuel management are substantial and widespread. Imagine a shipping company neglecting to optimize its vessel routes. This could result in longer transit times, higher fuel consumption, and ultimately, lower profits. Similarly, failing to implement proper fuel storage and handling procedures could cause expensive spills and environmental damage.

The Shift Toward Strategic Fuel Management

However, there are also compelling success stories. Companies investing in robust fuel management systems are seeing significant returns. These systems, often integrating advanced analytics and automation, allow operators to pinpoint and eliminate inefficiencies across their fleets.

This shift elevates fuel management from a purely operational concern to a key strategic advantage in today’s demanding maritime environment. This proactive approach minimizes costs, boosts operational efficiency, and reinforces a company’s commitment to environmental responsibility.

Technology Solutions That Actually Deliver Results

Marine fuel management is a constantly evolving field. New technologies are changing how ship operators optimize fuel use, cut costs, and lessen their environmental impact. These solutions offer a real return on investment, going beyond the hype to deliver tangible benefits.

AI-Powered Route Optimization

AI-powered route optimization is a major advancement in the field. These systems utilize machine learning algorithms to analyze data on weather patterns, ocean currents, and vessel performance. This helps determine the most fuel-efficient routes, saving both time and fuel. For further reading on fuel management, check out this article: How to master marine fuel management. Planning fuel stops and supply chains is essential, especially for complex journeys like cruising the Kimberleys.

Predictive Maintenance and IoT Sensors

Predictive maintenance systems are also playing a vital role. These systems use IoT sensors to track engine performance and detect potential problems before they become serious. This helps operators avoid expensive repairs and maintain optimal fuel efficiency. This proactive approach reduces downtime and avoids the wasted fuel associated with faulty equipment.

