A fuel hose pump is one of those simple tools that completely changes the game. At its core, it’s a dedicated device for moving fuel from a container—like a jerry can or a dockside tank—straight into your boat. It’s a self-contained system with a hose, a pump, and a nozzle, designed to make refueling safe, clean, and fast.

For any boater, this isn't just a nice-to-have gadget; it's a fundamental piece of equipment for safety and convenience. It replaces the old, clumsy, and often dangerous method of trying to pour fuel by hand.

Understanding Your Refueling Lifeline

Think of a fuel hose pump as the heart of your refueling process. It does one job and does it well: moving fuel from point A to point B with control and precision. Without one, you're stuck with the old-school way of hoisting heavy fuel cans and trying not to spill. We've all been there.

This simple tool solves a problem every boater faces. Manually pouring fuel is slow, a real strain on your back, and ridiculously easy to mess up. One little slip, and you've got fuel in the water, a stained deck, and dangerous fumes hanging around. A proper pump system gets rid of all that drama.

The Three Key Parts

No matter the brand or model, every fuel hose pump is built around three core components that work together to make your life easier:

- The Hose: This is the fuel's pathway. A good one is made from material that won't break down from contact with gasoline or diesel, so it stays flexible and won't spring a leak.

- The Pump: This is the muscle. It creates the suction that pulls fuel through the hose. Pumps can be manual (think hand-crank), but most modern ones are electric, running off a 12V DC source like your boat's battery.

- The Nozzle: This is where you have all the control. A quality nozzle lets you start and stop the flow instantly, so you can fill your tank right to the top without overfilling.

This kind of pump is a small piece of a huge industry. The global pumps market was valued at nearly USD 59.65 billion in 2024 and is still growing. The specific pump types used in these transfer systems are a key part of that growth, showing just how essential they are. You can discover more insights about the expansive pump market on GrandViewResearch.com.

A fuel hose pump isn't just about convenience—it's a critical safety upgrade. It turns a risky chore into a clean, controlled process, giving you more time on the water and less time stressing about refueling.

Why Every Boater Should Have One

A reliable fuel pump is for more than just filling up. It’s a versatile tool that helps you manage your boat more effectively. Whether you're balancing your boat's weight or simplifying maintenance, it's a real workhorse.

Here's a quick look at why so many boaters won't leave the dock without one.

Why Boaters Rely on Fuel Hose Pumps

| Application | Why It's a Game-Changer |

|---|---|

| Routine Refueling | Eliminates messy spills and the risk of fire from fumes. No more lifting heavy cans. |

| Tank Balancing | Easily move fuel between tanks to improve handling, performance, and fuel economy. |

| Emergency Fuel Transfer | A lifesaver if you need to help another boater or draw fuel for a generator. |

| Winterizing & Maintenance | Makes draining old fuel from tanks or fuel lines a simple, clean task. |

This little tool really punches above its weight. Take balancing your boat, for instance. If you have uneven fuel levels in dual tanks, it can seriously mess with how your boat handles. With a pump, you can transfer fuel from one tank to the other in minutes to get everything perfectly balanced. That simple fix leads to a better ride and more efficient cruising.

The Real-World Benefits of a Quality Fuel Pump

Sure, a fuel hose pump moves fuel from point A to point B. But when you look closer, a good one does so much more. It's not just about making a chore easier; it’s about fundamentally changing how you handle safety, efficiency, and even the reliability of your boat.

These perks are what elevate a simple pump from a "nice-to-have" gadget to a must-own piece of marine gear. Let's break down the four biggest ways a dedicated pump system really makes a difference out on the water.

Prioritizing Safety Above All Else

This is the big one. Manually pouring gasoline or diesel over an open tank is just plain risky. You’re juggling a heavy can, breathing in nasty fumes, and one clumsy move away from a dangerous spill.

A sealed fuel transfer system completely changes the game. The fuel travels through a contained hose directly from the can to the tank, which dramatically cuts down your exposure to flammable vapors. More importantly, this clean, enclosed process all but eliminates the chance of a spill—a huge win for both the environment and fire safety on your vessel.

A single accidental spill can lead to costly clean-ups and lasting damage to your boat’s finish and the marine ecosystem. A fuel hose pump is your first line of defense against these preventable accidents.

