Understanding What Makes Automatic Fuel Nozzles Essential

Automatic fuel nozzles are more than just a handy upgrade at your local gas station. They represent a significant advancement in how we dispense fuel. These devices play a vital role in preventing spills, which protects the environment and ensures efficient operations across various industries. Understanding how they work helps us appreciate their impact.

How Automatic Fuel Nozzles Work

The secret behind the automatic fuel nozzle lies in its shut-off mechanism. This mechanism uses a venturi, a small tube inside the nozzle, to detect pressure changes. As the fuel tank fills up, the rising fuel restricts the airflow within this venturi. This change in pressure triggers a valve inside the nozzle, stopping the fuel flow.

This simple but effective design is what prevents fuel from overflowing. It works much like the float in a toilet tank. Once the tank is full, the float rises and shuts off the water.

Key Benefits of Automatic Fuel Nozzles

Automatic fuel nozzles offer several advantages compared to manual nozzles:

- Spill Prevention: The main benefit is eliminating costly and environmentally damaging fuel spills. This is particularly important in marine environments, where spills can be devastating.

- Increased Efficiency: The automatic shut-off feature frees up personnel for other tasks, as they no longer need to constantly monitor the fueling process. This leads to faster fueling and increased productivity.

- Enhanced Safety: By preventing overflows, automatic nozzles reduce the risks associated with handling flammable liquids. This creates a safer environment for everyone.

- Environmental Protection: Fewer spills mean less release of harmful vapors and a lower risk of soil and water contamination.

Comparing Manual and Automatic Fueling

There's a big difference between manual and automatic fueling. With manual nozzles, the operator must constantly watch the tank level, which increases the risk of overfilling. Distractions or misjudgments can easily lead to spills. Automatic nozzles remove this human error factor, providing a consistent and reliable fueling method. This shift from manual to automatic systems represents a significant step towards greater efficiency, safety, and environmental responsibility.

This precision and reliability make automatic fuel nozzles essential for various applications, from fueling personal watercraft to large-scale commercial operations. Investing in these systems pays off through reduced fuel waste, minimized environmental impact, and improved overall operational efficiency.

Market Momentum: Why Smart Operators Are Investing Now

The automatic fuel nozzle market is booming. Several factors are driving this expansion, from stricter environmental rules to the demand for more efficient fueling. This isn't just a passing phase; it's a major shift in how industries handle fuel.

For example, tighter environmental regulations encourage businesses to find solutions that minimize spills and vapor emissions. Automatic fuel nozzles, designed to prevent spills, become a very attractive option.

The increasing costs of fuel spillage claims also provide a strong incentive. Cleaning up spills, dealing with environmental damage, and handling legal issues can be incredibly costly. Automatic nozzles offer a proactive way to reduce these risks.

This translates to direct cost savings, making them a wise long-term investment. The market is currently valued at about $2.5 billion (in 2025) and is projected to grow at a 6% Compound Annual Growth Rate (CAGR) from 2025 to 2033. This growth is fueled by the rising demand for safe and efficient fueling systems across various sectors like automotive, aviation, and industrial. Find more detailed statistics here

IoT Integration and Predictive Maintenance

The Internet of Things (IoT) offers even more potential for savings and efficiency. IoT-enabled automatic nozzles provide real-time data on fuel usage, tank levels, and potential maintenance needs. IoT allows operators to optimize fueling schedules, prevent downtime, and boost overall efficiency.

This shift from reactive to predictive maintenance cuts costs and enhances reliability.

Investment Opportunities

This market growth presents lucrative investment opportunities. Savvy operators recognize the potential for high returns. However, it’s important to understand the different market segments and pinpoint those with the best growth potential.

The aviation sector, with its strict safety and efficiency standards, is predicted to see substantial growth in automatic nozzle adoption. The industrial sector, with its large-scale fueling operations, also provides significant investment opportunities. Investors who understand the nuances of these sectors can position themselves for success.

By analyzing market trends and investing wisely, businesses can gain a competitive advantage and achieve long-term profitability.

