Understanding Cleats on a Boat: More Than Just Hardware

Cleats are essential hardware on any boat. They're the main points for securing lines, keeping your vessel safe in various situations, from a short stop at the fuel dock to anchoring overnight. These seemingly simple metal fittings can mean the difference between a peaceful night and a maritime mishap. Therefore, every boater should understand their function and how to use them correctly.

Why Cleats Matter: From Dinghy To Yacht

Whether you're on a small dinghy or a large yacht, cleats are vital for your safety and the security of your boat. Imagine trying to secure your boat to a dock without a sturdy cleat. The line could slip, potentially leading to damage or even injury. Understanding proper cleat usage is also crucial, as experienced boaters handle these fittings differently than beginners.

For more information, check out this Essential Cleat on a Boat Guide. A solid understanding of cleats and their proper use is fundamental to safe and responsible boating. This is especially relevant given the growth of the marine industry. The global boat cam cleat blocks market is expanding, reflecting the increasing interest in recreational boating. This market was valued at USD 150 million in 2024 and is projected to reach USD 250 million by 2033, growing at a 6.3% CAGR from 2026 to 2033. The U.S. boating industry contributed significantly to the economy, around $42 billion in 2022. You can find more detailed statistics here.

Common Misunderstandings And Their Risks

Many new boaters don't realize how important cleats are, potentially creating dangerous situations. One common error is tying lines directly to railings or other unsuitable parts of the boat. This can damage the boat and put excessive strain on the line itself. Another mistake is neglecting to check cleats for wear and tear. Over time, they can corrode or weaken, impacting their ability to hold a line securely. These errors highlight the need for proper education and awareness about the crucial role cleats play on a boat.

Finding Your Perfect Match: Cleat Types Compared

Choosing the right cleats for your boat is more important than you might think. The wrong cleats can make docking a nightmare, or even create a safety hazard. It's important for every boater to understand the different types of cleats, their uses, and the materials they're made from.

Cleat Types and Their Uses

There are several types of cleats designed for different boating needs. The most common are horn cleats, cam cleats, and pop-up cleats. Horn cleats, with their classic crescent shape, are versatile and work well for many docking and mooring situations. Cam cleats are designed for quick and easy line adjustments, making them a favorite for sailboats. Pop-up cleats offer a sleek, low-profile look when not in use, ideal for smaller boats or tight spaces. There are also specialized cleats for specific purposes, like mooring whips or anchor rodes.

Material Matters: Durability and Performance

The material a cleat is made from has a big impact on how it performs and how long it lasts. Stainless steel is a popular choice because it's strong and resists corrosion, especially in saltwater. Nylon cleats also have their advantages. They're lighter, less expensive, and don't get as hot as metal cleats in the sun. This makes them a good option for smaller boats or places where people might be barefoot.