This drive for safer fuel handling isn't just a boating thing. The global fuel pumps market, worth around USD 8 billion in 2024, is expected to hit USD 11.51 billion by 2034. That growth is fueled by a demand for safer, more efficient delivery systems—innovations that trickle down and directly benefit us boaters. For a deeper dive, check out the data on the growth of the fuel pump market from Precedence Research.

Gaining Unbeatable Efficiency

Your time on the water is valuable. The last thing you want to do is waste it wrestling with awkward, heavy fuel cans. A fuel hose pump is the simple solution that gives you that time back by making refueling quicker and a whole lot less strenuous.

Instead of heaving a 40-pound container and trying to aim, you just pop the hose in and let the pump do the work. This isn't just about speed; it's about making the job easier on your body and doable for anyone.

- Saves Time: A task that used to take several minutes of careful, slow pouring is now done in a fraction of the time.

- Reduces Effort: No more back strain or trying to keep your balance on a rocking boat.

- Keeps Things Clean: The nozzle gives you total control, so you can say goodbye to fuel-drenched hands and decks. No drips, no splashes.

Ensuring Engine Reliability

Here’s a benefit that’s easy to miss: using a pump is actually better for your engine. When you pour fuel from a can, it's incredibly easy for air to get trapped in the fuel line. Those air bubbles can starve your engine of fuel, causing it to sputter, hesitate, or even stall—usually at the worst possible time.

A fuel pump, on the other hand, delivers a steady, consistent flow that pushes air out of the system. This consistent stream ensures your engine gets the clean, bubble-free fuel it needs to run reliably. A solid fuel flow is the foundation of a dependable engine, and a pump helps you achieve that.

Unlocking Surprising Versatility

While its main job is refueling, a good fuel hose pump is a bit of a multi-tool. Its ability to move liquids cleanly and efficiently makes it incredibly useful for other essential boat maintenance jobs.

Many boaters find themselves using their pumps for all sorts of things:

- Oil Changes: Pumping old oil directly from the engine into a disposal container turns a messy, dreaded job into a clean, simple task.

- Winterizing: Need to drain fuel from tanks and lines for off-season storage? A pump makes it quick and painless.

- Bilge Draining: In a pinch, it can even be used to clear water out of those hard-to-reach spots.

Because it does more than just one thing, a fuel hose pump truly earns its keep on board. It quickly becomes a go-to tool for keeping your boat in top shape.

How To Choose The Right Fuel Hose Pump

Walking into a marine supply store or browsing online can feel like a guessing game. You're faced with dozens of fuel hose pumps, and it’s tough to know which one is the right fit for your boat. Choosing wisely isn't just about convenience—it's about safety, efficiency, and having a reliable tool when you need it most.

Don't worry, we'll break it down into simple, practical steps. We'll walk through the key things to look for, from pumping speed to the type of fuel it can handle. By the end, you'll be able to pick out a pump with confidence.

Match The Flow Rate To Your Needs

The first thing to look at is the flow rate, measured in Gallons Per Minute (GPM). This number simply tells you how fast the pump moves fuel from point A to point B. It’s tempting to think that faster is always better, but that’s not quite right.

Think of it like trying to fill a small glass with a firehose—it’s overkill and you'll just make a mess. The same idea applies here. You want to match the GPM of your fuel hose pump to the size of your boat's tank.

- For smaller boats or backup tanks (under 20 gallons): A pump with a 2-4 GPM flow rate is your best bet. It gives you a steady, manageable stream that helps prevent splashes and overfills.

- For mid-sized boats (20-100 gallons): Aim for something in the 5-8 GPM range. This is the sweet spot for most boaters, offering a great balance of speed and control.

- For larger vessels (over 100 gallons): A high-flow pump of 10+ GPM is a real time-saver. It gets a big job done quickly so you can get back on the water.

Getting the flow rate right makes refueling quick, easy, and stress-free.

Select The Right Power Source

Next, you'll need to decide how your pump gets its juice. This choice really defines where and when you can use it. The two most common options for boaters have their own clear advantages.

