You might think that standard red gas can from your garage will do the job on your boat, but that's a mistake that could put you in serious danger. Marine fuel cans aren't just a different color; they're built from the ground up to handle the unique abuse of being on the water—constant movement, corrosive saltwater, and punishing sun that would destroy a regular can.

Grabbing the right can isn't just a suggestion; it’s one of the most basic and important things you can do for safe boating.

Why Your Boat Needs a Specialized Marine Fuel Can

Picture this: you're having a perfect day on the water, miles from the nearest dock, and suddenly the engine cuts out. That beautiful day turns into a stressful, potentially dangerous situation all because of something simple—not having a reliable way to carry extra fuel. This is exactly why a proper marine fuel can is non-negotiable safety gear, not just another accessory.

The environment on a boat is a world away from your garage or the back of a pickup truck. Your equipment has to be tough enough to handle it.

The Unique Challenges of the Marine Environment

Boating introduces a punishing combination of forces that a standard can is simply not designed to survive. Once you understand what your gear is up against, it's easy to see why you need specialized equipment.

- Constant Motion and Vibration: A boat is never still. It’s always pitching, rolling, and vibrating, which puts constant stress on the seams and seals of a fuel can. This flexing can easily cause leaks and allow dangerous fumes to escape.

- Saltwater and Corrosion: The air on the water is loaded with corrosive salt. This salty spray and humidity will eat away at a typical metal can in no time. Even on a plastic can, the fittings and seals can degrade and fail if they aren't made for this environment.

- Intense UV Exposure: The sun's rays are much stronger on the water, reflecting off the surface and baking everything on deck. Without special UV inhibitors, the plastic of a regular can will become brittle, crack, and eventually split open, leading to a dangerous fuel spill.

A fuel leak on a boat is far more than just a messy cleanup. Gasoline vapors are heavier than air and can sink into the lowest parts of your boat, like the bilge. Down there, they create an invisible, explosive cloud that a single spark from your engine or electrical system could ignite.

Preventing Catastrophic Failures

Using the wrong fuel can isn't just about the risk of getting stranded. A leak or spill can cause serious environmental harm, lead to expensive repairs, and create a life-threatening situation for you and your passengers.

Marine-grade fuel cans are built differently. They have thicker walls, heavy-duty seals, and are made from materials specifically chosen to fight off corrosion and UV damage. Many also include critical safety features like flame arrestors in the spout, which prevent a fire outside the can from flashing back and igniting the vapor inside.

These aren't just minor upgrades; they are fundamental protections against the real-world dangers of carrying fuel on a boat. At the end of the day, spending a little extra on the right can is an investment in your safety and peace of mind.

Comparing Marine Fuel Can Materials and Design

Picking the right material for your marine fuel can is a lot like choosing the right foul-weather gear. You wouldn’t rely on a light windbreaker in a storm, and you wouldn't wear heavy-duty oilskins on a calm, sunny day. The same logic applies here—your choice depends entirely on the conditions you face on the water.

The two main players in the boat fuel can game are high-density polyethylene (HDPE)—a really tough plastic—and classic metal, usually steel. Getting to know the real-world pros and cons of each is the first step to making a smart, safe choice for your boat.

This isn't just about personal preference; it's a key part of a massive global market. The fuel storage container industry was valued at $29.9 billion in 2025 and is expected to hit $47.3 billion by 2035, and portable cans like these are a huge piece of that pie. You can read the full research on fuel storage containers here to see how the market is evolving.

The Lightweight Champion: High-Density Polyethylene

Think of a plastic marine fuel can as modern, high-tech sailing gear. It's incredibly lightweight, a breeze to carry, and completely shrugs off the rust and corrosion that saltwater throws at everything else. That natural immunity makes HDPE a no-brainer for the harsh marine environment.

But, just like any gear, it has its limits. Cheaper plastics can get brittle and crack after being beaten down by the sun's UV rays for a season or two. This is why a proper marine-grade plastic can is made with special UV inhibitors mixed right into the material. This protects it from sun damage and ensures it won’t give up on you when you need it most. They’re also molded as one seamless piece, which gets rid of any weak spots that could split from the constant vibration of a boat.

