Ever thought about your boat's marine fuel filler? It’s one of those things you probably don’t think about until there's a problem. But it's far more than just a simple cap—it's the gatekeeper to your boat's entire fuel system.

Think of it as the first line of defense, a critical safety device that protects your engine from nasty contaminants and prevents dangerous fuel spills.

The Unsung Hero of Your Boat's Fuel System

It’s easy to overlook this small part, but the fuel filler has a massive job. It stands between a smooth day on the water and some seriously expensive, trip-ruining headaches. A loose or damaged filler can let water seep into your fuel tank, leading to catastrophic engine damage. Even worse, it could allow volatile fumes to escape, creating a genuine fire hazard.

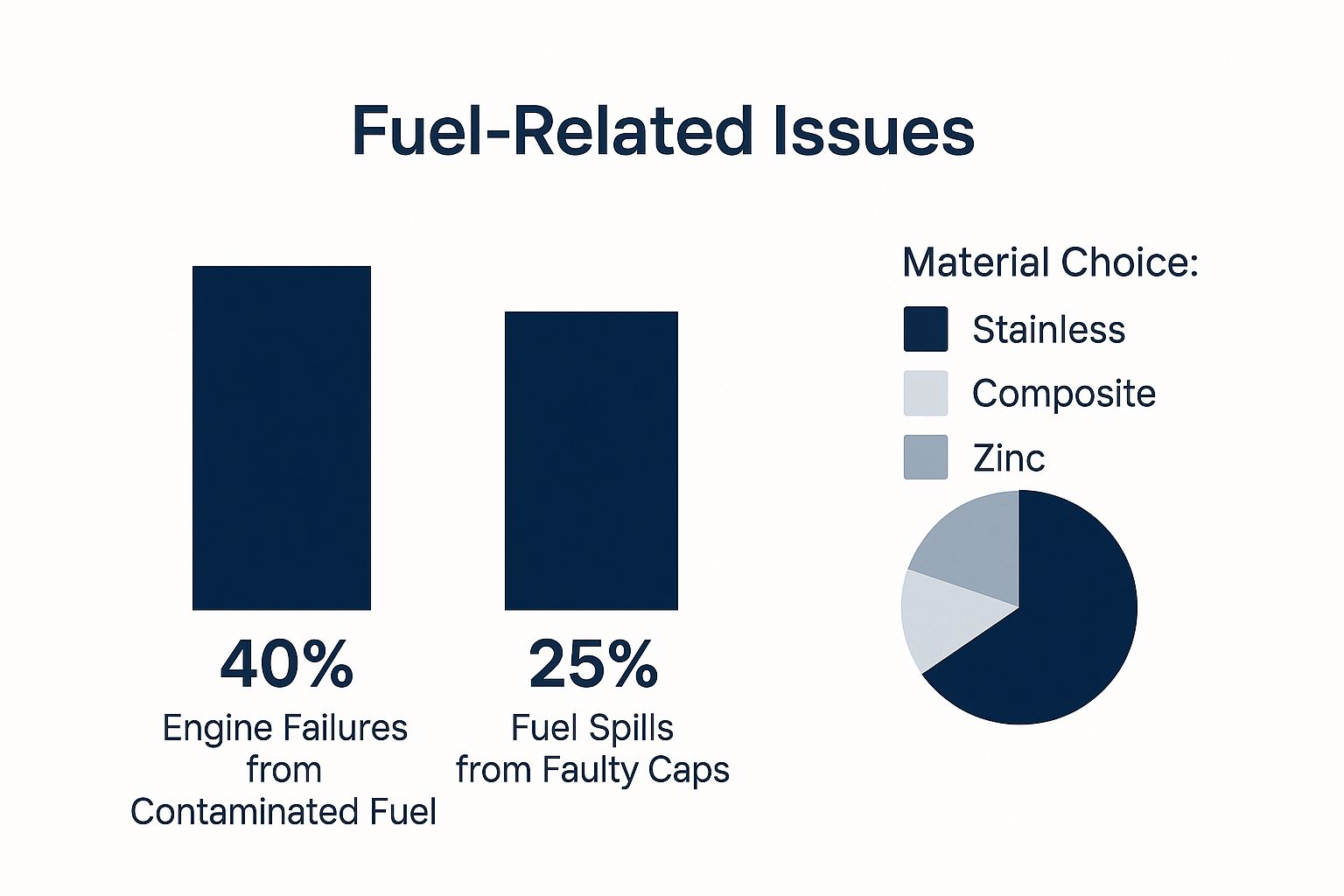

The consequences of a cheap or failing filler are no joke. Just look at the numbers.

That data says it all: nearly 40% of engine failures are tied to contaminated fuel. That’s a problem a good, secure filler is designed to stop dead in its tracks. This really drives home why choosing and maintaining the right one is so important for every boat owner.

When you're gearing up, it's easy to focus on the flashy stuff. But looking at the full picture means considering the integral boat components for marine activities that keep you safe and running. A reliable fuel filler is foundational, giving you peace of mind whether you're just cruising the bay or heading way offshore. It's a small detail, but ignoring it is a risk no boater should ever take.

Choosing the Right Material for Your Fuel Filler

When you're picking out a new fuel filler, the material is everything. It's your first line of defense against the relentless marine environment. Think of it like buying a coat for a storm—what you choose will dictate how well it holds up to a constant beating from sun, salt, and fuel.

The choice usually boils down to three main players: stainless steel, chrome-plated zinc, and modern composite plastics. Each one has its own personality on the water, and knowing the pros and cons is crucial for protecting your fuel system down the road.

Stainless Steel: The Undisputed Champion

If you're looking for pure, unadulterated toughness in saltwater, 316-grade stainless steel is the king of the hill. This isn't just any stainless; it's a specific alloy that includes molybdenum, an element that dramatically ramps up its resistance to salt corrosion. It’s like having built-in rust protection that simply won't quit.

