A fuel funnel filter is a pretty straightforward tool, but it's one of the most important ones you can own. Its whole job is to catch nasty stuff like water, dirt, and debris before it gets into your gas tank.

Think of it as a bouncer for your fuel system, making sure only clean fuel gets in while keeping the troublemakers out. This simple step can save you from some serious engine headaches and expensive repairs down the road.

Why Clean Fuel Is So Important

Let's use an analogy. You wouldn't drink water from a muddy puddle, right? Your engine feels the same way about dirty fuel. It's designed to run on pure, clean gasoline or diesel. When contaminants get in, things start to go wrong, fast.

Even if you buy your fuel from a reputable station, you'd be surprised what can end up in it. Underground storage tanks can rust, condensation can build up, and debris can get in during transport. A fuel funnel filter is your first and best line of defense against all of it.

Without that protection, tiny particles and water droplets can start a chain reaction of problems, from clogged fuel lines to complete engine failure.

The Hidden Dangers Lurking in Your Fuel

It doesn't take much to cause a big problem. A little bit of water or a few specks of dirt can be all it takes. Here are the main culprits a good filter is designed to stop:

- Water: This is a big one, and it often gets in through simple condensation. Water in your fuel leads to rust, messes with lubrication, and can destroy sensitive components like fuel injectors.

- Particulates: This is a catch-all for tiny bits of dust, dirt, and rust flakes. These things are abrasive, acting like liquid sandpaper inside your engine and wearing down critical parts.

- Debris: You'd be amazed what can fall into a gas can or an open fuel tank. Little bits of grass, paint chips, you name it. That junk can cause an instant clog.

A clean fuel supply is the lifeblood of any engine. Preventing contamination isn't just about maintenance; it's about ensuring reliability, preserving power, and extending the operational life of your valuable equipment.

Before we move on, let's take a quick look at the common contaminants and the kind of damage they can cause. It really drives home why a simple filter is such a smart investment.

Common Fuel Contaminants and Their Effects

| Contaminant Type | Source | Potential Engine Damage |

|---|---|---|

| Water | Condensation, improper storage, contaminated supply | Rust in fuel tank/lines, injector failure, poor combustion, microbial growth |

| Dirt & Dust | Contaminated fuel cans, airborne particles during refueling | Clogged filters, abrasive wear on pumps and injectors, reduced engine performance |

| Rust & Metal Flakes | Aging fuel tanks, drums, or gas cans | Clogged fuel lines and injectors, premature wear of internal engine parts |

| Organic Debris | Leaves, grass, insects falling into an open tank | Fuel system blockages, fuel starvation, engine stalling |

As you can see, the list is pretty nasty. Each of these can lead to costly and time-consuming repairs that are easily avoided.

This need for clean fuel isn't just for your lawnmower or boat, either. The global market for industrial-grade fuel filters is expected to hit USD 910.3 million by 2035. That growth is all about keeping massive, expensive machinery in sectors like transportation and manufacturing running smoothly. You can read more about this industrial trend from Future Market Insights.

Whether you're dealing with a chainsaw or a piece of heavy equipment, using a fuel funnel filter is a simple, proactive way to protect your investment.

How Fuel Funnel Filters Work

A fuel funnel filter might look like a simple piece of plastic, but there’s some clever engineering packed inside. Think of it as a bouncer for your fuel tank, physically stopping troublemakers like dirt, rust, and water from getting in while letting clean fuel flow right past.

The whole process kicks off the second you start pouring. The fuel’s first challenge is a coarse, stainless steel mesh screen. This is the first line of defense, designed to stop the big stuff—rust flakes from an old jerry can, clumps of dirt, or even a stray leaf that found its way into your container. This simple screen prevents the most obvious clogs before they can even start.

After clearing that first hurdle, the fuel continues down into the heart of the filter.

The Science of Separation

This is where the real work gets done. Deep inside the funnel, the fuel is pushed through a much finer, highly specialized filter material. This is the part that separates out tiny particles and, most importantly, water.

Many of the best fuel funnel filters use a polymer membrane with a hydrophobic coating, often made of Teflon. This material has one very cool trick up its sleeve: it hates water.