A 12V DC electric pump is the go-to for most. These pumps hook right up to your boat’s battery, giving you powerful, consistent performance wherever you are. They're the workhorses of fuel transfer, perfect for regular refueling. The only catch is you need to be able to access your boat’s electrical system.

On the other hand, a manual or battery-operated pump gives you total freedom. These are usually smaller, lighter, and don't need to be tethered to your boat. A simple hand-crank or a small battery-powered siphon pump is an awesome backup tool to have on board, and it's also a great primary choice for dinghies and jet skis.

It really comes down to a simple trade-off: reliable power versus go-anywhere portability. For their main refueling needs, most serious boaters stick with a solid 12V DC model.

Prioritize Material Compatibility And Safety

This part is non-negotiable. Fuel is corrosive stuff, not to mention highly flammable. You absolutely must use a pump that is specifically built and rated for the type of fuel you’re handling, whether it's gasoline, diesel, or kerosene.

Never, ever use a pump meant for water to move fuel. It's incredibly dangerous. The seals, hoses, and internal parts of a regular pump will quickly break down when exposed to fuel, leading to leaks, spills, and a major fire hazard. A proper fuel hose pump is built with fuel-grade materials that guarantee a safe, sealed transfer every time.

To help narrow down your search, take a look at our guide on the top portable fuel pump picks for 2025. We break down the best models based on their safety features and real-world performance.

Comparing Common Fuel Pump Types

To make the decision even easier, let's look at the different kinds of pump mechanisms you'll run into. Each one has its own strengths, making it better for certain jobs.

Here’s a straightforward comparison to help you choose the best fit for your boating style.

| Pump Type | Best For | Key Advantage | Consideration |

|---|---|---|---|

| Diaphragm Pump | General purpose gasoline and diesel transfer | Excellent at priming itself; can run dry for short periods without damage. | The flow can be a bit pulsed, which might not be ideal for some uses. |

| Rotary Vane Pump | High-volume, fast diesel refueling | Delivers a smooth, consistent, and high-pressure flow. | Generally not for gasoline due to spark risk; can't be run dry. |

| Manual Siphon Pump | Small jobs and emergency situations | Super portable, simple to use, and needs no power source. | Very slow flow rate and requires you to do all the work. |

By keeping these four things in mind—flow rate, power source, material safety, and pump type—you'll have no trouble picking out a fuel hose pump that you can count on for years to come.

Installing Your Fuel Hose Pump Step by Step

Having a great fuel hose pump is one thing, but getting it installed correctly is what truly makes it a reliable part of your boating gear. A proper setup is all about safety and making sure it works flawlessly every time you need to refuel. This guide isn't for seasoned mechanics; it's for boaters like you, walking through a typical 12V pump installation without any confusing jargon.

We're going to cover the small but crucial details—from picking the right spot to mount it, to making sure your electrical connections can stand up to the tough marine environment. The goal here is to get the job done right the first time, with safety as our top priority.

Pre-Installation Safety Checks

Before you even think about touching a wire or a hose, let's talk safety. You're working with fuel and electricity, and that combination demands your full attention. A few minutes of prep can prevent a serious accident.

- Kill the Power: The very first thing you should do is disconnect the negative terminal on your boat's battery. This simple move eliminates the risk of an accidental spark igniting fuel vapors.

- Get Some Air: Make sure you're working in a well-ventilated space. Open up the hatches, maybe get a fan going, and let fresh air circulate to clear out any fumes.

- Round Up Your Tools: Get everything you need ready before you begin. This means having the pump, hoses, clamps, wire connectors, an inline fuse, and your basic tools all within arm's reach.

Mounting and Positioning the Pump

Location, location, location. Where you decide to put your pump makes a huge difference in how well it works and how long it lasts. You're looking for a spot that's high, dry, and secure.

Try to mount the pump as close as you can to your fuel source, whether that's a jerry can or an auxiliary tank. At the same time, make sure it’s somewhere you can easily get to for connecting power. Definitely avoid putting it down in the bilge or anywhere else it might get swamped with water. A solid mounting will also cut down on vibration, which can shake connections loose over time.

Key Takeaway: Mount your fuel hose pump where it's easy to reach, safe from water, and keeps the fuel line from the source as short as possible. This puts less strain on the pump and gives you a much more dependable flow of fuel.