Sure, it's the priciest option upfront, but its incredible lifespan makes it a wise investment. For any boater who spends their time in coastal or offshore waters, a 316-grade fuel filler isn't a luxury—it’s a necessity for reliable, long-term performance.

Choosing the right material for marine fuel fillers is an investment in your boat's longevity. A corrosion-resistant material like stainless steel can prevent costly repairs and ensure safety over many seasons.

The Best of the Rest: Alternative Materials

Of course, not every boat lives in the ocean, and your budget is always a factor. Luckily, there are a couple of other great materials to consider, depending on where and how you boat.

- Chrome-Plated Zinc: This one gives you the bright, shiny look of stainless steel without the hefty price tag. The trade-off? The second that chrome plating gets scratched or chipped, the zinc underneath is exposed and becomes a magnet for corrosion, especially in saltwater. It’s a much better fit for freshwater applications.

- Composite Plastics: Modern polymers have a huge advantage: they are completely immune to rust and corrosion. They’re also lightweight and generally the most affordable choice. The main watch-out here is UV degradation, which can make the plastic brittle over many seasons of sun exposure.

So, for a freshwater angler, a high-quality composite filler could be the perfect fit. It eliminates any worry about rust and offers a durable, budget-friendly solution for a less punishing environment. The trick is to match the material to your boating reality.

Marine Fuel Filler Material Comparison

To make the decision a little easier, here’s a quick breakdown of how these materials stack up against each other.

| Material | Corrosion Resistance | Durability | Cost | Best Use Case |

|---|---|---|---|---|

| Stainless Steel (316) | Excellent | Very High | High | Saltwater, offshore, and coastal boating |

| Chrome-Plated Zinc | Fair to Poor | Moderate | Low to Medium | Freshwater boats; budget-conscious boaters |

| Composite Plastic | Excellent | Good (can be brittle) | Low | Freshwater; areas with less direct sun exposure |

Ultimately, the best material is the one that aligns with your environment, budget, and how you use your boat. Taking a moment to weigh these factors will pay off with a reliable and safe fuel system for years to come.

