A manual gasoline transfer pump is like a reliable straw that lets you move fuel with your hands—no electricity, no fuss. Stroke the handle and watch gas glide from one container into another, avoiding the mess and danger of traditional siphoning.

The Simple Tool For Safe Fuel Handling

Have you ever wrestled with a heavy five-gallon can, pouring gasoline into a narrow tank opening? It’s a juggling act that often ends in drips or costly spills. A manual pump solves that problem by giving you steady, controlled flow—think of it as a bridge between your fuel and your machine.

Whether you maintain your lawnmower, prep a generator for an outage, or fill your boat before a weekend trip, this pump saves you the awkward spills and burnt fingers.

Why Every Garage Needs One

The real value of a hand pump shows up in daily routines and surprise situations. It:

- Routine Refueling: Tops off lawnmowers, ATVs, and power tools without overfills.

- Seasonal Maintenance: Drains fuel tanks on motorcycles, boats, and snowmobiles before storage.

- Emergency Transfers: Moves gas between cars or from a backup can during a roadside hiccup.

A manual gasoline transfer pump isn't just a convenience—it's a safety safeguard. By sealing the fuel path, you cut down on fire risk, skin contact, and harmful spills.

Beyond The Basics Of Fuel Transfer

In the following sections, we’ll walk through:

- The inner workings of piston vs. siphon pumps, so you know which style fits your gear.

- A step-by-step selection guide: capacity, nozzle type, hose length.

- Hands-on maintenance tips to keep your pump primed for years.

For boat owners, proper fueling goes deeper. Check out our guide on boat fueling safety offers a complete protection playbook to complement these tips.

By the time you finish this guide, you’ll feel confident choosing and using a manual transfer pump—turning what used to be a headache into a smooth, simple task.

How a Manual Gas Pump Actually Works

Ever used a straw? You suck the air out, and the pressure outside pushes your drink up. A manual gas pump works on that same basic idea: creating a pressure difference. It uses a clever bit of physics to create a vacuum, pulling fuel from one container and pushing it into another—no electricity or motor required.

This simple mechanical magic comes in a few different flavors, and knowing the difference helps you pick the right tool for the job. We'll break down the three main types you'll find: siphon, piston, and rotary pumps.

The Siphon Pump: The Power of Gravity

The siphon pump is about as simple as it gets. It’s usually just a flexible hose with a squeeze bulb, and it uses gravity as its engine.

- Get Set Up: First, stick one end of the hose into your gas can and the other into the tank you're filling (like your lawnmower or boat). The key here is that the gas can must be sitting higher than the tank you're filling.

- Create the Vacuum: Give that bulb a few good squeezes. This pushes air out and then creates a low-pressure zone, which starts pulling gasoline up into the hose.

- Let Gravity Do the Work: Once you get the fuel flowing past the highest point of the hose, you can stop squeezing. Gravity takes over from there. The weight of the fuel heading downhill creates a continuous pull, siphoning the rest of the gas without you lifting another finger. It's like starting a mini, controlled waterfall.

This method is fantastic for quick, small jobs where you can easily get your source container elevated.

The Piston Pump: Controlled Suction

A piston pump gives you much more direct control, working a lot like a bicycle pump in reverse. You move a handle, which operates a piston inside a cylinder to draw and push the fuel.

- The Upstroke: When you pull the handle up, the piston creates a vacuum in the chamber. This suction pulls fuel from the gas can into the pump.

- The Downstroke: Pushing the handle down forces the fuel out of the chamber, through the hose, and into your tank.

Each full pump moves a set amount of gas, which is great for preventing spills and getting just the right amount of fuel where you want it.

