A hand transfer fuel pump is one of those brilliantly simple tools that solves a messy problem. At its heart, it's a manual device designed to move liquids like gasoline or diesel from one container to another, safely and without electricity. Think of it as a giant, high-tech straw that gives you total control, preventing spills and making the whole process cleaner.

What Is a Hand Fuel Pump and Why You Need One

Ever tried to pour gas from a heavy, awkward can into a small fuel tank? It’s a recipe for disaster—spilled fuel, wasted money, and a cloud of dangerous fumes. A hand transfer pump is the perfect answer to this age-old problem. It provides a clean, efficient, and surprisingly easy way to handle fuel when you're off the grid or just away from a power source.

This simple gadget is a lifesaver in so many situations, making it a must-have for anyone from weekend mechanics and DIYers to boat owners and outdoor adventurers. Its value isn't just about convenience; it’s about being safe, smart, and self-sufficient.

Everyday Uses for a Manual Fuel Pump

The real magic of a hand fuel pump is just how versatile it is. It's not just a tool for emergencies—it’s something you'll find yourself reaching for again and again to make routine tasks easier.

- Refueling Equipment: Easily top off your lawnmower, ATV, boat, or generator from a big fuel can. No more lifting heavy jugs or struggling with clumsy funnels.

- Vehicle Maintenance: Need to drain old, stale fuel from a car or motorcycle before winter storage? A hand pump lets you do it safely and completely, protecting your engine from damage.

- Emergency Fueling: If you ever run out of gas on the road, a hand pump makes transferring fuel from a spare can into your vehicle's tank a quick and clean job.

A hand pump gives you total control over the flow of fuel. While an electric pump can break down, a manual pump is all about mechanical simplicity. The power is literally in your hands.

An Enduringly Popular Tool

Even with all the automated tech out there, the humble hand transfer pump remains a popular tool worldwide. Why? Because you just can't beat its portability, low cost, and dead-simple operation.

The global market for these pumps was valued at nearly USD 1.2 billion in 2023, which just goes to show how essential they still are across countless industries. You can discover more about the market drivers for this essential tool and see for yourself why its old-school dependability is so highly prized. It’s a tool that empowers you to handle fuel with confidence, making it a cornerstone of any well-stocked garage or toolkit.

How Manual Fuel Pumps Actually Work

At first glance, a manual fuel pump looks almost too simple. How can a few bits of plastic and hose move gallons of fuel? The secret isn't brute force; it's about harnessing a basic principle of physics with a little bit of your own elbow grease.

It all comes down to creating a pressure difference.

Think of a hand transfer pump fuel system as being a bit like using a drinking straw. When you suck on a straw, you’re not really pulling the liquid up. Instead, you're creating a low-pressure area—a vacuum—inside the straw. The higher atmospheric pressure on the surface of your drink then does the work, pushing the liquid up the straw to fill that void. A hand pump does the exact same thing.

The Key Players in Fuel Transfer

This whole process relies on a few key parts working together seamlessly. Understanding how they interact makes it clear how such a basic tool can be so effective. The goal is to create a sealed, one-way street for the fuel to travel without any messy spills.

Here are the basic components you’ll find:

- The Pump Mechanism: This is the heart of the operation. It could be a squeeze bulb, a lever you pump, or a crank you turn. Its only job is to create that initial vacuum that gets the fuel flowing.

- Intake and Discharge Hoses: The intake hose goes into your fuel can, and the discharge hose goes into your vehicle's tank. For the best results, you want the end of the discharge hose to be lower than the fuel source—that way, gravity can lend a helping hand.

The real magic happens inside the pump, thanks to the check valves. These are tiny, one-way gates that act like bouncers at a club. They let fuel flow out toward the destination but immediately slam shut to prevent it from ever flowing back. This is what keeps the siphon going between each pump or squeeze.

The Growing Need for Reliable Fueling

This beautifully simple technology is a workhorse in countless industries, from farming and construction to boating and off-roading. The need for reliable fueling solutions is so massive that the global fuel transfer pump market was valued at USD 1.71 billion in 2021. Experts project it will climb to USD 2.47 billion by 2029, all because people everywhere need dependable ways to move fuel. You can read the full research on this growing market to get a better sense of how vital these tools are.