Automated Monitoring Systems

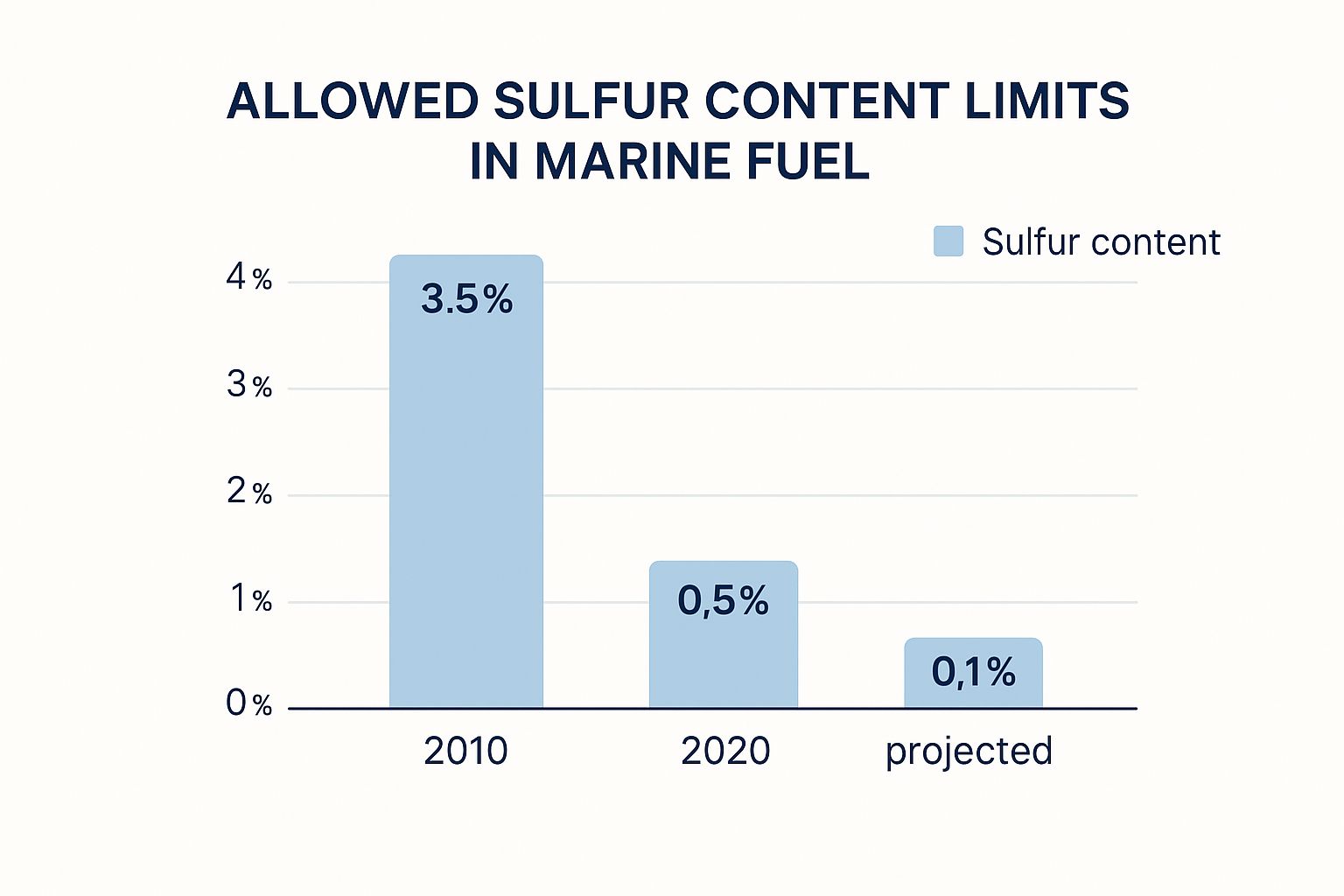

Automated monitoring systems give operators a real-time view of fuel consumption across their entire fleets. This data-driven insight helps identify trends, find areas for improvement, and make smarter decisions regarding fuel purchases and vessel operations. Operators can compare fuel efficiency across different vessels and identify best practices for optimal performance. This detailed information is essential for implementing data-backed changes to operational strategies. The chart below shows the impact of stricter sulfur limits on marine fuel over time.

The permitted sulfur content in marine fuel has dropped significantly, from 3.5% in 2010 to 0.5% in 2020. Projections indicate a further decrease to 0.1% by 2025. These stricter regulations encourage the use of cleaner fuels and technologies. Adapting marine fuel management strategies is therefore increasingly important.

This drive for cleaner operations, along with the increasing need for efficiency, promotes continuous innovation in the marine fuel optimization market. This market, valued at $12.01 billion in 2024, is expected to grow to $13.75 billion by 2025, a 14.5% CAGR. Learn more about this growing market here.

Evaluating Technology and Building Internal Capabilities

Selecting the right technology partners and developing in-house expertise is essential for successful implementation. Operators should carefully assess potential vendors, establish realistic integration timelines, and invest in training their teams to effectively utilize these new tools. This ensures the technology investment provides maximum value and supports long-term operational improvements. Adopting new software or hardware isn’t enough. These advancements require a change in approach, empowering teams to embrace data-driven decisions.

The following table provides a comparison of various marine fuel optimization technologies. It highlights their primary benefits, implementation costs, potential fuel savings, and the types of operations they best suit.

Marine Fuel Optimization Technology Comparison

| Technology Type | Primary Benefits | Implementation Cost | Expected Fuel Savings | Best Suited For |

|---|---|---|---|---|

| AI-Powered Route Optimization | Reduced fuel consumption, optimized transit times, improved weather routing | Moderate to High | 5-15% | Long-haul shipping, dynamic routing needs |

| Predictive Maintenance Systems | Reduced downtime, optimized engine performance, prevented breakdowns | Moderate | 2-8% | Fleets with older vessels, maintenance-intensive operations |

| Automated Monitoring Systems | Real-time fuel consumption tracking, identification of operational inefficiencies, data-driven decision-making | Low to Moderate | 1-5% | All fleet sizes, focus on operational efficiency |

This table summarizes the key differences between available fuel optimization technologies, enabling operators to select the most appropriate solutions for their specific needs and budget. Choosing the right technology can lead to substantial fuel savings and improve overall operational efficiency.

Navigating Alternative Fuels Without Breaking The Bank

The maritime industry is increasingly transitioning to alternative fuels. This shift is driven by environmental concerns and fluctuating traditional fuel costs. But this transition doesn't have to be a financial headache. With careful marine fuel management and planning, it can be a smooth, cost-effective process.

Assessing the Landscape of Sustainable Fuels

Several alternative marine fuels are available, each with its pros and cons. Liquefied natural gas (LNG) is a proven option, offering lower sulfur emissions than traditional fuels. However, it requires investment in specific infrastructure. Hydrogen and ammonia offer promising long-term potential as clean fuels. However, they’re still in early development stages, requiring significant technological advances for wider adoption.

Matching Fuel to Vessel and Operation

The right alternative fuel depends on the vessel type and its operational profile. For instance, LNG might suit large container ships on fixed routes with existing LNG bunkering infrastructure. Smaller vessels operating where infrastructure is limited might find biofuels or other emerging options more suitable. The key is to assess your needs and choose a fuel that fits your operations.

