The Birth and Evolution of FLO-FAST Pump Innovation

The FLO-FAST pump story began not in a sterile laboratory, but amidst the high-octane energy of a racetrack. This unique origin highlights the power of necessity as a catalyst for innovation. It’s the story of how a common yet frustrating problem – a fuel spill during race preparations – ignited an idea that would revolutionize fluid transfer across diverse industries.

This initial challenge became the foundation of FLO-FAST, a company committed to developing efficient and safe fluid handling solutions. The company's very essence is intertwined with solving real-world problems.

The FLO-FAST pump was born after inventor Norman Franks experienced a fuel spill while prepping his race car. Determined to find a better way, he dedicated two years to developing the FLO-FAST system. The official launch took place in 2006 at the Performance Industry Trade show in Orlando, Florida.

Initially targeting the racing and motorsports markets, the FLO-FAST pump quickly gained traction in other sectors thanks to its versatility and robust design. Learn more about the FLO-FAST story here. This early success validated the demand for a reliable and user-friendly fluid transfer solution.

From Racetrack to Workshop: Expanding Applications

Early adoption within the racing community provided crucial feedback. Racers, known for their high performance standards, pushed the FLO-FAST pump to its limits. This rigorous testing revealed areas for improvement and expansion.

The demands of quicker pit stops, for example, drove the development of higher flow rates. This user-driven evolution ensured the FLO-FAST pump wasn't just a solution to a single problem, but a platform for continuous innovation.

Continuous Improvement: The FLO-FAST Philosophy

FLO-FAST’s dedication to improvement extended beyond the initial product launch. The company adopted a customer-centric approach, actively seeking and incorporating user feedback into its design and engineering processes.

FLO-FAST also invests heavily in research and development. The company continually explores ways to enhance performance, durability, and versatility. This ongoing commitment has established the FLO-FAST pump as a leading fluid handling technology.

This has also led to a diverse product line of specialized pumps designed for specific applications and industries. From diesel exhaust fluid (DEF) to agricultural chemicals, FLO-FAST remains focused on meeting the evolving needs of its customers.