For most boaters, the mix of being corrosion-proof, lightweight, and tough makes plastic the clear winner. If you're looking for some solid recommendations, our guide on the top boat gas cans offers safe and durable options to get you started.

The Heavy-Duty Guardian: Metal Cans

If a plastic can is your technical jacket, a metal can is your pair of steel-toed work boots. It offers unmatched durability and puncture resistance, which is perfect for anyone who needs absolute maximum protection from physical knocks and drops. A dropped wrench or a bump against a sharp cleat is far less likely to be a problem for a steel can.

That ruggedness comes with a couple of trade-offs, though. Metal cans are noticeably heavier, and more importantly, they can rust—especially around saltwater. One little scratch in the paint can be all it takes for corrosion to start eating away at the can. They also dent, which can make them sit wobbly and create weak points in the metal.

To combat this, quality metal marine cans come with thick powder coatings or special internal linings to keep rust at bay. They need a bit more looking after, but for some jobs, you just can’t beat their sheer toughness.

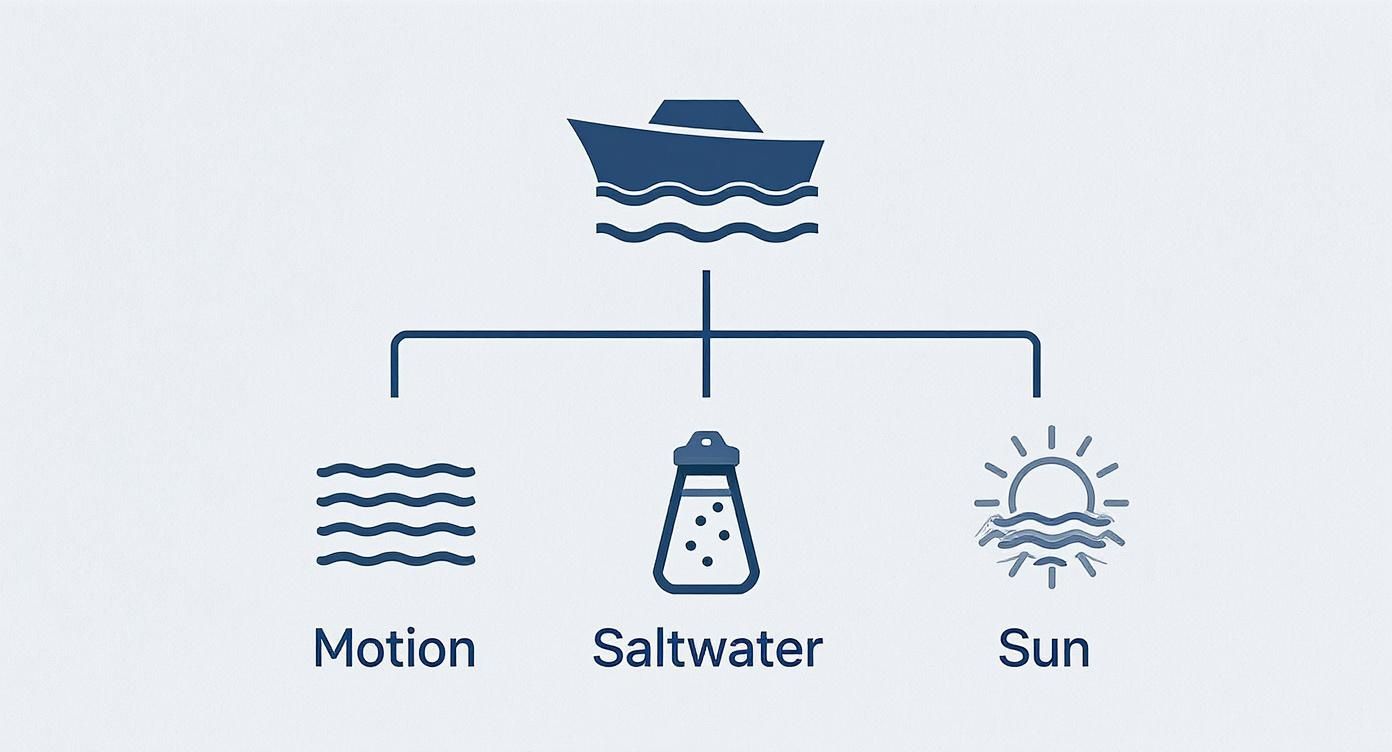

The image below breaks down the three big environmental challenges—motion, saltwater, and sun—that every single marine can, plastic or metal, has to be built to handle.

