Understanding Modern Fuel Management For Fleets

Imagine your fleet's fuel consumption as a symphony orchestra. Each vehicle represents an instrument, and for a harmonious performance (efficient operation), they need to play in sync. Fuel management isn't simply about filling tanks and sending drivers on their way; it's evolved into a sophisticated system that monitors every drop of fuel and every driving decision.

This evolution stems from a growing understanding of fuel's impact, not only on finances but also on the environment. Picture a dedicated financial advisor for your fleet, constantly analyzing expenditures and suggesting improvements. That's the power of a modern fuel management system. It provides real-time monitoring, catching fuel leaks or inefficient driving before they snowball into major issues. Furthermore, it offers predictive analytics, anticipating future fuel needs and avoiding costly surprises.

Core Components of Effective Fuel Management

Effective fuel management programs are built on several key pillars that work together to maximize savings and efficiency.

-

Real-Time Monitoring: Imagine having a constant pulse on your fleet’s fuel usage. Real-time monitoring gives you up-to-the-minute data on fuel levels, consumption, and vehicle location, enabling you to quickly identify and address any anomalies.

-

Data Analysis & Reporting: Robust reporting tools transform raw data into useful insights. This helps you understand trends, pinpoint areas for improvement, and measure the success of your fuel management strategies.

-

Fuel Card Integration: Seamless fuel card integration provides detailed transaction data, simplifies accounting, and helps prevent fraud, eliminating manual data entry and reducing errors.

-

Route Optimization: Efficient routing is like choosing the shortest path between two points – it’s crucial for minimizing mileage and fuel consumption. By optimizing routes, you can reduce unnecessary driving and ensure vehicles take the most efficient paths.

-

Driver Behavior Monitoring: Tracking driver behavior, such as speeding and excessive idling, helps identify areas where training can improve fuel efficiency. This empowers drivers to make smarter, more fuel-conscious choices.

Fuel management is so vital that the global fleet fuel management system market, estimated at $5 billion in 2025, is projected to grow at a CAGR of roughly 15% from 2025 to 2033. This growth is driven by rising fuel costs and stricter environmental regulations, encouraging companies to adopt these advanced technologies. Discover more insights into market growth. Treating fuel as just another expense is like throwing money away. By adopting a strategic approach to fuel management, fleets can optimize operations, reduce costs, and contribute to a greener future. Understanding these core components is the first step toward achieving those benefits.

The Silent Budget Killers Hiding In Your Fleet

Think of your fleet's budget like a sturdy ship. Obvious threats like rising fuel prices are like storms you can see coming. But what about the less obvious issues, the ones lurking beneath the surface? Fuel theft, inefficient routes, and excessive idling are like barnacles, slowly but surely dragging down your ship's performance. Imagine a delivery driver idling for just five minutes at each stop. Doesn't seem like much, right? But multiply that by multiple drivers, multiple stops, and multiple days a year, and you're talking about a substantial amount of wasted fuel.

Unmasking the Hidden Costs

These inefficiencies often go unnoticed, quietly chipping away at profits until the damage is done. It’s like discovering termites after they've already eaten away at the foundation of your house. Many fleet managers find themselves in this situation, scrambling to fix a problem that’s been brewing under the surface. Understanding the different parts of your fuel system, including the importance of regular fuel system maintenance, is the first step in taking control. This isn’t about playing the blame game. It’s about understanding the root causes and finding solutions.

Fuel theft, for instance, is a significant issue and can take many forms, from siphoning fuel to fraudulent fuel card usage. Inefficient routing is another major culprit. Dispatchers, often under pressure to get deliveries out quickly, may prioritize convenience over efficiency, unintentionally tacking on extra miles and burning more fuel.

The Psychology of Fuel Waste

There's often a disconnect between day-to-day actions and the big picture of company costs. Drivers might not realize the cumulative impact of their idling habits. They might think, "It's just five minutes," not realizing that those minutes add up to hours, and those hours add up to real money lost. The same goes for dispatchers. They may not be fully aware of the financial repercussions of their routing decisions.

