Think of your boat's gas tank as its lifeline. It’s not just a box holding fuel; it's a carefully engineered system that powers every adventure you have on the water. For any gas tank boat to run reliably, this single component has to be up to the task, handling a tough marine environment that would destroy a simple container.

Why Your Boat Gas Tank Matters More Than You Think

It's easy to overlook the gas tank, but it's much more than just a place to pour fuel. It’s an active system working constantly to protect your engine, stop dangerous leaks, and make sure you have enough range to get back to the dock safely.

Getting to know your fuel system is a cornerstone of smart boat ownership. A well-maintained tank is your first line of defense against fuel contamination—a nasty problem that can lead to expensive engine repairs and leave you stranded miles from shore.

This system is at the very core of your boat's reliability. It handles fuel delivery, prevents vapor lock, and endures the constant sloshing and vibration that comes with being on the water. Ignoring it is like ignoring a crack in your home's foundation; eventually, you're going to have a big problem.

The Heart of Your Boat's Performance

Your boat's performance is directly linked to the health of its fuel system. Let's break down exactly what the gas tank is doing for you:

- Protecting the Engine: It’s a gatekeeper, stopping water, dirt, and other gunk from getting into your engine's sensitive parts. A clean, steady fuel supply is everything.

- Ensuring Safety: A properly sealed and vented tank is a critical safety feature. It prevents explosive gasoline fumes from building up in the bilge, where one spark could be catastrophic.

- Maximizing Range: When your tank is sized correctly and working as it should, you can plan your trips with confidence. You'll know you have enough fuel in reserve for bad weather or an unexpected detour.

Beyond just the tank itself, being a responsible owner means thinking about the bigger picture, like securing proper boat insurance. From small recreational boats to massive commercial ships, the entire marine industry depends on reliable fuel systems.

In fact, the demand for specialized vessels is a major driver in the global marine market, which was valued at USD 112.3 billion and is expected to climb over USD 155.4 billion by 2034. You can explore more on the marine vessels market forecast on ResearchAndMarkets.com.

Choosing the Best Material for Your Boat's Gas Tank

The material of your boat's gas tank is a big deal—it directly affects safety, how long the tank will last, and even your boat's performance. Think about it: you wouldn't put the same tires on a dune buggy as you would a family sedan. The right tank material really depends on where you boat and how you use your vessel.

Let's break down the big three: aluminum, stainless steel, and polyethylene (plastic). Each one has its own set of pros and cons when up against the tough marine environment, where things like corrosion resistance, weight, and cost really matter.

Aluminum: The Lightweight Standard

Walk through any marina, and you'll find that most built-in fuel tanks are aluminum. There’s a good reason for this. Aluminum gives you a fantastic balance of strength without adding a ton of weight, which is great for your boat's performance and fuel economy. It's the go-to, versatile choice for many builders.

But aluminum has an Achilles' heel: corrosion. Saltwater is its enemy. If moisture gets trapped against the tank, especially by foam insulation, it can lead to pitting corrosion. This creates tiny, almost invisible pinhole leaks that are a serious safety hazard. If you have an aluminum tank, regular, thorough inspections are non-negotiable.

Polyethylene: The Durable Modern Choice

High-density polyethylene (HDPE), or plastic, has really taken over in recent years, especially in newer boats. These tanks are molded in one solid piece, which means there are absolutely no welds to fail or corrode. That seamless design makes them incredibly tough and leak-resistant from day one.

Better yet, plastic is completely immune to corrosion, which is a massive advantage in saltwater. They’re also lighter than their metal counterparts and can be molded into custom shapes to squeeze every last drop of fuel capacity out of tight spaces. For many boaters, knowing their tank will never rust away provides priceless peace of mind. To see how these materials stack up in different contexts, check out our guide to portable boat gas tanks.

Stainless Steel: The Premium Option

If you want the absolute toughest tank money can buy, look no further than stainless steel. It’s the heavyweight champion of materials, offering incredible strength and much better corrosion resistance than aluminum, particularly with high-quality grades like 316L. This is the top-shelf choice for boaters who prioritize durability above all else.

Of course, that strength comes with a price tag and extra pounds. Stainless steel tanks are the heaviest and most expensive option out there. That added weight can impact your boat's handling and fuel burn, which is why you don't see them as often in smaller boats. But for larger yachts where durability is king, it’s a rock-solid investment.