This really drives home the point that a can's design has to account for the constant rocking of the waves, the corrosive power of salt, and the damaging effects of the sun to keep your fuel secure.

Marine Fuel Can Materials: A Head-to-Head Comparison

To make the choice a little easier, let's break down the key differences between plastic and metal in a simple, side-by-side comparison.

| Feature | High-Density Polyethylene (Plastic) | Metal (Steel/Aluminum) |

|---|---|---|

| Corrosion Resistance | Excellent. Completely immune to rust from saltwater. | Poor to Fair. Prone to rust if coating is scratched. |

| Weight | Lightweight and easy to carry, even when full. | Heavy, which can be a hassle to move around. |

| Durability | High impact resistance but can become brittle with age/UV. | Excellent puncture and impact resistance. |

| UV Resistance | Good, but only if it contains UV inhibitors. | Excellent. The material itself is not degraded by sunlight. |

| Maintenance | Low. Requires simple cleaning and inspection. | Higher. Needs regular checks for dents and rust spots. |

| Cost | Generally more affordable. | Typically more expensive. |

Ultimately, both materials can serve you well. The best one for you just depends on your specific needs, how you store your cans, and your budget.

Critical Design Features to Look For

Beyond the material it's made from, a few specific design details separate a true marine fuel can from a regular one you'd find at a gas station. These aren't just nice-to-haves; they're essential for safety on the water.

- Flame Arrestors: This is a non-negotiable safety feature. It’s a small metal mesh screen inside the spout that acts as a one-way gate. It lets fuel and vapor out but stops an external flame or spark from flashing back into the can and causing an explosion.

- Vented vs. Non-Vented Caps: You might remember older cans with a second little screw cap you'd open to help the fuel pour smoothly. Today’s regulations require self-venting spouts that automatically release pressure as the temperature changes, so the can won’t swell up in the heat while still keeping fumes safely contained.

A flame arrestor is one of the most important yet overlooked safety components. It acts as a firewall for your fuel, transforming a potentially catastrophic ignition event into a manageable situation.

So, should you go with plastic or metal? It often boils down to your boating habits. If your can lives in a protected locker, extreme UV resistance might not be a priority. But if you're on a busy workboat where it might get knocked around, the ruggedness of a metal can could be the smarter choice.

Decoding Essential Safety Features

When you're out on the water, safety is everything. Your marine fuel can isn't just a container; it's your first line of defense against potential accidents, and its built-in features are critical. These aren't just bells and whistles—they're engineered to prevent fires, spills, and dangerous vapor buildup. Knowing how they work is a huge part of keeping everyone on board safe.

Think of it like the safety systems in your car. You trust your airbags and anti-lock brakes are there, working in the background, even though you hope you never need them. A proper marine fuel can works the same way. Using one without these protections is a risk you just don't want to take.

The Unseen Guardian: Flame Arrestors

One of the most important safety components inside any marine fuel can is the flame arrestor. It’s a small, fine metal mesh screen, usually sitting right at the base of the spout. Its job is simple, but absolutely vital.

It works a lot like the screen on your window, which lets a breeze in but keeps bugs out. A flame arrestor allows fuel to pour out smoothly but is designed to absorb and quench the heat from any external spark or flame. This stops a fire from flashing back into the can and igniting the highly flammable vapor inside.

This one little feature can be the difference between a close call and a total disaster. It’s no surprise that it's a mandatory component required by the U.S. Coast Guard for on-board fuel systems.

Smart Spouts and Venting Systems

Gone are the days of simple, leaky spouts. Modern marine fuel cans have gotten much smarter, with designs that prevent spills and manage the pressure inside the can—tackling two of the biggest hazards on a boat.

- Automatic Shut-Off Spouts: These brilliant spouts automatically stop the fuel flow the second your tank is full. No more messy, dangerous overfills that can ruin your boat's finish and pollute the water.