So, every time you squeeze that bulb or turn that crank, you’re just repeating a simple cycle: create a vacuum, let air pressure push the fuel, and let the check valves trap it. This creates a steady, controlled flow, proving that a little physics can go a long way—no batteries or power cords required.

Choosing the Right Hand Fuel Pump for Your Needs

Picking the right hand transfer pump fuel is a lot like choosing any other tool for your workshop. The little pump that’s perfect for topping off your ATV just isn't going to cut it when you need to drain a 55-gallon drum. Every design has its own sweet spot, built for specific jobs, fuel volumes, and how you prefer to work.

Not all manual pumps are built the same, and knowing the difference is key to getting one you won't regret buying. It really boils down to four main designs, each working a little differently and shining in its own way.

Siphon Pumps: The Simple Solution

Siphon pumps are about as straightforward as it gets. They rely on gravity, with just a little help from you to get things started. This makes them the go-to choice for simple, small jobs where you can place the fuel source higher than what you're filling. They're the quick-and-easy option for low-volume transfers.

- Bulb Siphon: This is the one everyone pictures, with a rubber bulb you squeeze a few times. Those squeezes create a vacuum, and gravity does the rest. They’re cheap, small, and get the job done.

- Shaker Siphon: A clever twist on the classic. This one has a small valve (usually just a marble) at the end of the hose. You just jiggle it up and down in the fuel to start the flow. No squeezing required.

Siphon pumps are incredibly easy to use, but their biggest weakness is their total dependence on gravity. If you need to move fuel uphill or just need more oomph, you’ll have to step up to a pump with more mechanical muscle.

