The Engineering Behind Baffle Fuel Tanks: How They Transform Performance

A baffle fuel tank is more than just a simple container for fuel. It's a precisely engineered component designed to enhance vehicle performance. This is achieved by minimizing the effects of fuel sloshing, which is the unpredictable movement of fuel inside the tank.

This sloshing can significantly affect a vehicle's stability, especially when accelerating, braking, or cornering. Think of a glass of water sloshing back and forth – the same physics apply to fuel within a tank, impacting the vehicle’s balance.

How Baffles Control Fuel Movement

Baffles are strategically positioned internal chambers and dividers within the fuel tank. These structures interrupt the free movement of fuel, breaking down large waves of liquid into smaller, more manageable surges. This dampening effect reduces the overall impact of fuel movement on the vehicle’s center of gravity.

The concept is similar to how breakwaters protect harbors from the full force of ocean waves, creating a calmer environment within.

The Physics of Fuel Slosh and Baffle Effectiveness

Conventional fuel tanks, without baffles, allow fuel to move around freely and erratically. During sharp turns, this sloshing shifts the vehicle's center of gravity, making handling unpredictable and potentially dangerous.

Baffle systems, on the other hand, reduce this shift, ensuring a consistent fuel supply to the engine even in challenging driving conditions. This also prevents fuel starvation, which occurs when the engine is temporarily deprived of fuel due to sloshing. Fuel starvation can lead to power loss and even engine damage.

The market for fuel tank innovation is expanding, driven by increased vehicle production and a demand for improved technology. The global vehicle fuel tank market was valued at $19.10 billion in 2023. It's projected to reach $28.62 billion by 2032, highlighting the demand for advanced fuel system designs. This growth indicates that innovations like baffle tanks are contributing to this expansion. Find more detailed statistics here. For more information about different tank types and their uses, articles about tanks are available.

Benefits in High-Performance Driving

The advantages of baffle fuel tanks are particularly noticeable in high-performance driving scenarios. In racing, for example, maintaining consistent fuel delivery and vehicle stability is essential. Baffles provide the precise fuel control necessary for optimal performance.

Similarly, in off-road vehicles navigating rough terrain, baffles ensure a constant fuel supply. This prevents engine starvation on steep inclines or during sudden maneuvers. The enhanced stability and predictable handling lead to improved driver confidence and overall performance.

Performance Advantages That Make Baffle Fuel Tanks Worth the Investment

Baffle fuel tanks offer a significant upgrade over standard fuel tanks, particularly when it comes to performance. This is due to their superior ability to control fuel movement, which leads to a more predictable and stable driving experience. Drivers can push their vehicles harder, knowing the fuel isn’t sloshing around and affecting handling.

During aggressive cornering, for example, fuel in standard tanks sloshes dramatically. This shifting fuel mass creates unpredictable changes in the vehicle’s center of gravity. A baffle fuel tank, however, minimizes this sloshing, resulting in more predictable handling and increased driver control.

Enhanced Handling and Stability

One of the key advantages of a baffle fuel tank is improved handling predictability. By controlling fuel slosh, these tanks prevent sudden shifts in the vehicle's center of gravity during maneuvers. This results in more consistent braking distances and stable vehicle dynamics, even during aggressive driving.

Baffle fuel tanks also promote consistent fuel delivery to the engine. This prevents fuel starvation during critical driving situations, ensuring the engine always has the fuel it needs for optimal power output. This reliability is especially important in high-performance driving or off-roading, where terrain and speed changes can compromise fuel delivery in standard tanks. You might be interested in: How to master....

Long-Term Benefits and Investment Value

The advantages of baffle fuel tanks extend beyond immediate performance gains. They also contribute to the long-term health and lifespan of your vehicle. Reduced fuel sloshing minimizes mechanical stress on the tank's mounting points and internal components.

Consistent fuel flow helps prevent damage to the fuel pump and engine, allowing them to operate more efficiently. The increasing use of baffle fuel tanks reflects a broader industry trend towards lightweight and efficient fuel systems. The global fuel tank market is projected to reach $27.89 billion by 2031, growing at a CAGR of 5.2% from $18.59 billion in 2023. This growth suggests baffle designs are playing a role in improving vehicle efficiency and safety. Explore this topic further. This long-term durability and reduced maintenance make baffle fuel tanks a smart investment for drivers wanting both performance and value.

