A hand transfer fuel pump is exactly what it sounds like: a simple, manual tool for moving fuel from one place to another. No electricity needed. It's the classic solution for those times when you're off the grid or just need a reliable way to get fuel from a can into a tank without making a huge mess.

Why You Need a Hand Transfer Fuel Pump

Ever run out of gas miles from the nearest station? Or maybe you've tried to refuel a boat on the water, wrestling with a heavy, sloshing can. These are the exact moments a hand transfer pump becomes your best friend.

Unlike electric pumps that are useless without a power source, these manual tools give you complete independence. They are a must-have for anyone who relies on vehicles, outdoor power equipment, or recreational toys.

Solving Everyday Fueling Problems

But it's not just about emergencies. A hand pump solves plenty of common, everyday frustrations with surprising ease. Think about refueling your lawnmower or generator. Instead of dangerously tipping a heavy gas can and hoping for the best, you get a clean, controlled flow. No more spills that can kill your grass or damage your equipment.

For mechanics, contractors, and farmers, a manual pump is an essential piece of kit. It’s a quick, portable way to transfer fuel between vehicles on a job site or top off machinery without having to drive it back to a central tank.

A hand pump eliminates the dependency on power, making it an invaluable asset for off-grid applications, emergency kits, and daily maintenance tasks where convenience and control are paramount.

The Core Benefits of a Manual Pump

At the end of the day, the real beauty of a hand transfer fuel pump is its sheer simplicity. It's a straightforward tool that just works, with no complicated parts or power cords to worry about. This makes it a fantastic, low-cost option for just about anyone.

Here's a quick look at why they're so popular:

- Portability: They're lightweight and compact. You can easily toss one in your car trunk, toolbox, or boat storage without a second thought.

- Cost-Effectiveness: Manual pumps are a fraction of the cost of electric models. You get the job done without a big investment.

- Reliability: With fewer moving parts and no batteries or motors, there’s very little that can break. They’re built to be dependable.

- Versatility: Many pumps aren't just for gasoline. They can often handle other liquids like diesel, oil, and even non-potable water, making them useful for all sorts of tasks.

To give you a clearer picture, here's a quick breakdown of what these pumps are all about.

Hand Transfer Fuel Pump at a Glance

| Key Feature | Description | Primary Benefit |

|---|---|---|

| Manual Operation | Operated by hand using a siphon, lever, or rotary action. | No electricity or batteries required, ensuring it works anywhere. |

| Simple Design | Consists of basic components like hoses, a pump mechanism, and a handle. | High reliability with minimal points of failure and easy maintenance. |

| Portability | Lightweight and compact, designed to be carried and stored easily. | Perfect for emergency kits, on-the-go refueling, and mobile work. |

| Controlled Flow | Allows the user to manage the speed and volume of the liquid transfer. | Reduces spills, prevents overfilling, and improves overall safety. |

This table shows how a simple tool can offer so much utility, from its fail-proof manual operation to its ability to prevent messy spills.

How Manual Fuel Pumps Actually Work

At the end of the day, a hand transfer fuel pump is all about one simple, powerful idea: creating a pressure difference. It might sound technical, but you've already mastered the physics behind it every time you've used a drinking straw.

When you take a sip, you lower the pressure inside the straw, and the normal air pressure outside pushes your drink right up into your mouth. A manual fuel pump is doing the exact same thing, just with fuel instead of soda.

You start by putting the intake hose into your fuel can and the outlet hose into the vehicle's tank. Then, it's time to get things moving.

Kicking Off the Siphon

Whether you're squeezing a bulb, turning a crank, or pumping a lever, that first action is all about pushing air out of the pump and the hose. This creates a partial vacuum—a pocket of lower pressure—that the fuel is just waiting to fill.

Nature can't stand a vacuum. So, the higher atmospheric pressure pushing down on the fuel in your can forces the liquid up the hose, moving it toward that low-pressure spot. Once the fuel gets over the hump (the highest point in the hose) and starts heading downhill, you've won. Physics takes it from there.

The real magic is in creating an unbroken column of liquid. As long as you don't let any air in, the weight of the fuel flowing down the outlet side keeps pulling more fuel up the intake side. This is what creates a self-sustaining siphon.

That continuous pull is what makes the whole process so slick once you get it started.

Letting Gravity Do the Heavy Lifting

While your pumping action gets the party started, gravity is the real MVP. For the easiest and fastest transfer, always try to place the source container higher than the tank you're filling.

Positioning makes a huge difference:

- Easier Start: It takes a lot less work to get the fuel moving when gravity is already giving it a nudge downhill.