The hydrophobic surface makes water molecules bead up and roll away from the fuel, preventing them from passing through the filter. It works just like rain on a freshly waxed car hood—the water just can't stick.

It’s an incredibly effective process. As you pour, the gasoline or diesel, which is lighter, slips easily through the filter’s microscopic pores. Meanwhile, the heavier water and any fine debris get trapped and collect in a small sump at the bottom of the funnel.

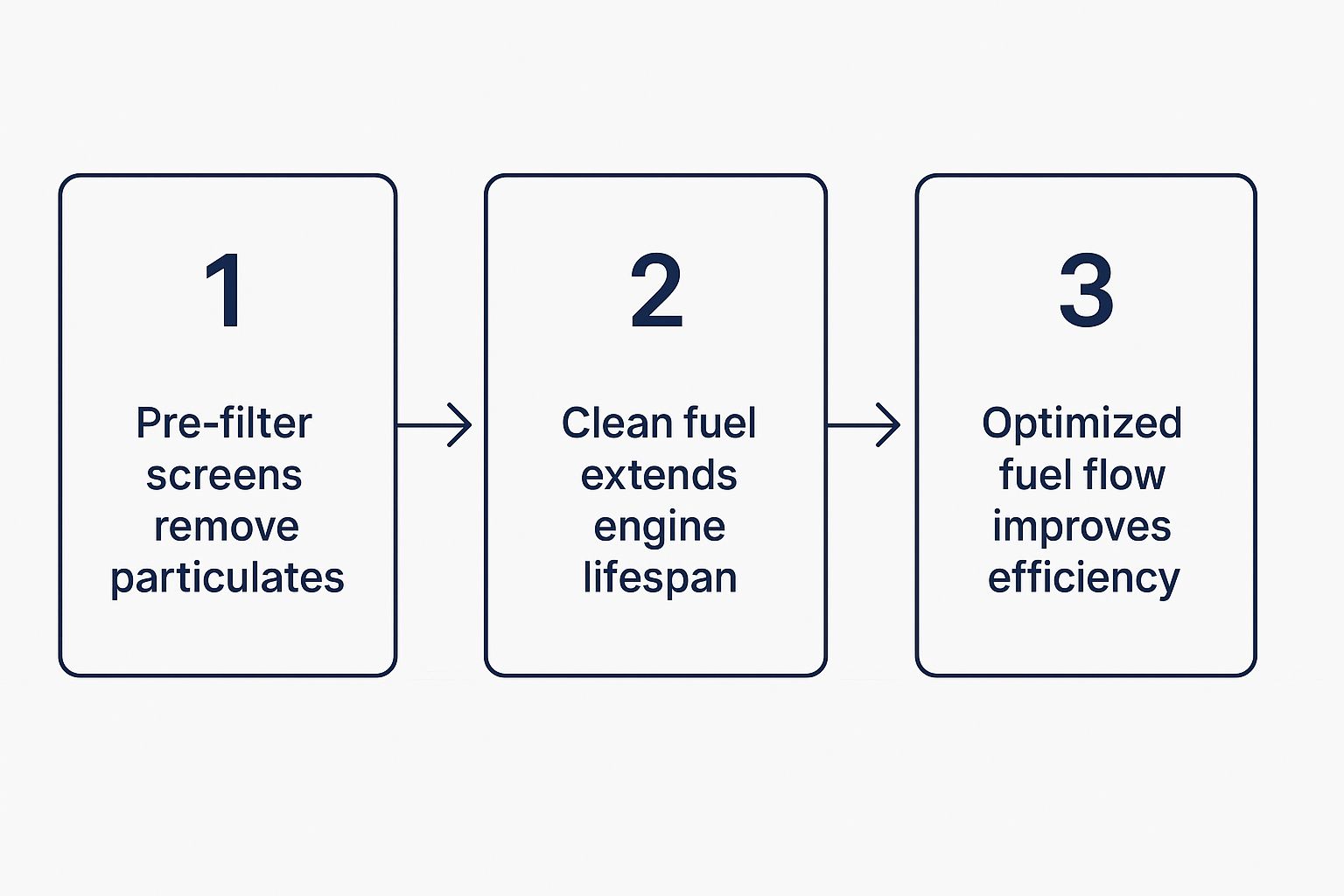

This image shows you just how that multi-stage process works to keep your engine safe and running smoothly.