Choosing the Right Baffle Fuel Tank for Your Vehicle's Needs

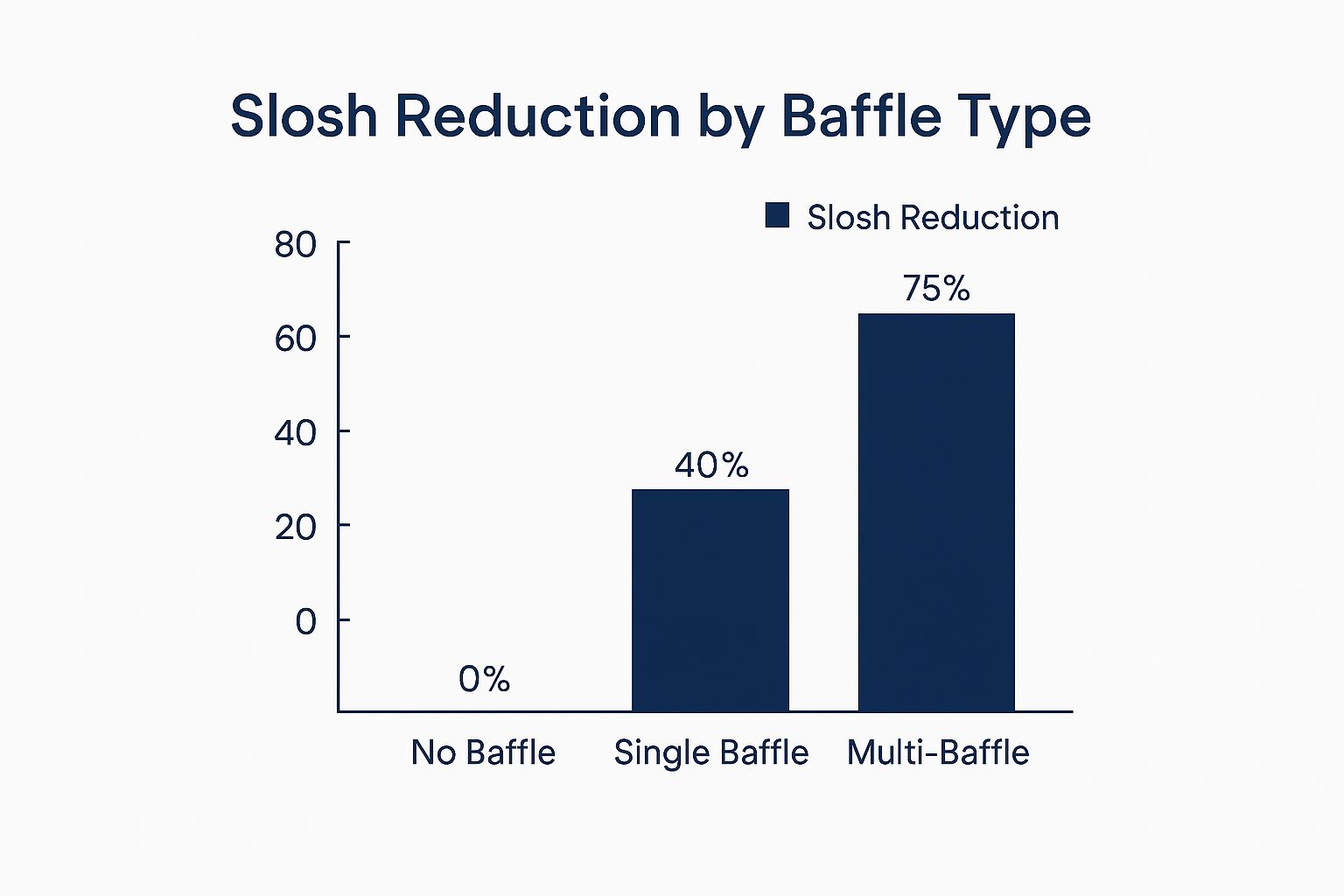

The infographic above shows how different baffle configurations reduce fuel slosh. Multi-baffle systems offer a big advantage, reducing slosh significantly more than single-baffle or no-baffle tanks. This means better stability and more predictable handling, especially in challenging driving conditions.

Baffle fuel tanks aren't all created equal. Picking the right one depends on several factors, like what you'll use the vehicle for, the type of fuel, and the performance you want. This section explores the different baffle fuel tank designs and helps you choose the best fit for your needs.