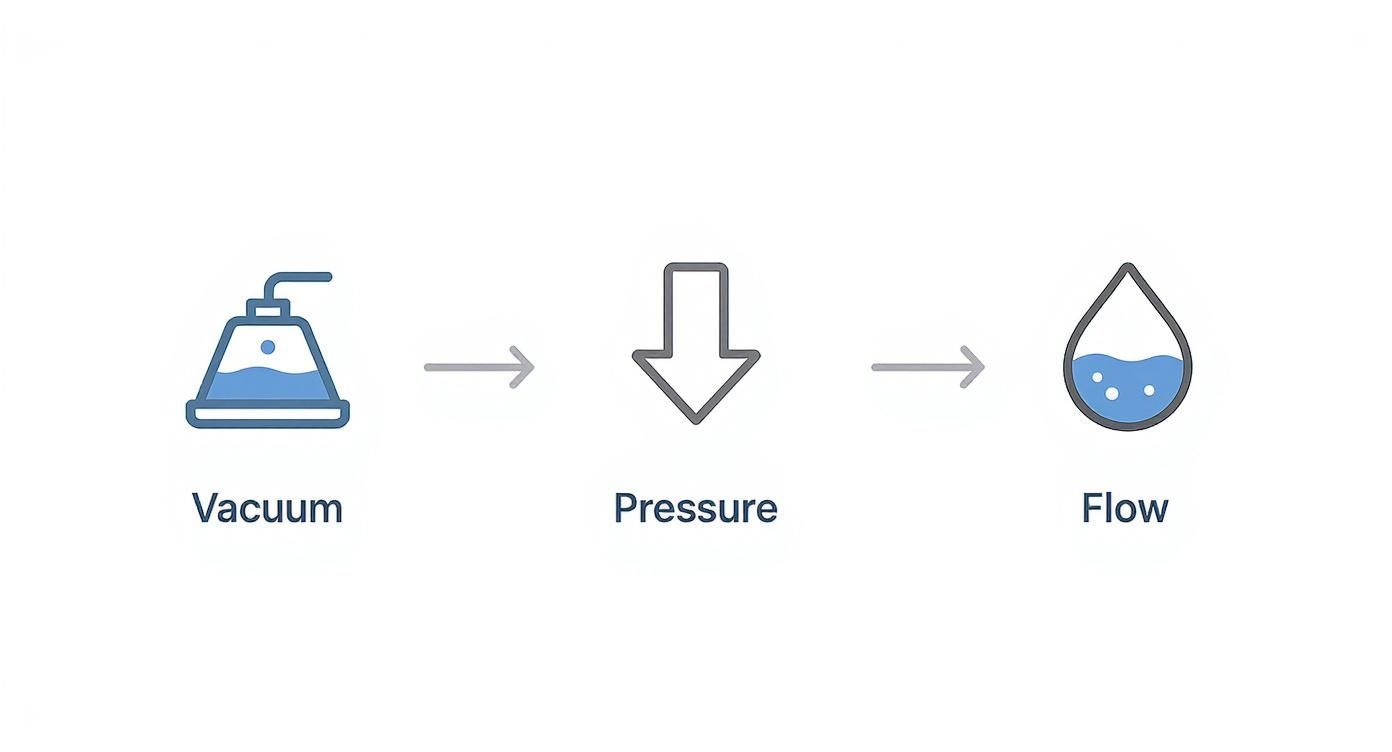

The infographic below breaks down the simple physics behind how these pumps work—creating a vacuum and generating pressure to get the fuel moving.

It’s a great visual reminder of how a little bit of manual effort can put physics to work, making a potentially messy job clean and efficient.

Piston and Rotary Vane Pumps: For Bigger Jobs

When you're dealing with larger amounts of fuel or fighting against gravity, you need a workhorse. That's where piston and rotary pumps come in. They give you far more power and control, making them perfect for tougher tasks like emptying a boat's fuel tank for the winter.

A Piston Pump works just like one of those old-fashioned water well pumps. You work a lever up and down, which pulls fuel into a chamber and then shoves it out the hose. This creates some serious suction, making it a champ at pulling fuel out of deep drums or pushing it up to a higher level.

For pure efficiency, nothing beats a Rotary Vane Pump. You turn a hand crank, and it pushes out a smooth, non-stop flow of fuel. As you crank, little vanes inside spin and move the liquid at a surprisingly fast clip, often hitting flow rates over 7 liters per minute. They are the best bet for anyone doing regular, high-volume fueling.

Comparison of Hand Fuel Transfer Pump Types

To make it even clearer, let's break down the key differences in a simple table. This should help you zero in on the exact type of pump that fits what you need to do.

| Pump Type | Mechanism | Best For | Typical Flow Rate | Price Range |

|---|---|---|---|---|

| Bulb Siphon | Squeezable bulb creates initial vacuum | Small, occasional jobs (e.g., lawnmower, ATV) | 1-2 GPM | $10 - $20 |

| Shaker Siphon | Jiggle motion with a one-way valve | Quick, gravity-fed transfers | 2-4 GPM | $15 - $30 |

| Piston Pump | Up-and-down lever action | Draining deep containers, moving fuel uphill | 3-5 GPM | $30 - $70 |

| Rotary Vane Pump | Hand-crank rotates internal vanes | High-volume, frequent use (e.g., 55-gallon drums) | 5-10 GPM | $50 - $150+ |

As you can see, the right choice really comes down to balancing how much fuel you're moving, how often you're doing it, and your budget. For a deeper dive into specific models and our top picks, feel free to check out our guide on the top manual transfer pump for fuel in 2025.

Your Step-By-Step Guide to Safe Fuel Transfer

Using a hand transfer fuel pump is pretty simple, but let's be clear: safety always comes first. Fuel is highly flammable, and one careless moment can create a very dangerous situation. If you follow a consistent, safety-focused process, what could be a risky job becomes just another routine task you can handle with confidence.

Before a single drop of fuel moves, you need to get your workspace ready. Think of it as creating a safety bubble around your fueling operation. The whole point is to get rid of potential risks before they even show up.

Setting Up for a Safe Transfer

First things first: ventilation. Fuel vapors are heavier than air and can settle in low, enclosed areas, which is a serious fire hazard. On a boat? Open every hatch and porthole. In a garage? Get that main door wide open so fresh air can move through.

Next, you have to clear the area of anything that could possibly ignite the fuel. This part is non-negotiable.