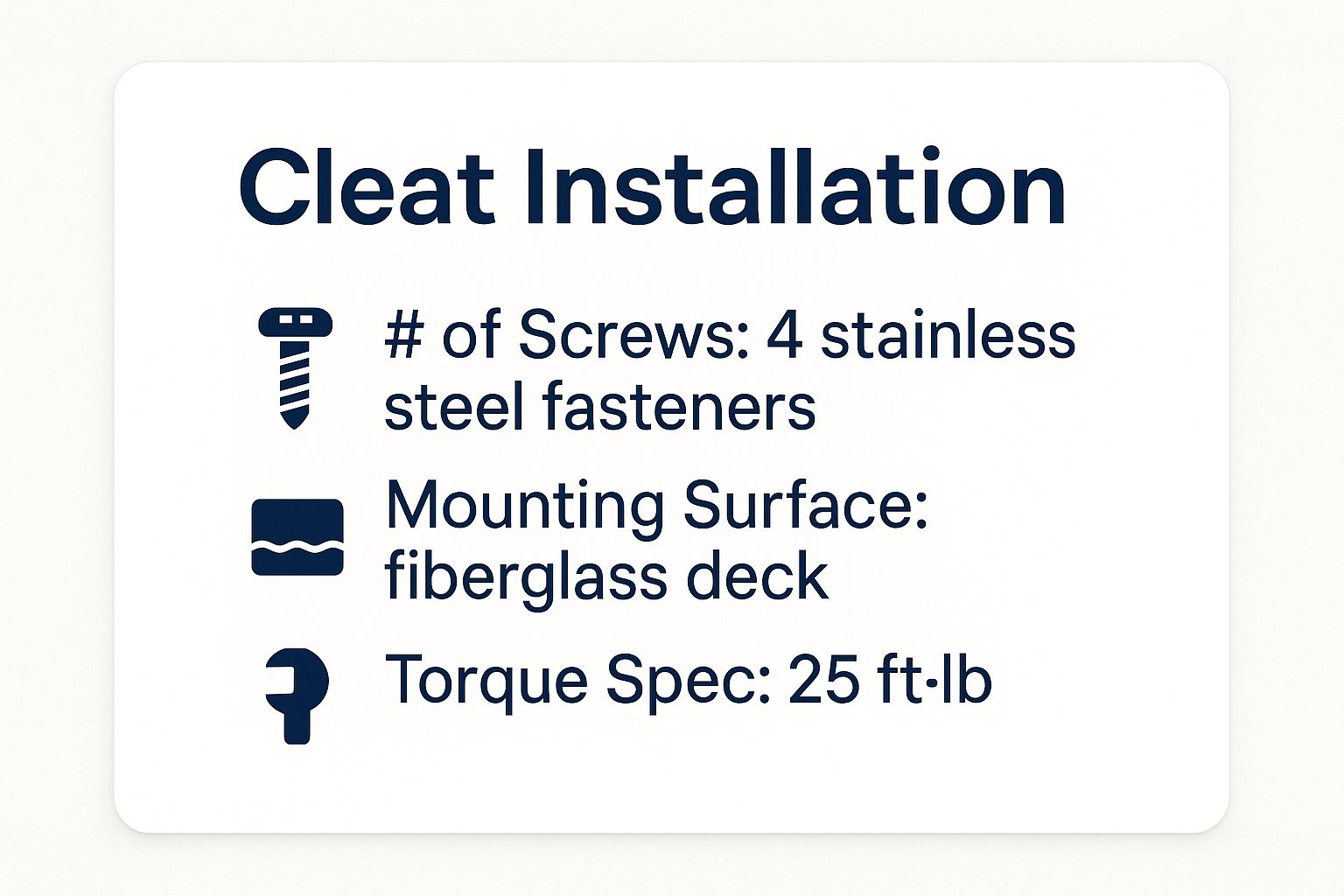

This infographic shows key information for installing cleats, including the number of screws, the mounting surface, and how much to tighten them. It recommends using four stainless steel fasteners on a fiberglass deck, tightened to 25 ft·lb. This will ensure a strong, secure cleat that can handle the stresses of boating.

Before we discuss choosing the right cleats, let's take a look at a comparison of common cleat types. This table summarizes key features and considerations to help you make the best decision.

Comparison of Common Boat Cleat Types

This table compares the most popular boat cleat types based on key selection factors that boaters should consider when making purchasing decisions.

| Cleat Type | Best For | Material Options | Price Range | Installation Difficulty | Pros | Cons |

|---|---|---|---|---|---|---|

| Horn | Docking, Mooring | Stainless Steel, Nylon, Aluminum | $10 - $100+ | Easy | Versatile, Strong, Secure | Can snag lines |

| Cam | Sailboats, Lines Under Load | Stainless Steel, Aluminum, Composite | $20 - $200+ | Moderate | Quick Line Adjustment, Secure Under Load | Not Ideal for Heavy Shock Loads |

| Pop-Up | Small Boats, Limited Space | Stainless Steel, Nylon, Composite | $15 - $150+ | Moderate | Sleek Appearance, Space-Saving | Lower Load Capacity Than Fixed Cleats |

| Cleat Hitch | Securing Lines to a Post or Rail | N/A | N/A | N/A (Knot) | Reliable, Adjustable | Requires Practice |

This table highlights the different strengths and weaknesses of each cleat type. Remember to consider your specific needs and boat type when choosing.

Matching Cleats to Your Boat and Boating Style

Different boats and boating styles need different cleat setups. A small sailboat might only need a few small cleats, while a large powerboat will need several larger, stronger ones. Where you boat also matters. If you mostly boat in saltwater, corrosion-resistant materials are essential. Your budget is also a factor. Stainless steel cleats are very durable, but they cost more than nylon. By thinking about your boat type, boating style, environment, and budget, you can choose the right cleats for safe and secure docking and mooring. For example, a center console fishing boat used in saltwater would benefit from several well-placed stainless steel horn cleats for fenders and docking lines.

Installing Cleats That Won't Fail When It Matters

Even the best boat cleats can fail if not installed properly. A poorly installed cleat can damage your deck, cause lines to slip, and even create hazardous situations. We'll explore best practices for cleat installation, drawing on insights from marine technicians. This ensures secure mounting and prevents future headaches. Knowing this is especially important given the rising popularity of recreational boating, especially in North America. This region drives a significant portion of the global cleat market, accounting for over 50% of global demand. Learn more about the boat cleat market.