- Self-Venting Mechanisms: Older cans made you manually open a separate vent. Today's cans are required to vent themselves. As temperatures fluctuate, the fuel expands and contracts, causing vapor pressure to build or drop. An integrated vent automatically releases this pressure, so the can won’t swell up in the sun or collapse in the cold—all without letting fumes escape.

These systems work hand-in-hand to make fueling cleaner and safer. If you’re looking to make refueling even easier, you can find out more about the best fast-fill gas cans for your needs and how their designs help get the job done quickly and safely.

Child-Resistant Caps and Robust Construction

Beyond managing the fuel itself, a good can needs to be secure. That means protecting against accidental openings and the kind of physical damage that’s just part of life on a moving boat.

Child-resistant caps are a must-have, especially if you have family on board. They require a specific push-and-twist motion to open, keeping the contents safe from curious little hands.

Never underestimate the importance of a compliant, feature-rich marine fuel can. Regulations from the EPA and the California Air Resources Board (CARB) mandate that all portable fuel containers sold in the U.S. must have features like automatic closing spouts and permeation-resistant materials. It's all about minimizing emissions and maximizing safety.

The very construction of a marine-grade can is a safety feature. The thicker walls and seamless molding of a quality plastic can, or the heavy-gauge steel of a metal one, give it the toughness to handle the bumps, drops, and constant vibration of being on a boat. When you check a can for these features, you’re not just looking for a sticker—you’re ensuring your fuel is stored in a container built for the real world.

How to Choose the Right Can for Your Vessel

https://www.youtube.com/embed/Mumt0k0dJVw

Picking the right marine fuel can isn't just about grabbing one off the shelf. It’s about finding the perfect match for your boat and how you use it. You need to think about practical things like capacity, color, and even the shape of the can itself. These details really matter out on the water.

It's a bit like packing a cooler. For a quick afternoon trip, a small one does the job. But for a weekend on the water? You're going to need something much bigger. The same common-sense approach applies to your fuel can—getting it right is key to both convenience and safety.

Matching Capacity to Your Vessel's Needs

First things first: how much extra fuel do you actually need to carry? There's no single right answer here, because the perfect size depends entirely on your boat and how far you typically travel.

For smaller boats—think jon boats, dinghies, or anything with a small outboard—a compact 1- to 3-gallon can is usually plenty. They’re light, easy to pour from, and give you just enough backup fuel for short runs without cluttering up your limited space.

But if you're running a bigger boat with a thirstier engine, a 5- or 6-gallon can is the standard. That's enough fuel to make a real difference, giving you a solid reserve to get you home if you push the limits of your main tank. It's a genuine safety net.

A classic boater's guideline is the "rule of thirds": use one-third of your fuel to get where you're going, one-third to get back, and keep one-third in reserve for the unexpected. Your portable fuel can is a huge part of that all-important reserve.

The Critical Importance of Fuel Color-Coding

On a boat, a simple mistake can turn into a very expensive problem. Putting the wrong type of fuel in your engine is one of the worst—and most avoidable—blunders you can make. This is exactly why the universal color-coding system for fuel cans is non-negotiable.

- Red Cans for Gasoline: Red means gas. Period. This bright, unmistakable color is the industry standard and prevents you from accidentally grabbing the wrong can at the dock.

- Yellow Cans for Diesel: Yellow is reserved exclusively for diesel fuel. If you have a diesel engine, you need a dedicated yellow can. No exceptions.

- Blue Cans for Kerosene: While you're less likely to see these on a recreational boat, blue cans are the designated color for kerosene.

Following this color code isn't just a "best practice." It's a fundamental safety habit that protects your engine, which is easily the most expensive piece of gear on your boat.

Considering Shape and Stability on Board

Boats move. They rock, they pitch, and they roll. The actual shape—or footprint—of your fuel can plays a surprisingly big role in how safely you can store it. A can that stays put is a safe can.

A low and wide can is naturally more stable. With a lower center of gravity, it's far less likely to tip over in choppy water. This design is great if you plan to store it on deck or in an open area where it needs to stand on its own.