As you can see, it's a simple but powerful sequence. By knocking out contaminants at each stage, you end up with nothing but pure fuel, which leads directly to a healthier, more efficient engine.

Ensuring a Pure and Steady Flow

The final challenge for a good filter is to do all this separating without slowing you down. A well-designed filter strikes the perfect balance between catching the tiniest contaminants and maintaining a fast, steady flow rate so you're not standing there all day.

Here's a quick rundown of how it all works together:

- Coarse Screening: The outer mesh catches large debris like rust and dirt right at the top.

- Fine Filtration: Fuel then passes through a finer polymer screen that traps smaller sediment.

- Water Separation: At the same time, the Teflon-coated surface pushes water away, forcing it to collect in the sump.

- Clean Fuel Output: The only thing left to pass through the spout is clean, pure fuel.

When you're finished, you just tip the funnel over to dump out the collected water and crud. It's a self-cleaning design, which means no messy cartridges to replace. This simple, physics-based system is all you need to give your engine the clean fuel it needs to run reliably for years to come.

Exploring Different Types of Fuel Funnel Filters

Not all fuel funnel filters are created equal. It's a bit like picking the right tool for any other job—the filter you need for a small generator is worlds apart from one used for a high-performance race boat. Understanding the key differences is crucial to getting the protection you need without making refueling a chore.

The journey to finding the perfect match starts with a simple choice: the material it's made from. This decision alone can impact everything from durability to safety, and each option has its own set of pros and cons depending on where and how you'll be using it.

Metal Versus Plastic Funnels

You’ll generally find two main options on the shelf: metal and plastic. Each has its own dedicated fan base for good reason.

Metal fuel funnel filters are the heavy-duty workhorses. Usually built from steel or aluminum, they're incredibly durable and can take a beating in a busy garage or on a construction site. Their biggest selling point is longevity. A well-cared-for metal funnel can easily last a lifetime.

On the other hand, plastic fuel funnel filters are often the go-to choice for everyday use. They’re lightweight, they won't corrode, and they're typically more affordable. Modern plastics used in these funnels are also designed to resist harsh fuel chemicals, making them perfectly safe for both gasoline and diesel. Many quality models even include anti-static properties to prevent dangerous sparks.

Understanding Micron Ratings and Flow Rates

Beyond the material, the real performance of a filter comes down to two key numbers: the micron rating and the flow rate.

The micron rating tells you just how fine the filter's mesh is. Think of it like the thread count on bedsheets—a lower micron number means a tighter weave that can trap smaller particles.

- Standard Filters (75-150 Microns): These are great all-rounders for things like lawnmowers, generators, or older vehicles. They'll stop the most common bits of debris without slowing you down too much.

- Fine Filters (50 Microns or Less): These are a must-have for modern, high-performance engines with sensitive fuel injectors. They provide top-tier protection against the tiniest contaminants that can cause big problems.

The flow rate, measured in gallons per minute (GPM), tells you how quickly fuel can pass through the funnel. A higher GPM is a lifesaver when you're filling a large tank. A slow funnel can make refueling incredibly tedious, especially on the water. If you're a boat owner, you know exactly what I mean. You can learn more about picking the right https://clixfueling.com/blogs/news/fuel-funnel-for-boat in our detailed guide.

Key Takeaway: The perfect fuel funnel filter is all about balance. You need a micron rating fine enough to protect your engine, paired with a flow rate that doesn't turn a simple task into a waiting game.

The demand for effective filtration is huge. The automotive fuel filter market was valued as high as USD 5.84 billion in 2025 and is expected to keep growing. A big driver of this is the need for clean diesel, as modern engines require robust systems to meet strict emissions standards. This just goes to show how critical clean fuel is for all kinds of vehicles and equipment.