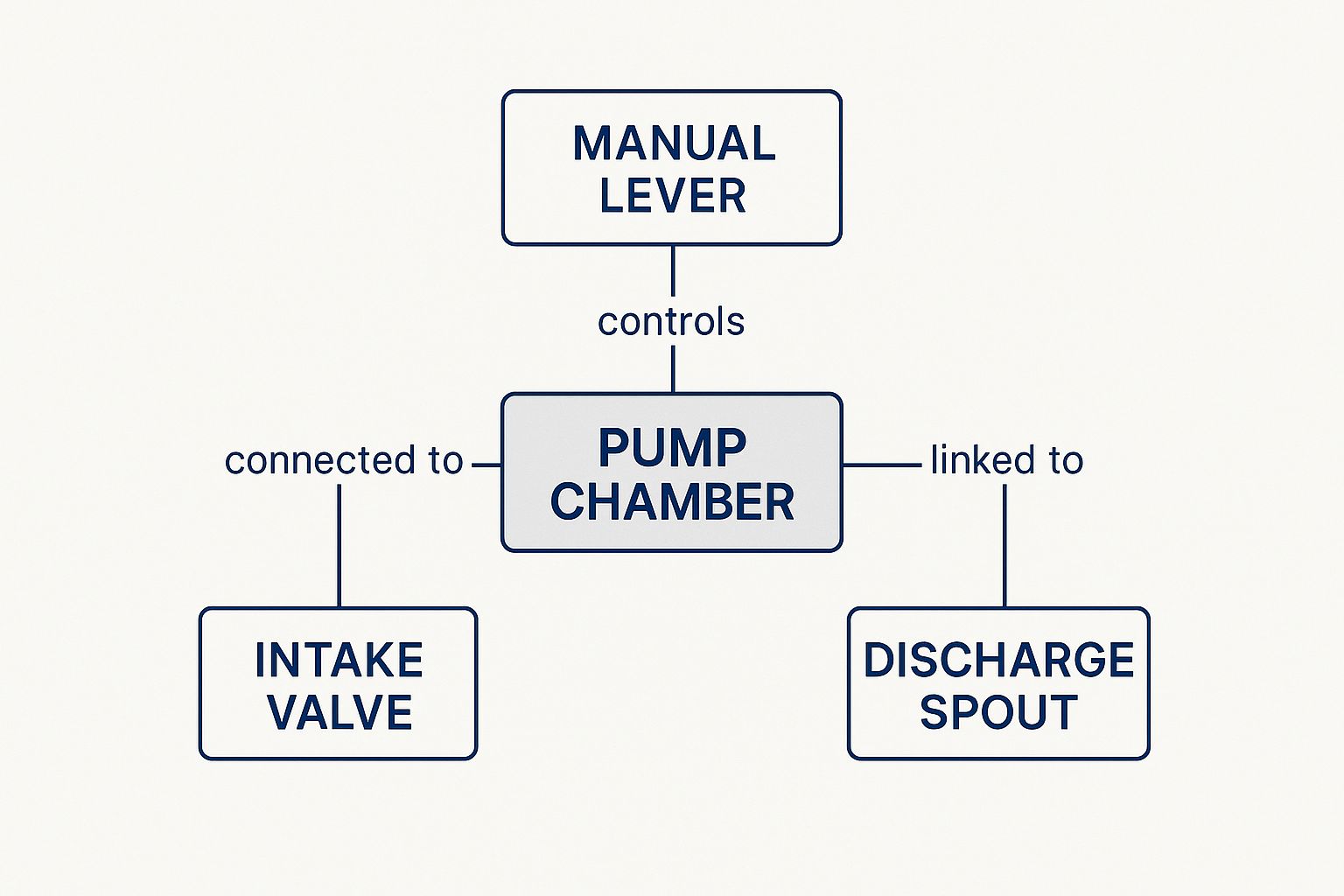

This diagram shows how the handle you operate is directly connected to the pumping action that moves the fuel.

As you can see, your simple up-and-down motion is what makes the whole system work, managing the intake and output with each stroke.

The Rotary Pump: Continuous Hand-Cranked Flow

When you need to move a serious amount of fuel, the rotary pump is your best friend. Instead of an up-and-down motion, this one uses a hand crank. Think of an old-timey water well, but you're cranking fuel instead of a bucket of water.

As you turn the handle, a set of gears or vanes spins inside a housing. This motion traps small amounts of gasoline and pushes them from the intake to the outlet, creating a smooth, steady flow.

Rotary pumps are the heavy lifters. Because they move fuel continuously, they're way more efficient for transferring 10 gallons or more at once. They're perfect for emptying large drums or refueling equipment out on a job site.

Choosing The Right Pump For Your Needs

Picking the right manual gasoline transfer pump isn’t about grabbing the fanciest or most expensive one off the shelf. It’s all about matching the tool to the job. Think of it like a kitchen knife—you wouldn't use a tiny paring knife to carve a turkey, and you wouldn’t use a giant cleaver to peel an apple. The same logic applies here.

To find your perfect pump, just ask yourself a few questions: What am I moving? How much of it? And how often? The answers will point you straight to a pump that's safe, effective, and just right for your garage, workshop, or boat.

Material Compatibility Is Non-Negotiable

First things first, and this one is critical: the pump's materials must be compatible with gasoline. Gas is a harsh solvent that can chew right through standard plastics and rubber. Using a pump designed for water or oil is a recipe for disaster, as the materials can dissolve, leak, and create a serious fire hazard.