Choosing The Right System For Your Specific Needs

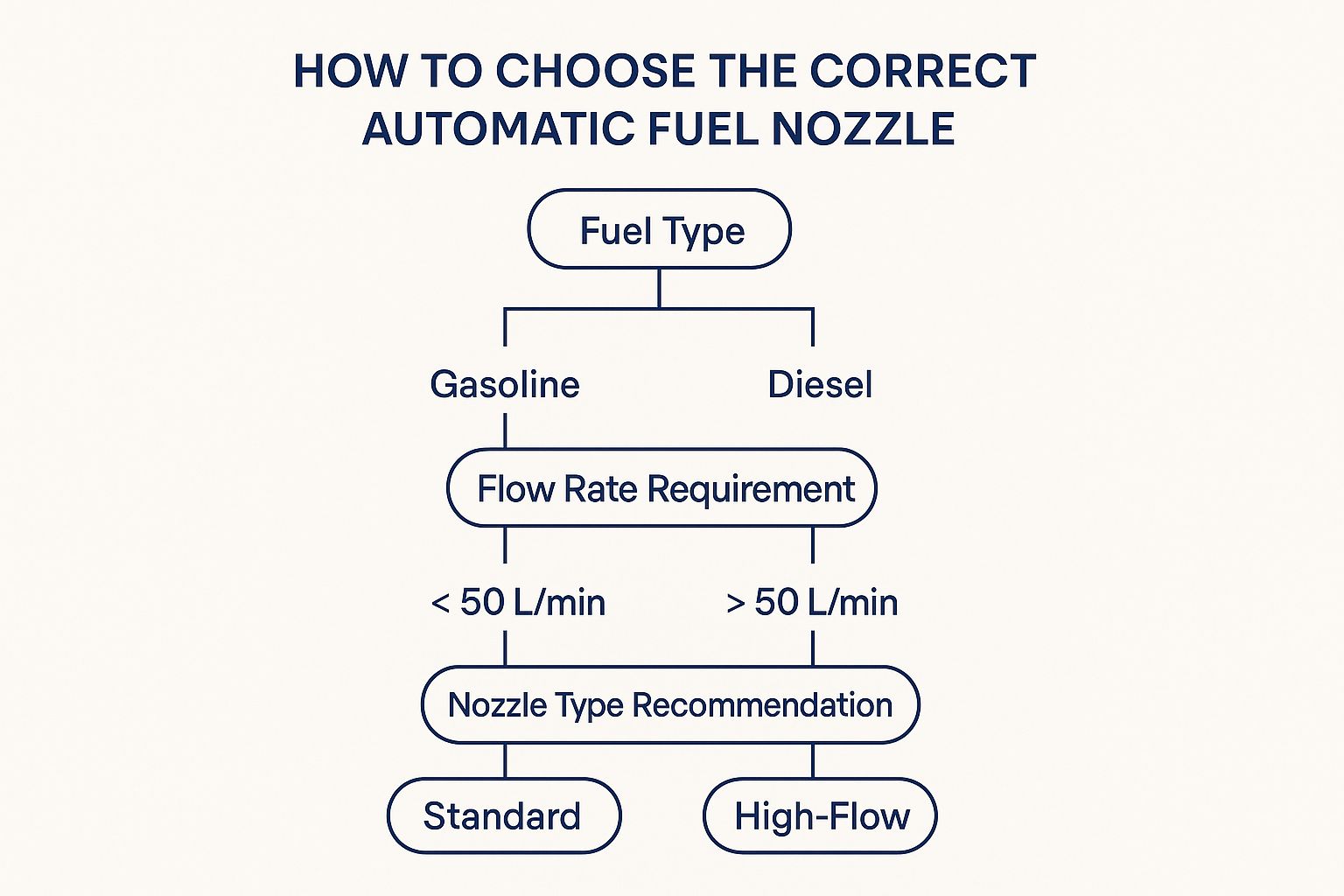

Picking the right automatic fuel nozzle is a big deal for efficiency, safety, and cost-effectiveness. The best choice depends on a few things. First, consider the type of fuel. Diesel and gasoline need different nozzle designs because they have different properties and flow rates.

Second, think about the flow rate requirement. In retail settings, where flow rates are lower, standard automatic nozzles usually work best. But for high-flow situations, like commercial refueling, you'll need specialized high-flow nozzles. This careful planning helps prevent spills and ensures everything works smoothly.

This infographic walks you through choosing a nozzle. You start with the fuel type and then look at the flow rate to find the best nozzle type. Matching the right nozzle to the fuel and flow rate is key for good performance. For example, a standard nozzle in a high-flow diesel situation could slow down fueling and make things less efficient. Using a high-flow nozzle for gasoline could lead to more spills.