It’s no surprise that these pumps are becoming more popular. The global hose pump market was valued at about USD 976.4 million in 2025 and is expected to hit roughly USD 1.56 billion by 2035. This boom is fueled by a need for tough, efficient pumps in many industries, and that innovation benefits all of us on the water.

Connecting Hoses and Electrical Wiring

Okay, the pump is mounted securely. Now it’s time to hook up the hoses and get the wiring sorted. This is where paying close attention to the details will save you from headaches with leaks or electrical issues later.

- Hose Connections: Before you push the hoses onto the pump's inlet and outlet, slide a marine-grade stainless steel clamp over each end. Make sure the hose is pushed all the way onto the fitting. Then, position the clamp about a quarter-inch from the end of the hose and tighten it down firmly. You need a perfect seal here to stop air from getting sucked in, which can make the pump lose its prime.

- Electrical Wiring: Let's get it powered up. Run the pump's positive (red) wire to your 12V power source, but make sure you put an inline fuse in between. Check the pump’s instructions for the right fuse size—this is your non-negotiable safety net against electrical shorts. The negative (black) wire just needs to be connected to a solid ground. For all your connections, use marine-grade heat-shrink connectors to keep moisture and corrosion out.

For a more in-depth look at getting your fuel system right, check out our guide on marine fuel line installation and care. It's packed with tips to keep everything safe and reliable.