On the flip side, some boats only have tall, skinny storage lockers. In that case, an upright can is your best bet. While it might be less stable on its own, its shape is perfect for fitting snugly into a tight compartment where it can't slide around or tip over.

Before you buy a can, grab a tape measure and check out your intended storage spot. Making sure it will fit securely is just as crucial as its capacity or color.

Getting the Most Out of Your Fuel Can: Best Practices

Just having a top-notch marine fuel can isn't enough. Real safety on the water comes from knowing how to handle it correctly. When you get into good habits, you'll prevent dangerous spills, extend the life of your can, and keep everyone—and the environment—safe.

Think of these practices as your pre-launch checklist for fueling. A few simple, consistent steps can turn that plastic or metal container into a truly reliable piece of safety gear.

How to Fill and Pour Without the Spills

Most fuel-related mishaps happen during transfer, either at the pump or into your boat's tank. This is when the risk of spills and static electricity is at its peak, so a disciplined approach is non-negotiable.

Before you even think about unscrewing the cap at the fuel dock, take the can out of your boat. Always place it on the ground before filling. This one small step grounds the can and prevents a static spark from turning invisible fuel vapors into a fire. It’s a simple move that can prevent a disaster.

When it's time to fuel your boat, get a stable footing. You don't want to be off-balance while holding a full can of gasoline. Pour slowly and steadily to avoid that "glugging" that sends fuel splashing everywhere. If your tank's opening is awkward, don't be a hero—use a funnel.

Pro Tip: Never fill a fuel can all the way to the brim. You need to leave about 5% of the space empty for expansion. Fuel expands and contracts with temperature changes, and that little bit of "headspace" prevents pressure from building up and causing a leak or even damaging the can itself.

Stowing Your Can Securely Onboard

A full fuel can rolling around the deck is an accident waiting to happen. It can get damaged, leak, or worse, go overboard. Proper storage isn't just about tidiness; it's about safety.

Here’s what you need to do:

- Tie It Down: Use bungee cords, purpose-built straps, or a dedicated bracket to lock the can in place. It shouldn't be able to slide, tip over, or bang around, even when the water gets choppy.

- Let It Breathe: Fuel cans should never be stored in an enclosed space like a cabin or down in the bilge. Gas fumes are heavier than air and can pool in low areas, creating a serious explosion hazard. Keep them in a spot with plenty of airflow.

- Stay Out of the Sun: Direct sunlight is tough on plastic, causing it to become brittle over time. It also heats the fuel, leading to that pressure buildup we talked about. A shaded, protected spot is always best.

Quick and Easy Maintenance Checks

Just like any other piece of your boating equipment, your fuel can needs a little attention. A quick once-over before each trip can help you spot a small issue before it becomes a major leak. It's the best way to make sure your can stays dependable for years to come.

Your pre-use inspection is simple:

- Check the Body: Look for cracks, deep gouges, or fading on plastic cans—all signs of UV damage. For metal cans, keep an eye out for dents or any rust, paying close attention to the seams.

- Inspect the Gaskets: The rubber seals on the cap and spout are critical. They should be soft and flexible, not cracked or brittle. If a gasket looks dried out, replace it. It’s a cheap and easy fix.

- Test the Cap and Spout: Make sure the cap screws on smoothly and seals tightly. Work the spout mechanism a few times to ensure it isn’t sticking. A finicky spout is a surefire way to make a mess.

If you find a deep crack or a spot of rust that's gone through the paint, it’s time to retire that can. Don't try to patch it up. A new can is a small price to pay for peace of mind.

Fuel Storage and Environmental Responsibility

When you're out on the water, handling fuel responsibly is about more than just your own safety—it's about protecting the very environment you're there to enjoy. Every boater plays a part in keeping our waterways clean, and that mission starts with preventing fuel spills, no matter how small.

Think of a modern, well-made marine fuel can as your first line of defense. Its tight seals, automatic shut-off spouts, and sturdy build aren't just for safety; they're designed to keep every single drop of fuel right where it belongs. An old, cracked, or leaky can is just an accident waiting to happen.