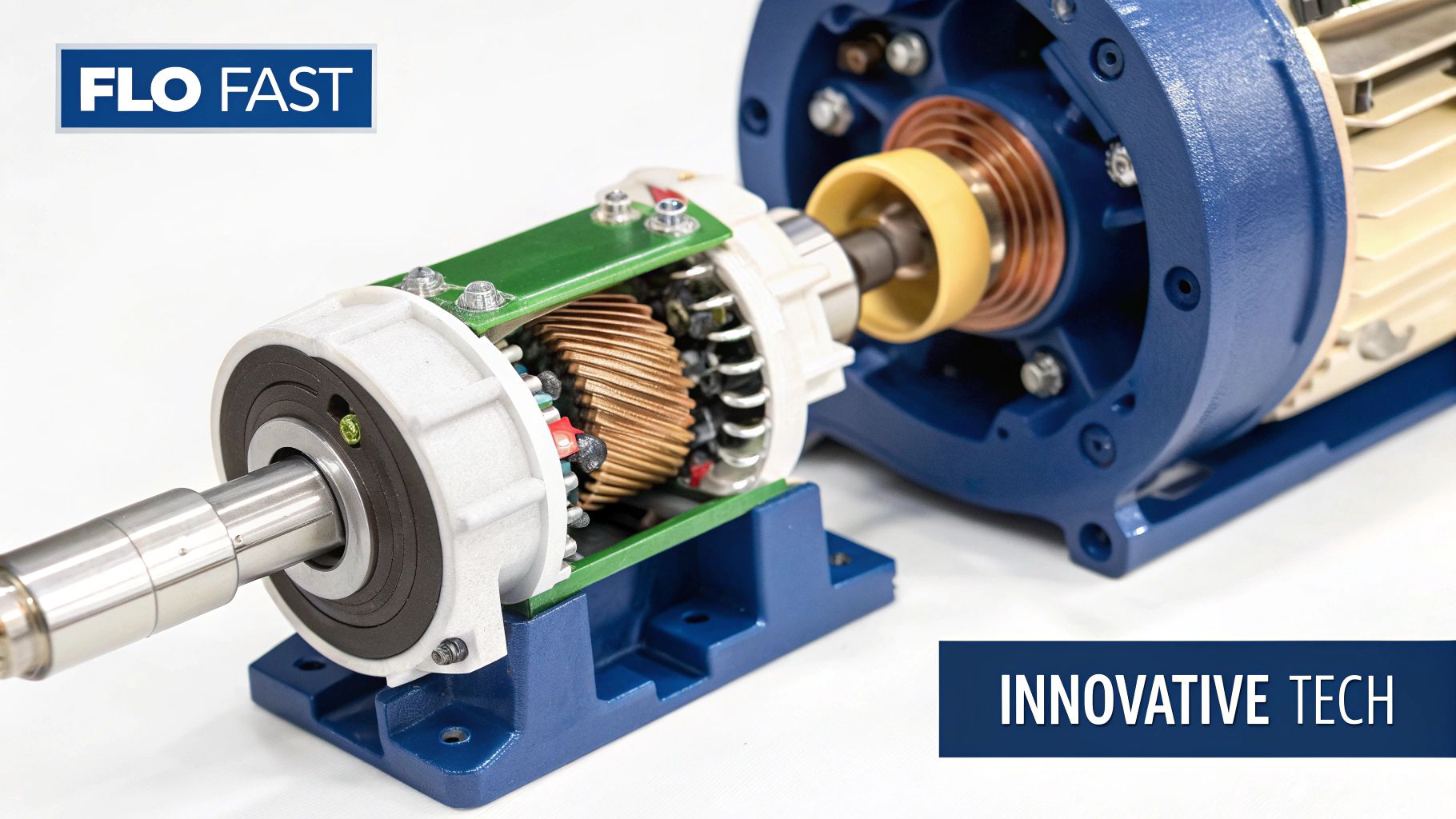

Inside the FLO-FAST Pump: Engineering That Delivers

The FLO-FAST pump stands apart from traditional fluid transfer methods. Its superior performance isn't a mystery; it's the result of clever engineering. Let's take a look at the key components that make this system so effective. This closer look will give you a better grasp of what makes the FLO-FAST pump different.

The Rotary Vane Heart of the FLO-FAST Pump

The core of the FLO-FAST pump is its rotary vane design. This mechanism generates a consistent and smooth flow, ensuring efficient fluid transfer. The vanes rotate inside the pump chamber, creating suction to draw fluid in and pressure to push it out.

This rotary motion allows for an impressive 8 gallons-per-minute transfer rate. The FLO-FAST pump's design lets it handle a wide variety of fluids—a major benefit over traditional transfer methods.

Preventing Leaks and Contamination: The Double-Seal System

The double-seal technology is another key feature. This system acts as a barrier against leaks and contamination. The dual seals give extra protection, minimizing spills and keeping fluids pure. This is particularly important when working with sensitive or hazardous materials.

This added layer of protection safeguards your fluids and extends the pump's lifespan. By preventing contamination, the double-seal system leads to fewer maintenance problems and a longer operational life.

Telescoping Draw Tube: Adaptability and Efficiency

The telescoping draw tube eliminates the need for multiple pumps. Its adjustable design works with containers of different sizes, making fluid transfer simpler. This single-pump solution saves you time and reduces equipment clutter.

The telescoping draw tube really shines in environments where various container sizes are common. No more switching pumps; the draw tube adjusts to fit the task.

Durability and Reliability: Engineered for Demanding Tasks

The FLO-FAST pump is built to last. Its tough construction and high-quality materials ensure reliable, long-term performance. This durability minimizes downtime and lowers replacement costs, making the FLO-FAST pump a wise investment.

You can depend on the FLO-FAST pump even in demanding conditions. Its robust design reflects the smart engineering behind the product.

To better understand the differences between FLO-FAST pump models, take a look at the comparison table below. It offers a comprehensive overview of the technical specifications for each model.

FLO-FAST Pump Technical Specifications Comparison

| Specification | Standard Model | Pro-Series | DEF Model |

|---|---|---|---|

| Flow Rate | 8 GPM | 10 GPM | 5 GPM |

| Material | Polypropylene | Stainless Steel | PTFE |

| Seal Type | Double Viton | Double Viton | Double EPDM |

| Inlet Port Size | 1" NPT | 1.5" NPT | 1" NPT |

| Outlet Port Size | 1" NPT | 1.5" NPT | 1" NPT |

| Telescoping Draw Tube | Yes | Yes | Yes |

As you can see, the Pro-Series offers a higher flow rate and stainless steel construction, while the DEF Model is designed specifically for DEF fluid with PTFE material and EPDM seals. The Standard model offers a balance of performance and affordability. Each model incorporates the key features discussed above, including the double-seal system and telescoping draw tube.