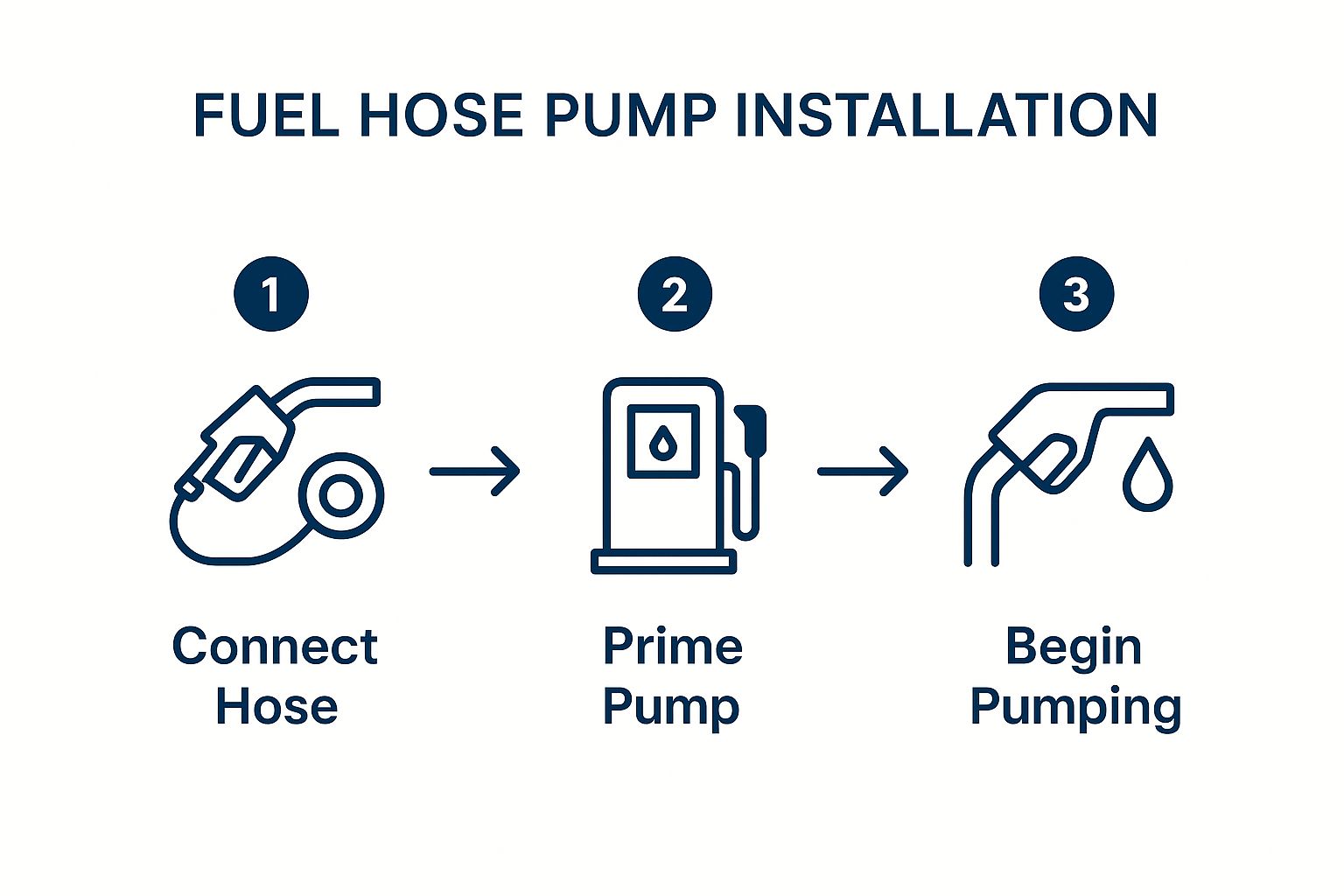

This simple graphic shows the three-step process for using the pump once you have it installed.

As you can see, once the hoses are connected, priming the pump is the key step before you start the actual fuel transfer.

Smart Maintenance and Troubleshooting Tips

A fuel hose pump that you take care of is one that will take care of you. Just like any other gear on your boat, a bit of preventative maintenance can save you from a major headache when you're miles from shore. The goal is simple: catch the small stuff before it becomes a real problem.

This proactive mindset keeps your pump ready to go at a moment's notice. It gives you confidence that your equipment won't let you down when you need it most. By building a simple routine, you can add years to your pump's life and keep it running reliably.

Your Simple Maintenance Checklist

Think of this as a quick, two-minute check-up you can do before each use. It’s a small habit that pays off big time.

- Visually Inspect Hoses: Take a quick look at the hoses. You're searching for cracks, brittle sections, or soft spots that could signal a future leak.

- Check Electrical Connections: Make sure all the wires are tight and free from corrosion. The marine environment is brutal on electronics, and a loose wire is a classic failure point.

- Examine Hose Clamps: Wiggle the hose clamps to ensure they're snug and not rusted out. A loose clamp is a common reason a pump struggles to prime because it lets air into the system.

- Clean Filters and Strainers: If your pump has an inline filter or a strainer on the intake, keep it clean. It doesn't take much debris to clog things up, which slows down the flow and overworks the motor.

Common Problems and Quick Fixes

Even with perfect maintenance, things can go wrong. The good news? Most issues are pretty straightforward to diagnose and fix yourself. Before you start to worry, run through these common scenarios.

When a pump stops working, the cause is usually pretty simple. A quick check of the power, connections, and for any blockages will solve over 90% of common fuel transfer problems without needing to order a single part.

Here’s a look at the most frequent issues boaters face and how to get things flowing again.

The Pump Runs But No Fuel Comes Out

This is probably the most common complaint, and thankfully, the fix is usually easy. The pump is getting power, but it isn't moving any liquid.

-

Possible Cause: The pump has lost its prime because of air in the system.

-

The Fix: Start at the fuel can and check every connection to the pump. A slightly loose hose clamp is the usual suspect. Tighten everything down and try priming it again. Also, make sure the intake hose is actually deep enough in the fuel.

-

Possible Cause: There's a blockage in the intake line.

-

The Fix: Pull the intake hose off and look for debris inside. Don't forget to check and clean the little strainer at the end of the hose—it's designed to catch gunk, and sometimes it does its job a little too well.

Pumping Is Much Slower Than Usual

If the pump sounds like it’s working its heart out but the fuel is just trickling through, you’re probably dealing with a restriction or a power issue.

-

Possible Cause: A clogged filter is choking the flow.

-

The Fix: If you have an inline fuel filter, it's likely full of sediment. Clean or replace it based on what the manufacturer recommends.

-

Possible Cause: Low voltage is making the pump run slow.

-

The Fix: Check your battery. A weak battery can't give the pump the juice it needs to run at full speed. Also, double-check that your electrical connections are clean and tight, as corrosion can cause voltage to drop.