Different Nozzle Types for Diverse Applications

There are several different nozzle types designed for specific needs. Vapor recovery nozzles help reduce harmful emissions, which is important for environmentally friendly operations. These nozzles capture fuel vapors during refueling, so they don't go into the air.

High-flow commercial nozzles are made for speed and efficiency in high-volume refueling. Their wider diameter and better flow significantly cut down fueling time, boosting productivity.

To help you choose the right nozzle, take a look at this comparison table:

Automatic Fuel Nozzle Types by Application

| Nozzle Type | Primary Application | Key Features | Flow Rate | Best Use Case |

|---|---|---|---|---|

| Standard Automatic Nozzle | Retail gasoline dispensing | Automatic shut-off, spill prevention | Low to Medium | Passenger vehicles at gas stations |

| High-Flow Commercial Nozzle | Commercial diesel dispensing | Large diameter, fast fueling | High | Trucks, buses, heavy equipment |

| Vapor Recovery Nozzle | Retail gasoline dispensing in regulated areas | Vapor capture, emissions reduction | Low to Medium | Gas stations in areas with strict environmental regulations |

| Marine Nozzle | Marine fueling | Corrosion-resistant materials, safety features | Varies | Boats, ships |

| Agricultural Nozzle | Agricultural equipment fueling | Versatile fuel compatibility, durable construction | Varies | Tractors, combines, other farm machinery |

This table summarizes the main types of nozzles and where they're typically used. It highlights the key features and flow rates of each type, helping you find the best match for your situation.

Factoring in ROI and Specialized Applications

When choosing a nozzle, it's important to consider the return on investment (ROI). Vapor recovery systems might cost more upfront, but they can save you money in the long run by reducing fuel loss and avoiding environmental penalties. High-flow commercial nozzles increase ROI by increasing throughput and lowering labor costs.

Specialized areas like marine fueling or agricultural applications also have special needs. Marine applications often require nozzles with corrosion-resistant materials and safety features to handle harsh marine environments. For more information on marine fuel tanks, check out this article: How to master your boat fuel tanks. Agricultural nozzles often need to handle different types of fuel and operate in tough conditions. The automatic fuel nozzle market is huge. It was worth USD 140.7 billion in 2023 and is expected to reach USD 192 billion by 2031. You can learn more about [the automatic fuel nozzle market] here: https://www.marketresearchintellect.com/product/global-automatic-fuel-nozzle-market/ This growth, estimated at a 7% CAGR from 2024 to 2031, covers various segments like manual, automatic, vapor recovery, and high-flow nozzles across many industries.

Choosing Wisely

Making smart choices about automatic fuel nozzles is essential for successful operations. Thinking carefully about the fuel type, flow rate, specific application needs, and long-term ROI will help you choose the right system for maximum efficiency, improved safety, and minimal environmental impact.

Safety Features That Actually Protect Your Investment

Automatic fuel nozzles are more than just a convenience; they're essential for safeguarding your valuable assets and ensuring overall safety. Going beyond regulatory compliance, the right safety features can prevent costly incidents, leading to significant long-term savings. This translates to a tangible return on investment by minimizing risks and protecting your bottom line.

Automatic Shut-Off Mechanisms: Preventing Costly Disasters

The core safety feature of any automatic fuel nozzle is the automatic shut-off. Utilizing pressure changes within the nozzle, this mechanism stops fuel flow when the tank is full. This seemingly simple function prevents overflows, which can create dangerous and expensive problems. For instance, overflowing fuel can damage a boat's gelcoat, resulting in costly repairs. In industrial settings, a spill could mean halting operations and initiating extensive cleanup procedures.

Pressure-Sensitive Components: A Worthwhile Investment

Beyond the shut-off mechanism, pressure-sensitive components inside the nozzle play a vital role. These components constantly monitor pressure during fueling, ensuring a safe and controlled flow. They act as a safety net, detecting potential issues before they escalate. This proactive approach minimizes the risk of leaks and ruptures, protecting both personnel and equipment.

Vapor Recovery Systems: Protecting Your Facility and Community

Many automatic fuel nozzles include vapor recovery systems. These systems capture fuel vapors released during refueling, preventing their escape into the atmosphere. This benefits the environment by reducing harmful emissions, and it also protects your facility and the surrounding community. Furthermore, these systems can minimize fuel loss from evaporation, increasing their cost-effectiveness. For more insights on boat fueling safety, check out this helpful resource: How to master boat fueling safety.