When you're shopping, always look for pumps specifically marked as safe for flammable liquids like gasoline. Here’s what to keep an eye out for:

- Viton Seals: This type of synthetic rubber is built to withstand gasoline and ethanol, which means no leaks and a much longer lifespan for your pump.

- Anti-Static Hoses: These are a must-have. They safely dissipate static electricity, preventing a stray spark from igniting fuel vapors.

- Durable Body Construction: Look for sturdy materials like aluminum, cast iron, or high-grade, fuel-resistant plastics that won't degrade over time.

Remember: a pump that isn't explicitly rated for gasoline isn't just a poor choice—it's a dangerous one. Always put safety first.

Matching Flow Rate To Your Tasks

Flow rate tells you how quickly a pump can move fuel, usually measured in gallons per minute (GPM). But faster isn't always better. It’s about finding the right speed for your specific job to maintain control and avoid messes.

For instance, consider these two scenarios:

- Small Jobs (Siphon Pumps): If you're just topping off a lawnmower or a small generator, a simple siphon pump is perfect. Its lower flow rate gives you precise control, preventing messy overfills.

- Big Jobs (Rotary Pumps): Need to empty a 55-gallon drum or refuel a tractor? A rotary pump is your best friend. It can move 5-10 GPM or more, turning a long, tedious task into a quick one.

It’s easy to think of these as simple tools, but they’re part of a massive global industry. The hand fuel transfer pump market hit about USD 1.2 billion in 2023, with demand from agriculture, construction, and automotive sectors driving its growth. You can see more about this trend over on Dataintelo.com.

Hose Length And Flexibility Matter

Finally, don't forget about the hose. It seems like a minor detail, but its length and flexibility can make or break your experience. A hose that’s too short is useless, while one that’s too stiff can be impossible to snake into tight spots. Before you buy, think about the distances you'll be working with.

This is especially true for boats, where fuel tanks can be in awkward, hard-to-reach places. If you’re often refueling on the water, you might find our specific guide on selecting a marine fuel transfer pump useful. A flexible, kink-resistant hose makes all the difference when you're leaning over the side of a boat.

Manual Gasoline Pump Comparison

To help you decide, let's break down the three main types of manual pumps and see where each one shines. This table gives you a quick snapshot to compare them side-by-side.

| Pump Type | Best For | Pros | Cons |

|---|---|---|---|

| Siphon Pump | Small-volume tasks, like filling lawnmowers or generators. | Inexpensive, simple, offers precise control. | Slow transfer speed, requires gravity assist. |

| Piston Pump | General-purpose use, moving moderate amounts from cans. | Versatile, good flow control, easy to operate. | Can be tiring for large volumes, more moving parts. |

| Rotary Pump | High-volume transfers, such as from 55-gallon drums. | Very fast (5-10+ GPM), efficient for big jobs. | More expensive, overkill for small tasks. |

Ultimately, choosing between a siphon, piston, or rotary pump comes down to how you'll be using it most often. By considering materials, flow rate, and the hose, you can easily find a manual gasoline transfer pump that will serve you well for years to come.

A Step-by-Step Guide to Safe Fuel Transfer

Using a manual gasoline transfer pump is pretty simple, but let's be honest—handling gasoline demands your full attention. It's highly flammable stuff, and its vapors can ignite with just one tiny spark.

The good news is that following a consistent, safety-first process makes the whole thing a straightforward, spill-free routine. We've broken down the entire procedure into three clear stages to make sure every transfer is a safe one.

Before You Begin The Transfer

Preparation is everything. Seriously, this is the most important step for preventing accidents. Before a single drop of fuel moves, just take a minute to set up your area and give your gear a once-over. This little bit of time upfront eliminates almost all the common risks.

First, find a well-ventilated spot, ideally outdoors. This helps scatter any flammable vapors and keeps you from breathing them in. Make sure you are well away from any potential ignition sources.

- No flames or sparks: This means no pilot lights, running engines, cigarettes, or even static electricity from your clothes.

- Inspect your gear: Give your manual gasoline transfer pump a quick look. Are there any cracks, splits, or brittle spots on the hoses? Make sure all the connections are tight, too. Air leaks can kill a siphon or cause messy drips.

Critical Safety Warning: Always wear the right personal protective equipment (PPE). Nitrile gloves are a must to keep gas off your skin, and a good pair of safety glasses will protect your eyes from any accidental splashes.

During The Fuel Transfer

Alright, with your area secure and your equipment checked, you’re ready to start the transfer. The key here is to stay in control and work at a nice, steady pace. Rushing is a recipe for splashes and overfills.