Choosing the right material is a balancing act between durability, weight, and cost. To make it easier to see how they stack up, here’s a quick comparison.

Boat Gas Tank Material Comparison

| Material Feature | Aluminum | Stainless Steel | Polyethylene (Plastic) |

|---|---|---|---|

| Corrosion Resistance | Good, but vulnerable to pitting | Excellent, especially 316L grade | Immune to corrosion |

| Weight | Lightweight | Heaviest option | Lighter than stainless steel |

| Durability & Strength | Strong, but welds can be weak points | Superior strength and impact resistance | Very durable, seamless design |

| Cost | Moderate | Most expensive | Cost-effective |

| Best For | All-around use, performance boats | Large yachts, demanding conditions | Saltwater use, complex spaces |

Ultimately, the best choice depends on your boat, your budget, and how you plan to use it.

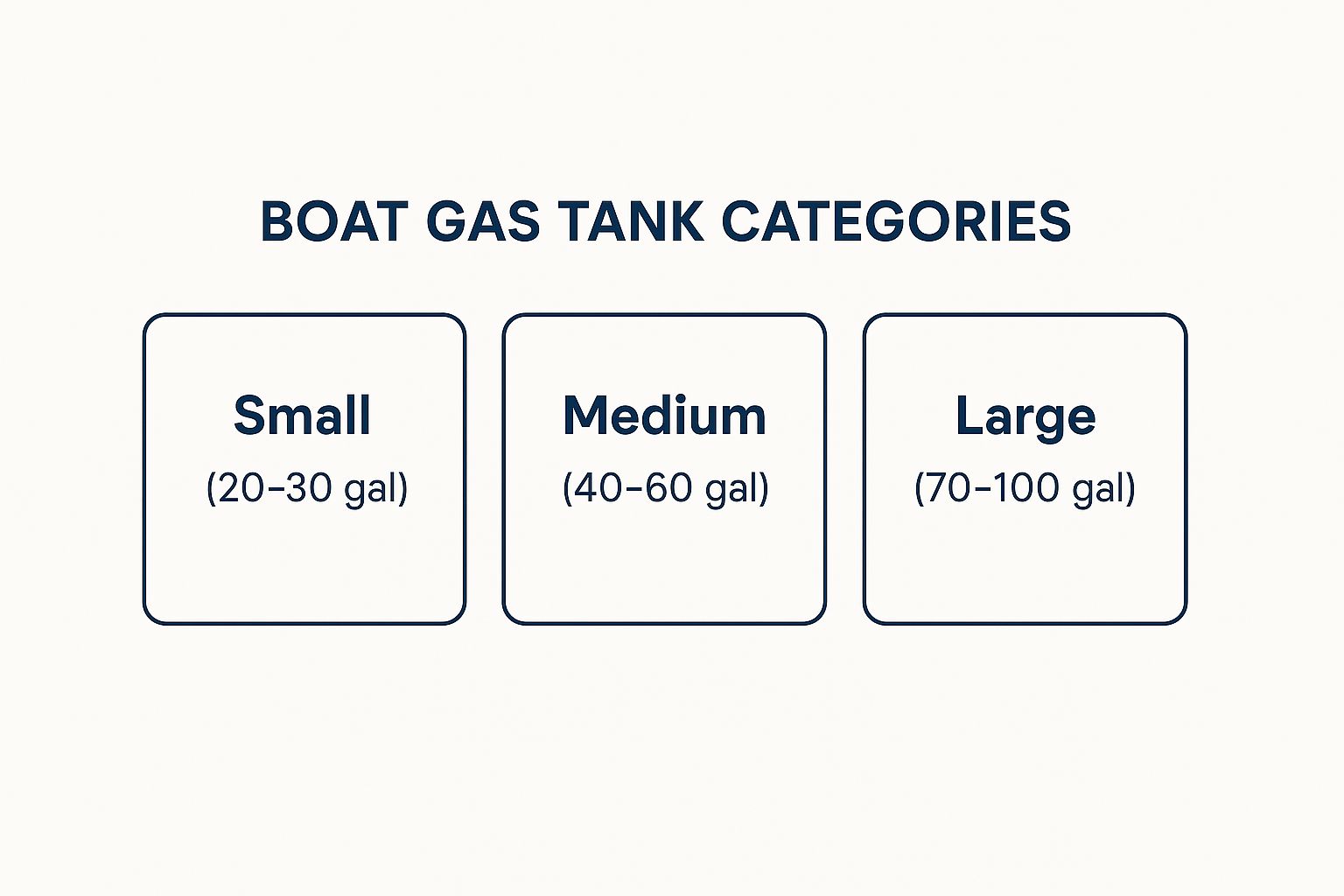

The infographic below puts fuel capacity into perspective, which often goes hand-in-hand with material choice.

As you can see, bigger boats need bigger tanks, and that's when the weight and cost of materials like stainless steel become a more significant part of the equation.

Figuring Out the Right Fuel Tank Size for Your Boat

There’s a feeling every boater dreads: watching the fuel gauge drop faster than you expected when you're miles from shore. Running out of gas on the water isn’t just an inconvenience; it’s a serious safety risk that can leave you stranded.

That's why picking the right gas tank isn't a guessing game. It's about being smart, planning for your trips, and always leaving yourself a safety cushion.

The gold standard for fuel management on the water is the Rule of Thirds. It’s a simple, time-tested principle that has kept boaters safe for generations.

The Rule of Thirds

Use one-third of your fuel to get where you're going, one-third to get back, and keep the final one-third in reserve for the unexpected.

Think of that reserve third as your get-out-of-jail-free card. It's for when the weather turns nasty, you hit a strong current, or you just want to explore a little longer. Sticking to this rule is the bedrock of responsible boating.

What Makes Your Boat Thirsty?

Your boat's fuel burn isn't just about the distance you cover. Several key things have a huge say in how quickly you'll drain that tank. Getting a handle on them is crucial for an accurate estimate.

The engine is the biggest player, of course. A beefy V8 engine will gulp down fuel far faster than a small outboard, even at the same speed. Your boat's hull design matters, too. A deep-V hull built to slice through offshore waves has more drag—and uses more fuel—than a flat-bottomed boat that skims across a calm lake.