Comparing Fuel Funnel Filter Features

To help you visualize the options, here’s a quick comparison of the common filter types you'll encounter. This table breaks down what each one is best suited for, so you can easily pinpoint the right choice for your needs.

| Filter Type | Best For | Micron Rating | Key Feature |

|---|---|---|---|

| Standard Plastic | General home/shop use, small engines | 75-150 microns | Lightweight, affordable, corrosion-proof |

| Anti-Static Plastic | Gasoline engines, high-risk environments | 50-100 microns | Prevents static sparks for enhanced safety |

| Heavy-Duty Metal | Industrial sites, farm equipment, diesel | 100-200 microns | Extreme durability and longevity |

| Fine-Mesh Coated | High-performance and marine engines | 50 microns or less | Superior filtration for sensitive injectors |

Ultimately, whether you choose a simple plastic funnel for your lawnmower or a specialized fine-mesh filter for your boat, the goal is the same: to feed your engine the cleanest fuel possible.

How to Choose the Right Fuel Funnel Filter

Picking out the right fuel funnel filter isn't rocket science, but you do need to match the tool to the job. If you get it wrong, you could be stuck with painfully slow fill-ups, poor filtration, or a filter that falls apart. Just focus on three main things—fuel compatibility, flow rate, and micron rating—and you’ll find the perfect filter for your needs.

First things first, you have to consider fuel compatibility. Not all plastics and metals play nice with every type of fuel. For example, certain additives in gasoline can eat away at the wrong kind of plastic, while diesel's oily nature demands its own specific materials. Always double-check the manufacturer’s specs to make sure the filter you're eyeing is approved for the fuel you’ll be using.

Grabbing the wrong one can cause the filter itself to break down over time, which ironically releases new gunk into your fuel system. That completely defeats the purpose.

Match the Filter to Your Fueling Speed

Next up is the flow rate, which is just a fancy way of saying how fast the fuel can pour through the filter. It's usually measured in gallons per minute (GPM). A slow flow rate might be fine if you're just topping off a small generator, but it’ll drive you crazy when you're trying to fill a big boat or truck tank.

Think about how you typically refuel:

- Small Engines (under 5 gallons): A basic filter with a 3-5 GPM flow rate will get the job done without feeling like a chore.

- Large Tanks (10+ gallons): You’ll want a high-performance model that can handle 10 GPM or more. Otherwise, you’ll be standing there forever.

A filter's job is to protect your engine, not to test your patience. Matching the flow rate to your equipment ensures that clean fuel and efficient refueling go hand-in-hand.

For anyone with a boat, a high flow rate is a must-have. You can get a much deeper look into marine fuel systems in our boat fuel tank guide to choose and maintain one easily.

Decoding the Micron Rating

Finally, let's talk about the micron rating. This number tells you how small of a particle the filter can actually trap. It's simple: a lower micron number means a finer filter. A 50-micron filter will stop tiny particles that a 150-micron filter would let right through.

So, which one do you need? It really depends on your engine. Modern, high-tech engines with sensitive fuel injectors need finer filtration—think 50 microns or less—to prevent clogging. For older, tougher equipment like a lawnmower or a log splitter, a standard filter around 100 microns offers plenty of protection.

This push for better filtration isn't just a niche concern. The global automotive fuel filter market hit about USD 2.93 billion in 2024, all driven by the need to keep sophisticated modern engines running clean. By keeping these three simple factors in mind, you can easily pick the perfect fuel funnel filter to protect your gear.

Best Practices for Using and Maintaining Your Filter

So, you've got yourself a top-notch fuel funnel filter. That's a smart move. But like any good tool, its real magic comes from knowing how to use it right and keeping it in good shape. Think of it as a high-quality chef's knife—useless if you don't use it properly and keep the blade sharp. Following a few simple habits will ensure your filter does its job perfectly, every single time.

When you're ready to refuel, the steps are simple but crucial. First, get that funnel seated firmly in the fuel tank opening. You want it stable before you even think about pouring. A wobbly funnel is just asking for a messy spill.