- Faster Flow: The bigger the height difference, the faster the fuel will move. You're basically giving gravity a steeper hill to work with.

- Less Work for You: With a good height advantage, you often just need a few quick pumps to kick things off. Then you can just stand back and watch it flow, no more effort required.

It’s like giving a sled a good shove at the top of a snowy hill. You put in that initial burst of energy, and gravity takes care of the rest. That simple combination of a little elbow grease and basic physics is what makes the hand transfer pump such a brilliantly reliable tool.

Choosing the Right Type of Hand Fuel Pump

Not all manual fuel pumps are created equal. Picking the right hand transfer fuel pump is a lot like choosing any other tool for a job—the best one really depends on what you’re trying to do. Are you just topping off a lawnmower, or are you emptying a massive 55-gallon drum? There’s a specific pump designed for each scenario.

Think of it like this: you wouldn’t use a tiny screwdriver to drive a lag bolt. Using the wrong pump can be just as frustrating, leading to slow, messy transfers and a whole lot of wasted effort. Let's walk through the three main types so you can find the perfect fit.

Siphon and Bulb Pumps

This is the simplest design out there and probably the one most people are familiar with. It's basically two hoses connected by a squeezable bulb. A few quick squeezes get the fuel flowing, and from there, gravity does the rest of the work.

- Best For: Small, quick jobs. They’re perfect for stashing in an emergency car kit, refueling a generator, or topping off a boat or jet ski.

- Typical Flow Rate: Don't expect speed. You'll get around 1-2 gallons per minute. It's slow, but it's incredibly portable and couldn't be easier to use.

- Material Compatibility: These are usually made from basic plastic or rubber. That's fine for gasoline and diesel, but they won't hold up well against thicker fluids like oil.

For anyone who only needs a pump occasionally, this is the go-to for pure convenience.

Rotary and Crank Pumps

When you've got a serious amount of fuel to move, you need a workhorse. That's where the rotary pump comes in. You operate it with a hand crank, and it’s designed to screw directly into large fuel drums. The flow rate is much, much higher than a simple siphon.

As you turn the crank, a set of internal vanes or gears spins, pulling a continuous stream of fuel through the pump. This steady mechanical action is why you see them everywhere in agricultural, industrial, and marine settings where moving large volumes is a daily chore.

A rotary pump is hands-down the best tool for emptying large drums or tanks efficiently. Its continuous flow cuts transfer time dramatically, saving you a ton of time and elbow grease compared to a basic siphon.

This is your reliable, high-volume solution for more demanding jobs.

Piston and Lever Action Pumps

What about thicker liquids? Or situations where you need a bit more muscle? For that, you’ll want a piston or lever action pump. Just like the name says, you pump a lever up and down. Each stroke pulls liquid into a cylinder and then forcefully pushes it out through the hose.

This design generates a lot more pressure than the other manual types. It’s uniquely suited for transferring not just fuel, but also heavier oils, lubricants, and even some chemicals that would be too much for a siphon or rotary pump to handle.

- Best For: Viscous fluids like motor oil, hydraulic fluid, and gear oil. They're also great for pumping diesel from barrels in a workshop or garage.

- Typical Flow Rate: Pretty decent. You can expect somewhere between 5-10 gallons per minute, though this depends on how thick the fluid is and how fast you're pumping.

- Material Compatibility: These are built tough, often with steel components, to handle thicker liquids and last for years.

While it might not be as fast as a rotary pump for thin fuels like gasoline, its raw power makes it the only real choice for heavier-duty liquids.

To help you visualize the differences, here's a quick comparison of the three main types.

Comparison of Hand Transfer Fuel Pump Types

| Pump Type | Mechanism | Best For | Pros | Cons |

|---|---|---|---|---|

| Siphon & Bulb | Gravity-fed flow initiated by a manual bulb | Small, low-volume transfers (e.g., lawnmowers, generators) | Extremely portable, simple to use, inexpensive | Very slow flow rate, not for thick fluids |

| Rotary & Crank | Hand-cranked internal vanes or gears | High-volume transfers from large drums (55-gallon) | Fast and continuous flow, efficient for large jobs | Bulkier, requires mounting to a drum, more expensive |

| Piston & Lever | Manual lever action forces fluid through a cylinder | Thick, viscous fluids (e.g., oil, lubricants, diesel) | High pressure, durable construction, versatile | Slower than rotary for thin fuels, requires more effort |

Ultimately, the right choice comes down to the volume and type of fluid you're moving. A simple siphon is great for convenience, a rotary is best for speed, and a piston pump is the powerhouse for thick liquids.