Here’s what you need to keep in mind:

- Engine Horsepower: More power usually means more fuel. Simple as that.

- Boat Weight: Every cooler, passenger, and piece of gear adds weight, making your engine work harder.

- Hull Shape: How your boat moves through the water directly impacts its efficiency.

- Weather and Water Conditions: Heading into strong winds or choppy waves can increase your fuel consumption by 25-50%, sometimes even more.

The best way to get a true sense of your boat's needs is to calculate its fuel consumption rate in gallons per hour (GPH). For a deep dive into the numbers, check out our guide on how to calculate boat fuel consumption.

Match the Tank to Your Adventures

Ultimately, the perfect tank size comes down to how you actually use your boat. A wakeboard boat that spends all day on a small, inland lake has totally different fuel needs than an offshore fishing boat heading 50 miles out into the ocean.

Let's put it in perspective. An offshore angler might need a 100-gallon tank (or even larger) to have enough range for a long trip and still keep that one-third reserve. On the flip side, a family cruising on a pontoon boat might be perfectly happy with a 25-gallon tank for an afternoon on the local reservoir.

The key is to plan for your longest, most ambitious trips, not just your average Sunday cruise. Always make sure your tank size can support your biggest adventures while still respecting the Rule of Thirds.

Your Essential Fuel System Maintenance Checklist

If you want a reliable boat, you need a well-maintained fuel system. It's as simple as that. Think of these proactive checks as your best defense against engine trouble, saving you a world of headaches and expensive repairs down the line. It's a regular health check-up for your boat’s heart and soul.

Putting off fuel system maintenance is a gamble you just don't want to take. A tiny issue, like a cracked hose or a loose clamp, can snowball into a massive problem, and the last place you want that to happen is miles from shore. This checklist will walk you through everything you need to keep your gas tank boat in prime condition.

Inspecting Hoses and Clamps

Your fuel lines are the arteries of your boat, and they need your attention. Day in and day out, they’re exposed to fuel, engine heat, and the harsh marine environment, which can make them brittle and cracked. Remember, a leaking fuel line isn't just a performance problem—it's a serious fire hazard.