This means education is key. Drivers and dispatchers need to understand how their choices directly affect the bottom line. Building a culture of fuel consciousness is a crucial part of a successful fuel management program.

But it’s not just about driver behavior. Vehicle maintenance plays a surprising role. Something as simple as a clogged air filter can decrease fuel economy across your entire fleet. Similarly, underinflated tires increase rolling resistance, making the engine work harder and burn more fuel. These seemingly small oversights, when multiplied across a fleet and over time, can add up to significant waste. And, of course, ignoring regular maintenance can lead to bigger, more costly mechanical issues, further compounding fuel inefficiency.

Even with all the advancements in fuel management technology, challenges persist. A 2025 survey revealed that over 50% of fleet professionals juggle multiple tools for fuel and maintenance, highlighting the complexities of modern fleet operations. Discover more insights on this topic. For further information, you might also find this interesting: Marine Fuel Management: Expert Strategies That Cut Costs.

Ultimately, tackling these hidden costs requires a multifaceted strategy. It’s about using technology wisely, training your team effectively, and fostering a company culture that prioritizes fuel efficiency. By addressing these often-overlooked issues, fleet managers can unlock significant cost savings and boost overall operational efficiency.

Technology That Actually Delivers Results

Forget dashboards crammed with charts that gather dust. Let's talk about fuel management technology that makes a real difference to your fleet's bottom line. We're diving into the practical tools and systems that help fleets thrive, from GPS tracking that reveals hidden route inefficiencies to telematics that turns fuel-guzzling driving habits into valuable learning opportunities.

Choosing the Right Tools for Your Fleet

Picking the right technology is like choosing the right tool for a job. You wouldn't use a hammer to tighten a screw, right? The same principle applies to fuel management systems. A system designed for long-haul trucking won't be the best fit for a local delivery service. Instead of falling for flashy sales pitches, analyze your fleet's specific needs. Do you need to know your fuel levels at a glance? Is driver behavior a major concern? Answering these questions will guide you toward technology that aligns with your goals. For specialized fleets, resources like Top Marine Fuel Management Systems of 2025 to Optimize Efficiency offer helpful advice.

Empowering Drivers with Data

Data is powerful, but too much can be overwhelming. Smart fleet managers use data to build accountability, not to micromanage. Think of it like a coach giving feedback to a player – the goal is to improve performance, not to criticize. Present fuel consumption data in a way that empowers drivers. Highlight their successes and offer constructive suggestions. This fosters a sense of shared responsibility and creates a more engaged team.