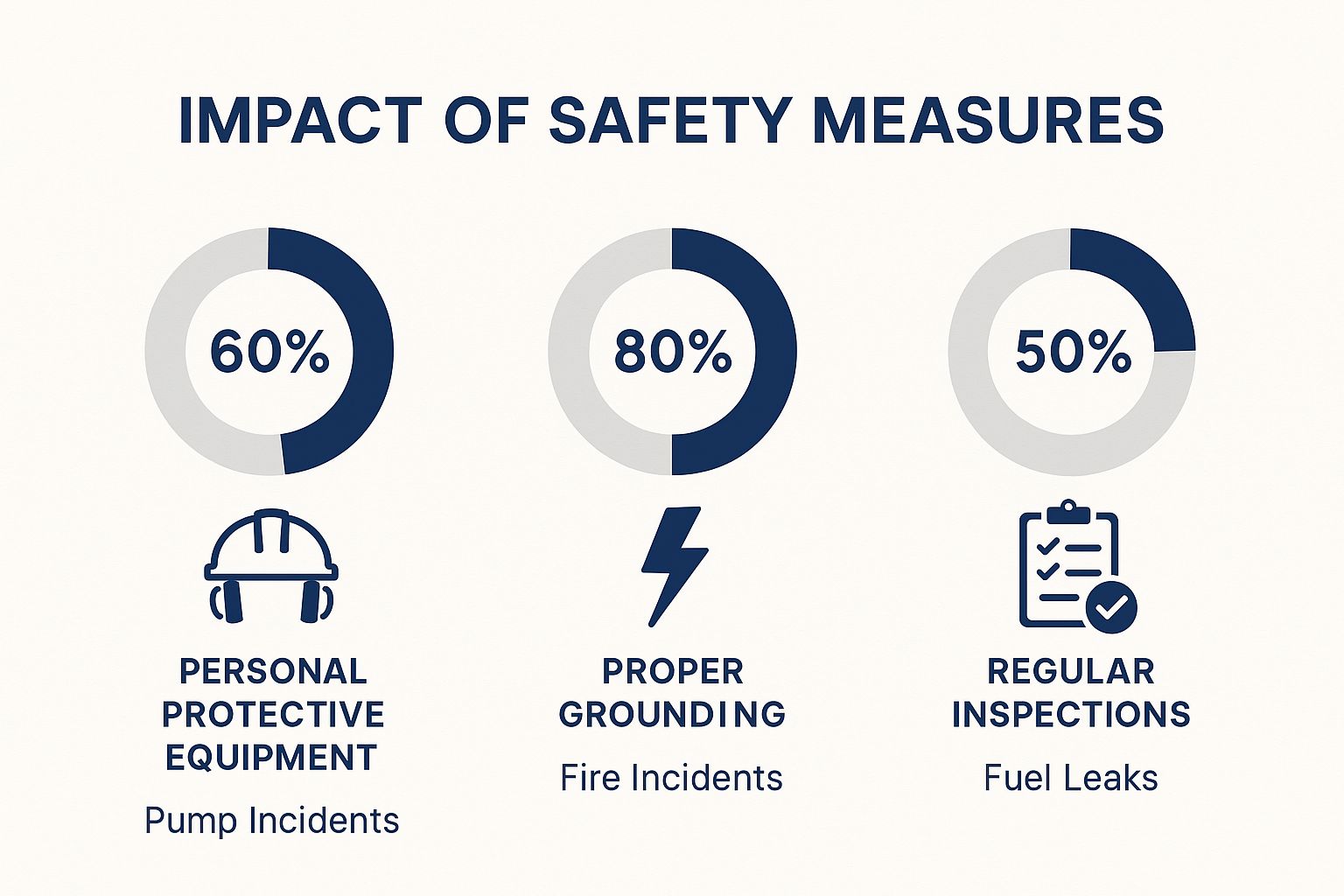

No matter which pump you end up with, safety is always the top priority. The infographic below really drives home how much of a difference basic safety protocols can make.

This infographic visualizes the dramatic impact of key safety protocols on reducing common incidents associated with fuel transfer.

The data makes it crystal clear: simple steps like proper grounding and regular equipment checks are your best defense against dangerous fires and leaks.

The data makes it crystal clear: simple steps like proper grounding and regular equipment checks are your best defense against dangerous fires and leaks.