Get into the habit of giving all your fuel hoses a good look-over, from the tank right up to the engine.

- Cracks or Brittleness: Give the hoses a gentle squeeze. If they feel hard as a rock or you see any cracks, they need to be replaced. No questions asked.

- Soft or Spongy Spots: This is a bad sign. It often means the hose is breaking down from the inside out.

- Swelling: Any bulging, especially around fittings, is a huge red flag that a hose is about to fail.

- Corroded Clamps: Check every single clamp for rust. A rusted clamp can snap, letting a hose pop loose and dump fuel into your bilge.

Pro Tip

When you replace hoses, don't just grab anything. Always use marine-grade (USCG Type A1-15 or B1-15) fuel lines. They're built to resist fuel permeation and fire, adding a critical layer of safety you can't afford to skip.

Managing Fuel Filters and Contaminants

Fuel filters are the unsung heroes of your engine. They sit there quietly, trapping water and gunk before it can do any real damage. Changing them is one of the most important, non-negotiable jobs on your maintenance list. A clogged filter will starve your engine of fuel, causing it to sputter and die when you least expect it.

Most boats have two filters: a primary fuel-water separator and a smaller secondary one on the engine. Plan on replacing that primary filter at least once a season or every 100 hours of engine time, whichever comes first.

When you pull the old filter, pour what's inside into a clear glass jar. Let it settle for a minute and look for two tell-tale signs of trouble:

- Water: It’s heavier than fuel, so it will settle at the very bottom of the jar.

- Debris: Look for little black specks, rust flakes, or any slimy, gel-like gunk. That could point to microbial growth or a tank that's starting to deteriorate.

Offseason Storage and Fuel Stabilizers

Getting your fuel system ready for the offseason is absolutely critical if you want a smooth start next spring. When a boat just sits for months, fuel starts to go bad, and the constant temperature swings can cause condensation to build up inside your tank.

Here's the best way to handle it: fill the tank to about 90% capacity and add a good-quality marine fuel stabilizer. A nearly full tank leaves very little room for moist air, which cuts way down on condensation. The stabilizer keeps the fuel fresh and stops it from forming that nasty varnish that clogs up carburetors and fuel injectors.

It’s a simple step that protects the entire system, from the gas tank boat itself to the sophisticated marine engines that power it. And protecting those engines is big business. The marine engine market, valued at USD 13.31 billion, is expected to climb to USD 17.46 billion by 2032, all driven by the need for more efficient and reliable power on the water. You can discover more insights about the marine engine market on Fortune Business Insights.

How to Fuel Your Boat Safely and Avoid Spills

Fueling up might seem like a simple task, but the gas dock is the last place you want to be on autopilot. One little distraction can lead to a messy, dangerous fuel spill that harms the environment and poses a serious fire risk. A simple, consistent safety routine can make all the difference.

Before you even think about grabbing the fuel nozzle, run through a quick pre-fueling checklist. First, get everyone off the boat. Then, kill the power to everything—that means engines, electronics, lights, and radios. Double-check that all open flames, like a galley stove or a grill, are completely out. This is your number one defense against stray sparks meeting fuel vapors.

The Right Way to Fill Your Tank

Once your boat is tied securely to the dock and everything is shut down, you can start the fill. It's crucial to keep the nozzle in constant contact with the fill pipe. This simple action grounds the nozzle and prevents static electricity from building up and causing a spark.

Pay attention to the sound. As fuel flows into the tank, you'll hear it. When the tank gets close to full, the sound will change—it becomes a higher-pitched gurgle. That's your signal to slow the flow way down to prevent fuel from burping out of the tank vent.

Never Top Off Your Tank

It's tempting to squeeze in that last little bit of gas, but don't do it. Fuel expands when it gets warm. If you fill your tank to the brim, that expanding gas has nowhere to go but out the vent and into the water. Aim for about 90% full, and call it a day.

This careful approach is essential for all gas tank boats, protecting your vessel, the people on it, and the water you enjoy.

Modern Solutions for Spill-Free Fueling

Tired of the guesswork? Technology has stepped in to help. Smart systems like CLiX Fueling Solutions are engineered to stop the fuel flow automatically the moment your tank is full. No more listening, no more guessing—just a clean, reliable shutoff every single time. It makes the whole process safer and spill-free. For a deeper dive, check out this complete guide on safely filling your boat's gas tank.