What to Look For in a High-Quality Fuel Filler

When you're outfitting your boat, it's the small details that make a huge difference. A fuel filler might seem like a simple part, but the right features can prevent some of the biggest headaches a boater can face. Let's break down what separates a run-of-the-mill filler from one you can truly depend on.

The single most important component is the O-ring or gasket. This little rubber ring is your first line of defense, creating a tight seal that locks out water and seals in dangerous fuel vapors. A cheap, flimsy seal is guaranteed to crack and fail over time.

That failure can lead to water in your fuel—a problem responsible for nearly 40% of engine failures. A top-notch O-ring, usually made from tough nitrile rubber, gives you a vapor-proof and watertight seal every single time.

Smart Features for Convenience and Security

Beyond the seal, a few thoughtful features can make your life on the water much easier and your boat more secure.

A tethered cap is a classic example of simple, brilliant design. That small chain or plastic strap is the only thing standing between you and the classic "oops" moment of dropping the cap overboard. It’s a tiny feature that prevents a minor fumble from becoming a real problem.

A locking mechanism is another must-have, especially if you dock at a public marina. A keyed filler cap is your best bet against fuel theft or, even worse, someone tampering with your tank.

Finally, you can't overlook clear labeling. A filler must be clearly marked "GAS" or "DIESEL". This obvious visual cue, often paired with color-coding, is crucial for preventing a catastrophic fueling mistake that could destroy your engine.

Getting these details right comes down to solid manufacturing. If you're interested in the processes that ensure parts meet these tough standards, this overview of quality assurance in manufacturing is a great read.

These features all work together to keep your fuel safe in the tank. To keep it clean going in, check out our guide on the top fuel funnels with filters.

Getting Your Fuel Filler Installed and Maintained Right

Even the best marine fuel filler on the market won't do you any good if it's installed poorly. A solid installation creates a secure, leak-proof connection that will protect your boat for years. Think of it as cheap insurance against some very expensive engine problems down the road. It’s all about setting a reliable foundation for your entire fuel system.

First things first, you have to pick the right spot. You need a place on deck that’s easy to get to when you’re refueling, but it should also be well away from any hatches, windows, or potential ignition sources. The last thing you want is fuel fumes getting into the cabin.

The seal is everything. This is one job where you absolutely cannot cut corners. You must use a premium, marine-grade sealant. This stuff creates a tough, waterproof bond between the filler’s flange and the deck, stopping water from seeping into your hull or, even worse, your fuel tank.

A Quick Pre-Season Maintenance Checklist

Before you hit the water for the first time each season, a quick five-minute inspection can save you a world of hurt. It’s all about catching the small problems before they become big, expensive ones.

- Inspect the O-Ring: Take a close look at the O-ring or gasket inside the cap. Is it cracked, brittle, or squashed flat? If so, replace it immediately. A bad O-ring is the number one reason fuel cap seals fail.

- Check the Cap Tether: Give the tether a gentle tug. You want to make sure it's secure and not frayed. A broken tether is just asking for you to lose your cap overboard, leaving your fuel tank wide open to the elements.

- Clean the Threads: Grab a clean rag and wipe down the threads on both the cap and the filler neck. Getting rid of any salt, sand, or gunk ensures you can tighten the cap properly for a perfect seal.

If you catch a persistent whiff of fuel near your filler, that's a serious red flag. It means flammable vapors are escaping from a bad seal—a safety hazard you need to address right away.

Don't Forget to Ground It

One of the most critical—and most forgotten—steps is properly grounding the fuel filler. A small grounding wire should connect the metal filler neck to your boat's bonding system. This simple wire is incredibly important because it prevents static electricity from building up while you're refueling. A static spark is the last thing you want around gasoline vapors.

Following this simple maintenance routine is one of the smartest preventative things you can do for your boat. To see how this one part fits into the bigger picture, you can learn more about what a marine fuel fill does for your entire system. A little bit of care here ensures your fuel filler does its one critical job: keeping fuel in and water out.