Pro-Series FLO-FAST Pumps: Premium Features That Matter

Professionals in various industries are increasingly choosing FLO-FAST Pro-Series pumps for their fluid transfer needs. But what sets these pumps apart from standard models and traditional methods? This section explores the key advantages of investing in these premium fluid transfer solutions, focusing on practical benefits and real-world efficiency.

Built to Last: Enhanced Durability in Demanding Environments

The Pro-Series pumps are built for enhanced durability. The reinforced crank handle, supported by dual shaft bearings, ensures a longer service life, especially in demanding environments like busy workshops or motorsports events. The dual bearings distribute stress evenly, reducing wear and tear.

The Pro-Series also features dual seal technology, crucial for handling aggressive fluids. This added protection prevents contamination and leakage, keeping corrosive chemicals contained and avoiding costly spills.

Versatility and Efficiency: The Telescoping Draw Tube System

A standout feature of the FLO-FAST Pro-Series is the telescoping draw tube system. This adaptable design allows one pump to handle various container sizes, from 5 to 15 gallons. This eliminates the need for multiple pumps, saving storage space and money. Think about the convenience – one pump for everything from small jugs to large drums!

The FLO-FAST Pro-Series pumps offer several advanced features for improved durability and performance:

- Stronger crank handle with dual shaft support bearings

- Dual seals for increased resistance against corrosive fluids

- PTFE pump vanes for longer life

- Telescoping draw tube fitting all jug sizes from 5 to 15 gallons without extra parts

This versatility makes the Pro-Series a popular choice. Learn more about FLO-FAST pumps here. You might also be interested in: CLiX Fueling Solutions Sitemap.

User Testimonials: Real-World Performance Differences

The advantages of the Pro-Series aren't just on paper. Real users report noticeable performance improvements. Many praise the smooth, efficient operation, even with thicker fluids. Others highlight the pump's durability and long lifespan, emphasizing its ability to withstand daily use. These testimonials demonstrate the value of investing in a premium pump for long-term benefits.

FLO-FAST Pump Performance: Speed When It Matters Most

When every second counts, the FLO-FAST pump truly delivers. This section explores the performance metrics that make these pumps invaluable in time-sensitive situations. We'll examine how their impressive flow rate translates into real-world time savings, from rapid pit stops to efficient industrial fluid transfers.

Real-World Time Savings: From Pit Stops to Industrial Transfers

Imagine the need to transfer liquids quickly. Perhaps it’s refueling a race car during a pit stop, or maybe it’s moving chemicals in an industrial setting. The FLO-FAST pump’s speed offers a significant advantage. A traditional hand pump might take minutes to transfer a few gallons, while a FLO-FAST pump can accomplish the same task in mere seconds. This difference can be a game-changer.

The FLO-FAST Professional Model pump boasts a transfer rate of up to 8 gallons per minute (GPM). This impressive speed allows users to empty a 7.5-gallon container in under 60 seconds. This dramatically increases efficiency for both recreational and commercial applications. The pump's durable plastic composite construction and corrosion-resistant 3-vane rotary pump design make it suitable for a variety of fluids, including water, fuels, and some harsh chemicals. Its adaptable design also allows compatibility with industry-standard containers and barrels using appropriate adapters.

This rapid transfer capability directly translates to time saved, increasing productivity and minimizing downtime. In motorsports, where every second is critical, the FLO-FAST pump helps teams gain a competitive edge. In industrial settings, faster transfers mean increased efficiency and potentially lower labor costs.

Optimizing Pump Efficiency: Factors Affecting Performance

Several factors can affect the efficiency of a FLO-FAST pump. Fluid viscosity plays a significant role, with thicker fluids generally transferring slower than thinner ones. Temperature also influences performance. Cold temperatures can increase viscosity, potentially reducing transfer rates. Finally, the condition of the pump is essential. Regular maintenance, including cleaning and lubrication, ensures optimal performance and prolongs the pump's lifespan.

Understanding these factors helps users optimize their pump's performance. Choosing the correct pump for a particular fluid type is essential. For instance, thicker fluids might benefit from a pump model specifically designed for higher-viscosity liquids. Regular maintenance is key to consistently achieving high flow rates.