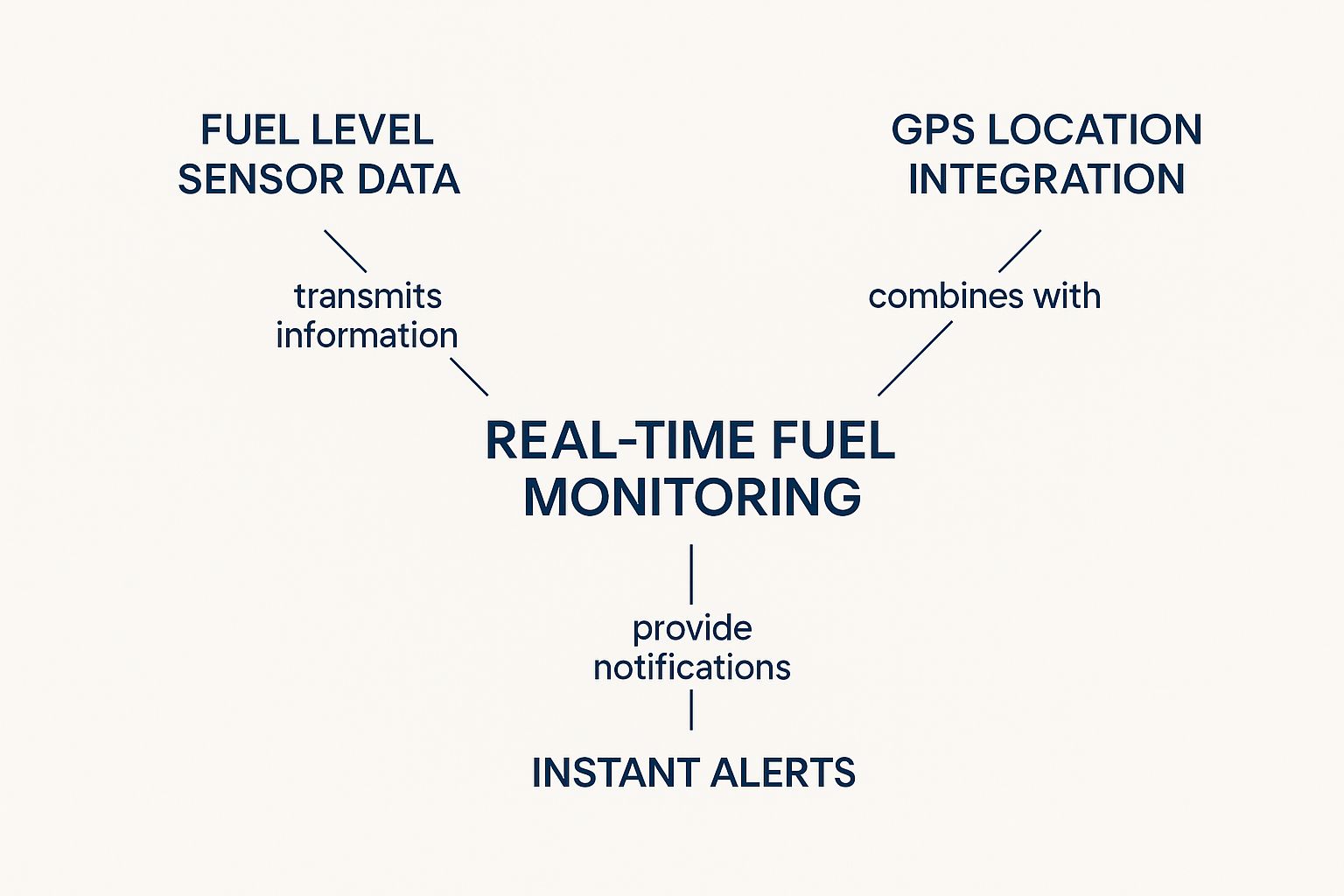

The following infographic shows how real-time fuel monitoring brings together sensor data, GPS location, and instant alerts to give you a complete picture.

This illustrates how real-time monitoring becomes your central hub, taking in information from various sources and giving you immediate insights. This technology has led to big efficiency gains – some fleets have seen up to a 20% drop in fuel consumption after putting these systems in place. They get real-time data on fuel usage, driver behavior, and vehicle health, allowing managers to make informed decisions based on hard numbers. Discover more insights. Looking at your entire supply chain can also uncover opportunities to save fuel. For example, you can learn about strategies to improve supply chain efficiency.

Building a Connected Ecosystem

Effective fuel management isn't about isolated systems – it's about connection. Imagine different departments in a company working in silos. Information gets lost, and opportunities are missed. The same happens with fuel management technology. Connect your GPS tracking, telematics, and fuel card systems so they share data and give you a complete view of your fleet. This helps you spot patterns, pinpoint problems, and make smarter decisions. Effective route planning is another essential piece of the puzzle, affecting both fuel efficiency and happy customers. Much like a well-organized supply chain reduces waste, optimized routes can significantly cut down on fuel use and boost overall performance.

Practical Implementation Strategies

Introducing new technology can be tricky. Get your drivers and mechanics on board from the start. They're the ones using the systems every day, so their feedback is invaluable. Provide thorough training and address any concerns. Make the transition smooth by offering ongoing support and celebrating early wins. This builds confidence and encourages long-term use. Remember, technology is just a tool – its success depends on the people using it.