Material Considerations: Aluminum vs. Steel

One of the first things to consider is the tank material. Aluminum is lightweight, which can improve fuel efficiency. However, it might not be as durable as steel, especially for off-roading where impacts are more common. Steel is stronger and more resistant to damage, but it adds weight.

This often means choosing between weight and durability. A race car might prioritize the lighter aluminum, while a heavy-duty truck might need the strength of steel.

Mounting Position and Handling Characteristics

Where you place the fuel tank in your vehicle affects how it handles. A lower position in the chassis creates a lower center of gravity. This improves stability and reduces body roll when turning. But a lower position can also expose the tank to more damage from road debris or off-road obstacles.

The mounting system itself needs to be strong enough to handle the movement of the fuel. A weak mounting system can lead to wear and tear, leaks, or even structural damage. Read also: How to Master...

Specialized Designs for Specific Applications

Different types of driving require different fuel systems. For track use, a tank with multiple chambers and complex pathways keeps fuel flowing even during hard cornering and braking. Off-road vehicles need tough tanks with baffles placed strategically to prevent fuel starvation on uneven terrain.

- Track Warriors: These prioritize lightweight materials and complex baffle designs for the best fuel delivery during high-G maneuvers.

- Off-Road Enthusiasts: These drivers need durable tanks and strategically placed baffles to maintain a consistent fuel supply on rough terrain.

- Commercial Heavy-Duty Operations: These often use large tanks with strong baffles designed for daily use and changing loads.

To help understand the differences between tank types, let's look at a comparison table.

To help you understand the different options, the following table summarizes key information about various baffle fuel tank types and their typical applications.

Comparison of Baffle Fuel Tank Types by Vehicle Application

| Tank Type | Primary Applications | Material Options | Capacity Range | Baffle Configuration | Special Features |

|---|---|---|---|---|---|

| Aluminum Racing Fuel Cell | Racing, High-Performance | Aluminum Alloy | 5-50 Gallons | Multi-Chamber, Swirl Pot | Lightweight, Anti-Slosh, High Flow |

| Steel Off-Road Fuel Tank | Off-Roading, Overlanding | Steel | 20-40 Gallons | Single/Multi-Baffle, Sump | Skid Plate Protection, Durable |

| Heavy-Duty Truck Tank | Commercial Trucking, Agriculture | Steel, Polymer | 50-200 Gallons | Multi-Baffle, Sump | High Capacity, Impact Resistant |

| Marine Fuel Tank | Boats, Personal Watercraft | Aluminum, Polymer | 10-100 Gallons | Multi-Baffle, Anti-Siphon | Corrosion Resistant, Level Sensors |

| Aircraft Fuel Tank | Aviation | Aluminum Alloy, Composites | Varies widely | Bladder, Compartmentalized | Leak Detection, Fuel Balancing Systems |

This table outlines some key distinctions between fuel tank types based on their intended use. Notice how material choices, capacity, and special features all play a role in determining the optimal tank for a given application.

These specialized designs ensure the fuel system meets the specific needs of each application, maximizing performance and reliability. Choosing the right baffle fuel tank is a critical decision that affects vehicle performance, safety, and how long it lasts. By considering these factors, you can make a smart choice for your needs.

How Baffle Fuel Tanks Revolutionized Motorsport Performance

The quest for speed and efficiency in motorsports has always pushed innovation. One of the most significant breakthroughs is the baffle fuel tank, a technology that dramatically changed competitive racing. It addressed a critical challenge: managing fuel dynamics under extreme conditions. By controlling fuel slosh, baffle tanks provide drivers with a significant advantage, proving that fuel management can win races.

From Fuel Starvation to Consistent Power: A Motorsport Breakthrough

In the high-pressure world of racing, even minor interruptions in fuel delivery can be disastrous. Before baffle fuel tanks, race cars often experienced fuel starvation during hard cornering, braking, or acceleration. Imagine a Formula 1 car losing power mid-corner—the consequences could be catastrophic. Baffle tanks used internal baffles (dividers) to control fuel movement inside the tank. This ensured a consistent fuel supply to the engine, even under the intense G-forces of racing.

This innovation wasn't limited to Formula 1. Rally cars, enduring jarring impacts and unpredictable terrain, also benefited greatly from impact-resistant baffle fuel cells. These robust tanks kept fuel secure and flowing, allowing drivers to push their limits without fear of fuel starvation or tank damage.