Maximizing Flow Rates: Actionable Techniques

To get the best performance from a FLO-FAST pump, consider these practical tips:

-

Prime the pump properly: This ensures optimal flow rates from the start.

-

Use the correct adapters: This creates a tight seal, minimizing leakage and maximizing transfer efficiency.

-

Store the pump correctly: A clean, dry environment protects the pump and keeps it ready for use.

By following these simple steps, users can maximize flow rates and extend the life of their FLO-FAST pump. Reliable and consistent operation ensures the pump delivers when needed, saving valuable time and effort.

Beyond Basics: Specialized FLO-FAST Pump Applications

The FLO-FAST pump isn't just for standard fuel and water transfer. It's become a valuable tool across specialized industries, offering solutions for challenging applications. This shows FLO-FAST's commitment to meeting diverse fluid transfer needs. Let's explore some of these specialized uses.

Handling Harsh Chemicals: The DEF Pump

Diesel Exhaust Fluid (DEF) poses a unique challenge due to its corrosive nature. Pumps handling DEF must be resistant to degradation and prevent contamination. FLO-FAST offers a dedicated DEF pump to address this. This specialized pump ensures the safe and efficient transfer of DEF, maintaining fluid integrity and protecting your equipment.

FLO-FAST's product line now includes specialized pumps like the DEF pump. This model handles DEF and other harsh chemicals with the same durability and efficiency as the standard Professional Model. It features a telescoping draw tube and double-seal technology for safe, leak-free operation. Learn more about this pump here. This expansion demonstrates FLO-FAST's dedication to diverse fluid transfer requirements.

Agriculture: Safe and Efficient Chemical Transfer

Safe handling of chemicals and fertilizers is critical in agriculture. FLO-FAST pumps offer a significant advantage with their sealed systems. These systems minimize waste and reduce exposure to potentially harmful substances, protecting both workers and the environment.

The efficiency of FLO-FAST pumps also leads to faster application times. This is a major benefit during crucial periods like planting and fertilizing, maximizing productivity and minimizing disruption.

Marine Applications: Combating Corrosion in Coastal Environments

Corrosion is a constant threat in marine environments. Saltwater and humid air can quickly damage equipment. FLO-FAST provides salt-resistant models designed to withstand these harsh conditions, ensuring reliable performance and a longer lifespan for coastal applications.

Boat owners and marina operators can rely on these pumps for various tasks, including fuel transfer, bilge pumping, and deck washing. This durability leads to lower maintenance costs and improved operational reliability.

Adapting to Diverse Needs: Real-World Examples

The FLO-FAST pump's adaptability is evident across many sectors. From racetracks to farms, its specialized applications demonstrate its value. In industrial settings, these pumps handle various fluids, including oils, lubricants, and cleaning solutions. This versatility makes them an essential tool for maintaining efficient operations.

These real-world examples highlight how FLO-FAST’s specialized fluid transfer solutions deliver tangible benefits. The company's focus on addressing specific industry needs positions it as a leader in fluid handling solutions. The FLO-FAST pump continues to evolve, driven by the demands of diverse industries and the company’s commitment to innovative solutions.

Maximizing Your FLO-FAST Pump's Lifespan and Performance

A FLO-FAST pump is a valuable investment. Maximizing its lifespan and performance ensures you get the most out of it. This guide offers practical advice, based on user experiences and technical expertise, to keep your FLO-FAST pump in top shape for years. Proper care prevents common issues and maintains efficient operation.

Post-Use Procedures: Preventing Common Failures

Simple post-use habits can significantly extend your pump's life. Flushing is crucial. After each use, flush the pump with a compatible cleaning solution. The right solution depends on the fluid you’re transferring. Water works for most non-corrosive fluids, while a specialized cleaner might be necessary for harsher chemicals. This removes residue, preventing buildup and corrosion. For more information, check out these FLO-FAST resources.

Proper storage is also key. Keep your pump in a cool, dry place, away from direct sunlight and extreme temperatures. This prevents seal deterioration and keeps the pump working optimally.

Troubleshooting Common Issues: Step-by-Step Solutions

Even with regular maintenance, issues can still pop up. Reduced flow rate is a common one. Often, this is due to clogs in the intake or output lines. Disassembling and cleaning the pump components can restore flow. Another common issue is difficulty cranking. This often happens when fluid dries or debris gets stuck. Lubricating the moving parts with a compatible lubricant usually solves this.