Real-World Impact and ROI

These safety features have a proven history of preventing incidents and saving businesses money. Automatic shut-offs prevent spills that could lead to fines, cleanup costs, and even legal issues. Vapor recovery systems lessen environmental impact and may even offer tax benefits depending on the region. The reduced risk also lowers insurance premiums, contributing to a measurable ROI. By preventing accidents, automatic fuel nozzles protect not only your equipment, but also your employees and the environment. This focus on safety builds a positive brand image and promotes a culture of responsibility.

Essential vs. Nice-to-Have Features

While all automatic fuel nozzles provide a basic level of safety, understanding which features are crucial for your particular needs is important. A marina, for example, might prioritize corrosion-resistant materials and spill containment features. A high-volume trucking operation, on the other hand, might require high-flow nozzles with robust shut-off mechanisms designed for continuous use. Carefully assessing your requirements ensures you select the right automatic fuel nozzle system that truly protects your investment.

Regional Opportunities: Where The Smart Money Is Moving

While established markets for automatic fuel nozzles may seem saturated, emerging regions offer exciting prospects for savvy investors. Understanding these regional dynamics is key to maximizing returns and capitalizing on growth. This means identifying specific geographical areas experiencing rapid expansion and uncovering the factors driving this growth.

For instance, government regulations play a significant role. Stringent environmental policies in some regions are driving the adoption of automatic nozzles to minimize spills and emissions. In addition, economic factors such as rising fuel costs and increasing labor expenses make the efficiency and spill-prevention features of automatic nozzles very appealing. Together, these forces create a compelling investment opportunity.

Asia-Pacific: A Hub for Growth

The Asia-Pacific region is a particularly promising market for automatic fuel nozzles. This growth is largely due to the rapid industrialization and substantial infrastructure development in countries like China, India, and Japan. The growing emphasis on fuel efficiency and reducing environmental impact in both the automotive and aviation sectors further fuels this demand. Explore this topic further

Emerging Markets and Infrastructure Development

Growth opportunities extend beyond Asia. Infrastructure development in other emerging markets is creating a considerable need for advanced fuel dispensing systems. As these economies expand, so does the demand for reliable and efficient fueling solutions. This presents a unique opportunity for equipment suppliers and service providers to enter new markets and build a strong presence.

Identifying High-ROI Regions

For businesses investing in the automatic fuel nozzle market, understanding regional ROI is crucial. Some regions offer higher returns due to various factors, including regulatory incentives, market demand, and local economic conditions. Thorough market analysis is essential for identifying these high-potential areas and making informed investment decisions. This could involve examining government subsidies for environmentally friendly technologies or studying fuel consumption trends within particular industries.

Positioning for Success

To succeed in these diverse regional markets, companies must adopt a localized approach. This involves recognizing the unique needs and challenges of each region. For example, adapting product designs to local fuel standards or providing multilingual customer support can significantly improve market penetration. Building strong relationships with local distributors and partners is also vital for navigating regulatory hurdles and fostering trust. By understanding these regional nuances and adjusting their strategies accordingly, businesses can position themselves for long-term success in the dynamic automatic fuel nozzle market.

Installation And Maintenance: Avoiding Costly Mistakes

Proper installation and maintenance of your automatic fuel nozzle system are crucial for maximizing its lifespan and avoiding unexpected downtime and expenses. These steps go beyond simply following the manual; they're about protecting your investment and ensuring smooth, efficient operations. This proactive approach significantly reduces the need for costly emergency repairs and replacements.

Critical Installation Requirements

Manufacturers provide installation guidelines, but some crucial details are often overlooked. For example, proper grounding is essential to prevent static electricity buildup, a potential fire hazard. Secure mounting is also vital to prevent damage and ensure accurate dispensing.

Another frequently missed step is verifying compatibility with your specific fuel type and flow rate requirements. Overlooking these seemingly small details can lead to significant problems down the road.

Effective Maintenance Schedules

A regular maintenance schedule is key to keeping your automatic fuel nozzle system in optimal condition. This goes beyond routine cleaning and includes checking components like seals and valves for wear and tear. A well-defined schedule helps identify potential issues early, saving you money and preventing disruptions.

- Daily Inspection: Look for visible damage, leaks, or obstructions.

- Weekly Cleaning: Clean the nozzle and surrounding area to remove debris and fuel residue.

- Monthly Inspection: Examine seals, valves, and connections for wear and tear.