How Baffles Changed the Game: Real-World Examples

The impact of baffle fuel tanks is evident in many motorsport victories. Consider grueling endurance races where consistent performance is paramount. Teams with superior fuel management systems maintain consistent lap times, often gaining an edge over competitors struggling with fuel slosh. This advantage, often measured in fractions of a second, can mean the difference between winning and losing.

The adoption of baffle tanks also improved safety. By preventing fuel slosh and potential leaks, the tanks minimized the risk of fires and other hazards associated with older fuel systems. This enhanced driver safety and race integrity. The automotive fuel tank market, including various tank types like baffle tanks, is experiencing significant growth. By 2025, the market is projected to reach $21.67 billion, up from $20.19 billion in 2024. This growth is driven by industry expansion and innovations like smart fuel management solutions. While specific data on baffle tanks within this market isn't readily available, their role in advanced designs suggests their importance for future developments. Discover more insights about this growing market.

From Track to Street: Baffle Technology's Lasting Legacy

The benefits of baffle fuel tanks extend beyond the racetrack. The technology eventually made its way into production vehicles, improving performance and safety for everyday drivers. Many high-performance cars and trucks now incorporate baffle technology, demonstrating how motorsport innovation can benefit everyone. This transfer of technology highlights racing's crucial role in pushing the boundaries of automotive engineering.

Baffle fuel tanks have undoubtedly changed motorsports, turning fuel management from a potential liability into a competitive advantage. From the precision of Formula 1 to the rugged demands of rally racing, these tanks have shaped the sport. The ongoing development of baffle technology promises further improvements in fuel efficiency, performance, and safety, both on and off the track.

Expert Guide to Installing and Maintaining Your Baffle Fuel Tank

A baffle fuel tank can significantly improve your vehicle's performance. However, realizing its full potential hinges on proper installation and consistent maintenance. This guide covers key aspects of mounting, fuel line routing, ventilation, and upkeep to ensure your baffle fuel tank operates at peak efficiency.

Mounting Your Baffle Fuel Tank: A Step-by-Step Guide

Proper mounting is critical for both safety and performance. Incorrect installation can lead to stress on the tank, leaks, and even damage to your vehicle's structure. Follow these steps for a secure and effective mount:

-

Choose the Right Location: Select a spot that minimizes the tank's exposure to impacts while keeping a low center of gravity for improved handling.

-

Reinforce Mounting Points: The mounting area needs to be structurally sound and reinforced. This ensures it can handle the weight of a full tank, especially during dynamic driving.

-

Use Vibration Isolators: Installing vibration isolators between the tank and the mounting points reduces stress and prevents material fatigue.

-

Secure Mounting Hardware: Always use high-quality, corrosion-resistant hardware. Tighten all bolts and fasteners to the manufacturer's specified torque.

Fuel Line Routing and Ventilation: Best Practices

Efficient fuel delivery and proper tank ventilation are essential for optimal engine performance. Keep these guidelines in mind:

-

Minimize Bends and Restrictions: Route your fuel lines to avoid sharp bends or kinks. These can restrict fuel flow and negatively impact engine performance.

-

Use Proper Clamps and Fittings: Secure all fuel lines with the correct clamps and fittings to prevent leaks.

-

Ensure Adequate Ventilation: A properly functioning vent system is crucial. It prevents pressure buildup or vacuum, which can affect fuel delivery.

Maintaining proper airflow is just as important as fuel flow. A blocked vent can create a vacuum, restricting fuel and potentially harming your fuel pump.

Maintaining Your Baffle Fuel Tank: A Proactive Approach

Regular maintenance is key to extending the lifespan of your baffle fuel tank. Here’s a recommended maintenance schedule:

To help you stay organized, we've put together a handy table outlining a comprehensive maintenance schedule:

A well-maintained baffle fuel tank provides optimal performance and longevity. The table below offers a comprehensive maintenance schedule to help you stay on top of essential tasks.