Placement Strategies: Location, Location, Location

Cleat placement is key for optimal performance. Consider how you'll use your cleats and where they'll be easiest to access. On a center-console fishing boat, cleats should be strategically placed for tying off fenders, securing docking lines, and even anchoring. A cruising sailboat, however, might require cleats for spring lines, mooring lines, and other specific uses. Thinking about your boat type and its usage will guide effective cleat placement.

Backing Plates and Fasteners: The Foundation of a Strong Cleat

Choosing the right backing plates and fasteners is just as critical as the cleat itself. Backing plates distribute the force over a wider area, preventing the cleat from ripping out of the deck. They provide a strong base, especially vital for fiberglass decks. Use appropriately sized stainless steel fasteners for your cleats and backing plates. Oversized fasteners can damage the deck, while undersized ones can fail under pressure. You might be interested in: How to master cleat installation.

Sealing Techniques: Keeping Water Out

Proper sealing is essential to prevent water damage and corrosion. Use a marine-grade sealant around the fastener holes and under the backing plate for a watertight seal. This stops water from seeping into the deck's core, which can lead to rot and structural issues. Regularly check the sealant and reapply as needed to maintain the barrier. This is much like maintaining caulking around your house.

Load Distribution and Aesthetics: Function Over Form

While looks matter, load distribution is paramount for cleat installation. A cleat should distribute the load evenly across the deck. This prevents stress points that can cause cracks or failures. Consider the direction of pull on the cleat and ensure the backing plate and fasteners are positioned to handle it. Sometimes, a slightly less aesthetically pleasing placement might be the stronger, more reliable option. A correctly installed cleat, even if not perfectly aligned, will be much more secure and last longer than a poorly installed one, regardless of its appearance.

Mastering Line Techniques That Professional Captains Use

Beyond simply tying a knot, effective line handling is a skill that sets experienced boaters apart. This involves understanding how to correctly use a cleat, adjusting your technique for different conditions, and avoiding common mistakes that can create hazardous situations.

The Cleat Hitch: A Foundation of Secure Docking

The cleat hitch is the most common method for securing a line to a cleat. It's a simple but highly effective knot that allows for easy adjustment and quick release. Mastering this hitch is essential for any boater. Begin by wrapping the line around the cleat's base. Then, bring it over the first horn, under the second, and back over the first, creating a figure-eight. Finally, secure the line with a locking turn over the top horn, opposite the direction of the figure-eight. This locking turn acts as a clamp, preventing slippage.

Adapting to the Elements: Wind, Current, and Tide

Professional captains adapt their line handling based on prevailing conditions. In strong winds or currents, using spring lines is critical. These lines run diagonally from the bow and stern to the dock, preventing excessive movement and surge. Tidal changes also require adjustments to line length. Larger vessels might need multiple cleats working in concert to distribute the load. Proper cleat installation is fundamental, and this often involves detailed process documentation. For more on documenting procedures, check out this resource on process documentation software.

Common Errors: Prevention is Key

Common line handling mistakes include insufficient wraps around the cleat, incorrect hitches, and neglecting tidal changes. These errors can lead to lines slipping or jamming, causing potential damage or dangerous scenarios. A loosely tied line can come undone in rough conditions, while a jammed line can be difficult to release quickly during an emergency.

Advanced Techniques for Demanding Situations

Complex situations, like securing large vessels in strong currents, demand advanced techniques. Strategically placed spring lines and the use of multiple cleats become vital. Understanding how different cleat types perform under load is also crucial.

To help illustrate best practices for various boating scenarios, the following table provides a quick guide to appropriate line handling techniques.

Line Handling Techniques for Different Conditions

| Condition | Recommended Technique | Additional Security Measures | Common Mistakes to Avoid |

|---|---|---|---|

| Calm Conditions | Standard Cleat Hitch | Double-check line tightness | Insufficient wraps on the cleat |

| Strong Winds/Currents | Spring Lines | Extra lines, chafe protection | Not adjusting for tidal changes |

| Large Vessels | Multiple Cleats, Spring Lines | Regular line inspections | Uneven load distribution |

| Challenging Docking | Pre-planning, clear communication with crew | Fenders readily available | Rushing the process |

This table summarizes key approaches for secure line handling, emphasizing the importance of adapting to specific conditions. Remember, proper technique contributes significantly to overall boating safety.

By mastering these techniques and attending to details, you can ensure your boat is securely moored, protecting your vessel and contributing to a safer and more enjoyable boating experience.