- No Smoking: Put out any cigarettes, cigars, or pipes far away from where you're working.

- No Open Flames: This means pilot lights on water heaters or stoves, and definitely no nearby grills.

- No Running Engines: Shut down any engines, generators, or other equipment that could throw a spark.

Once the area is secure, grab your safety gear. You’ll want a B-I rated fire extinguisher within easy reach. It's also a smart move to have a spill kit or some absorbent pads handy to deal with any accidental drips right away. If you want to be fully prepared, check out our guide on fuel spill cleanup procedures provides an expert response plan.

Executing the Pumping Process

Alright, you're ready to start moving fuel. Place your source container—like a gas can—on a stable, flat surface. If you can, set it just a bit higher than the tank you're filling. This lets gravity give you a little help with the siphon, meaning less work for you.

Critical Safety Warning: Static electricity is a silent threat. Before you do anything else, touch the metal nozzle of the discharge hose directly to the metal fill opening of the tank. Keep that metal-to-metal contact going the entire time you're transferring fuel. This grounds the system and prevents a static spark from ruining your day.

Follow these steps for a spill-free transfer:

- Insert the Hoses: Put the intake hose deep into the source container so it hits the bottom. Then, place the discharge nozzle securely into the tank you're filling.

- Prime the Pump: Start pumping with a slow, steady motion. It doesn't matter if you're squeezing a bulb or working a lever—don't pump too fast or aggressively. That can cause fuel to splash and release more vapors.

- Listen and Observe: Pay attention. You can actually hear the sound of the fuel filling the tank. As it gets closer to full, that sound will change, which is your cue to slow down and get ready to stop.

- Finish Cleanly: Once the tank is full, carefully lift the discharge hose out, letting any leftover fuel in the hose drain back into the original container. Cap both containers tightly right away.

By sticking to this disciplined approach, you can make sure every fuel transfer is done safely and efficiently, without any drama.

A Little Maintenance Goes a Long Way

Your hand transfer fuel pump is like any other trusted tool in your workshop or on your boat—a little bit of regular care keeps it working reliably for years. Taking a few minutes for simple maintenance means you can count on it to work safely and efficiently every time, avoiding a frustrating breakdown when you need it most.

The best habit you can get into is cleaning the pump after every use. It's easy to forget, but fuel residue can be surprisingly nasty, especially gasoline. Over time, it will eat away at plastic and rubber parts, making them brittle and prone to cracking. A leaky fuel pump isn't just an annoyance; it's a safety hazard.

All you have to do is pump the last bit of fuel out of the hoses and give the whole thing a quick wipe-down. This one simple step prevents the kind of gunk and corrosion that causes major headaches later on.

Quick Checks and Proper Storage

Where you store your pump is just as important as keeping it clean. Your pump’s worst enemy is direct sunlight. The UV rays will slowly break down the hoses, making them stiff and weak. Always tuck it away in a cool, dry spot, like a dedicated locker or storage box, far from engine heat or sunny areas.

Before storing it, make a habit of giving it a quick 30-second once-over. This is the easiest way to catch small problems before they become big ones.

- Look for Cracks: Gently bend the hoses and check for any tiny cracks or signs of brittleness.

- Check the Connections: Make sure all the fittings are tight and the seals look solid, with no signs of wear or drips.

- Test the Action: Give the bulb a few good squeezes or work the lever a couple of times. It should feel smooth and build pressure without any hitches.

It's easy to think of these pumps as small tools, but they're a massive global business. In 2021, the Asia Pacific region alone accounted for a 35.9% share of the fuel transfer pump market, thanks to huge industrial and manufacturing demand. That kind of scale just highlights how critical it is to have reliable, well-maintained equipment, whether you're on a factory floor or just fueling your lawnmower. You can learn more about these global fuel transfer trends.

By building these simple habits, you'll dramatically extend the life of your hand fuel pump and ensure it's always a dependable tool for the job.

Troubleshooting Common Pump Problems

Even the best hand transfer pump fuel system will hit a snag now and then. When your pump decides to stop working, don't panic. The cause is usually something simple and easy to fix, and a little bit of detective work will have you back up and running in no time.