These simple solutions don’t require special tools, so you can fix them quickly and easily.

Recognizing Warning Signs: Preventing Catastrophic Failure

Recognizing warning signs can prevent major problems. A leaking seal, for example, needs replacing. Continuing to use the pump with a damaged seal can cause more damage and even contaminate the fluid. Unusual noises during operation could mean internal wear. Addressing these issues early prevents serious failure and expensive repairs.

Regularly inspect your FLO-FAST pump. Look for wear and tear like cracks in the housing or handle damage. These visual cues can alert you to problems before they get serious.

Extending Service Life in Demanding Applications

For heavy-duty use, consider extra protection. Inline filters prevent debris from entering the pump, reducing wear. Regularly lubricating moving parts with a compatible lubricant minimizes friction and extends component life.

These practices help your pump last longer, even in tough conditions. A little preventative maintenance goes a long way in terms of performance and lifespan. Following these tips keeps your FLO-FAST pump running efficiently for years, maximizing your investment and ensuring reliable fluid transfer whenever you need it.

Selecting Your Perfect FLO-FAST Pump: A Buyer's Guide

Choosing the right pump from the many FLO-FAST options can be a daunting task. This guide simplifies the selection process, offering clear advice based on your individual needs. We'll cover the key factors to consider, helping you make a smart investment in the perfect FLO-FAST pump from the outset.

Key Decision Factors: Finding The Right Fit

Several factors will influence your choice of FLO-FAST pump.

First, consider fluid compatibility. What type of fluid will you be transferring? Water? Fuel? Diesel Exhaust Fluid (DEF)? Other chemicals? FLO-FAST pumps are designed for specific fluids for safe and efficient transfer. For instance, the DEF pump is engineered to handle the corrosive properties of DEF.

Next, think about your required flow rate. How quickly do you need to transfer fluids? For time-sensitive applications like racing or industrial use, a high flow rate pump, such as the Pro-Series, might be ideal. For less demanding tasks, a standard model may be sufficient.

Container adaptability is also important. Do you use various container sizes? FLO-FAST's telescoping draw tube system allows a single pump to work with a range of containers. This versatile feature streamlines the process and eliminates the need for multiple pumps.

Finally, evaluate your durability needs. How often will the pump be used and under what conditions? For frequent or heavy-duty use, a more robust model like the Pro-Series, with its reinforced crank handle and dual shaft bearings, is a worthwhile investment, ensuring a longer lifespan and dependable performance even in challenging environments.

Matching Models To Your Needs: Real-World Scenarios

Let's see how these factors play out in real-world situations. A standard FLO-FAST pump might be perfectly adequate for a weekend race enthusiast’s fuel transfer needs. A professional racing team, however, might prefer the Pro-Series for its higher flow rate and increased durability during frequent pit stops.

In an industrial setting involving harsh chemicals, a dedicated chemical pump or the DEF pump is essential for safe and efficient transfer. For agricultural uses, a standard model can handle water and some fertilizers, while specialized pumps are available for more corrosive chemicals.

Making a Confident Selection: Evaluating Your Priorities

To help you choose the right FLO-FAST pump, the following table compares different models:

Finding Your Ideal FLO-FAST Pump: Model Comparison Detailed comparison of different FLO-FAST pump models based on applications, fluid types, and user needs

| Model | Best For | Fluid Compatibility | Container Sizes | Price Range |

|---|---|---|---|---|

| Standard | Occasional use, basic transfers | Water, Fuel | 5-15 gallons | $$ |

| Pro-Series | Frequent use, demanding tasks | Various, DEF | 5-15 gallons | $$$ |

| DEF Model | DEF transfer | DEF | 5-15 gallons | $$$ |

| Specialized | Specific chemicals | Varies | Check specifications | Varies |

This table summarizes key features and benefits to guide your selection. Consider factors like fluid type, flow rate, container size, and durability to make the best choice. You might also be interested in the CLiX Sitemap. By carefully assessing your needs, you can confidently select the FLO-FAST pump that will best serve your specific application, ensure efficient fluid transfer, and provide a strong return on your investment.

Are you ready for a smoother fueling experience? Consider upgrading to CLiX Fueling Solutions and see how we're changing the way boaters fuel up.