Real-World Costs and ROI of Alternative Fuels

Looking beyond the per-unit fuel price is crucial. Factor in infrastructure investments like specialized storage tanks and bunkering facilities. Also consider crew training and vessel modifications for the new fuel type. Evaluating the return on investment (ROI) of alternative fuels means looking beyond immediate fuel cost savings. Consider the long-term environmental benefits and potential future regulations penalizing traditional fuels. The liner shipping sector is rapidly adopting renewable fuels. In fact, 69% of the sector's order book by vessel count, and 79% by deadweight tonnage (DWT), is designed for renewable fuels as of 2025. Learn more here.

Building Flexibility into Your Fuel Strategy

Flexibility is essential in the rapidly changing fuel landscape. Design your marine fuel management strategy to adapt as new, efficient fuels and technologies emerge. This could involve incorporating dual-fuel or multi-fuel capabilities into new vessel designs. This allows switching between fuel types based on cost, availability, and regulations. This forward-thinking approach ensures competitiveness and compliance as the marine industry transitions to a sustainable future.

Practical Strategies for a Smooth Transition

Successfully transitioning to alternative fuels requires a phased approach. Begin by assessing your current fuel consumption and identifying areas for improvement. Explore suitable alternative fuel options. Develop a detailed implementation plan with clear timelines, budget, and performance metrics. Collaborate with fuel suppliers, technology providers, and regulatory bodies to ensure a coordinated, efficient transition. These steps will help you confidently navigate the changing fuel landscape and position your operations for long-term success.

Staying Compliant Without Losing Your Mind

Regulatory compliance in marine fuel management can feel overwhelming. But it doesn't have to be a constant source of stress and unexpected penalties. By implementing practical strategies, you can integrate compliance smoothly into your everyday operations.

Building Robust Systems for Compliance

Successful operators treat compliance as an ongoing process, not a one-time fix. They build strong systems that address the key regulations of marine fuel management. This proactive approach helps avoid costly violations and maintains operational flexibility. These systems typically include detailed fuel records, regular equipment checks, and clear procedures for fuel changes and bunkering.

Managing Sulfur Caps and Emission Control Areas

Regulations like sulfur caps and Emission Control Areas (ECAs) demand careful attention. Staying up-to-date on current and future regulations is crucial. Using compliant fuels and implementing exhaust gas cleaning systems (scrubbers) are vital for meeting these standards. Regular reviews and updates to procedures ensure ongoing compliance with evolving regulations.

Navigating Emerging Carbon Pricing Mechanisms

Carbon pricing mechanisms are becoming increasingly important. Understanding how these mechanisms impact your operations allows for better planning and financial management. Some operators are exploring carbon offsetting programs, while others invest in fuel-efficient technologies to minimize their environmental impact. Addressing carbon pricing proactively helps mitigate financial burdens and demonstrates environmental responsibility.

Practical Approaches for Compliance

-

Supplier Quality Assurance: Define clear criteria for fuel suppliers to ensure the quality and regulatory compliance of your fuel. Regular supplier audits and detailed record-keeping reinforce this process.

-

Documentation Management: Effective record-keeping is essential. This includes documenting fuel purchases, bunkering activities, and equipment maintenance. Organized documentation helps demonstrate compliance during inspections and audits.

-

Contingency Planning: Create contingency plans to address potential regulatory changes and fuel supply disruptions. This might involve securing alternative fuel sources or adapting vessel routes.

Turning Compliance into a Competitive Advantage

Instead of seeing compliance as a burden, leading operators use it to their advantage. Demonstrating a commitment to environmental regulations and best practices builds a strong reputation and attracts environmentally conscious clients. This proactive approach to marine fuel management can even unlock new business opportunities and partnerships. By building a culture of compliance, companies differentiate themselves in a competitive marketplace.

By adopting these strategies, operators can navigate the complexities of marine fuel regulations, minimizing risks and maximizing operational efficiency. This transforms compliance from a potential problem into a strategic advantage.

Smart Procurement Strategies That Cut Real Costs

Effective marine fuel management involves a strategic approach to fuel procurement. It's more than just finding the cheapest fuel; it's about balancing cost with quality, reliable supply, and smooth operations. This comprehensive strategy can significantly impact a company's profits.

Spot Buying Vs. Long-Term Contracts

A key decision in fuel procurement is choosing between spot buying and long-term contracts. Spot buying lets you take advantage of good market conditions and potentially get lower prices in the short term. However, it also leaves you open to price fluctuations.