- Position Your Containers: Put the source container (your gas can) on a stable surface that’s higher than whatever you’re filling (like your car’s tank). For a siphon pump, this height difference is what lets gravity take over and do the heavy lifting.

- Insert the Hoses: Place the intake hose securely into the gas can, making sure it goes all the way to the bottom to get as much fuel as possible. Then, put the outlet hose deep inside the receiving tank’s opening so it doesn't pop out unexpectedly.

- Start the Flow: Now it's time to get things moving. If you have a siphon pump, give the bulb a few firm squeezes until you see fuel flowing through the hose. For a piston or rotary pump, just start a smooth, consistent pumping motion. Whatever you do, avoid pumping too fast or aggressively—that’s how you get fuel surging and splashing everywhere.

This image is a great example of the proper hand placement. A controlled grip and a steady rhythm are all it takes to create a smooth, manageable flow and avoid spills.

After You Are Done

You're not quite finished when the tank is full. The job is done when your equipment is cleaned up and put away properly. This last part prevents the pump from getting gummed up and keeps it ready for the next time you need it.

Once the transfer is complete, lift the intake hose out of the gas can to break the siphon. Keep pumping for a moment to push any remaining fuel out of the hoses and into the tank. Pumping air through for a few seconds is a good way to clear the lines. For a deeper dive, our guide on expert tips for safe fuel transfer hand pump use has even more valuable insights.

Give the pump and hoses a good wipe-down with a clean, dry rag to get rid of any leftover fuel. Never use water to clean a gasoline pump—it can cause the internal parts to rust.

Finally, store your pump in a cool, dry, and well-ventilated place away from sunlight and anything that could start a fire. A clean and properly stored manual gasoline transfer pump will be a reliable tool for years to come.

Keeping Your Pump in Top Shape: Simple Maintenance and Troubleshooting

A manual gasoline transfer pump is one of those tools you want to work every single time you need it. And with a little bit of care, it will. Think of it less like a complex piece of machinery and more like a trusty tool in your garage—a few minutes of attention after each use is all it takes to keep it ready for years of service.

Proper care prevents the most common headaches and ensures your pump is reliable, whether you're just topping off the lawnmower or dealing with an unexpected roadside situation. It's really about avoiding the gunk and grime that can build up over time.

A Quick and Easy Maintenance Routine

You don't need a complicated checklist for this. The whole routine boils down to a couple of simple habits: cleaning the pump right after you use it and giving it a quick look-over now and then. This simple process is your best defense against the number one enemy of fuel pumps: residue buildup.

Gasoline, especially the ethanol-blended stuff, can leave a sticky film behind as it dries. That varnish can jam up the internal valves or make a squeeze bulb feel stiff and useless. A quick flush-and-wipe stops that problem before it ever starts.

Here's a straightforward routine to adopt:

- Clear the Lines: Once you're done transferring fuel, pull the intake hose out of the gas can. Keep pumping for a few more seconds to force all the remaining gasoline out of the hoses.

- Pump Some Air: With the lines empty, just pump air through the system for about 30 seconds. This helps any leftover droplets evaporate, leaving the inside clean and dry.

- Wipe It Down: Grab a clean rag and wipe down the outside of the pump and hoses. This gets rid of any spills and dirt.

- Store It Smart: Find a cool, dry place for your pump. Keeping it out of direct sunlight is key, as UV rays can make plastic and rubber brittle over time.

Quick Fixes for Common Issues

Even the best-maintained tools can act up sometimes. The good news is that most problems with these pumps are incredibly easy to diagnose and fix right on the spot. Before you give up and toss it, run through these common scenarios.

Don't be too quick to blame the pump if it's not working. Over 90% of transfer failures aren't because the pump is broken, but because of simple things like an air leak or a blockage. A quick check can save you a trip to the store.

Here’s a rundown of the most common frustrations and what to do about them:

-

Problem: The Pump Won't Start a Siphon

- Solution: Check for Air Leaks. This is almost always the problem. A good seal is everything. Make sure both hoses are shoved on tight to the pump fittings. The tiniest air gap is enough to kill the suction.

- Solution: Check Your Elevation. With a siphon pump, gravity does the work. Your source container has to be higher than the tank you're filling. No exceptions. Give gravity a helping hand.

- Solution: Look for Cracks in the Hose. Give the hoses a quick inspection, especially near the ends where they connect. A tiny pinhole or crack will let air in and prevent a siphon from starting.