To understand the different options available, let's compare some common fuel management technologies:

Fuel Management Technology Comparison

This table compares key features, benefits, and things to consider when implementing different fuel management technologies. It helps illustrate the diverse landscape of solutions available and highlights which technology might be best suited for different fleet needs.

| Technology Type | Primary Benefits | Implementation Complexity | Typical ROI Timeline | Best Suited For |

|---|---|---|---|---|

| Fuel Cards | Automated tracking of fuel purchases, potential discounts, reduced administrative burden | Low | Short-term | Fleets of all sizes, especially those with frequent fueling needs |

| GPS Tracking | Real-time vehicle location, route optimization, improved dispatch efficiency | Low | Short-term | Fleets focused on route efficiency and delivery optimization |

| Telematics | Driver behavior monitoring, vehicle diagnostics, predictive maintenance | Medium | Mid-term | Fleets concerned with driver performance and vehicle health |

| Fuel Management Software | Comprehensive data analysis, fuel consumption reporting, integration with other systems | High | Long-term | Larger fleets seeking in-depth analysis and control |

Key Insights from the Table

As you can see, each technology offers unique advantages. Fuel cards provide a basic level of tracking and cost control, while telematics dives deeper into driver behavior and vehicle performance. Fuel management software offers the most comprehensive features but comes with higher implementation complexity. Choosing the right combination of technologies for your specific needs is key.

Creating A Culture Where Fuel Efficiency Matters

The best fleet fuel management isn't just about fancy technology. Think of it like buying a top-of-the-line treadmill: it won't do you any good if it sits unused. Similarly, even the most advanced fuel management system is useless without team buy-in. Building a fuel-efficient culture is about teamwork, communication, and a shared desire to succeed.

Turning Drivers into Efficiency Champions

Your drivers aren't just employees; they're your partners in fuel efficiency. Instead of setting strict rules, empower them. Start by educating them. Show them how saving fuel helps the company and improves their own performance. Explain how reducing idling and optimizing routes means less time on the road and more time for other tasks. Turn them into active participants who understand the impact of their choices. For those considering electric vehicles, programs like California’s EnergIIZE Fast Track 2025 can help with the transition.

The Power of Positive Reinforcement

Incentives are great, but they should be used wisely. Avoid creating a competitive environment. Instead, focus on the positive. Reward improvements, no matter how small. Publicly acknowledge efforts and celebrate team successes. This builds collaboration and a drive for constant improvement.

Communicating Fuel Performance Data Effectively

Data is crucial for tracking progress, but how you present it matters. Don’t use it to criticize. Instead, present it as a learning tool. Give drivers regular feedback, highlighting their strengths and offering helpful suggestions. This encourages them to see data as a resource for improvement, not a source of negativity.

Training That Sticks

Training isn't a one-time event; it's an ongoing process. Offer regular refreshers on fuel-efficient driving. Create opportunities for drivers to share tips and learn from each other. Reinforce these practices with coaching and mentorship. This makes fuel efficiency a daily habit.

Measuring and Celebrating Success

Regularly monitor and track fuel efficiency gains. Celebrate milestones and recognize both individual and team accomplishments. This builds momentum and underscores the value of fuel conservation. By creating a shared sense of responsibility and continuous improvement, fleet managers can transform fuel efficiency from a mandate into a team-driven initiative.

Addressing Resistance and Building Buy-In

Change can be tough. Address concerns openly and honestly. Involve skeptical team members, asking for their input. Show them the direct benefits of fuel efficiency, like reduced workload and greater recognition. Often, the biggest skeptics become the strongest supporters once they see the value and the positive outcomes. Turn resistance into enthusiasm by showcasing the real advantages of a fuel-efficient culture.

Route Optimization That Actually Works

Planning routes for a delivery fleet isn't simply about connecting Point A to Point B. It's a lot more like planning a road trip with multiple stops, unpredictable traffic, and maybe even a few detours thrown in for good measure. Let's explore some smart strategies that go beyond basic navigation and consider the many moving parts involved in real-world fleet operations.

Balancing Customer Service and Fuel Economy

Think of it like this: you’re juggling customer satisfaction with fuel efficiency. You absolutely have to deliver on time, but burning extra fuel to do it eats into your profits. Experienced fleet managers understand this tightrope walk. They use strategies that make deliveries more efficient without impacting their customers’ experience.