Long-term contracts provide stable prices and predictable budgeting. But they could mean missing out on potential savings if market prices fall.

This means the best strategy often involves a mix of both. Check out this helpful resource: 2025 Fleet Fuel Management Solutions to Cut Costs. A company might lock in a portion of its fuel needs with long-term contracts for stable pricing, while using spot buying for the rest to capitalize on market dips.

Leveraging Market Intelligence

Effective procurement depends heavily on market intelligence. Understanding market patterns, global events, and regulations helps anticipate price changes and make informed decisions.

This means using strong data analysis tools and staying updated on industry news. This proactive approach allows operators to time their purchases strategically, maximizing cost savings.

Hedging Strategies

Hedging is a risk management tool that protects against unwanted price swings. It involves using financial tools like futures contracts to lock in a future fuel price.

Hedging can reduce price risk, but it also limits potential gains if market prices drop below the agreed price. Carefully consider the potential pros and cons of hedging relative to your company’s risk tolerance.

Adapting To Operational Needs And Risk Tolerance

There's no universal approach to marine fuel procurement. The best strategy depends on each company’s specific needs and risk tolerance. Smaller operators with limited resources may choose simpler methods. Larger companies with more complex operations may use more advanced strategies involving market analysis and hedging.

To illustrate different approaches, let's look at a comparison table:

Marine Fuel Procurement Strategy Analysis: This table analyzes different fuel buying approaches, highlighting cost impact, risk, and best-use scenarios.

| Procurement Method | Cost Advantage | Risk Level | Market Volatility Impact | Best For |

|---|---|---|---|---|

| Spot Buying | Potential for significant savings during market lows | High exposure to price fluctuations | Strong impact, both positive and negative | Companies with high risk tolerance and flexible operations |

| Long-Term Contracts | Price stability and predictable budgeting | Lower risk, but potential for missed savings | Less impact, provides a buffer against volatility | Companies prioritizing budget certainty and stable operations |

| Hybrid Approach (Spot + Contracts) | Balances cost savings potential with price stability | Moderate risk | Controlled impact | Companies seeking a balance between cost optimization and risk management |

This table highlights how different approaches suit different business needs. Choosing the right strategy requires careful consideration of your specific situation.

Evaluating Total Cost Of Ownership

It’s crucial to look beyond the initial fuel price. Total cost of ownership considers all costs associated with fuel, including transport, storage, handling, and quality checks.

This broader view helps identify hidden costs and make better decisions about sourcing and logistics. A cheaper fuel source might require extra pre-treatment, increasing the total cost.

Building Strong Supplier Relationships

Strong relationships with fuel suppliers are more than just price negotiations. It’s about building partnerships that offer more than just the immediate transaction. This could include market insights, flexible delivery, and technical help.

These relationships improve supply chain stability and give a competitive edge.

Aligning Procurement With Broader Business Objectives

Fuel procurement should align with your overall business goals. If sustainability is a priority, sourcing alternative fuels or working with environmentally responsible suppliers is key.

If operational efficiency is paramount, reliable and timely delivery takes center stage. By linking procurement with broader business strategy, companies maximize the value of their marine fuel management.

Measuring What Matters For Continuous Improvement

Effective marine fuel management depends on measuring the right things. Simply tracking overall fuel consumption isn't enough. This section explores how data-driven insights can lead to smarter decisions and significant cost savings.

Identifying Key Performance Indicators (KPIs)

World-class fuel management programs don't just collect numbers; they establish Key Performance Indicators (KPIs) that offer actionable insights. These KPIs go beyond basic fuel consumption.

They include factors like fuel efficiency per nautical mile, engine performance, and idle time. This helps pinpoint areas for improvement and measure how effective changes are.

For example, tracking fuel consumption relative to cargo weight or distance traveled gives a more detailed understanding of efficiency. This is much more useful than simply measuring total fuel used.

Practical Data Collection and Analysis

Collecting and analyzing data doesn't have to require a huge investment. Practical approaches involve using existing shipboard systems and simple data logging tools. By focusing on the most important metrics, operators can gain valuable insights without expensive software.

Starting with just a few key metrics can be a great foundation. Over time, this can grow into a more complete data analysis program. Learn more in our article about top marine fuel management systems.

Turning Data into Action

Data is useless unless it leads to action. Proven methods for turning data into improvements include setting clear targets based on inefficiencies. Testing new approaches with pilot programs and regularly reviewing results are also important.