Essential Safety Rules for Fuel Transfer

Working with a hand transfer fuel pump is simple enough, but let's be honest—handling fuel demands respect and your undivided attention. Gasoline and diesel are incredibly flammable, and their fumes aren't something you want to be breathing in. A few common-sense safety rules are all it takes to make sure every transfer goes off without a hitch.

The absolute first thing to consider is your location. Always work in a well-ventilated area. That means no fueling in a closed garage, a shed, or any other enclosed space. Fumes can accumulate in a hurry, creating a dangerous fire hazard and a real health risk if inhaled. Your best bet is always to be outdoors where the fresh air can carry any vapors away.

Getting this right is the most critical first step. From there, it's about getting yourself and your immediate area ready for the job.

Eliminate All Ignition Sources

This is the golden rule, the one you can't ever bend. An ignition source is anything that can make a spark or a flame, and that's all it takes to turn a routine task into a catastrophe.

Before you even uncap the fuel can, do a quick sweep and get rid of every potential risk:

- No Smoking or Open Flames: This one's a no-brainer. Cigarettes, lighters, tiki torches—keep them far, far away from where you're working.

- Turn Off Engines: Make sure the engine of whatever you're fueling is completely off. The same goes for any other engines running nearby, whether it's a lawnmower or a truck.

- Static Electricity: This is the invisible danger people often forget. A tiny, unseen spark from static discharge can ignite fuel vapors in an instant. If you can, ground your equipment. Also, stick to containers specifically made for fuel; regular plastic buckets can build up a static charge.

Safety First: Most fueling fires aren't started by a lit cigarette. They’re started by a tiny, unseen static spark that ignites invisible fuel vapors. Always take a moment to ground yourself and your gear before you start pumping.

The need for safe fuel handling isn't just a backyard issue; it's a massive global concern. In 2023, North America alone accounted for nearly 26.9% of the fuel transfer pump market, which was valued at roughly USD 1.91 billion. This just goes to show how many of these pumps are in use and why sticking to safety standards is so important for everyone.

Use the Right Gear and Prepare for Spills

Think of your personal protective equipment (PPE) as your last line of defense. At a minimum, you should always wear nitrile gloves to keep fuel off your skin and a pair of safety glasses to protect your eyes from any unexpected splashes.

No matter how careful you are, spills can still happen. The key is to be ready for them. Keep a bag of cat litter, sand, or a proper spill kit nearby. If a small spill occurs, don't panic. Just cover it with your absorbent material, give it a moment to soak everything up, and then sweep it up for proper disposal according to your local rules.

For those working on the water, the stakes are even higher. You can find more specific advice in our complete boat fueling safety playbook.

Keeping Your Hand Pump in Top Condition

A hand transfer fuel pump is a simple tool, but like any good piece of equipment, a little care goes a long way. Proper maintenance is what makes the difference between a pump that works reliably every time and one that fails when you need it most.

The single most important habit? Clean the pump after every use. Fuel residue left inside is a magnet for dirt and grime, and it slowly eats away at the internal seals and hoses.

All you have to do is pump any leftover fuel out, then give it a few more pumps in a well-ventilated spot to push air through until it's totally dry. This prevents contamination next time and stops corrosive gunk from damaging the pump in storage.

Performing Regular Inspections

Before you put your pump away or grab it for a new job, take 30 seconds for a quick visual check. It’s like a pre-flight check for your gear and is your best defense against messy surprises.

Here's what to look for:

- Check the Hoses: Run your eyes along the entire length of the hoses. You're looking for any cracks, brittle spots, or kinks that could cause a leak or block the flow.

- Examine Seals and Connections: Make sure every connection is snug and tight. Look closely at any visible gaskets or seals—if they look dry, worn, or cracked, they're on their way out.

- Test the Pumping Action: Give the handle a few squeezes or turns. It should feel smooth and create a solid suction. If it feels stiff or weak, something's not right inside.

Taking a moment for a quick visual inspection can prevent a small issue, like a cracked hose, from becoming a dangerous and messy fuel spill during a transfer.

Proper Storage for Longevity

How you store your hand transfer fuel pump is just as crucial as how you clean it. Letting it bake in the sun or freeze in the winter will absolutely destroy its plastic and rubber parts.

Always keep your pump in a cool, dry place away from direct sunlight, like a garage cabinet or a storage shed. UV rays from the sun are notorious for making hoses brittle and weak. A little bit of thought about where it lives will ensure your pump is always ready for action.

For more detailed advice, especially if you're using a pump in a marine environment, you can explore our expert boat fuel pump maintenance tips.