- Annual Service: Schedule a thorough inspection and service of the entire system with a qualified technician.

This proactive approach minimizes the risk of unexpected failures and extends the equipment's lifespan.

Training Your Team for Proactive Problem Solving

Training your team to recognize early warning signs is crucial. This empowers them to address minor issues before they escalate, saving on costly repairs. For example, a small drip could indicate a worn seal—an easy fix if caught early. Ignoring it, however, could lead to a much larger and more expensive repair down the line.

Cost-Benefit Analysis of Proper Maintenance

Regular maintenance involves upfront costs, but the long-term benefits significantly outweigh the expenses. It's similar to regular oil changes for a car: a small investment that prevents major engine problems. Likewise, a well-maintained automatic fuel nozzle system operates more efficiently, reduces fuel waste, and minimizes the risk of costly spills.

The table below, "Maintenance Schedule and Cost Analysis", outlines recommended maintenance intervals and associated costs for different aspects of your automatic fuel nozzle system. This information will assist in understanding the investment required for each task and its importance in preventing larger issues.

| Maintenance Task | Frequency | Estimated Cost | Critical Level | Required Expertise |

|---|---|---|---|---|

| Nozzle Cleaning | Weekly | Low | Low | Basic Training |

| Seal Replacement | Annually | Moderate | Medium | Trained Technician |

| Valve Overhaul | Every 2 Years | High | High | Certified Technician |

| System Calibration | Annually | Moderate | Medium | Trained Technician |

As this table shows, while some maintenance tasks require specialized expertise and have higher costs, they are essential for preventing significant failures and maximizing the system's lifespan. Investing in regular maintenance protects your investment and ensures smooth and efficient fueling operations.

Future-Proofing Your Investment: What's Coming Next

The automatic fuel nozzle industry is constantly evolving. To ensure a wise investment, it's crucial to understand the trends shaping the future of fuel dispensing. This means looking beyond the current features and considering emerging technologies. By anticipating these advancements, you can ensure your investment remains valuable and competitive for the long haul.

AI-Powered Predictive Maintenance

One of the most promising developments is integrating Artificial Intelligence (AI) into predictive maintenance. AI algorithms analyze data from IoT-enabled automatic fuel nozzles to predict potential problems before they occur. This proactive approach reduces downtime and extends the lifespan of your equipment. For example, AI could predict a seal failure, allowing for replacement during scheduled maintenance, avoiding unexpected breakdowns.

Advanced Sensor Integration

The future also holds more sophisticated sensors. These sensors will provide more precise data on fuel flow, temperature, and pressure. This data optimizes fueling efficiency, identifies potential safety issues, and can even detect fuel quality problems. Integrating these sensors with AI systems further enhances predictive maintenance, predicting the remaining useful life of components.

Connectivity and Smart Grid Integration

Increased connectivity is another key trend. Future automatic fuel nozzles will integrate seamlessly with other systems, like fuel management software and even smart grids. This creates a more efficient and automated fueling process. For instance, smart grid integration could allow for dynamic pricing based on real-time energy demand. You might be interested in this article about fuel management: Top Marine Fuel Management Systems of 2025 to Optimize Efficiency

Alternative Fuel Compatibility

As the world transitions to alternative fuels, automatic fuel nozzles need to adapt. This means designing nozzles that handle various fuels, like biodiesel, ethanol blends, and even hydrogen. Investing in systems with flexible fuel compatibility ensures your equipment remains relevant as the energy landscape shifts. This adaptability also safeguards your investment against future regulations.

Separating Hype From Reality

It's important to distinguish between genuine advancements and marketing hype. Focus on innovations offering tangible benefits like improved safety, increased efficiency, or cost reduction. A futuristic touchscreen might look appealing but may not offer practical advantages over a simpler, more reliable system.

Evaluating Future-Proof Systems

When evaluating systems, consider their long-term potential. Key factors include:

- Scalability: Can the system adapt to future growth?

- Interoperability: Will it integrate with other technologies?

- Upgradability: Can the system be updated with new software and features?

- Cybersecurity: Does it have robust security measures?

By considering these factors, you can choose a system that remains competitive. Investing in an automatic fuel nozzle system is a significant decision. By understanding future trends and evaluating systems with a long-term perspective, you can make a smart, value-driven investment.

Ready for the future of fueling? Explore CLiX Fueling Solutions: CLiX Fueling Solutions