Creating a culture of data-driven decision-making within the organization is also crucial. This makes sure that insights from data analysis are used to improve operations. Smart procurement strategies also help minimize costs. This guide explores ways to reduce shipping costs, a key part of overall cost optimization.

Building Organizational Capabilities

Success in marine fuel management requires building the right organizational capabilities. This means investing in training to develop in-house expertise. It also means establishing clear roles and responsibilities for fuel management.

Companies also need a system for adapting to changing conditions and new regulations. This makes fuel management a core part of the company’s culture, not just a task for one department.

By consistently measuring what matters, implementing data-driven changes, and building a culture of improvement, marine operators can save money and operate more efficiently. This approach to marine fuel management sets companies up for long-term success in a competitive industry.

Key Takeaways

Marine fuel management is more than just a simple task; it's crucial for success in the maritime industry. This section highlights key strategies to optimize your fuel management, transforming it from a cost center into a competitive advantage.

Optimize Your Fuel Consumption With Data-Driven Decisions

To truly reduce fuel consumption and optimize resources, a fundamental shift is needed. Moving from reactive to proactive, data-driven strategies is key. This involves implementing monitoring systems to collect real-time data on fuel usage across your fleet. Analyze this data to identify inefficiencies and make informed decisions.

For instance, by analyzing fuel consumption trends across different vessels, you can identify best practices and implement them fleet-wide. This not only saves fuel but also provides valuable insights into operational performance, leading to overall efficiency gains.

Embrace Technology For Enhanced Efficiency

Integrating the right technology is essential for efficient marine fuel management. AI-powered route optimization, predictive maintenance, and automated monitoring systems offer significant advantages.

- AI-Powered Route Optimization: Utilize machine learning to analyze weather patterns, ocean currents, and vessel performance to create the most fuel-efficient routes.

- Predictive Maintenance: IoT sensors allow for proactive detection of potential engine problems, minimizing downtime and maintaining optimal fuel efficiency.

- Automated Monitoring: Real-time insights into fuel consumption empower data-driven decisions and efficient fuel control across your fleet.

Adopting these technologies can effectively optimize fuel use, reduce operational costs, and minimize your environmental impact.

Navigate the Transition to Alternative Fuels Strategically

Transitioning to alternative fuels is vital for long-term sustainability, but it demands careful planning and implementation. The best alternative fuel depends on your vessel types, operational profiles, and current infrastructure.

Consider the costs associated with infrastructure upgrades, crew training, and vessel modifications. Factor in not only immediate fuel costs but also the long-term return on investment, including environmental benefits and future regulations. A flexible strategy, such as incorporating multi-fuel engine capabilities, allows you to adapt as new fuel options emerge.

Master Compliance Management for Smooth Sailing

Navigating regulatory compliance might seem daunting, but it can be streamlined. By establishing robust systems for documentation, supplier assurance, and contingency planning, you can seamlessly integrate compliance into your operations.

- Supplier Assurance: Set clear standards for fuel quality and supplier compliance.

- Documentation: Implement a reliable system for tracking and managing fuel purchase, usage, and compliance documentation.

- Contingency Planning: Prepare for potential regulatory shifts or fuel supply disruptions.

Transforming compliance into a strength involves incorporating robust safety protocols and demonstrating your commitment to environmental stewardship.

Rethink Your Fuel Procurement Strategy

Fuel procurement should be a strategic process that balances cost with quality, supply security, and operational effectiveness. Consider a combination of spot buying and long-term contracts to manage fuel costs effectively while minimizing risk.

Use market intelligence to strategically time fuel purchases and explore hedging strategies to protect against price volatility. Strong supplier relationships can offer valuable insights and help navigate the intricacies of fuel procurement. Choose suppliers who share your sustainability objectives and contribute to a more responsible fuel management approach. Optimizing your fuel procurement strategy can significantly improve your bottom line and overall operational efficiency.

Implement Continuous Improvement Through Performance Measurement

You can't improve what you don't measure. Establish Key Performance Indicators (KPIs) that extend beyond basic fuel consumption. Monitor metrics like fuel efficiency per nautical mile, engine performance, and idle times.

This data-driven approach helps identify areas for improvement, implement targeted changes, and assess the effectiveness of your strategies. By cultivating a culture of continuous improvement, your fuel management program will consistently deliver value and adapt to the ever-changing maritime landscape.

Ready to transform your marine fuel management? Explore how CLiX Fueling Solutions can simplify your fueling operations and enhance operational efficiency. Visit CLiX Fueling Solutions today!