Preventing Spills and Protecting Waterways

It’s shocking how much damage a tiny amount of fuel can do. A single drop can pollute a massive amount of water, threatening fish, birds, and the entire aquatic ecosystem. Good fuel handling is just part of being a good boater.

Here are a few simple habits that make a world of difference:

- Use an absorbent pad: Before you refuel, place a fuel-absorbent pad or bib around the fuel intake. It’s an easy way to catch any stray drips.

- Don't top it off: Always leave about 5% of empty space in the can. Fuel expands in the heat, and this "ullage" space prevents it from being forced out.

- Inspect before you pour: Give your can a quick once-over for cracks or worn-out gaskets before each use. It only takes a second.

For more in-depth advice, check out our guide on how to store gasoline safely. It’s packed with tips that are crucial for anyone handling fuel.

The Future of Marine Fuel and Can Design

The boating world is slowly but surely moving away from traditional gasoline. This isn't some far-off idea; it's happening right now and will change the gear we use, including the trusty fuel cans we rely on.

This shift is fueled by a worldwide demand for cleaner energy. In fact, the market for sustainable marine fuels is expected to skyrocket from USD 13.22 billion in 2024 to an eye-popping USD 648.79 billion by 2034. That’s a massive change, and you can see the full market analysis for more on this trend.

As new fuels like green methanol and ammonia gain traction, the cans we use to carry them will have to evolve. These alternatives have completely different chemical makeups, so they'll need new materials and safety features to be handled properly.

This means the fuel cans of the future might have special linings to handle corrosive methanol or different venting systems designed for new biofuels. By choosing a high-quality, compliant can today, you’re not just being safe now—you're getting in step with where the entire marine industry is headed. Every responsible choice you make helps ensure a cleaner future for the waters we all love.

Frequently Asked Questions About Marine Fuel Cans

Even after getting the hang of the basics, a few questions always seem to pop up about marine fuel cans. Let's tackle some of the most common ones I hear from other boaters. Getting these right will help you handle your boat's fuel with total confidence.

Can I Use a Regular Red Gas Can on My Boat?

I get this one a lot, and the answer is a hard no. It's a really bad idea to use a standard automotive gas can on a boat, even though they look almost identical.

Think about it: marine fuel cans are built tough for a life on the water. They're designed to handle saltwater spray, the constant thrum of engine vibrations, and relentless sun exposure—all things that will quickly break down a regular can.

More importantly, true marine cans have critical safety features like flame arrestors that you won't always find on their land-based cousins. Using the wrong can is just asking for a fuel leak, a dangerous buildup of fumes, and a serious fire risk. It's not worth it.

What Is the Best Way to Store Fuel Cans on a Boat?

How you store your fuel is just as important as the can you put it in. The golden rule is to keep your cans upright in a well-ventilated spot. You absolutely have to secure them so they can’t tip over or slide around when you hit a wake. Bungee cords, straps, or a purpose-built holder will do the trick.

Never, ever store fuel cans in an enclosed cabin or a poorly ventilated space like the bilge. Gasoline fumes are heavier than air. They'll sink to the lowest point of your boat and just sit there, creating a ticking time bomb waiting for a single spark.

Also, try to keep them out of direct sunlight and away from heat sources like the engine compartment. A bit of shade goes a long way in protecting the can and stopping the fuel from expanding too much in the heat.

How Often Should I Replace My Marine Fuel Can?

There's no hard-and-fast expiration date on a fuel can, but you do need to inspect it regularly. A quick once-over before you fill it up can save you a world of trouble.

- Plastic Cans: Look for cracks, deep gouges, fading, or any sign the plastic is getting brittle.

- Metal Cans: Check for dents, rust, and corrosion, paying close attention to the seams where they are weakest.

- All Cans: The gaskets in the cap and spout are your first line of defense against leaks. If they're cracked, dried out, or stiff, replace them immediately.

As a general guideline, a lot of safety-minded boaters I know will replace their plastic marine fuel cans every 5 years or so, and even sooner if they spot any signs of wear. A new can is cheap insurance.

Ready to eliminate spills and make fueling your boat effortless and safe? The CLiX Fueling Solutions device prevents overfills and protects your boat and the environment. Discover a better way to fuel up by visiting https://clixfueling.com.