Leveraging Data for Smarter Routing

Historical data and predictive analytics can be like having a roadmap of the future. Think about how past traffic patterns, weather reports, and even seasonal changes can offer clues about what to expect on the road. By analyzing this information, you can anticipate potential delays and plan routes accordingly. This helps minimize the impact of unexpected events on your fuel costs.

Dynamic Routing: Adapting to the Unexpected

Static, pre-planned routes can be like following a paper map in a world of digital navigation. Dynamic routing, on the other hand, is like having a smart GPS. It adapts in real-time to unexpected events like traffic jams or road closures. This flexibility is key for staying efficient on the go.

Optimizing Multi-Stop Routes

Traditional routing often struggles with multi-stop deliveries. Imagine a delivery driver zig-zagging across town. The order of those stops can dramatically impact how much fuel they use. Smart algorithms can take into account traffic, delivery windows, and the distance between stops to find the most fuel-efficient sequence. This helps avoid unnecessary miles and wasted fuel.

Fuel Planning: Saving Before You Start

Efficient routes are just one piece of the puzzle. Smart fuel purchasing is equally important. Think about how gas prices fluctuate depending on the location and even the time of day. By factoring fuel prices into your planning, you can strategically refuel at cheaper locations, stretching your fuel budget further. It's like comparison shopping for groceries, but for fuel.

Integrating Route Optimization with Other Factors

Route optimization shouldn't happen in a vacuum. It needs to connect with other aspects of fleet operations, like driver schedules, vehicle maintenance, and, of course, customer expectations. For example, a route might be fuel-efficient, but if it takes a driver far from their scheduled maintenance appointment, it creates new inefficiencies. Integrating these factors ensures a more streamlined approach.

Quantifying the Impact of Route Optimization

The advantages of route optimization are real and measurable. To illustrate, let’s look at some potential scenarios:

Let's take a look at the potential impact of different route optimization strategies. The table below shows how even small improvements can add up to significant savings.

Route Optimization Impact Analysis

| Optimization Strategy | Average Fuel Savings | Implementation Cost | Payback Period | Additional Benefits |

|---|---|---|---|---|

| Basic Route Planning | 5% | Low | Short-term | Reduced mileage, improved delivery times |

| Dynamic Routing | 10% | Medium | Mid-term | Real-time adaptation to traffic and road conditions, improved customer satisfaction |

| Multi-Stop Route Optimization | 15% | High | Long-term | Minimized wasted miles, optimized delivery schedules, increased driver productivity |

| Fuel Price Optimization | 3-5% | Low | Short-term | Reduced fuel expenses |

It’s important to remember that these are just examples. The actual impact will vary depending on the specific characteristics of each fleet and its operations. However, this table shows the potential for significant savings and efficiency gains. By taking a strategic approach to route planning, fleet managers can shift fuel management from a cost center to a source of competitive advantage. This leads to real financial benefits and a more sustainable operation.

Measuring What Actually Matters

The old saying, "What gets measured gets managed," absolutely applies to fuel management for fleets. But focusing on the wrong metrics is like trying to fill a bathtub with a sieve – frustrating and ineffective. This section dives into the key performance indicators (KPIs) that actually drive savings and how to avoid those misleading "vanity metrics" that look good but don't tell the whole story.

Identifying the Right KPIs for Your Fleet

Think of choosing the right KPIs like choosing the right fishing lure. You wouldn't use a lure designed for trout if you're fishing for bass. The same principle applies to fleet metrics: generic industry standards might not address your specific needs. For example, fixating solely on miles per gallon (MPG) might mask a hidden fuel-waster: excessive idling. Idling burns fuel without adding miles to the odometer. A more effective approach is to consider a broader range of KPIs:

-

Cost per mile: This metric captures the big picture – the total cost of running each vehicle, including fuel, maintenance, and other expenses.

-

Idling time percentage: This KPI shines a spotlight on fuel wasted due to unnecessary idling.

-

Fuel consumption per delivery/route: This metric connects fuel usage directly to the work being done, providing a more practical measure of efficiency.

-

Number of unplanned maintenance incidents: Unexpected repairs can indicate underlying problems that impact fuel efficiency. This KPI helps you connect those dots.