The global marine fuel market is huge and still growing, projected to hit USD 171.5 billion by 2030. As more boats hit the water, our collective responsibility to fuel safely grows right along with it. Adopting smarter tools and habits isn't just a good idea; it's our part in keeping our waters clean for years to come.

A Few Common Questions About Boat Gas Tanks

When you're out on the water, the last thing you want to worry about is your fuel system. But let's be honest, gas tanks can be a source of a lot of questions. From what kind of fuel to use to knowing when a tank is about to fail, getting the right answers is key to keeping your boat running smoothly and safely.

Here are a few of the most common questions I hear from fellow boaters, along with some straightforward, experience-based advice.

How Does Ethanol in Gasoline Affect My Boat's Gas Tank?

This is a big one. Ethanol-blended gasoline is everywhere, but it can be a real headache for boat owners. The main problem? Ethanol loves water. It's hygroscopic, which means it pulls moisture right out of the humid marine air and draws it into your fuel.

Once enough water gets in there, you get a nasty situation called phase separation. The ethanol and water mixture literally separates from the gasoline, sinking to the bottom of your tank. This creates a highly corrosive sludge that your engine was never meant to burn.

- For Aluminum Tanks: This watery gunk is a fast track to corrosion, causing pits and pinhole leaks from the inside out.

- For Older Fiberglass Tanks: Ethanol can actually act like a solvent, slowly dissolving the resins that hold the tank together. The result is a thick, sticky mess that will clog your entire fuel system.

- For Polyethylene Tanks: While they hold up better, even plastic tanks can swell, deform, or become brittle after long-term exposure.

Your best move is to always use ethanol-free gasoline (often called REC-90) if you can find it. If you can't, a high-quality marine fuel stabilizer is an absolute must with every single fill-up. It's cheap insurance against very expensive ethanol-related damage.

What Are the Warning Signs of a Failing Gas Tank?

A failing gas tank almost always gives you a few warnings before it completely gives up. Learning to spot them can be the difference between a simple repair and a truly dangerous situation on the water.

The most critical warning sign is the persistent smell of fuel in your cabin or bilge. Don't just dismiss it. Gasoline fumes are heavier than air, so they sink to the lowest points of your boat, creating a massive explosion risk. A fuel smell means you have a leak, period.

Beyond smell, keep your eyes open during regular checks:

- Metal Tanks (Aluminum/Steel): Look for obvious rust, corrosion, or white, chalky-looking oxidation. Pay very close attention to the welds and fittings, as that's where leaks love to start.

- Plastic Tanks (Polyethylene): Check for any cracks, especially around the corners and fittings. If the plastic looks chalky, swollen, or feels soft in spots, it’s a sign the material is breaking down.

Another huge red flag is constantly clogged fuel filters. If you find yourself changing them all the time, cut an old one open. If you see rust flakes, little plastic shavings, or gritty sludge inside, that's a clear signal that the inside of your tank is deteriorating and contaminating your fuel.

Can I Replace a Boat Gas Tank Myself?

I get this question a lot. While a few highly skilled boat owners might tackle this job, for about 99% of people, this is a job for a professional marine mechanic. I can't stress this enough.

Replacing a fuel tank is way more involved than just swapping parts. You're dealing with draining large amounts of highly flammable liquid, disconnecting electrical wiring for the fuel sender, and then making sure every single hose, clamp, and fitting is perfectly sealed and grounded.

One tiny mistake—a poorly tightened clamp or improper grounding—can lead to disaster. You could end up with a slow leak that fills your bilge with explosive fumes or create a stray spark that ignites them.

Professional marine techs are trained to follow strict safety protocols from groups like the American Boat and Yacht Council (ABYC). They have the right equipment and experience to handle the job safely. With something this critical, the risk just isn't worth the reward. Hiring a pro is the smartest and safest call you can make.

Eliminate the risk and guesswork of fueling your boat. CLiX Fueling Solutions offers a simple, automatic shut-off system that prevents dangerous and costly fuel spills every time. Protect your boat, the environment, and your peace of mind by upgrading to a spill-free fueling experience. Learn more about how CLiX works.