Baffle Fuel Tank Maintenance Schedule

A comprehensive maintenance timeline showing recommended inspection intervals and service procedures for optimal baffle fuel tank performance

| Maintenance Task | Frequency | Tools Required | Signs of Potential Issues | Professional Assistance Needed? |

|---|---|---|---|---|

| Visual Inspection of Tank, Lines, and Fittings | Every 6 months | Flashlight, Rag | Leaks, Cracks, Corrosion, Loose Fittings | Potentially, if damage is found |

| Fuel Compatibility Check | With every fuel fill-up | None | Performance Issues, Fuel System Damage | Yes, if incompatible fuel is used |

| Vent System Inspection | Annually | Small Wire/Tube | Slow Fuel Flow, Tank Deformation | Potentially, for complex vent systems |

| Mounting Hardware Check | Annually | Wrench/Socket Set | Loose Tank, Unusual Noises | Potentially, if mounting points are damaged |

Regular maintenance is essential for optimal fuel tank performance. This schedule highlights key tasks to help you prevent issues and ensure long-lasting reliability.

Troubleshooting Common Issues

Even with preventative maintenance, problems can occasionally arise. Here's how to address some common baffle fuel tank issues:

-

Fuel Smell: A fuel smell typically indicates a leak. Inspect all connections and replace any damaged parts immediately.

-

Reduced Fuel Flow: This can be caused by several issues, including a clogged fuel filter, a kinked fuel line, or a malfunctioning vent. Check these components and clean or replace them as needed.

-

Excessive Noise: Unusual noises coming from the tank could point to a loose mounting bracket or a problem within the baffle system itself. Inspect and tighten or repair as necessary.

Remember to consider the specific needs of your vehicle and your driving habits. High-performance driving, for example, might necessitate more frequent inspections and specialized maintenance. For more information on fuel systems, you can refer to resources like Clix Fueling. By following these installation and maintenance guidelines, you can ensure your baffle fuel tank provides optimal performance and reliable service for years to come.

The Future of Baffle Fuel Tank Innovation: What's Coming Next

Baffle fuel tank technology is constantly changing. New materials and designs are pushing the boundaries of fuel management. This leads to lighter, stronger, and more adaptable baffle systems with better performance. Proper fittings are essential for any tank installation, including baffle fuel tanks. For a reliable option, consider a Stainless Steel Bulkhead Tank Fitting.

Advanced Materials: Composites and Polymers

One of the most interesting developments is the use of advanced composites and specialized polymers. These materials offer advantages over traditional metals like aluminum and steel. Composites provide high strength and stiffness at a lower weight. This results in improved fuel efficiency and better overall vehicle performance.

Polymers offer excellent corrosion resistance and design flexibility. This makes them perfect for complex baffle geometries that optimize fuel flow and reduce sloshing. Imagine a baffle system that adapts its internal structure based on driving conditions.

Intelligent Fuel Systems: Integration with Vehicle Electronics

Integrating baffle fuel tanks with vehicle electronics is another area of rapid innovation. Sensors and actuators are used to monitor fuel levels, temperature, and sloshing dynamics. This data allows the vehicle’s control system to adjust fuel delivery instantly, optimizing performance and efficiency.

This means the fuel system can adapt to changes in driving conditions. For example, during hard cornering, the system can adjust fuel flow to prevent engine starvation. This also improves fuel efficiency by minimizing unnecessary fuel movement.

Autonomous Vehicles and Extended-Duration Operation

The rise of autonomous vehicles presents new challenges and opportunities for fuel system design. These vehicles need reliable and efficient fuel management for extended periods. Baffle fuel tanks play a crucial role in meeting these demands.

New baffle designs are being developed for autonomous vehicles, maximizing fuel capacity and minimizing sloshing during long trips. This is especially important for commercial applications like delivery trucks and long-haul transportation.

Alternative Fuel Compatibility: Hydrogen and Hybrid Systems

The shift toward alternative fuels is impacting baffle fuel tank design. From hydrogen storage solutions to hybrid systems accommodating multiple energy sources, baffle technology is adapting.

Hydrogen presents unique storage challenges due to its low density. Baffle tanks are being redesigned to handle the larger volumes needed for hydrogen storage while maintaining safety. Hybrid vehicles need fuel systems that seamlessly switch between fuel types. Baffle technology ensures smooth transitions and optimal fuel delivery regardless of the energy source. These advancements contribute to a future of cleaner transportation.

Looking for a reliable fueling solution for your boat? CLiX Fueling Solutions offers a spill-free and stress-free way to fuel up on the water. Their automatic shut-off system prevents overfilling and protects your boat and the environment. Learn more about CLiX Fueling Solutions.