Protecting Your Investment: Cleat Care That Works

Smart boaters know that cleats are essential for safety and security. They're not just another piece of hardware. Neglected cleats can lead to failures, often at the worst possible moment. Regular maintenance is crucial for extending their lifespan. This translates to safer and more enjoyable boating. Read also: Marina Safety Guidelines for a Secure Boating Experience.

Material-Specific Care: Addressing Unique Challenges

Different cleat materials have unique care requirements. For stainless steel cleats, the main concern is galvanic corrosion. This happens when different metals touch in corrosive environments like saltwater. Regularly rinsing with fresh water and using a protective coating can greatly reduce this risk. Synthetic cleats, such as nylon, are susceptible to UV degradation. Using UV-resistant products and covering them when not in use helps protect them from sun damage.

Recognizing Warning Signs: Prevention Is Key

Recognizing the signs of cleat failure is essential. Corrosion, cracking, and bending all signal potential issues. A keen eye for these problems allows for early intervention, preventing major failures. Regular inspections should be a habit. This simple practice can prevent costly repairs and potential safety hazards.

Environmental Factors: Understanding the Impact

Environmental conditions play a big role in cleat longevity. Saltwater accelerates corrosion in metal cleats. Temperature extremes cause materials to expand and contract, which can lead to stress fractures. Boaters in harsh environments need to be especially diligent with maintenance. Consider the sun's effect on synthetic materials. Factoring these conditions into your maintenance plan helps maximize cleat lifespan.

Refurbishment Vs. Replacement: Making Informed Decisions

Knowing when to refurbish versus replace a cleat is important for cost-effective boat maintenance. Minor corrosion or surface damage is often fixable with cleaning and polishing. However, significant structural issues usually require replacement. Understanding the difference helps boaters save money without compromising safety. Replacing a damaged cleat ensures a crucial piece of equipment is reliable. The global cleat market (marine and sports) was valued at USD 201.1 billion in 2024 and is projected to reach USD 370.3 billion by 2033. You can explore more about this market here.

Choosing Cleats That Match Your Boating Reality

Choosing the right cleats for your boat isn't a one-size-fits-all process. It requires careful consideration of your vessel's specific characteristics, your typical boating activities, and the conditions you frequently encounter. This means looking beyond general advice and focusing on what truly matters for your individual boating needs.

Sizing Cleats Appropriately: Beyond Generic Recommendations

Many boaters rely on general guidelines for cleat sizing, but this can be a risky approach. A more practical method involves considering your boat's length, weight, and the potential maximum loads it might experience. For example, a small personal watercraft needs smaller cleats than a large cruiser, even if both are used recreationally. A larger, heavier vessel naturally requires more robust cleats capable of handling higher loads.

Activity-Specific Configurations: Optimizing for Your Boating Style

Different boating activities demand specific cleat configurations and placements. An offshore fishing boat, for instance, experiences significantly different forces than a coastal cruiser. Offshore vessels contend with larger waves and stronger currents, requiring more robust cleats strategically placed for securing heavy-duty fishing gear. A coastal cruiser, on the other hand, might prioritize cleats for fenders and docking lines. Understanding these nuances is critical for ensuring adequate security and preventing equipment failure.

Load Calculations: Ensuring Real-World Performance

The theoretical breaking strength of a cleat is only one factor. You also need to consider how load calculations affect real-world performance. A cleat rated for a certain load might perform differently under dynamic loads, like those experienced in rough seas or during a quick stop. Marine engineers often recommend a safety factor, meaning the cleat should handle significantly more than the expected load. This buffer accounts for unexpected circumstances and ensures reliability in challenging situations.

Case Studies: From PWC to Cruiser

Let's look at a few examples. A personal watercraft (PWC) typically requires small, lightweight cleats for securing docking lines. A small sailboat might need a few mid-sized cleats strategically positioned for handling sails and docking. A larger cruising sailboat, however, might benefit from several larger cleats, some specifically for spring lines and anchor rodes. Finally, a large powerboat or cruiser will need numerous heavy-duty cleats capable of withstanding significant loads and various docking scenarios.

Evaluating Your Current Setup: A Practical Framework

Use this information to evaluate your current cleat setup. Are your cleats appropriately sized for your boat and boating activities? Are they correctly positioned for optimal function and load distribution? Are they showing signs of wear or corrosion? By honestly assessing your current configuration, you can identify areas for improvement and make informed decisions about upgrades or replacements. Proper cleat care is important to the overall maintenance of your boat. For more on that, consider website maintenance services. Investing in the right cleats and installing them properly enhances both your boating experience and safety.

Ready to upgrade your fueling experience? Explore CLiX Fueling Solutions at https://clixfueling.com. Our automatic shut-off system eliminates spills and overfills.