How Fuel Fillers Fit Into Modern Boating Regulations

Your marine fuel filler is more than just a cap—it's your boat's first line of defense in a world of changing environmental rules and fuel technologies. Picking the right one isn't just about avoiding spills anymore; it’s about making sure your boat is ready for the future.

Regulations are constantly evolving, pushing the marine industry toward cleaner and more complex fuel blends. The catch is, these new formulas can be less stable and more vulnerable to contamination if they aren't handled just right. This is precisely why a high-quality, perfectly sealed filler has become so critical.

A solid seal, usually created by a tough O-ring, is non-negotiable. It does two crucial jobs: it keeps water out and stops harmful volatile organic compounds (VOCs) from leaking into the atmosphere, a major focus for environmental agencies.

The Bigger Picture of Marine Fuel

This shift isn’t just a small industry trend; it’s part of a massive transformation in the global marine fuel market. The industry is on track to hit USD 171.494 billion by 2030, a boom fueled by the switch to low-sulfur fuels and other green initiatives. A top-notch fuel filler is your best bet for protecting these advanced—and often more expensive—fuels from breaking down. You can see more data on the growing marine fuel market on knowledge-sourcing.com.

Think of your fuel filler as the gatekeeper for your entire fuel system. A quality filler protects the integrity of modern fuels from the second they leave the pump, which in turn protects your engine and keeps you on the right side of the regulations.

Of course, a secure filler is just one piece of the puzzle. For example, a perfect seal won't do much good if your tank isn't vented properly. To see how it all connects, check out our guide on choosing the right fuel vent for boats. At the end of the day, maintaining your filler isn't just about performance—it's about being a responsible boater.

Got Questions About Your Fuel Filler?

Even the most seasoned boaters run into questions about their gear. When it comes to something as critical as your marine fuel filler, having the right answers can mean the difference between a minor fix and a major headache. Let's tackle some of the most common things I hear from other boaters.

Think of this as your go-to guide for handling everyday situations and making smart choices for your fuel system. A little knowledge upfront goes a long way toward keeping you safe and confident out on the water.

How Often Should I Replace My Marine Fuel Filler?

There's no hard-and-fast rule for replacing the whole unit, but regular checks are non-negotiable. I give my fuel filler's O-ring and cap tether a quick once-over before every single trip. Then, at the start of each season, it gets a more detailed inspection.

If you spot any serious corrosion, cracks in the body, or notice the cap just isn't sealing tight anymore, replace it immediately. A faulty fuel filler isn't something to mess with—it's a major safety hazard. A bad seal can let water into your fuel or, worse, allow dangerous fuel vapors to escape.

What’s the Difference Between a Fuel Filler and a Fuel Vent?

These two work as a team, but they have completely different jobs. It's an easy thing to mix up.

- The Fuel Filler: This is simply where you stick the fuel nozzle. Its job is to give you a secure, sealed opening to get fuel into the tank.

- The Fuel Vent: This is a separate fitting that lets air out of the tank while you're fueling up. It also lets air back in as the engine burns fuel, which stops a vacuum from forming.

Both are absolutely vital for a safe fuel system, but you can't swap one for the other. The filler is for fuel coming in; the vent is all about managing air pressure.

Can I Upgrade to a Locking Fuel Filler?

Absolutely, and it's a great idea. For most boats, you can easily swap a standard filler with a locking one of the same size. I highly recommend this upgrade to stop fuel theft or tampering, especially if you keep your boat at a public marina or in a spot that isn't totally secure.

Just make sure the new locking filler has the same diameter and hose connection as your old one. It's also critical to get one made from marine-grade materials that can handle the salt and sun. It’s a simple change that delivers a lot of peace of mind.

Stop wasting fuel and risking spills. CLiX Fueling Solutions offers a spill-free, automatic shut-off system that makes refueling effortless and safe. Discover how CLiX can protect your boat and the environment today.