Hand Pumps vs. Electric Pumps

Deciding between a manual and an electric fuel pump is a bit like choosing between a classic wrench and a power tool. Both will get the job done, but how they do it—and where they shine—are worlds apart. Your choice really boils down to three things: cost, portability, and speed.

A hand transfer fuel pump is the clear winner when it comes to simplicity and price. With no motor or fancy electronics, they're much cheaper to buy and have very little that can break. Their biggest perk? They don't need electricity. You can toss one in the back of your truck or on the boat and know it’s ready to go anywhere, anytime. This makes them perfect for emergencies or the occasional top-off.

When Speed and Volume Matter Most

Then you have electric pumps. These are the heavy lifters, built for jobs where speed and high volume are everything. They cost more and need a power source, of course, but they move fuel at a pace that a hand pump just can't touch. For farms, construction sites, or industrial shops where you're constantly refueling large equipment from barrels, an electric pump is the only way to go.

To really get a sense of the difference, it's helpful to look at automated solutions like powerful electric self-priming pumps, which move liquids with almost no effort from the operator.

The core trade-off is simple: A hand pump gives you incredible portability and rock-solid reliability for a low cost. An electric pump delivers raw power and speed for demanding, high-volume work.

Making the Right Choice for Your Needs

The fact that manual pumps are still so popular says a lot. The global market for them was valued at around USD 1.2 billion in 2023 and is only expected to grow. It’s a testament to how many industries rely on flexible, off-grid fueling solutions.

So, which one is for you?

- Choose a hand pump if: You need a cheap, portable pump for emergencies, occasional tasks like fueling a lawnmower, or for situations where there's no power outlet in sight.

- Choose an electric pump if: You're transferring large amounts of fuel on a regular basis, need to get heavy machinery back to work quickly, and have easy access to a power source.

If you find yourself leaning towards a powered option, our guide on the top electric fluid transfer pump solutions is a great place to dig deeper.

Got Questions About Hand Fuel Pumps? We've Got Answers.

Even for a tool as simple as a hand transfer fuel pump, a few questions always pop up. Whether you're trying to fix a small hiccup or just want to know what else it can do, getting the right information is key to using your pump safely and getting the job done right. Let's tackle some of the most common things people ask.

A big one is whether these pumps can move anything besides fuel. The short answer? Usually, yes. Many are designed to handle non-potable water, oil, and even antifreeze.

But—and this is a big but—you must check the manufacturer's guidelines first. Pumping an unapproved chemical can eat away at the seals and hoses, causing leaks and ruining the pump. It's also a golden rule to never use the same pump for fuel and drinking water. Always give it a good cleaning between different types of fluids to avoid cross-contamination.

What to Do When Your Pump Stops Working

Another frequent headache is a siphon pump that just quits mid-flow. Nine times out of ten, the culprit is an air leak that has broken the vacuum seal the siphon needs to work.

If this happens to you, run through this quick checklist:

- Check Your Positioning: Start with the basics. The source container has to be higher than the one you're filling. Gravity is doing the heavy lifting here, so give it a helping hand.

- Inspect the Hoses: Make sure the ends of both hoses are completely underwater (or, in this case, under-fuel). If the intake hose sucks even a little bit of air, the flow will sputter to a halt.

- Hunt for Leaks: Give the hoses a close look for any tiny cracks or holes. Also, make sure every connection point on the pump itself is screwed on tight to keep things airtight.

A siphon is all about maintaining a perfect, sealed column of liquid. Even a tiny, pinhole-sized leak can throw off the pressure balance and stop the entire process cold.

Storing Your Pump and a Look at the Bigger Picture

Once the job is done, storing your pump correctly is crucial, especially if you've been working with gasoline. Find a well-ventilated spot outdoors and pump it until it's as dry as you can get it. This lets any leftover fumes evaporate safely.

After it's dry, stick it in a sealed bag to keep any lingering smells contained. Then, store it somewhere cool and dry, far away from any potential sparks or flames.

The sheer number of these pumps in use shows just how vital they are. Back in 2021, the global market for fuel transfer pumps was valued at a whopping USD 1.71 billion, and it's only expected to get bigger. You can read the full research on fuel transfer pump market trends to see how things are shaping up.

For a different take on the whole manual vs. electric debate, this article on paddleboard pumps has some interesting points that apply here, too: Paddle Boards With Electric Pump Why You Might Not Need One With Loco S Manual Pumps.

Stop worrying about messy fuel spills and dangerous overfills. With CLiX Fueling Solutions, you can refuel your boat with total confidence, knowing our automatic shut-off system has you covered. Protect your boat, the environment, and your peace of mind by visiting https://clixfueling.com today.