-

Problem: The Fuel is Flowing Super Slowly

- Solution: Unkink the Hose. Just like a garden hose, a kink will choke off the flow. Make sure the lines are straight and have a clear path from one container to the other.

- Solution: Check the Filter. Many pumps have a small screen on the intake end to keep debris out. It can get clogged with sediment from the bottom of a gas can. Pull it out and see if it needs a quick cleaning.

How Your Hand Pump Fits into the Global Fuel Market

It’s easy to think of that simple hand pump in your garage as just another tool. But in reality, it’s your little piece of a massive, global industry built around one simple need: moving fuel from one place to another.

This connection between your own needs—whether for a project or an emergency—and worldwide economic trends is what ensures you have access to a quality tool. Let's take a look at why a manual gasoline transfer pump is such a vital piece of equipment, not just for you, but for millions around the world.

The Asia-Pacific Powerhouse

The demand for non-electric fuel solutions isn't just about topping off a lawnmower in the suburbs. It's largely driven by explosive growth in regions where reliable electricity isn't always a given, making manual pumps an absolute necessity.

The Asia-Pacific region, in particular, is the dominant force here. Countries like China and India are seeing huge expansion in their manufacturing, construction, and agricultural sectors. Think about it: farmers refueling tractors in remote fields or construction crews powering generators on-site all need a dependable way to transfer fuel.

This constant, large-scale need pushes manufacturers to innovate, leading to more durable, efficient, and safer pumps for everyone.

The numbers back this up. The entire fuel transfer pump market, including manual versions, was valued at a whopping USD 1.71 billion back in 2021. The Asia-Pacific region claimed the lion's share of that, with 35.9% of the revenue. If you're curious, you can dig into more data on these global fuel market trends to see just how big this industry is.

So, what does this all mean for you? It's great news. This huge, competitive global market is why you can find high-quality, safe, and affordable manual gasoline transfer pumps so easily. Your need for a reliable tool is being met by a worldwide industry that’s always working to make these simple devices even better.

Frequently Asked Questions About Gas Pumps

Even with a tool as simple as a manual pump, you're bound to have a few questions. Getting the right answers is key to using your pump safely and making sure it works when you need it most.

Here, we've compiled straightforward answers to the questions we hear all the time. Think of this as a quick reference guide to help you solve common issues and get the most out of your pump.

Can I Use My Gasoline Pump for Other Liquids?

It’s a tempting thought—using one pump for gasoline, water, maybe even oil. But it's a really bad idea. While some pumps claim to be multi-purpose, using a manual gasoline transfer pump for anything other than fuel is asking for trouble.

Pumping water, for instance, can leave trace amounts of fuel behind, contaminating the water supply. Try to pump something thick like motor oil, and you’ll find it's often too viscous for a simple siphon pump. You'll likely just end up damaging the pump's internal parts.

The golden rule is simple: one pump, one purpose. Dedicate your pump only for fuel. This completely avoids dangerous cross-contamination and ensures the pump’s seals and hoses, which are made specifically to resist gasoline, don't break down.

How Do I Properly Clean My Fuel Transfer Pump?

A little bit of cleaning goes a long way in keeping your pump safe and extending its life. After you're done using it, just take a minute to clear out any leftover fuel. It's a quick process that doesn't require any special tools.

First, pump any remaining gasoline back into an approved container. With the lines mostly empty, just keep pumping air through the system for about a minute. This helps the last bits of fuel evaporate from the hoses and the pump itself.

Once that's done, find a well-ventilated spot to store it, away from direct sunlight or any heat sources. And here's a crucial tip: never use water to clean the inside of your pump. Water can cause corrosion and will quickly ruin the internal seals.

What Is the Most Common Reason a Siphon Pump Fails?

Nine times out of ten, if your siphon pump isn't working, it’s because of an air leak. Siphons need a completely sealed system to create the vacuum that gets the fuel moving. Even the tiniest leak will break that seal and stop it from working.

Before you get frustrated, do a quick check of these common culprits:

- Hose Connections: Are the hoses pushed all the way onto the pump bulb? Make sure they are snug and secure.

- Hose Integrity: Look over the entire length of both hoses. You're searching for any small cracks or pinholes, especially near the ends where they connect.

- Container Placement: Don't forget the basics of gravity! The gas can you're pumping from must be physically higher than the tank you're pumping into.

Running through this simple checklist will solve the vast majority of pump failures without needing to grab a single tool.

For a truly spill-free and stress-free fueling experience on the water, trust CLiX Fueling Solutions. Our innovative system automatically stops the flow when your tank is full, protecting your boat and the environment. Discover the difference at CLiX Fueling Solutions.