The most frequent problem you'll run into is a loss of suction. You're pumping away, but absolutely no fuel is moving. Nine times out of ten, this points to an air leak somewhere in the system. Air is a lot easier for the pump to pull than liquid, so it will always find the path of least resistance—sucking in air through a tiny gap instead of creating the vacuum needed to lift the fuel.

Diagnosing Pump Suction Issues

Your first move should be to check the most obvious suspects. A loose connection is the number one cause of suction loss, so you’ll want to go over your setup piece by piece.

- Tighten All Connections: Make sure both the intake and discharge hoses are screwed on good and tight. A fitting that’s even a little bit loose can be enough to break the seal.

- Inspect the Intake Hose: Is the end of the intake hose fully submerged in the fuel? If it's sitting too high and sucking in air, you'll never get a proper siphon going.

- Check for Cracks: Give the hoses a good look-over, especially near the connection points where they get bent around the most. A tiny, hard-to-see crack is all it takes to let air in and ruin the vacuum.

Here's a pro tip for finding a sneaky leak: After you've cleaned all the fuel out of the pump and hose, submerge the whole thing in a bucket of water. As you operate the pump, look for a stream of air bubbles—they'll show you exactly where your leak is hiding.

Fixing Blockages and Weak Flow

What if you have suction, but the flow is just a trickle or completely stopped? This usually means you've got a blockage on your hands. It's surprisingly easy for a bit of debris from a fuel can, like a tiny rust flake or some dirt, to get sucked into the intake and jam up one of the pump's internal one-way valves.

For boat owners, this is a particularly common headache. If you're tired of dealing with bad fuel, you can learn more about how to diagnose and prevent common boat fuel problems in our detailed guide.

To clear a blockage, just disconnect the hoses from the pump. You can then try flushing them out with a small amount of clean fuel or even a blast of compressed air. This is almost always enough to dislodge whatever is stuck in there and get you back to a strong, steady flow.

Got Questions About Hand Fuel Pumps? We’ve Got Answers.

Even with a tool as simple as a hand transfer fuel pump, it's natural for questions to come up. Getting the right answers isn't just about convenience; it's about staying safe and keeping your gear in good working order. Let's clear up some of the most common questions we hear.

A big one people often ask is whether they can use the same pump for different liquids, like gasoline and water. The short answer is a hard no. Fuel pumps are built differently, using special anti-static materials to prevent sparks—a feature that a standard water pump just doesn't have.

Using the same pump for both is asking for trouble. You risk cross-contamination, sure, but the real danger is creating a fire hazard. It's simple: dedicate one pump strictly for fuel and another for everything else.

Can I Use the Same Hand Pump for Gasoline and Water?

Absolutely not. It's incredibly unsafe to use the same pump for both fuel and water. Pumps designed for fuel are made with specific materials that can handle harsh chemicals and, crucially, prevent static buildup.

If you use a fuel pump for water, you risk leaving behind flammable residue that can contaminate the water later. Even worse, using a regular water pump for fuel is a massive gamble. It doesn't have the built-in safety features, meaning a simple static spark could ignite the fuel vapors.

The most important fuel transfer safety tip is to always work in a well-ventilated area and eliminate every possible source of ignition. Fuel vapors are highly flammable, so this means no smoking, open flames, or running engines nearby.

What’s the Best Way to Prime a Manual Fuel Pump?

Priming is just a fancy word for getting the air out of the line so the liquid can flow freely. How you do it depends on the kind of pump you have.

- Siphon Pumps: The trick here is gravity. Make sure the intake hose is fully submerged in the source container and that the pump's bulb is positioned lower than the fuel level. Give the bulb a few good squeezes until you feel the liquid start to move through it.

- Lever or Piston Pumps: These are even more straightforward. Just give the handle a few smooth, steady strokes. This action will pull the fuel up, push out any air trapped in the system, and get a consistent flow going.

At CLiX Fueling Solutions, our goal is to make every fueling experience safe and completely spill-free. Our smart system automatically cuts the flow the second your tank is full, which protects your boat and our waterways. Find out how you can refuel smarter over at https://clixfueling.com.