These metrics provide a clearer picture of your fleet's performance, offering valuable insights into areas ripe for improvement. They move beyond simple fuel usage and delve into the operational heart of fuel management.

Setting Realistic Benchmarks and Tracking Progress

Once you've chosen your KPIs, the next step is setting realistic benchmarks. Don't set the bar so high that it discourages your team. Think of it like training for a marathon: you wouldn't start by trying to run 26 miles on day one. Instead, use your fleet's historical data and industry averages as a starting point. For example, a reasonable initial goal might be a 5% reduction in idling time.

Track your progress regularly and adjust your benchmarks as needed. This iterative approach fosters a sense of accomplishment as each milestone is reached.

Remember to consider external factors that can influence your data, like seasonal temperature changes, fuel price fluctuations, and changes in the types of vehicles in your fleet. These variables can significantly impact your KPIs. For instance, fuel consumption typically rises in winter due to colder temperatures and longer engine warm-up times. Factoring in these variables provides a more accurate assessment of your progress.

Building a Data-Driven Fuel Management Culture

Effective reporting is about providing useful insights, not overwhelming your team with data. Imagine a pilot trying to land a plane while staring at every single gauge in the cockpit. Information overload can be just as distracting. Instead, use dashboards that clearly present key metrics and highlight areas needing attention. This streamlined approach allows for quick analysis and swift action.

Finally, use your data strategically to uncover hidden opportunities. Regularly review your KPIs and look for trends. For instance, a spike in fuel consumption on a particular route might warrant further investigation. Is it due to increased traffic, road construction, or driver behavior? By using data as a diagnostic tool, you can constantly refine your fuel management strategy and ensure your program adapts and evolves with your business.

Your Practical Roadmap To Fuel Management Success

Real success in fuel management isn't about chasing the latest tech. It's about building a system that consistently delivers tangible results—the kind that improve your bottom line. This roadmap helps you transform your fleet's fuel management from a cost center into a source of savings and efficiency.

Prioritize and Plan: One Step at a Time

Overhauling your entire fuel program at once is like trying to renovate your whole house simultaneously—chaotic and inefficient. Instead, prioritize. Where are the biggest fuel drains? Are inefficient routes costing you? Is driver behavior a concern? Focus on the largest pain points first. Set achievable goals, like reducing idling by 5% in three months. Small wins build momentum.

Spot the Warning Signs: Early Detection Is Key

Think of it like a car: a small rattle can indicate a minor issue, but ignoring it might lead to a major breakdown later. The same applies to fuel management. Consistently increasing fuel costs, driver complaints about fuel efficiency, or a sudden spike in maintenance issues are all red flags. Addressing them early, maybe with some driver training or route optimization, can prevent bigger problems and expenses down the line.

Evaluate and Implement: The Right Tools for the Job

Choosing a fuel management solution is like selecting the right tool from your toolbox. A hammer isn't going to help you loosen a bolt. Create a checklist of your fleet's needs and use it to evaluate different solutions. Focus on features that solve your specific problems, not just the shiny extras. And when you're implementing new technology, involve your drivers and mechanics from the beginning. Their feedback is invaluable for a smooth rollout. Proper training and addressing their concerns will make the transition much smoother.

Here's a look at CLiX Fueling Solutions, highlighting its user-friendly interface:

This screenshot showcases the website's clean design and straightforward navigation, making it easy for users to find the fueling solutions they need.

Measure and Maintain Momentum: The Long Haul

Tracking your progress is essential. Choose key metrics, like cost per mile or idling time, that directly reflect your goals. Regularly monitor these KPIs and acknowledge improvements—this keeps everyone engaged. For more strategies, check out our guide on 2025 fleet fuel management solutions to cut costs. Fuel efficiency isn't a one-time fix, it's a continuous process. Regularly review your strategy, adjust to changes, and always look for new ways to improve.

Ready to take charge of your fleet's fuel costs and improve your bottom line? CLiX Fueling Solutions offers innovative tools to minimize fuel waste and maximize efficiency. Visit CLiX Fueling Solutions today to explore your options.