Next, pour your fuel at a smooth, steady pace. Don't just dump it in. Give the filter a chance to do its work without getting overwhelmed. If you tilt the can too much and create a tidal wave of fuel, you can clog up the filter membrane and slow everything to a crawl.

Keeping Your Filter Clean and Effective

The single most important part of owning one of these is keeping it clean. A dirty filter is an ineffective filter, and a clogged one will have you standing there all day waiting for your tank to fill. The good news? Cleaning is a breeze.

Most of these funnels are designed to practically clean themselves. Once you're done fueling, just flip the funnel upside down and give it a solid tap. This simple move, known as back-flushing, knocks all the trapped water and gunk loose, and it just falls right out.

A clean filter is an effective filter. Regularly back-flushing your funnel after each use takes only a few seconds but makes a massive difference in performance and longevity.

If you’ve been dealing with some seriously nasty fuel and feel it needs a deeper clean, you can rinse it out with a little bit of clean fuel or a mild solvent. Just make sure you let it air dry completely before using it again. You don't want any of those cleaning agents mixing with your fresh fuel.

When to Clean and When to Replace

So, how do you know when it's time for a clean? Your funnel will tell you. If you notice the fuel flow slowing down to a trickle, that's a dead giveaway the filter mesh is getting clogged. Time for a quick back-flush.

As a rule of thumb, it's a good habit to clean it after every 10-15 uses. If you're consistently pouring from older, questionable fuel cans, you'll want to do it even more often.

These funnels are built tough, but nothing lasts forever. Here are the tell-tale signs that it’s time to retire your old filter and get a new one:

- You see visible cracks or damage to the plastic body.

- The filter screen itself is torn or has pulled away from the housing.

- The filter is no longer stopping water or obvious debris from passing through.

Taking care of a simple tool like a fuel funnel is just one piece of the puzzle. It's the first line of defense, but it works as part of a team. Protecting your engine’s main filters is the end goal, which is why it's also smart to understand how a fuel water separator filter works. For a broader look at general filter replacement services that keep your entire vehicle running smoothly, expert resources can provide some great insights.

Got Questions About Fuel Funnel Filters? We’ve Got Answers.

Even after you get the hang of these handy tools, a few questions always pop up. Let's tackle the most common ones so you can use your fuel funnel filter like a pro.

Can I Use the Same Filter for Gas and Diesel?

It's tempting, but you really need to check what the manufacturer says. Many top-shelf filters are built to handle both, but some are designed specifically for the different properties of gasoline versus diesel.

Using the wrong filter might not just be ineffective—it could damage the filter media or let the very gunk you're trying to stop slip right through into your engine. Always play it safe and read the instructions.

How Do I Know Which Micron Rating I Need?

This all comes down to what you're fueling. For everyday equipment like your lawnmower or a portable generator, a standard 100-micron filter will do the job just fine.

But if you're dealing with a modern, high-performance engine in a boat or a newer vehicle, you'll want much finer protection. Look for a filter rated at 40 microns or less to give those sensitive fuel injectors the clean fuel they need to run smoothly.

Think of it this way: the more sensitive your engine, the finer the filter mesh you need. A finer mesh gives you better protection, while a standard one allows for a faster flow when a little debris isn't a deal-breaker.

How Often Should I Clean My Fuel Funnel Filter?

A good baseline is to give it a clean after every 10-15 uses.

The real tell, though, is flow rate. If you notice that filling up is taking noticeably longer, that's your filter screaming for a cleaning. And if you're regularly using fuel from old jerry cans, you'll want to clean it more often to keep up with the extra sediment.

Will a Filter Slow Down Refueling?

A little bit, yes, but it shouldn't be a pain. A clean, correctly-sized filter is engineered for high flow, so the difference in time is usually tiny.

If fueling suddenly feels like it's taking forever, that’s not a design flaw. It's a sign that the filter has done its job, caught a bunch of gunk, and is now clogged. Time for a quick clean-up!

For a fueling experience that's truly spill-free and protects both your boat and the water, check out CLiX Fueling Solutions. Discover our innovative system at clixfueling.com.