Fueling Safely and Protecting the Environment

Using a fuel hose pump makes refueling a whole lot cleaner and easier, but let’s be honest: handling gasoline on the water always requires your full attention. Safety isn't just about following a checklist; it's about developing the right habits to protect yourself, your crew, and the waters we all love to be on.

Before a single drop of fuel flows, you need to prep your boat. Gasoline fumes are sneaky—they're heavier than air and love to pool in low spots like your bilge. A stray spark is all it takes to turn a peaceful day into a disaster. Always open up all your hatches and ports, and make sure to run your blower for a few solid minutes both before and after you fuel up.

The golden rule of fueling is straightforward: Never leave the nozzle unattended. It only takes a second of distraction for a spill to happen, creating a serious fire risk and damaging the marine environment.

Your Essential Safety Kit

Before you start pumping, take a moment to make sure your safety gear is ready to go. This isn't just a friendly suggestion; it's a critical step. Having these items within reach can mean the difference between a minor cleanup and a major emergency.

- Fire Extinguisher: Keep a marine-rated fire extinguisher close by. Don't stow it away where you can't get to it in a hurry.

- Absorbent Pads: Have a spill kit or some fuel-absorbent pads on hand. They can quickly soak up any drips or small splashes before they hit the water.

- Ignition-Protected Gear: Check that any electrical equipment near your fueling area, especially your fuel hose pump, is certified as "ignition-protected." This design prevents sparks that could ignite dangerous vapors.

Preventing Spills, Protecting Our Waterways

One of the best things about using a proper fuel hose pump is that it drastically cuts down on the risk of spills compared to wrestling with heavy fuel cans. But remember, you are still the most important part of the safety equation. Listen for the change in sound as your tank gets full and be ready to stop the flow to prevent an overflow.

Want to dive deeper? Our complete guide on boat fueling safety offers a complete protection playbook that covers everything you need to know. Following these simple procedures keeps everyone safe and helps ensure our waterways stay clean for years to come.

Got Questions About Fuel Hose Pumps?

Even after you've got the basics down, you're bound to have some questions when it comes to the nitty-gritty of marine equipment. Let's tackle some of the most common ones boaters ask about fuel hose pumps so you can handle yours like a pro.

Can I Use the Same Pump for Gasoline and Diesel?

That’s a hard no. You should never use the same pump for both gasoline and diesel unless the manufacturer has specifically designed and rated it for dual-fuel use.

Gas and diesel have very different chemical makeups, and pumps are built with materials compatible with one or the other. More importantly, cross-contaminating your fuel is a surefire way to cause serious engine damage. The only safe bet is to have a dedicated pump for each type of fuel.

What Does "Ignition Protected" Actually Mean?

This is a term you absolutely need to know. An ignition protected pump is built to prevent its electrical parts from creating a spark that could ignite fuel vapors. On a boat, where fumes can easily get trapped in tight spaces, this isn't just a nice feature—it's a critical safety requirement that helps prevent fires and explosions.

A huge mistake we see is people using a standard automotive pump on their boat. Those pumps are not ignition protected and are a massive fire hazard in a marine environment. Always, always check that your pump has the right marine safety certifications.

What’s a Good Flow Rate for My Boat?

The right flow rate, measured in Gallons Per Minute (GPM), really just comes down to the size of your fuel tank. Here’s a quick guide:

- Small boats (under 20 gallons): A pump with 2-4 GPM will give you plenty of control.

- Mid-sized boats (20-100 gallons): Look for something in the 5-8 GPM range. It’s the sweet spot between speed and precision.

- Large vessels (over 100 gallons): You’ll want 10+ GPM to save yourself a lot of time at the dock.

How Do I Prime a Pump That Has Run Dry?

If you can hear the pump running but no fuel is coming out, it’s probably lost its prime. This just means there’s air trapped in the line, and it’s usually an easy fix.

First, make sure the intake hose is all the way down in the fuel. Then, work your way from the tank to the pump and check every single hose clamp to make sure it's airtight. Often, just tightening a loose clamp is enough to get the suction back and the fuel flowing.

Ready to make refueling simple and spill-free? CLiX Fueling Solutions offers a patented system that automatically stops the flow when your tank is full, protecting your boat and the environment. Discover a smarter way to fuel up at https://clixfueling.com.